Cable Repair Sleeves – Heat Shrink Wraparound Cable Jacket Repairs

Cable Repair Sleeves – Heat Shrink Wraparound Cable Jacket Repairs

Repairing Damaged Cables

Wraparound cable repair sleeves for low voltage cable joints offer an easy to apply effective solution for the repair of damage to outer sheaths for all cable types, including temporary or permanent armoured or unarmoured power cables.

Heat shrink wraparound cable repair kits (sheath and jacket) are used extensively worldwide to provide the outer protection and sealing of telecommunication cables, they are equally useful for power cable joint outer sealing reducing trench excavation. The cable repair kits are adhesive lined and the heat shrink wraparound cable repair sleeve is complete with a flexible stainless-steel closure channel/rail and cable cleaning sachet.

The wraparound cable repair sleeves can be installed over live cables without cutting the cables, shutting down power or de-energising LV MV HV cable circuits.

Heat Shrink Wraparound Cable Jacket Repairs

The following table enables the selection of the correct cable repair sleeve to reinstate the damaged sheath of LV MV HV cables.

Thorne & Derrick can deliver Cable Repair Solutions to suit high performance (Low Smoke Zero Halogen LSZH | Fire-Resistant | Seawater Resistant | Flexible & Trailing) and high voltage cable applications including 11kV (Triplex), 33kV (BS7870 BS6622), Protolon and 66kV offshore Inter-Array Cables (IAC).

Heat shrink technology provides versatile, range-taking repairs to damaged cables with excellent electrical insulation levels, water resistance and mechanical protection for cables installed underground direct buried into cable trench or in airborne cable management applications including harsh and hazardous area locations

| SPS Part Number | Exp Dia (mm) | Rec Dia (mm) | Length (mtr) |

| SWRS 43/10 | 42 | 10 | 1000mm |

| SWRS 50/15 | 50 | 15 | 1000mm |

| SWRS 75/22 | 75 | 22 | 1000mm |

| SWRS 105/30 | 105 | 30 | 1000mm |

| SWRS 146/38 | 146 | 38 | 1000mm |

| SWRS 198/55 | 188 | 55 | 1000mm |

| SWRS 210/60 | 210 | 60 | 1000mm |

Cable Repair Sleeves – Materials

| Item | Test Condition & Material | Requirement |

| Bursting Strength | Test Temp: 23±5°C | Min 3000N |

| Thermal Ageing Bursting Strength | 168Hrs at 150±2°C (After Free Shrinkage) | Min 5000N |

| Dielectric strength | Electrode Surface Dia: 6mm. Weight: 50±2gms. Voltage Steps: 2kV/20sec | Min 12 kV/mm |

| Split Resistance | Temp: 200±2°C. Test time 23±3°C | No split Propagation |

| Carbon Content UV Res of Out/layer | Heating Rate: 20°C/min. Gas Flow Rate: 300cc/min | Min 2.5% |

| Cold Crack Resistance | Test temp: ≤-40°C | No crack |

| Resistance to Aggressive Media Bursting Strength |

Test Media: Fuel Oil, Petroleum Jelly. Test Temp: 70 ± 2°C | Min 2000N |

| Environmental Stress cracking | 10% Igepal Co 630. Solution Immersion Time: 30 days Test Temp: 50 ± 3°C |

No cracking |

| Temp. indicating paint conversion | Scraped Off Paint From Sleeve | 230-250°C |

CABLE REPAIR SLEEVES – Hot Melt Adhesive

| Item | Test Condition & Material | Requirement |

| Peel Strength | -PE at 23±2°C. -PE at 23±2°C. -Pb at 23±2°C | Min 100N/25mm |

| Shear Strength | At 23±2°C | Min 200N |

| Corrosive Effect | Copper Mirror Test Test Time:16hrs. Test Temp:60±2°C | No Effect |

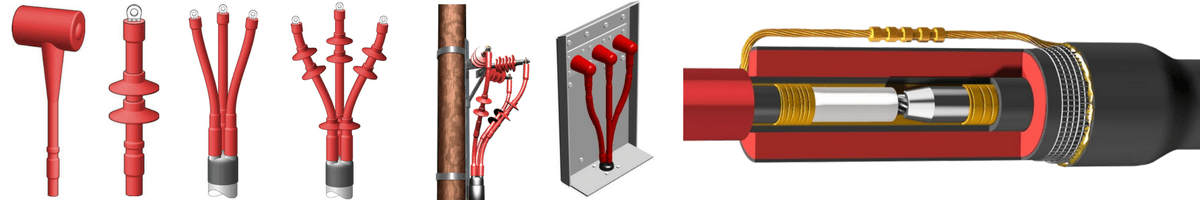

6.6kV 11kV 33kV Cable Joints & Terminations – heat shrink provides safe and reliable cable connections and joints for LV MV HV cables