Cable Heaters For Straightening 33kV & High Voltage (HV) Cables

Published 20 Jun 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Heating High Voltage Cables

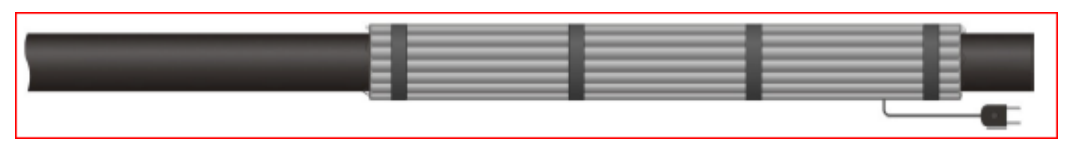

Working closely with HV and EHV cable manufacturers Thorne & Derrick have designed and developed a standard range of cable heating jackets for straightening and relaxation of high voltage cables prior to installing MV HV Joints, Terminations & Connectors – T&D supply a complete HV cable straightening set focusing on safe, exact and consistent heating of high voltage cables with adjustable temperatures up to 100°C.

The unique cable straightener solution with extension pieces gives the HV jointer the most flexible cable heating solution to cover several different cable dimensions with fully homogeneous load density for XLPE insulated cables.

Cable straighteners are used to heat voltage class MV HV cables: 33kV 66kV 132kV 275kV

Cable Heaters Specification

The following table provides technical data to cover the performance and application of cable heater blankets for MV HV cables – please note this is for standard cable straightening applications up to 132kV. T&D working with MV HV cable manufacturers and installers can provide customised cable heating solutions for all types of polymeric (XLPE) type cables.

The cable heaters feature an in built overtemperature switch at 110°C.

| Operating Voltage | 220-240VAC or 110-120VAC |

| Cable Heating Range | Ø70-190 mm or Ø40-69 mm (Outside Diameter) |

| Cable Heating Temp. | 95°C (adjustable setpoint, PID/rampable by time control) |

| Insulation Thickness | 25mm |

| Cables | 5m power supply, 5m cable from controller to cable heating jacket |

| RCD | 30mA, Type A |

| IP Rating | IP44 |

| Cable Heating Voltages | 33kV 66kV 132kV 275kV |

Cable Heaters Selection

The following table includes the standard Cable Heating Jackets – should you require any specification support or technical advice to select the correct cable straightening jackets please do not hesitate to contact us.

| Order Code | Operating Voltage | Cable Diameter | Cable Heater Length |

| CSR 70-115 Cable Heater Blanket up to 190mm Diameter | |||

| Single Set CSR 70-115/1-1500-230 | 220-240VAC | 70-115 | 1500mm |

| Double Set CSR 70-115/2-1500-230 | 220-240VAC | 70-115 | 1500mm |

| Extension CSR EP25-1500-230 | 220-240VAC | – | 1500mm |

| Single Set CSR 70-115/1-2000-230 | 220-240VAC | 70-115 | 2000mm |

| Double Set CSR 70-115/2-2000-230 | 220-240VAC | 70-115 | 2000mm |

| Extension CSR EP25-2000-230 | 220-240VAC | – | 2000mm |

| Single Set CSR 70-115/1-1500-115 | 110-120VAC | 70-115 | 1500mm |

| Double Set CSR 70-115/2-1500-115 | 110-120VAC | 70-115 | 1500mm |

| Extension CSR EP25-1500-115 | 110-120VAC | – | 1500mm |

| CSR 40-69 Cable Heater Blanket up to 69mm Diameter | |||

| Single Set CSR 40-69/1-2000-230 | 220-240VAC | 40-69 | 2000mm |

| Double Set CSR 40-69/2-2000-230 | 220-240VAC | 40-69 | 2000mm |

| Cable Straightening Aluminum Profile | – | – | – |

| CSR SP2000 | – | – | 2000mm |

Pfisterer Heaters

Here is shown the Pfisterer range of cable heating blankets used to pre-heat and straighten medium/high voltage XLPE insulated power cables prior to termination with their pluggable CONNEX range of inner cone terminations.

33kV Cable Heating & Straighteners

The following information is published from the Western Power Distribution company directive CA3C/2 Relating to General Requirements for 33kV Cable Jointing and specifically to the sub-section Heat Straightening of 33kV High Voltage Cables.

With dry designs of medium/high voltage polymeric cable after the removal of the oversheath and metallic sheath, the polymeric XLPE cable has a tendency to bend. This can give rise to problems associated with the fitting of the cable terminations or straight joints. Because of this there is a need for a heat treatment process to be applied to each cable core to relieve the mechanical stresses that are locked into the cable insulation.

With the wet designs of polymeric cable the polymeric cable has a tendency to bend, even after being set into their final position. This can give rise to problems associated with the fitting of the cable terminations or straight joints. Because of this there is a need for the heat treatment process to be applied to the core to relieve the mechanical stress that is locked into the cable insulation

Apply the tube, fitted with the heater tape and thermocouple, over the cable end and onto the PVC packing. Ensure that the thermocouple is not directly under the heater tape. Wrap the complete assembly with a thermal blanket.

Heating 33kV Cables Figures 1

Switch on the controller and bring the temperature of the cable up to 90°C, once the cable has reached the required temperature the heating time is determined by the cable size.

Given below: –

4 hours for conductor sizes up to and including 500sqmm

6 hours for conductor cross sections above 630sqmm and up to 1600sqmm

After the requisite time, switch off. Remove the cable heating blanket, heater tube complete with heater tape, thermocouple and PVC packing. Wearing appropriate gloves carefully straighten the cable into the correct position by hand.

Heating 33kV Cables Figures 2

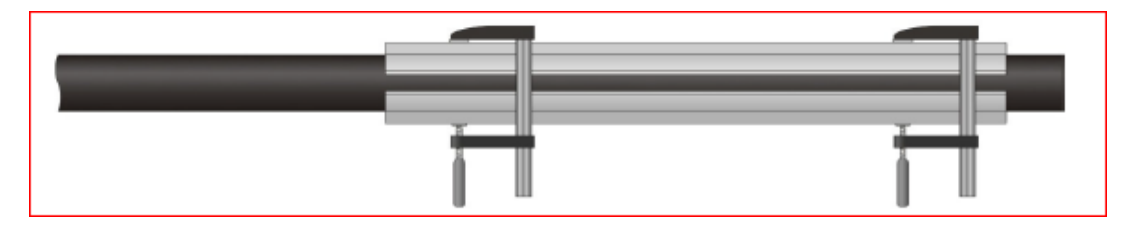

Clamp the cable into position on a V shaped angle irons or channel irons and allow the cable to cool for a minimum of two hours, insuring the angle iron or channel irons stay in the correct position during the cooling process.

132kV

Jointers depend on 132kV cable heating jackets and blankets to straighten EHV power cables prior to installing Pfisterer CONNEX type inner cone cable terminations into high voltage gas insulated switchgear and susbtations.

How Else Can We Help?

➡ Drum Heating & Cable Straightening Jackets For 132kV Extra High Voltage Cable Terminations

Joints, Terminations & Connectors for HV High Voltage Cables

Thorne & Derrick are stockists of market-leading manufacturers of Cold Shrink, cold applied, heat shrink and EPDM type joints, terminations and connectors up to 66kV.

MV HV cable heaters are designed to provide consistent surface heating to the cables of XLPE insulated type – when cables are pulled from the coiled state on a cable drum they have a tendency to naturally attempt to recoil. The heating process provides linearity of 33kV/66kV/132kV cables to enable optimum installation of cable joints, terminations or connectors in Cold Shrink, heat shrink or EPDM type rubber technology.