BASEC | Cable Quality LV HV

How To Write A Good Cable Specification

September 3rd, 2019

-

Blog Written By BASEC | 5 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

The easiest, low risk way to procure cables is to specify products that have proven their quality in similar projects. However, this may not always be possible as the end use may impose requirements that an established cable cannot meet.

If so, the next-best option is to insist that cables must meet relevant national or international standards, plus independent approval and certification requirements. By doing so, the onus of meeting the specification is placed upon the supplier.

A third option is to generate your own cable specification, which sounds efficient and attractive, but may have some pitfalls. This article discusses these alternatives and offers some useful guidelines for writing bespoke cable specifications. It applies to installations intended to conform to the likes of the UK IET Wiring Regulations but can be extended to other codes where relevant.

Standards and variations

Standards allow the issue of supply tenders which are manufacturer-neutral. The cable specification and tender can be kept simple by tying together the relevant standard and certification requirement, but nothing else.

For example, low smoke halogen free armoured cables for use in the UK may be easily specified by stating: “BS 6724, BASEC approved”.If a specifier decides instead to write out a detailed specification, they assume the risk of any omissions or modifications made.

It is therefore advisable to check existing standards using the same materials, voltage rating and performance characteristics in order to establish, for instance, appropriate insulation thicknesses as safety is paramount in cable design.

Also, it is sometimes tempting to over-specify products, including excessive detail that is already included in a related specification such as a standard.

By specifying conformity solely to the standard, all the construction, material detail and applicable testing listed in the standard are by default included and need not be repeated.Items which may need specifying are, where applicable, choice of insulation or sheathing materials (for example EPR or XLPE for medium voltage cable insulation), core colours (where alternatives are needed and allowed) or any other variable options which are often set out in the cable standard, for example fire performance.

Although some cable standards include an informative section on ‘what to state on your order’, which can be a useful guide for specification; it is recommended that you familiarise yourself with the cable standards you use so that you can better understand the stipulations, and keep the latest copies for ease of referencing them.

UK IET Wiring Regulations

Potential risks can arise when a cable standard does not clearly recognise precise construction and performance characteristics that may be required.

This can occur when standards set restrictions on the allowable constructions; for example, some medium and high voltage cable standards do not currently include low smoke halogen free sheath materials as an option, even though these materials have in some sectors become de facto minimum specifications.In these cases, it is tempting to make a short statement requiring such materials.

However, there is a danger of creating a specification that misses out key items and can create future problems unless four key conditions are met:

- All conflicting requirements are removed

- Changes are made to material definitions

- Correct applicable tests are listed

- Performance specifications are added

Confusion concerning fire resistant or circuit integrity cables is also widespread. Several fire tests may be applied to cables, but many have limited applicability. For example, BS EN 50200 and its variants, Annex E and BS 8434-2, which are common tests for small-scale fire alarm cables, have a maximum testing size limit of 20mm outer diameter (OD). These methods cannot be used for larger cables and alternatives tests such as IEC 60331-1 must be used.

Electrician in front of switchboard holding specification

By contrast, the Category F2 tests in BS 7846 fire resistant armoured cables are based on the protocols given in BS 6387, which also includes a 20mm OD limit, but are modified in the cable design standard to permit testing of larger cables.

Sometimes test parameters, such as the minimum 20mm OD limit in BS 8491, also called up by BS 7846 for higher fire performance cables, mean that some smaller cables such as mineral insulated cables cannot be formally tested even though they may meet the requirements of the test.

Nevertheless, specifying a test that cannot be applied to the cable in question can result in numerous difficulties.

With the arrival of fire performance requirements such as the Construction Products Regulation (CPR), which is mandatory for permanently installed cables in the European Union, end users have been empowered to better specify fire performance classes, such as given in the format Cca-s1a,d0,a1.

These classes are not included in British or European manufacturing design cable standards, although they are increasingly being included in national and local regulation and must be treated as additional specifications.

This may reduce the product choice because not every manufacturer of a given cable design will offer it with all fire performance classes, so the desired class may not be immediately available for the chosen cable.

Testing, Reporting & Approval

Specifying the testing, reporting and ongoing approval regime should be an integral part of the technical aspects of the cable.

End users or regulators in some sectors and territories often request original test reports as well as approval and quality management systems certificates.

BASEC’s view is that a valid, current BASEC approval certificate should be sufficient on its own, as this means that the manufacturer has completed full type testing to gain the BASEC certificate and is undergoing regular surveillance testing and factory visits.

Electrical Terminal Being Serviced By Technician

However, test reports, especially some fire test reports, do offer some additional information that may be used by specifiers for selection purposes, such as whether the cable was found to be close to pass/fail limits or had suffered some test failures.

Note that it is important to understand the test reports’ meaning before relying on them; for example, are any tests missing, and where was the testing undertaken? Seeking advice from an accredited testing and certification body on test reports can avoid problems later.

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Conclusion

Bespoke cable specification can be fraught with pitfalls unless the writer is highly experienced in cable standards and knows exactly what is wanted. If in doubt, always consult with experts to ensure trouble-free procurement.

It is usually best to consult specialist cable manufacturers or trade bodies, although an expert testing and certification body such as BASEC may be able to review your specifications in line with your requirements and application.

BASEC – British Approvals Service for Cables

As industry experts in CPR (Construction Products Regulation) testing BASEC has issued over 3,000 CPR classification reports, delivered through in-house laboratory equipment and by working closely with manufacturers to raise cable product classifications for higher fire performance characteristics.

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

How Do You Measure Fire Resistance?

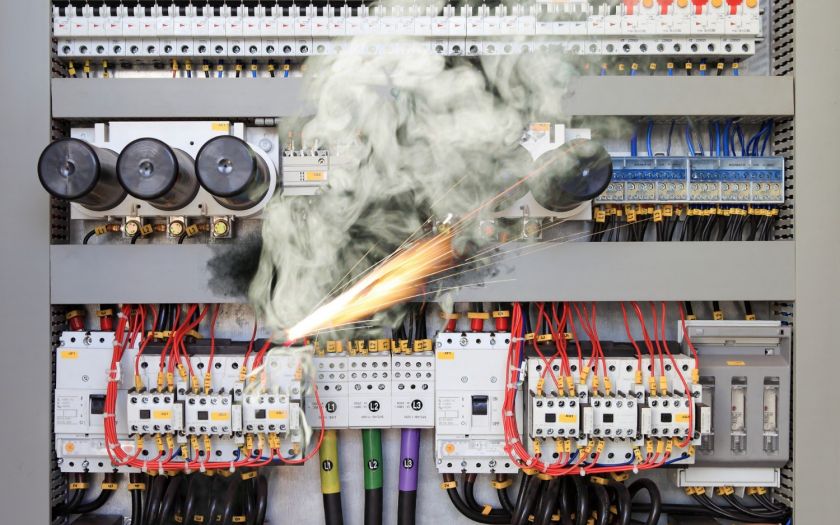

The video below shows that electrical failures and malfunctions are leading sources of ignitions for fires.

In the event of a fire, the resistance class of your electrical cable is critical to how much and how quickly the fire could spread.

54.4% of fires caused by electricity with an average of 4 fatalities per day. Specifying BASEC cables can help you to achieve higher fire classifications through independent cable testing.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

End User Specification Of Approved Cable Products: Where Is The Value?

September 3rd, 2019

-

Blog Written By BASEC | 2 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Specifying independently approved cable products, in projects, provides end users with confidence that the cable installed in their facilities meets the highest standards.

Quality and safety are key concerns for end users, who constantly depend on cables to perform essential activities throughout the day. If cable is damaged or faulty there is a direct impact on the end user.

This can result in the inability to ensure smooth running of operations or even, in the worst cases, the loss of power to facilities.

As a result, the cable may then need to be replaced or repaired, which could lead to significant costs for the facilities manager. Some of this cost may have to be absorbed by other parties who were involved with the specification of the unsuitable cable, for example contractors.

Specifying BASEC-approved cable in construction projects gives the end user a distinguishing factor – a marking on the cable itself, acting as a tool delivering the assurance that the cable installed is of the highest quality and has been independently tested to the relevant standards.

While the initial purchase cost may appear slightly higher than other cables, a cable costing a penny or two more could be the differentiator reflecting additional levels of quality.

Utilising a cable manufacturing source who has undertaken third-party independent testing, to test the properties and materials of a cable product, is an indicator that demonstrates their ongoing commitment to producing cable that is safe and fit-for-purpose.

Powering and maintaining smooth operations

As a member of any buying or purchasing team, assessing or comparing two products, attention should be given to weighing up the initial overall cost of a cable product versus the potential costs of managing an incident.

The costs incurred to rectify or compensate for damage or serious harm to users within the facility can be astronomical in scale.The additional cost, therefore, of specifying BASEC-approved cable at the very start of a project would be considered minimal in comparison.

End users, as well as the supply chain, also benefit from the knowledge, that when they see the BASEC mark, the cable specified and installed has met the prescribed standard or relevant regulatory requirements.

BASEC’s cable product approvals include testing for electrical, mechanical, material, chemical and fire & smoke performance to British, European, international and a range of customer-specific or local standards.

Cable design standards have been developed to ensure that cable products are suitable for their specific applications. Understanding the requirements for compliance, to known industry standards, in key applications, including cable use in MV HV power, utilities, transport and fire performance settings, provides end users with assurance that the cable products installed will be durable and long-lasting.

Electrical Installation

In regions or parts of the world where standardisation is less prevalent, there are few requirements for achieving compliance, meaning that there is also a higher risk involved in using non-approved products.

This only serves to further highlight the importance of obtaining independent testing to verify cable quality.BASEC’s comprehensive testing regimes include rigorous electrical, mechanical, material, chemical and cable fire testing to ensure that cable products perform in the toughest conditions.

While the independent nature, of a UKAS-accredited organisation, means that any tests performed are done so impartially.Cable sampling and testing at BASEC is more stringent than any other cable testing body, with cable manufacturers being required to submit samples in batches; with a clear targeting of cable products in order to obtain consistent levels of quality across manufacturer’s ranges.

Specify & check for quality cables

There is a great deal of long-term value in utilising a measure of cable quality. So why take the risk when it comes to your cable?When you can rest assured in the knowledge that BASEC is respected worldwide for its’ specialist service and commitment to cable industry.

It is this respect that leads the world’s most astute consultants and project managers to specify BASEC-approved cables for prestigious projects, some of which include the Shard, London UK and the Burj Khalifa, Dubai UAE.

BASEC – British Approvals Service for Cables

As industry experts in CPR (Construction Products Regulation) testing BASEC has issued over 3,000 CPR classification reports, delivered through in-house laboratory equipment and by working closely with manufacturers to raise cable product classifications for higher fire performance characteristics.The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.Do not miss your opportunity to build your awareness of cable quality.Click here to register now.

Middle East Electricity 2020, Dubai

BASEC Why specify approved cable?

The video below shows why you should specifiy BASEC as your measure of assured compliance and safety. Substandard cable is everywhere and as an installer you are responsible if non-compliant cable is installed.The importance of good quality cable that is both compliant and safe cannot be understated.The BASEC mark is trusted around the world as a symbol of premium quality and achieving the BASEC mark is not easy. Testing, auditing and certification is to the most rigorous criteria in the industry and is becoming relevant to all international cable markets.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Fire Testing Of Cables Is Important, But Not At The Expense Of Other Performance Characteristics

September 3rd, 2019

-

Blog Written By BASEC | 3 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Learn why a comprehensive testing regime is essential to validate overall cable performance thanks to the latest BASEC blog installment.

Construction projects in the Middle East and Africa are rapidly on the rise, as there is significant commercial investment in the region. As development increases, care should be taken to ensure that effective product testing is undertaken, especially in relation to cable products.

Cable products in the region are required to operate in challenging conditions, enduring harsh sunlight, high temperatures and strong winds. These conditions may increase the likelihood of fire, which is a key concern for those responsible for developing regulations.

Many of these construction projects take place in locations with limited land area available, which leaves contractors with no choice but to build upwards, adding to the cost of development and requiring more technical construction techniques and better-quality materials.

As much of the infrastructure is relatively new, architects often specify the building materials used must meet the standards they are familiar with; including their local or the widely recognised British, European or international standards.

In many cases, specifiers will state that all installed product must also be certified or approved to these standards in order to evidence their quality. An easy way to verify quality is through product certification provided by an independent accredited testing facility.

Engineers installing cable

Knowledge of proven quality standards and their application is an approach to specification which has led to a wide spread of standardisation throughout the region. There is, however, concern that those specifying the products may not be familiar with the real importance of why approved products must be used, and therefore their full benefit may not have yet been realised.

Cable quality is sometimes given less thought than other, more visible, construction materials or components that are used in the design and construction of a building. This can result in low quality cable product being installed, as it is considered last when much of the project budget has already been spent.

Poor quality or unsafe product comes with a danger, putting the people who live or work in the building at greater risk, if something were to go wrong. Many specifiers believe cable will be fit for purpose provided it meets the functional requirements of the specification. As offices, buildings and homes are full of cables, failing to source product that have been independently verified, to prove that the product is what is claims to be, could be a grave mistake.

Why do we need cable?

Cables may be visible or invisible, buried in trucking, walls or other hidden void spaces, taking the form of power cables, optical fibre cables or copper communication cables in many sizes and shapes. If cables are damaged or faulty, equipment and machinery will not function as it was designed to, resulting in an inability to complete essential tasks and increasing the potential risks that a failed electrical product poses to end users.

Most cables are designed and constructed using materials that are suitable for a specific application, for example: a fire alarm cable needs to be fire resistant. If an unsuitable cable was specified for installation with fire alarms, in the event of a fire the unfit product would burn and degrade.

The resultant damage to the cable could mean that the alarm would fail to alert the building occupants to the fire risk, ultimately meaning a higher potential chance for loss of life. In the same way, cables that are laid underground or outdoors will have different requirements to those specified for use inside buildings. For example, outdoor cables require additional braiding or water-resistant sheath linings and UV rating to avoid degradation of the outer sheathing.

Simply specifying a cable that meets a recognised standard does not guarantee it will be suitable for the project or application. It is encouraged therefore, to identify your requirements so that the right cable product and standards can be applied to meet the application criteria at the start of the specification process.

Types of cable testing

Fire cable testing demonstrates what happens when a cable sets alight and confirms whether it is capable of functioning during a fire. When cables burn, they may produce significant volumes of heat, smoke, toxic or corrosive fumes and falling flaming materials (known as burning droplets).

The volume and spread of these emissions can be critical to the further escalation of a fire scenario. The heat can cause items surrounding the source to ignite, while the smoke and corrosive gas can incapacitate those within the vicinity, impairing their senses, making evacuation difficult to undertake.

As cables are routed around a building, this can create a path that makes it easy for fire to spread quickly. Alongside the risks to life, some long term affects to sensitive electrical equipment can also be encountered.

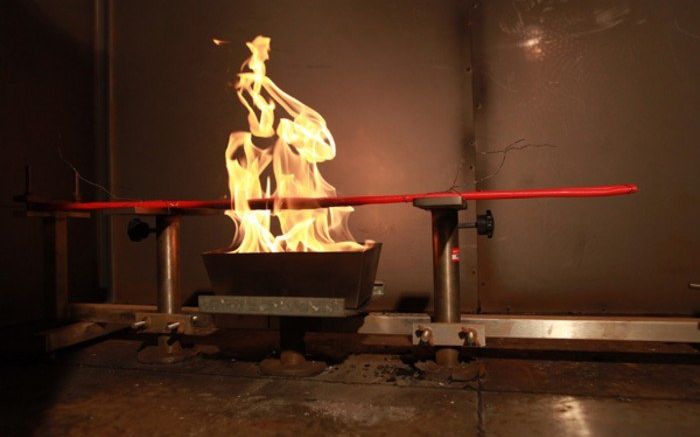

Single Flame Cable Test

While fire testing of cables is extremely important, a comprehensive testing regime should be adopted to validate overall performance. Testing is essential to ensure cables are fit for-purpose, will perform in challenging conditions and will not fault electrically, mechanically or otherwise which may spark and lead to fire.

Completing a range of tests provides a more robust and accurate indication of how a cable will perform during normal use as well as in emergencies. All cables should be tested for a wide range of characteristics to ensure they meet quality and safety standards, and relevant regulatory requirements.

Which other properties are important?

The below introductions will give you an insight into why testing additional performance characteristics, beyond fire testing, should give you confidence in your selected cable products.

Electrical testing assesses the performance of insulation, conductors and cable armour through the application of voltage and use of specialist laboratory equipment.

High voltage and insulation resistance tests are most frequently called up in standards, as these are designed to detect defects and ensure insulation quality is consistent across all cables. Conductor resistance testing is also essential as this assesses the amount and quality of the conductor material within the cable, ensuring that it will successfully carry the current it was designed to.

Overload Electrical Circuit Board

Mechanical testing assesses how well cables will perform in the environmental conditions it may have been specified for.

Flexing tests assess the operation of cable when subjected to regular movement and torsion throughout their lifespan, while abrasion, shrinkage and tensile strength tests are frequently called up by standards as conductors can be exposed during cable operation, which can pose a safety risk and danger.

In the same way, cold impact tests are conducted to check that cable can withstand bending and impact at low temperatures during installation and normal use.

Material testing assesses the durability and longevity of sheathing and insulation, by exposing cables to high temperatures over a sustained period.

Tests range from one hour to over six months in duration and simulate service conditions to understand the typical lifespan these cables are expected to exhibit.

Hot set tests are used to check a suitable level of cross-linking is present within various insulation and sheathing materials, while hot pressure tests check that materials are suitably resistant to indentation at elevated temperatures.

Chemical testing assesses how cable conductors and insulation react to exposure to chemicals.

Other tests check for corrosive and acid gas, pH and conductivity, and the presence of halogens, which may also form part of effluent testing when burning. They also assess oil and grease resistance as exposure to these substances can cause insulation to degrade and crack.

Common chemical tests also include the measurement of tin coating applied to conductors and the weight of zinc coating which is applied to armour wires. Checking these properties ensures that a suitable quantity of each material has been applied in the production of the cable.

Fire testing is important because it assesses how well cables perform in the event of a fire. Single flame testing is the minimum performance requirement called up in standards, and the purpose of this test is to measure flame spread characteristics of both materials and cable construction.

A vertical ladder test works in the same way but on a larger scale and applies to multiple cable lengths. Circuit integrity tests check that cables will continue to operate sufficiently well during a fire to supply power to emergency apparatus, while smoke emission tests measure the density of smoke produced.

Burned Cable Ladder

Each of these testing criteria assess specific characteristics of cable performance and help to provide a more robust view of quality and safety. While cables may be appropriate in terms of their fire performance, this does not guarantee they will perform effectively when exposed to extreme temperatures or power surges.

It is therefore critical that a range of characteristics are known and quantified for the end user to specify correctly the right product for any given application.

Cable testing and building regulations

Cable performance should be integral to the tendering process for any building contractor and is often included within codes of practice and local, National and International regulatory requirements. While requirements vary between regions, the main objective is usually to ensure the health and safety of those who will be inhabiting the buildings. With new building codes having recently been published in Ghana1 and Nigeria2, building regulations continue to evolve around the world.

Whether a country has existing building regulations, or an organisation is seeking the additional peace of mind that independent testing provides, comprehensive testing of building components is recommended. Partnering with BASEC to help you deliver your commitment to quality and safety is your choice.

The Construction Products Regulation (CPR), for example, has required since July 2017 that all cables sold into Europe intended for permanent installation in a building or civil engineering work are CE marked, to validate compliance to the fire performance requirements of EN 50575.

The CPR awards a fire classification based upon how well cables have performed through a range of fire tests EN 50399, EN 60332-1-2, EN 61034-2 and EN 60754-2, with ratings ranging from classes Aca (the highest) to Fca (the lowest).

Dubai Tower Fire

As cables are safety critical items, quality and safety should be at the forefront of your mind when specifying and selecting the right cable for application.

Cable must be fit for purpose and manufacturers not only have a responsibility to themselves but also to the end user that the cable they manufacture will function as designed and has been independently approved and verified.

Cables can be simple or complex and minor changes to the design, material inventory or manufacturing process can significantly affect their properties, potentially causing them to no longer function as expected, either in normal use or extreme conditions, which can have a serious impact on life and property.

Failure of systems can have tragic consequences as the recent fires at The Address Tower in Dubai and Grenfell Tower in London have demonstrated.

BASEC is the preferred testing and certification partner to the worldwide cable industry. The mark of independently approved quality and safety is only awarded when cable products have been rigorously tested to meet the highest industry recognised standards. The BASEC name is synonymous with quality and safety and our independent cable certification and testing is trusted and respected around the world.

For over 45 years BASEC has been a mark of reassurance for those manufacturing, specifying and installing cable. Our comprehensive product testing approvals, stockists and control cable certification schemes provide purchasers and contractors with the peace of mind that the cable they install is compliant, safe, fit for purpose and will provide years of reliable service. To discuss your requirements, contact the team now.

1Construction Review Online

2Global Construction Review

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

BASEC – British Approvals Service for Cables

As industry experts in CPR (Construction Products Regulation) testing BASEC has issued over 3,000 CPR classification reports, delivered through in-house laboratory equipment and by working closely with manufacturers to raise cable product classifications for higher fire performance characteristics.

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

How Do You Measure Fire Resistance?

Electrical failures and malfunctions are leading sources of ignitions for fires.

In the event of a fire, the resistance class of your electrical cable is critical to how much and how quickly the fire could spread.

54.4% of fires caused by electricity with an average of 4 fatalities per day. Specifying BASEC cables can help you to achieve higher fire classifications through independent cable testing.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Top Dos And Don’ts – Cable Delivery, Pulling And Installation

September 3rd, 2019

-

Blog Written By BASEC | 4 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Although present everywhere, cables seldom impact their users; they are usually hidden from view, and, if they are fulfilling their role correctly, require no attention. They should perform reliably for many decades if they have been correctly specified, conform to relevant standards and specifications, carry BASEC or another recognised approval, and have been carefully maintained. Protection from environmental and mechanical stress is also essential.

However, even cables that are sourced responsibly are at risk during initial delivery and installation. During this phase, they will be subjected to movements, stresses and strains – and if these exceed the cable design limits, damage becomes a strong possibility. Even simple issues like snagging on sharp edges can have serious consequences.

Installation cable damage can lead to customer dissatisfaction, significant delays in project completion, extra resources being needed, and in particular, additional costs imposed on installers for removing and replacing damaged cables.

These problems can be exacerbated if the effects of any damage do not become apparent, potentially affecting the supply of power, control or communications, until after the installation has gone into service.

Below are some top tips for a clean, trouble-free installation:

Cable delivery and cutting to length: Safe handling of cable starts with the supplier, often a distributor or wholesaler. Manufacturers will deliver cables on an appropriately sized drum or reel, loaded under controlled factory conditions.

Cutting the cable to length, and redrumming onto an often-smaller delivery drum can result in over-bending if the drum belly diameter is too small; additionally, the cable may suffer external scuffing damage.

Cable caps: If suitable end caps are not fitted onto the cut length, water may penetrate the cable during storage or on site.

Bend radius – armoured cables: Bend radius is a key consideration, particularly for armoured cables and for higher voltages of 11kV or more. Minimum bend radius is generally defined by cable standards, or is advisory; it should be communicated by manufacturers and passed on by suppliers to the installers. Sometimes two figures are used; a dynamic radius for the pull, and a possibly smaller final static radius for when the cable is no longer under tension.

Maximum cable tension and sidewall pressure limits can both cause damage if exceeded when pulling cables. To prevent this, cable installation routing should be closely assessed, and several rollers or guides used at any bend points. A single cable roller or guide’s external radius is always likely to be much lower than the cable’s minimum bend radius. As a simple rule of thumb, for a four-core armoured cable larger than 40mm OD, a full-sized bicycle wheel should fit within the bend.

Bend radius – screened cables: With screened cables such as BS 7629-1- rated fire alarm types, the minimum bend radius must be maintained to ensure fire integrity. Kinks in the screening or over-tight entry into accessories may compromise fire performance. All such cables will have been fire tested at a specified bend radius, which the manufacturer should communicate to their suppliers and users.

Bend radius monitoring: Monitoring the bend radius on site is not straightforward. Many installers use simple go / no-go templates, but these can sometimes miss the tight parts of bends. Purpose-designed radius gauges can measure extremely accurately, providing reassurance that a cable installation has been completed correctly and safely.

Cable pulling: Problems can occur where cables are pulled in two directions from a common mid-point. Some cable is initially pulled in one direction, then the remaining cable is laid out from the cable drum before being pulled in another direction.

This approach can cause significant damage to a cable that cannot twist freely during installation, or where loops of cable introduce twists. Damage to armour can result in bird-caging and sheath splits.

Workers pulling cable across pipes to supply energy to a neighbourhood

Avoiding cable torsion when pulling is important, and is largely addressed by using rotating pulling heads and a suitable cable pulling sock. Pulling the cable through a rope will restrict rotation and can create problems. Tension built up around each bend will propagate back down the cable, causing issues nearer the drum.

Conclusion

Competent and experienced cable installation teams, using the correct equipment including tension-monitored cable winches, cable pulling socks, and a generous quantity of rollers and guides, should experience fewer problems while ensuring a trouble-free installation.

Cable Rollers | Drum Lifting Jacks | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

BASEC – British Approvals Service for Cables

As industry experts in CPR (Construction Products Regulation) testing BASEC has issued over 3,000 CPR classification reports, delivered through in-house laboratory equipment and by working closely with manufacturers to raise cable product classifications for higher fire performance characteristics.The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.Do not miss your opportunity to build your awareness of cable quality.Click here to register now.

Middle East Electricity 2020, Dubai

BASEC Why specify approved cable?

The video below shows why you should specifiy BASEC as your measure of assured compliance and safety. Substandard cable is everywhere and as an installer you are responsible if non-compliant cable is installed.The importance of good quality cable that is both compliant and safe cannot be understated.The BASEC mark is trusted around the world as a symbol of premium quality and achieving the BASEC mark is not easy. Testing, auditing and certification is to the most rigorous criteria in the industry and is becoming relevant to all international cable markets.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Specifying Quality Cable For Your Projects

September 3rd, 2019

-

Blog Written By BASEC | 7 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Specifying quality cables for construction projects may not be top-of-mind when preparing building specifications, however, failures in cable can result in costly damage and even loss of life. Purchasing independently-verified cable is one way to ensure the cable you specify is safe to use and meets all relevant regulations.

As your customer’s first point of contact, at the specification stage, construction projects will have key requirements or a need for specific criteria to be adhered to.You’ll often be involved in assessing and awarding the main contractor who will be responsible for conducting the risk assessments and ensuring control measures have been put in place, prior to the project commencing.

Ensuring quality materials and cable accessory products are specified at the start of a project, is one of the most effective ways to manage risks and minimise any potential costs of poor quality, which may arise from using substandard materials or products.

Working closely with the main contractor, electrical installers with the appropriate credentials can be selected. Special attention from the experts can be used to your advantage to ensure that any issues with cable quality can be identified and addressed, prior to any significant impact on the project.

When on-time delivery is a critical component of a project cable products, if decided upon late in a project’s timing plan, may not be available or could have long-lead times associated to them.

Cable products are almost always made to order, however if the timing plan has not accounted for these lead times a margin of error can be built into the project without full realisation. Off the shelf products may at this point be sought based on availability, meaning that they may not potentially be the right product for the application.

In the same way that buildings are required to meet regulatory standards for a wide range of requirements, cable products must also meet specific standards for quality and safety. However, simply meeting a standard does not guarantee a cable will be suitable for its application.

To ensure that cable products specified are of the highest quality and will perform as intended, in the right application, products should be independently verified. A comprehensive set of tests should be conducted on a cable at the manufacturing source to confirm how the product will perform in long-term service.

Many high-profile projects specify cable products, prescribing that they must be tested independently to provide an objective assessment of performance and conformity.

Your role in cable specification

As a trusted advisor, customers rely upon your guidance to help meet their business or project objectives and to ensure that the products specified for use in their projects will meet all relevant standards and regulations.

Keeping up-to-date with the latest industry developments in materials and regulations can also be difficult, as these continue to evolve rapidly.

Who is BASEC?

BASEC is the preferred testing and certification partner to the worldwide cable industry. Partnering with cable manufacturers around the world BASEC is focused on improving product quality and safety. Cable manufacturers who are BASEC approved, have undertaken a rigorous auditing programme which looks in detail in how the business and its factories are operating, as well as the processes and production methods they follow.

Product samples are randomly selected from the product ranges undergoing product certification and these are sent to BASEC’s laboratory for testing. Once product approvals are awarded, these are publicly displayed on www.basec.org.uk, giving access to all members of the supply chain a live platform to check and verify documentation from their suppliers.

Alongside factory assessments manufactures management systems for quality, environment and health and safety can be assessed. A key purpose of verifying cable quality at the beginning of the supply chain is to ensure manufacturers consistently produce high-quality products.

What is the Registered Stockist scheme?

BASEC’s stockist scheme is a new certification scheme, which opens the doors of approval to the supply chain and increases the level of independent market surveillance within the cable market. Industry can now cross check cable quality at the point of sale.In years gone by, BASEC was a certification that could only be obtained by those who had their own manufacturing factories and plants. In a bid to drive higher levels of quality and safety, stockists and wholesalers alike can become approved suppliers.

Becoming a Registered Stockist means that measures are in place to test the quality of the product just before it enters the market, where BASEC can in confidence verify performance test results against those achieved at the manufacturing source.

Why should I specify independently-verified cable?

By specifying BASEC approved cable, you can have complete confidence that the product selected has been tested independently to ensure it meets the performance requirements specified. The BASEC mark is recognised around the world, which give you and your end customer complete peace of mind that the product installed will be safe and resilient in operation.

The Registered Stockist BASEC mark provides assurance throughout the supply chain of assured quality, scrutinised at various check points, from source to end user.

How can I find a registered stockist?

Registered Stockists will be listed in a stockist selector application on the BASEC website www.basec.org.uk, following the formal awards ceremony this summer. Where the pioneers of the stockist market, entering the scheme right now, will showcase their certification.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV