Jointers Blogs

Brugg Cable Tools For Jointing & Straightening HV EHV Cables

May 11th, 2021

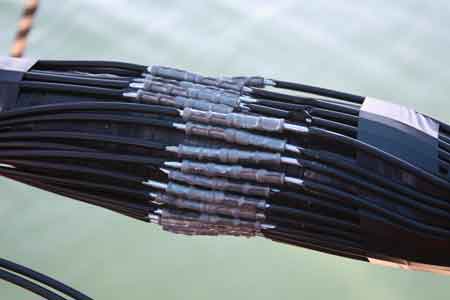

Image: Dean Wilson – Owner Director at D.C. Jointing Ltd

D.C. Jointing Ltd are Specialist Electrical Cable Jointers with a team of 15 skilled staff in all aspects of offshore and onshore cable jointing up to 132kV, including cable jointing LV, HV and EHV, major projects with Regional Electricity Companies, onshore wind farms, offshore windfarms, power stations and National Grid.

Pictured: Brugg Cable Tools For Jointing & Straightening HV EHV Cables

BRUGG CABLES

The development of high voltage XLPE Cable Systems goes back to the 1960’s. Since then production and material technology have significantly improved, to provide reliable and maintenance-free products to the utility industry.

At present, numerous high voltage XLPE cable systems with nominal voltages up to 500 kV and with circuit lengths up to 40 km are in operation worldwide.

Cable systems are equipped with accessories, which have passed the relevant type tests pursuant to national and international standards, such as long-duration tests. As one of the first XLPE cable manufacturers worldwide Brugg Cables passed a Prequalification Test on a 400 kV XLPE Cable System according to the relevant international standard IEC 62067 (2001).

This test required one year of operation, along with the thermal monitoring of all cables, joints and terminations installed. It was successfully completed at CESI Laboratory in Milan, Italy in 2004.

As one of just a few providers worldwide, Brugg Cables can offer a broad range of both XLPE cables (up to 500 kV) and oil-filled cables (up to 400 kV) as well as their accessories.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

May 6th, 2021Images Courtesy of: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services).

HV Cable Splicers: Douglas Page & Jeff Silliphant.

Application: 3M 44kV Cold Shrink Submarine Cable Joint (Single Core 250 MCM).

Location: Lake Couchiching, Ontario. Canada.

Please note aspects of the installation were unable to be photographed as 4 hands were required simultaneously to be cable jointing and no stand-in photographer was available.

Let’s start Cable Jointing….

1. The cable splicing barge comes alongside the buoy marker for a previously installed cable and pulls it up onto the barge, secures it, and anchors all four corners of the barge.

2. The “reel” barge backs up and connects to the cable splicing barge and anchors all four corners, the cable is pulled to the cable splice point and secured.

3. Both 44kV cables are prepared to manufacturers specifications, in this case they were prepared using Speedy Systems high voltage cable preparation tools not hand tools.

4. All of the 3M Cold Shrink Cable Termination kit parts are slid on the appropriate sides and the cable is crimped together.

5. 3M supplied silicon grease is applied by the HV cable splicers – we believe it was changed to colour red to determine if it was actually used in the event of a future cable splice failure.

6. Inner 3M Cold Shrink cable splice body is cold shrink installed without the requirement for a heat source associated with the jointing of cables using heat shrink cable terminations. Aligned with marker tapes previously installed, then the concentric neutrals are brought back across the cable splice.

7. In this situation the high voltage splicing design was to have the neutrals individually crimped to each other, a soft mastic bed is made for the crimp sleeves to lie in to prevent damage to the insulation shield.

8. After the neutrals are all crimped and the shaped into their final position for the cable splice.

9. Once shaped they are evenly spread out and held in place to prevent hang up points for installation of the outer jacket 3M Cold Shrink tube.

10. Very important, the cable jacket is abraded, then two rows of multiple layers of aqua-seal mastic is installed, then the outer jacket is cold shrunk on.

11. To enhance the water-blocking ability of the cable joint the HV cable splicer applies extra wraps of 3M mastic tape.

12. After the outer jacket is installed and sealed using mastic and tape then the submarine armour is wrapped back around the high voltage cable .

13. The submarine cable armour wires are then individually crimped together using Burndy crimping tools and then wrapped in mastic and tape.

14. The entire 3M Cold Shrink cable splice is covered in three layers of 3M Armorcast, (installed wet and sets solid). Then all anchors are pulled, the barges stay attached and the cable barge travels the route, paying off the cable to the end of the reel.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

110kV Cable With Stainless Steel Sheath Plumbed/Wiped To Copper Sheath Cable

May 6th, 2021Image Courtesy of: Andy O’Malley (IBEW 258 EHV Cable Jointer/Splicer).

“This is a stainless steel super sheathed 110kV cable in Brisbane Australia – the high voltage cable had an HDPE graphite coated outer sheath then a stainless steel sheath.”

“A PVC sheath was below the stainless steel then below that a copper sheath. Finally, inside the sheath layers was a 1600sqmm copper conducted XLPE cable.”

“Great project with the Energex boys,” comments Andy.

Further Reading

Confined Spaces Cable Jointing Using 3M Cold Shrink Straight Joint Splice (25kV)

3M Cold Shrink Terminations Connecting Nexans 12kV (MV) Cable Onto Copper Busbar

132kV Termination Using Pfisterer IXOSIL EST SUB Self Supporting Cable Termination

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

25kV Elastimold Tee Connector Terminations Connected To S&C Vista Switchgear

May 6th, 2021Image Courtesy of: Andy O’Malley (IBEW 258 EHV Cable Jointer/Splicer).

Location: Vancouver, Canada.

We have the greatest pleasure in showcasing this first example of Andy’s jointing expertise on our Photoblog – terminating medium voltage cable into S&C switchgear using Elastimold Connectors.

We have plenty more Jointers Blogs from Andy, including an image series featuring the pulling, laying and terminating of 138kV Southwire EHV cable using NKT cable terminations.

Jointing is in the O’Malley genes. Andy’s father Patrick inspired him to follow in his footsteps – we hope to soon run some “old-skool” photo’s from the family archive of Patrick’s splicing work.

Whether down the trench or up the pole, Andy is a key member of the Allteck team.

Allteck are international leaders in the design, construction, maintenance and upgrade of overhead and underground high voltage electric power utilities.

S&C Electric Company – Vista® SD Underground Distribution Switchgear

S&C Electric Company offers another choice in metal-enclosed gear.

Economical new Vista SD Underground Distribution Switchgear is the first practical solid-dielectric medium voltage switchgear with a visible open gap and field-replaceable bushings.

The elbow-connected MV switches and fault interrupters are encapsulated in an environmentally friendly solid-dielectric insulating material.

S&C Electric Company Blog – GridTalk

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Prysmian 132kV GIS EHV Cable Termination – Connector Welded & Cleaned

May 6th, 2021Images Courtesy: David Young – HV/EHV Cable Jointer at CRS Ltd

Pictured: Prysmian 132kV GIS EHV Cable Termination – Connector Welded & Cleaned

Prysmian 132kV

- 132kV XLPE Cable 630mm² Cu/Pb

- 132kV XLPE Cable 1000mm² Cu/Pb

- Composite Outdoor Cable Terminations

- Single Core Transition Cable Joints

- Three Core Transition Cable Joints

- Link Boxes

- Bonding Lead

Prysmian BICON Cable Joints Cable Glands Cable Cleats Jointing Tools

T&D are distributors for Prysmian Cable Components which includes their range of Bicon cable joints, cable cleats, cable glands and jointer tooling for LV, MV and HV cables.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.