Blog

How To Splice A 15kV Cable Using 3M Mining Cable Splice Kit 3103

May 20th, 2021

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

This video by 3M Electrical shows how to splice a 15kV SHDC cable using 3M Mining Cable Splice Kit 3103 safely.

3M Mining Cable Splice Kit 3103 may be used for flexible conduit and mining jacket repairs, as well as for cable splicing and jointing mine and portable cable.

3M 3103 cable splices and joints are for use on 3-conductor mine and portable cables, type SHD-GC, MPF-GC and MPF; # 6 AWG-500 kcmil; 5kV, 8kV, 15kV.

3M Mining Cable Splice Kit 3103 Kit Contents

- 2 rolls 3M Scotch 31 heavy duty mining cable tape

- 1 roll 3M Temflex 1700P vinyl electrical tape

- 3 rolls 3M Scotch 24 shielding tape

- 2 rolls 3M Scotch 2228 rubber mastic tape

- 2 CC2 Dry cable cleaning & preparation kits

- 3 rolls 3M Scotch 13 semi electrical conductive tape

- 3 rolls 3M Scotch 130C linerless rubber self-amalgamating tape – 1 ½” x 30 ft

- 3 rolls 3M Scotch 130C linerless rubber self-amalgamating tape – ¾” x 30 ft

Cable Preparation

Position cable end so that the colour rotation matches. Circle cut the cable jacket 12” from each end. Be sure not to damage the cable conductors. Measure 14” from the cable end and fully taper down to the circle cut.

Remove 12” of the cable jacket and cable fillers. Scuff and clean 4” of the cable jacket beyond the top of the taper. Hold back the grounds and ground check conductors and temporarily tape to cable with Temflex 1700P vinyl tape.

Select one conductor and cut at 9”. Match this conductor with the same colour conductor on the opposite end. Take the next conductor at 6”. Remove ¾” of the braid or tape metallic shielding from each conductor plus one half the connector length plus ¼”.

Remove cable semi con to ¼” of the shielding. Remove insulation for one half of the connector length plus ¼”. Pencil the insulation for ¾” and sand it smooth and even with electrical graded abrasive cloth.

Connecting Phase Conductors

Once the cable is prepared, join the power connectors with the proper connectors and cable crimping tool. Be sure the conductors butt up against the centre indents of the connector.

Note that ground wires and ground check will be joined later.

Applying Primary Insulation

Apply two highly stretched half lapped layers of Scotch 13 from the edge of one taper to the other, making sure to completely overlap the exposed semi conductive shield. Next apply highly stretched half lapped layers of Scotch 130C and up onto the tapers.

Build up half lapped layers building onto the existing insulation to 1/8” from the edge of the original cable semi con. The taper should be wrapped equal or greater than the original insulation.

Apply 2 highly stretched half lapped layers of Scotch 13 over the Scotch 130C overlapping the edges of metallic shielding.

Starting 2” up on the exposed metallic shielding wrap 1 half lapped layer of Scotch 24 over semi conductive tape continuing onto the opposite shielding for 2”.

Secure with a half inch square knot and trim the ends. Repeat connecting the phase conductors and applying primary insulation for the remaining phases.

Connecting Ground Connectors

Beforre cutting the ground wires reposition the spliced power conductors so that the conductors are returned to the natural helix of the cable. Lay the ground wires in their natural position in the valley between the two power conductors. Allow the ground to link staggered so as to avoid connection over the power conductor connections.

Join the conductors with the proper connectors and appropriate crimping tool. If present, connect the ground check conductor after trimming it to the proper length and remove one half connector length of the insulation from each lead.

On the ground check, clean the insulation 1” on both sides of the connection and apply one half lapped layer of 3M Temflex 1700P, one half lapped layer of Scotch 130C and one half lapped layer of 1700P over the connector and the clean insulation. Connect the remaining ground wires.

Jacketing The Splice

Bundle the cable assembly and bind it with 3M Temflex 1700P tape. Cover 1700P tape with one half lapped layer of Scotch 2228 and starting half way up the tapers, wrap half lapped layers of Scotch 130C building up and across the splice until the tape is equal to or greater than the original jacket thickness and extends 1” past the top of the jacket tapers.

Start 2” beyond the Scotch 130C tape and wrap one half lapped layer of Scotch 31 tape extending 2” beyond the 130C tape on the opposite end. Always wrap the Scotch 31 tape toward the machine end of the cable.

Start 1“ past the Scotch 31 and apply 3 half lapped layers of 3M Temflex 1700P to each end to temporarily secure the ends of the Scotch 31 tape jacket until the jacket reaches full bond.

Repairing Damaged Cable Jacket

Remove damaged cable jacket and taper the jacket approximately 2”. Scuff and clean 4” of the cable jacket beyond each split end. Bundle the cable assembly and bind with 3M Temflex 1700P tape.

Cover the Temflex 1700P tape with one half lapped layer of Scotch 2228. Wrap half lapped layers of Scotch 130C building up and across the splice until it is equal to or greater than then original jacket thickness and extends 1” beyond the top of the jacket tapers.

Start 2” beyond the Scotch 130C tape and wrap one half lapped layer of Scotch 31 tape extending 2” beyond the 130C tape on the opposite end. Always wrap the Scotch 31 tape toward the machine end of the cable.

Start 1“ past the Scotch 31 and apply 3 half lapped layers of 3M Temflex 1700P to each end to temporarily secure the ends of the Scotch 31 tape jacket until the jacket reaches full bond.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Mining Cable Splice Kit 3103.

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

154kV XLPE Pfisterer Cable Joints

May 20th, 2021Images Courtesy of: Cengiz Karasu – Chief Jointer Supervisior (Mass Cable)

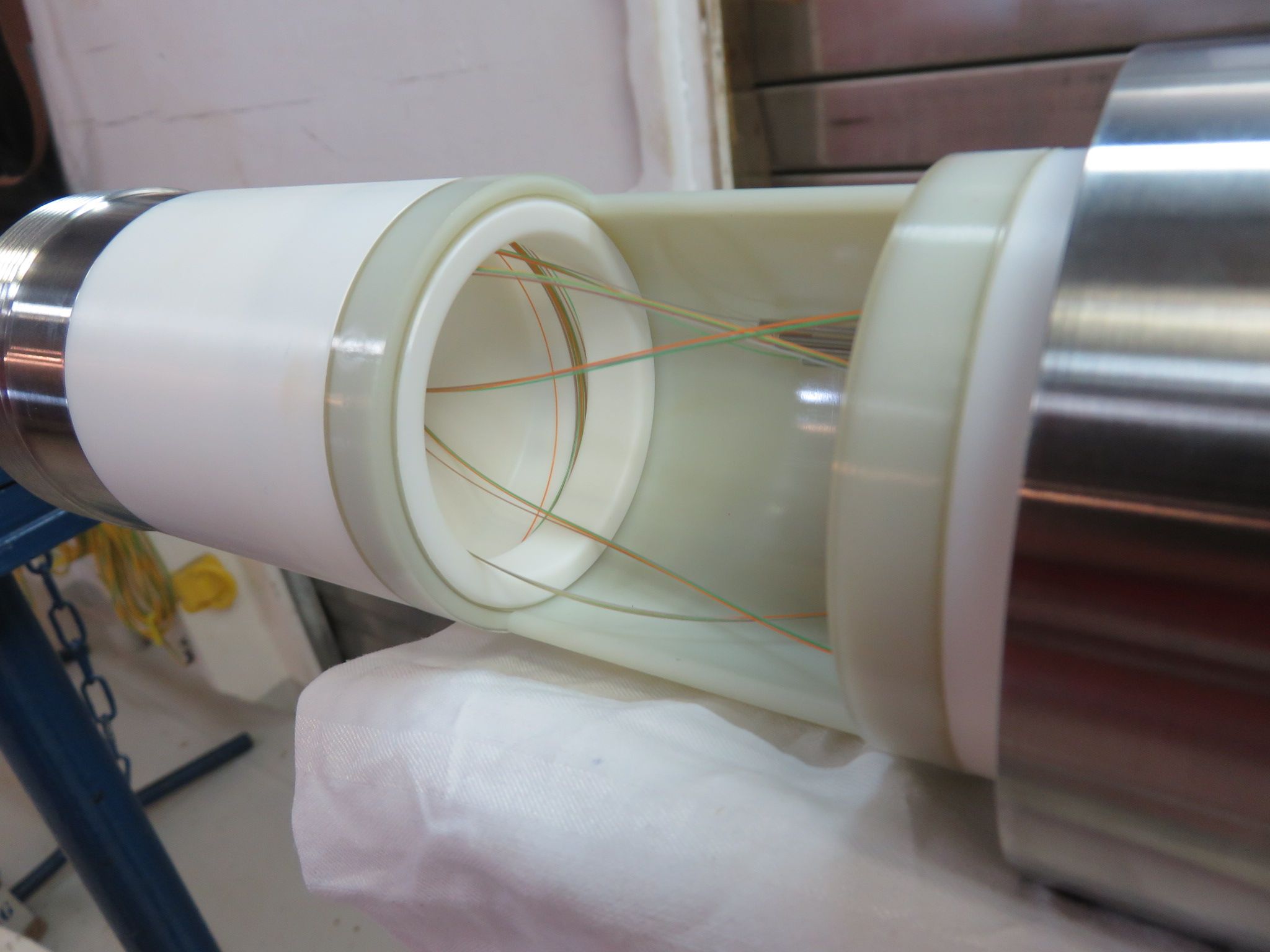

Pictured: 154kV XLPE Cable Joints Pfisterer

T&D are Main Distributors & Stockists for the Pfisterer range of Medium Voltage Power Products including Connex Plugs, SEANEX Connectors, Cable Jointing Tools, Sicon Connectors, Surge Arresters and Electrical Safety Equipment.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Jointing & Connecting Submarine Cables

May 20th, 2021

Images Courtesy of: Steven Onley – Submarine Cable Project Manager at 33Below Pty Ltd and Matthew Shields – Technical Director & Marine Engineer at Vocus Communications.

Steven Onley has 30 years of experience in submarine cable marine installation, covering all facets from contract bidding to system handover, including all offshore operations such as survey, shore ends, jointing, main lay, plough burial, PLIB and repairs as well as office-based project management. Services provided:

- Desktop Studies

- Route Surveys

- Route & Cable Engineering

- PLGR/RC

- Cable Transfers

- Shore End Landings (Direct & Pre-laid)

- Main Lay & Burial

- Post Lay Inspection & Burial (ROV)

- Cable Repairs

- Land Cable

- Procedures & Reporting

Pictured: Jointing & Connecting Submarine Cables

Steven explains ‘How do you connect submarine cable? It is not quite as simple as just making a fibre splice. Cables may only have 6-12 fibres in them, but a cable joint may take a team of 4 cable jointers as long as 18 hours to complete.

As well as making a low loss splice (<0.1dB), we need to reinstate the mechanical strength of the cable (>8 tonnes min breaking load, depending on the cable type), and also the high voltage electrical insulation (up to 12kV DC). This takes some very specialised skills.

An added complication is that each supplier like ASN or SubCom has their own proprietary method of jointing their cable. It would be impractical for repair ships to be equipped with a complete set of every supplier’s equipment, so the suppliers created the Universal Joint Consortium. A UJ (Universal Joint) kit can connect almost any type of cable to any other type of cable, regardless of supplier. Thanks to Mathew Shields for some of these photos, showing an ASN (Alcatel Submarine Networks) cable joint’

Further Reading

- Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

- How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

- Splicing, Wiping & Laying Submarine Cable In San Francisco Bay (1936)

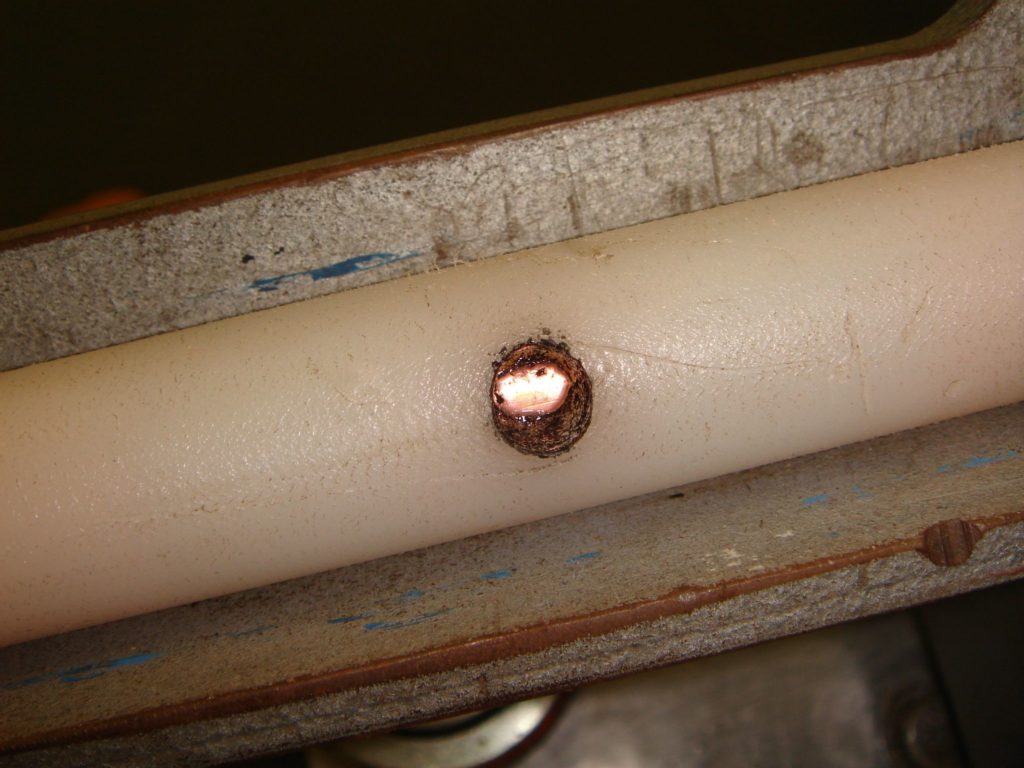

This is what can happens when there is a small scratch or contamination in the cable insulation. Submarine cables are usually powered with several thousand volts DC, which can cause a blow-out of the plastic insulation.

This example is only small (<10mm across – white cable is 21mm diameter) but it was quite spectacular when it arced as it ran along the deck while powered. You can see the burn marks around the edges as the plastic melted.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Nexans Successfully Achieves Electrical Type Test for 525kV DC GIS Cable Sealing End

May 20th, 2021

Nexans 525 kV DC GIS Cable Sealing End

Nexans has achieved electrical Type Test of a 525kV DC Gas Insulated Switchgear (GIS) Sealing End according to CIGRE TB 496 with the cooperation of Siemens Energy

In the frame of the high voltage direct current (HVDC) market, the cables with an insulation composed of cross-linked polyethylene (XLPE) have emerged in the last ten years and allowed the deployment of innovative electrical grids in Europe and worldwide.

Nexans’ ecosystem encompasses best-in-class partners who share our values, working together to continually deepen our ability to stay a step ahead of what the market needs.

GIS type ends constitute an interesting component in the HVDC links due to the flexibility and compaction they allow in the connection of cables of different structures, especially in congested spaces such as an offshore platform. It is also suitable for use in back-to-back mode, thus constituting a mixed joint (e.g. between cables of different technologies).

- Nexans developed a dedicated GIS cable sealing end for a 525kV DC XLPE cable system. The studies on electrothermal aspects of the interface resulted in an optimized accessory design. The solution consists in a Nexans GIS termination plugged in a Siemens Energy DC GIS enclosure both compliant with IEC 62271-209 standards dimensions.

- The validation of the solution has been successfully completed through an electrical 525kV DC VSC Type Test according to CIGRE TB 496. The test was accomplished in Nexans Calais high voltage laboratory under the certification of an independent third-party. This technologic breakthrough allows Nexans to offer competitive products for the deployment of HVDC links with direct connection to DC GIS.

Nexans developed a dedicated GIS cable sealing end for a 525kV DC XLPE cable system.

At Nexans, we are leading the charge to the new world of electrification: safer, sustainable, renewable, decarbonized and accessible to everyone – connecting us all to new opportunities, technologies and behaviours that will build a better future.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Five Steps to Landing a Wind Turbine Technician Role

May 20th, 2021

-

Special thanks to Freya Mortimer from Eden Scott for sharing the article

Wind Turbine Technician Role

It’s an exciting time for the wind power industry here in Scotland with the first ever floating wind farm opening on the 18th of October 2018 off the coast of Peterhead and millions of pounds being invested across the board into onshore and offshore wind developments. So what better time to finally break into renewables and make moves to become a wind turbine technician?

Eden Scott have put together a quick ‘how to’ guide covering the basics of preparing yourself for a wind turbine technician job. Whether you’re looking for an entry level position, or you are more experienced candidate looking to move from another industry, these top tips will help you get yourself ready and qualified.

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Wind industry.

Complete range of MV Cable Accessories to suit wind energy power cables – this includes joints, terminations and connectors from manufacturers including 3M, Pfisterer, Nexans Euromold and Prysmian.

1. LEARN AND TRAIN

Whether you’re an experienced technician looking to change industries or looking for your first position, there are many companies are willing to train technicians on the job.

However, one of the most challenging parts of landing your first role can be building that initial experience and knowledge. If you’re worried that a lack of background in the industry is holding you back, there are a wide variety of options that will allow you to learn and develop those key skills.

Fife College offers a one year multidisciplinary renewable engineering technician course, and Ayrshire College offers a City and Guilds one year wind turbine technician qualification. Both of these are perfect for aspiring technicians with any level of experience outside of renewables; they will prepare you for the job and show you are ready to work and put your new knowledge into practice.

If a year of studying isn’t for you and you want to get stuck right in, there are quick courses that provide industry and technical insight to add to your existing skillset to give you that extra edge. For instance, the European Energy Centre for instance offer a SQA accredited two days long ‘Wind Power Qualification’ that can be taken online or at Napier University.

Sign up for renewable jobs here.

2. GET CERTIFIED

Academic courses are a beneficial, but not a necessary stage in targeting technician roles. However, certain qualifications, licenses and certificates are key requirements. Get a driving license if you don’t have one already; not only are a lot of sites in remote locations, but almost all positions will specify a license as a core requirement. You will often be expected to travel to different sites across the country. The good news is, some organisations offer car allowances or access to company vehicles, you just have to bring the license!

Specific turbine qualifications may need to be undertaken. For example, employers frequently look for wind turbine safety rules (WTSR) or Vestas certification. Requirements change role to role so it is crucial you fully read the job description. You can also find a niche and take training courses in specific types of turbine or blade. Although this limits the variety of positions you’d be qualified for, targeting a specific area can give you a strong chance when these opportunities arise.

Inevitably, many courses come with financial implications. They can be completed and paid for yourself on or offline, but some companies may put you through your training so it is crucial you express a will to build these skills from your first contact with the organization. This will show your commitment and puts you at less of a disadvantage against others who may already be qualified.

3. CLIMB!

Working at a height is an integral part of being a wind turbine technician. You also need to be physically fit, so taking up climbing as a hobby is a great way to keep in shape and simultaneously get comfortable with heights. There are plenty of recreational training centers such as Glenmore Lodge and EICA at Ratho that offer classes and certificates at all levels and have the facilities for you to just give it a go by yourself.

It’s also possible to build up some related height experience in completely different industries; taking up work or odd jobs doing window or gutter cleaning actually puts you in very similar environments and shows your capability working in them!

It’s also possible to pick up an industry qualification showing you know the ropes; this is especially beneficial if you’re from a more ‘hands off’ background. For instance, Talon NDT, who have sites in Edinburgh, Aberdeen and Blackpool, offer a variety of training including Industrial Rope Access Trade Association. If specifically targeting rope access roles, it’s commonplace for employers to look for this at level 1.

Specifically involving heights, employers generally require a CSCS work at heights card which can be taken by Construction Support at a variety of UK locations. As with other elements of learning on the job some employers can put you through these courses and certifications, but if you have the means to put yourself through them you’ll be at a strong advantage when applying for positions.

4. KNOW YOUR LINGO, KNOW YOUR FACTS

When applying or interviewing for jobs it goes without saying that some background research into the role and company is a necessary step. However, it is particularly important if you’re looking at entry level jobs or coming from a science or engineering background outside of renewables.

Showing you know what’s involved in the job, the names and details of the turbines, and how they work will not only make you better prepared when it comes to the interview, but show yourself as a knowledgeable candidate who is ready to learn more on the job. Make sure you have the right lingo to reflect your knowledge and interest in the industry; think turbines and blades, not windmills and fans…

If you’re looking into undertaking formal qualifications you will pick up this information on the course alongside more advanced knowledge, but this isn’t the only way to pick up the basics. There is a wide variety of information and easy to understand guides online explaining the ins and outs of turbines, such as on Good Energy’s website.

There are also of plenty wind power and renewable organisations you can follow on Twitter and LinkedIn, such as Scottish Renewables who regularly post updates and articles about the industry. The fresher and deeper your knowledge, the more appealing you are to hiring managers.

5. SHOW YOUR SKILLS

Make sure the right skills and keywords are on your CV.

This is particularly true for service engineers/technicians looking to move into renewables from another industry; a lot of companies are willing to train you up in the sector on the job, but will be looking to make sure the base skills are there.

Does the role look for knowledge of hydraulics or maintenance?

Make those skills clear. It’s worth remembering that this is for the benefit of both employer and candidate. It might be assumed within your current or previous sector that certain skills and experience come hand in hand with the amount of time served and your job title; but hiring managers might not know this. Make sure all technical experience is included even if it’s not related to the wind industry.

Don’t just focus on STEM experience; more and more roles are looking for demonstrable experience of basic IT. Generally this is Microsoft office programs such as Word and Excel, and even if you might not think it’s relevant, it’s worth indicating if you have an awareness and experience of this software.

If your tech skills are feeling a bit out of touch there are plenty of excellent tutorials on YouTube, or if there’s someone quite tech-savvy among your friends or family you could ask them for a quick refreshed course before your interview.

About Eden Scott

Eden Scott opened the doors of our recruitment agency in 2003; with eight consultants equipped with a computer, a telephone, and a passion for the trade. 17 years on, they’ve grown to be a leading Scottish recruitment agency with over 50 consultants, operating in offices across Edinburgh, Glasgow and Aberdeen.

Eden Scott deliver performance centric recruitment solutions specialising in over 20 different markets across permanent contract and temporary roles.

As well as recruitment, they also design and deliver assessment centres, create compelling digital recruitment campaigns and provide services specifically crafted for start-ups and early stage companies.

See how T&D support, supply and service the Renewable Energy industry.

Thorne & Derrick

T&D are Specialist Distributors to the Renewable industry sector of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold