Blog

Switchboard Building – 2 x 2500A Switchboards With Generator ACB & B/C

March 16th, 2021

Image Courtesy of: Daniel Probert – Senior Electrical Engineer at Johnson & Phillips (Capacitors) Ltd.

Johnson & Phillips (Capacitors) Ltd are market-leading providers of LV – HV Power Engineering Services throughout the UK and internationally. They offer services such as cable jointing, retrofitting, switchgear systems to 8500A, transformer testing, maintenance and repairs.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Non-intrusive Maintenance By Lucy Electric Of Yorkshire | Ringmaster & Oil Filled Transformer

March 16th, 2021

Image Courtesy of: Martin Avis – Energy Services at Lucy Electric

Lucy Electric is a leader in secondary power distribution solutions with over 100 years of industry experience. Specialising in high-performance medium voltage switchgear for utility, industrial and commercial applications, enabling the safe and reliable distribution of energy to homes and businesses worldwide.

Lucy’s best-in-class products are at the cutting edge of medium voltage design and innovation, providing switching, protection and automation solutions with reliability, safety and value built-in as standard.

Thorne & Derrick distribute Lucy Electric and Lucy Zodion low voltage distribution product portfolio including a comprehensive range of indoor and outdoor heavy duty cut outs and service cut outs.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

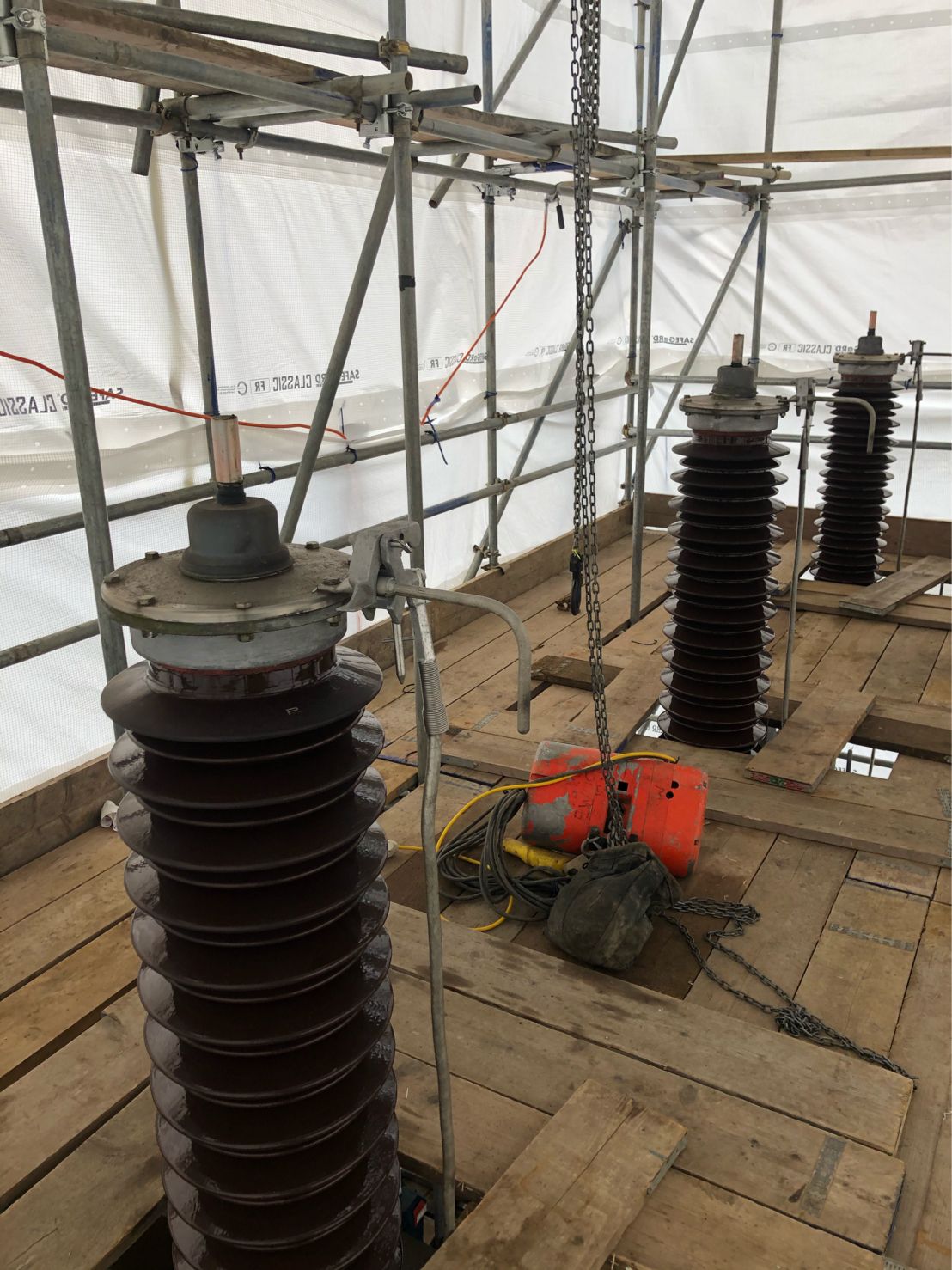

132kV Dry Type ODSE Installed At 275kV National Grid Substation

March 16th, 2021

Pictured: 132kV Dry Type ODSE (Outdoor Sealing Ends) at Kirkby National Grid 275kV Substation

Images Courtesy of: Tom Pickering – HV/LV Cable Jointer at Prysmian Group

Further Reading

- 132kV Outdoor Sealing Ends (ODSE) Manufactured By nkt Cables Installed

- LS 220kV Cross Bonded Joint XLPE 2500sqmm Copper

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

A Faulted UKPN LV Resin Straight Joint (PILC to Waveform)

March 16th, 2021

Pictured : A Failed Excavated Resin Cable Joint, LV .2″ Imperial PILC Cable Jointed to 185sqmm Waveform Cable.

Cable Joint : Sicame straight joint and shell encapsulated with Prysmian JEM Resin.

Image Courtesy of : Gavin Duke (LV 11kV 33kV UKPN Cable Jointer)

Sicame Key Product Groups – Mechanical Connectors for Straight Service Joints, Service/Mains Branch Joints, Single Service Joints, Double Service Joints, Mains Service Breech Joints, CNE Joints, Mains Straight Joints, Mains Breech Joints and Termination Lugs.

Thorne & Derrick are UK Distributors for Sicame

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cable Strikes | High Pressure Gas Main Strike Failure Upper Thames Crossing

March 15th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is usually caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The first in the series is a safety alert thanks to Highway England regarding a cable strike to a high pressure gas main works for trial pits/boreholes.

There are some of the more usual process failures when it came to use of cable and pipe detection equipment and visual assessment of the site. But it raises some important points about design work to ensure there are no conflicts with already present cables and pipes. Also procedures around the electronic device storage and use of design data and ensuring it’s validity for the works about to be undertaken.

With more and more designs, permits and approvals taking place electronically on devices at the worksite this shows a really good example of what can happen should a controlled process not be fully in place.

Thankfully the strike did not rupture the pipe in this incident and it is with thanks that this learning document has been shared for the greater good of the industry.

Incident Overview

Cable Strike – Thames Crossing

On the morning of the 2nd November a mechanically excavated trial pit was programmed to commence at TP01302.

Following the issue of the design to Perfect Circle (AECOM JV), it was identified within AECOM’s GIS system as directly over a high-pressure gas main, which was a clear failure of the CDM 2015 design process.

Managing the risks passed on to AECOM by the design, the trial pit was relocated 9m away from the high-pressure gas main and surveys of the area were instructed on the 1st May 2020.

These surveys returned additional risks and a second and final relocation was selected 29m away from the gas main and surveyed. Survey was completed on the 20th October 2020, this time demonstrating a risk free area of works.

On the morning of the 2nd November a permit to dig and work authorisation pack was prepared for TP01302 with the coordinates detailing the position of the third and final location. The sub-contractor was issued with the works authorisation pack and the trial pitting team travelled to the area to set up the works location.

The sub-contractor set out the location of TP01302 using a digital GPS devise, however the data within this device had not been updated since May 2020 and as a result TP01302 was set out in its original location, directly over the high pressure gas main.

The engineer also failed to check the information within the work authorisation pack which stated the location had been moved twice and contained a single set of co-ordinates to the correct location.

Following procedure, the area around the works area is required to be checked for signs of furniture which could suggest the presence of services and a CAT & Genny scan of the works area undertaken.

Both requirements were not completed to a suitable standard, missing the opportunity to identify a high-pressure gas marker board 10m away or the 500mm cast iron service below the position.

The engineer then completed a Point of Work Risk Assessment (POWRA) and the Permit detailing that the area had been checked, scanned and set out in line with the permit requirements and works were authorised to proceed based on this declaration.

At 3m the excavator operator felt unusual resistance as a 50mm scrape of the excavation was being undertaken. On inspection, the high-pressure gas pipe was identified. All works were immediately stopped and the emergency plan followed calling to site the service provider.

Accident Underlaying Cause

While the root cause of this incident is a failure of the non-AECOM design team to eliminate the risk through design. The poor management of data within digital devices was a significant underlying cause.

Lessons Learnt

When using digitally stored setting out data within GPS devices;

- Ensure that the change management system seeks conformation of changes and updates to digital data sources and storage

- Storage of setting out data within digital devices should be kept to an absolute minimum, with data being inputted to the devise within 24hrs of its use

- Prior to any setting out being undertaken from stored data within a GPS device, the coordinates within the device are to be checked against those within the permit to work / work authorisation pack

- A photo should be taken of the GPS device screen displaying the location coordinates, matching those on the permit and attached to the permit prior to final permit approval to instruct breaking ground

- The numbering convention for relocated trial pits and boreholes should ensure that when any proposed or commenced location is moved, it is issued with a new trial pit / borehole number

Utility contractors working on the installation of underground pipes, cables and ducts in congested excavations should utilise Personal Protection Equipment, including arc flash clothing and insulating gloves to protect against the inherent dangers of electrical arc flash incident: typical applications include cable laying, jointing, ploughing and moling. ATP.

Cable Strikes

An underground service cable strike can lead to injury or loss of life and the costs to business can be substantial. Cable strikes are a growing problem for utilities companies and it is an issue that has challenged the industry for many years.

Despite deploying a variety of cable avoidance tools, staff training and learning and development programmes, cable strikes are still happening.

Power cable strikes have spiked since lockdown prompting the supply industry’s trade body to raise the alert in construction.

Underground powerline strikes from July to September 2020 alarmingly jumped 20% to 475 incidents compared with the same time last year.

The figures for Q3 are running 46% above the previous quarter (April – June 2020) total of 325.

It is not clear whether the surge has come from a rise in utility and roadworks or whether workers returning from furlough or shutdown are now neglecting basic safety procedures.

Research released today by the Energy Networks Association reveals 93% of construction workers believed they always dig safely, yet almost a third (31%) admitted to not always checking for underground electricity cables before beginning work.

Despite the threat to life, the main reasons workers did not check for underground electricity cables was because they felt it was not their responsibility (15%), or they would not dig deep enough to hit anything (24%).

Worryingly, almost one in six said if they uncovered an underground electricity cable encased in concrete, they would attempt to break them out, which could put them at immediate risk of life-threatening injuries.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.