Blog

AN Wallis | Record Sales Results 2020

December 22nd, 2020

MORE NEWS! | 2020 RECORD SALES RESULTS with AN Wallis

Its high time now to offer a most sincere and personal thanks to the transformative B.D.M Jason Leatherland for assisting an almost 80% year-on-year sales growth with Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment – we met, planned, grafted and we delivered+ on mutual promises. Noses never left the grindstone.

Significant UK & European projects wins in the renewable, rail and substation sectors have secured this outstanding performance.

Contact T&D for competitive prices on your Earthing & Lightning Protection Systems.

Thanks also to AN Wallis Team – Andrew Trew, David Beard, Mark Rimmington, Jamie Wright & Andy Chaluda – have a Very Merry Christmas and a Happy + Healthy New Year.

Duct Rod Pushers | Installing Cables Into Conduits

December 22nd, 2020

Duct Rod Pushers – contact us for a quotation or further information

Duct Rod Pushers

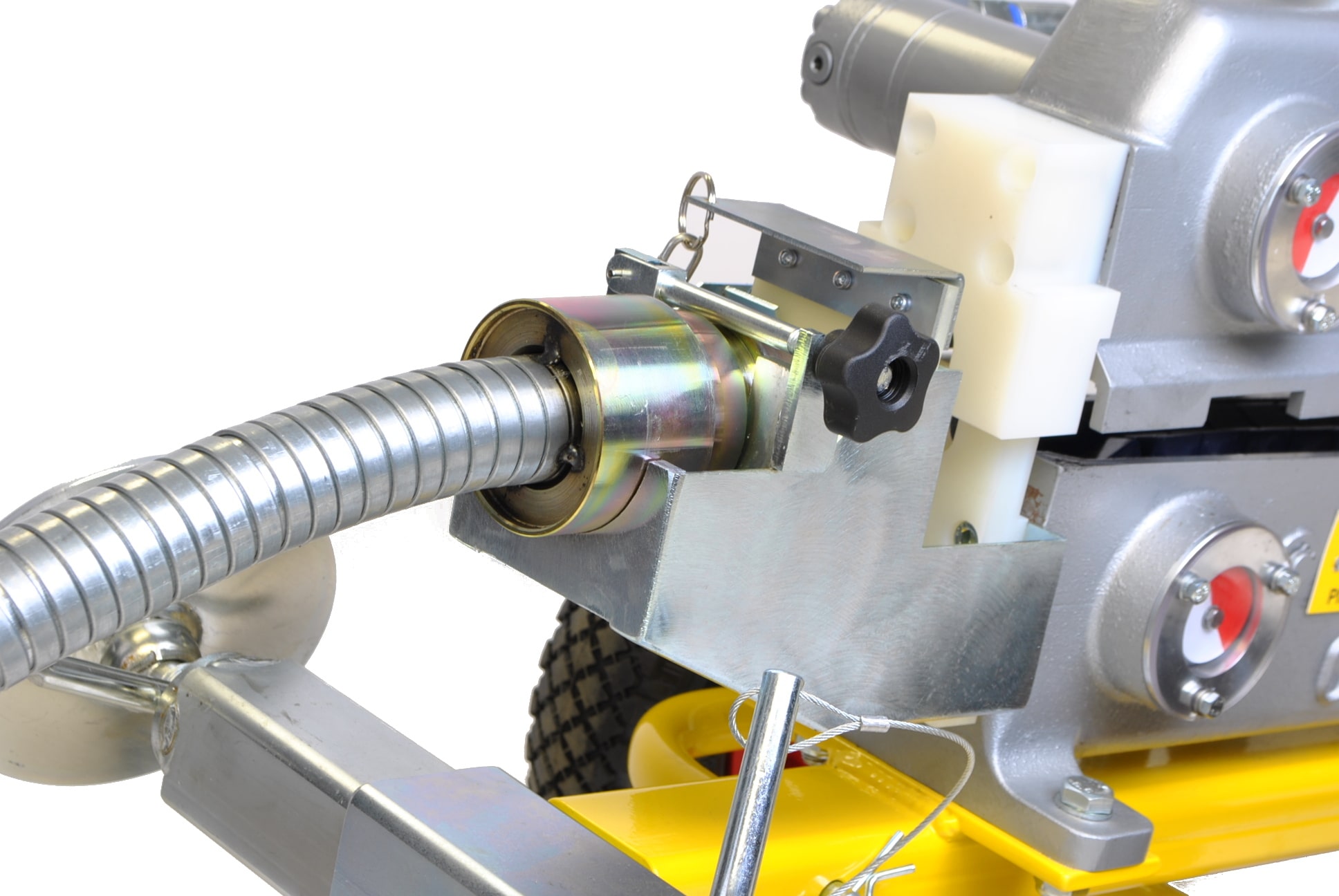

The CBS duct rod pushers are designed to assist in conduit and duct rodding operations.

Duct rod pushing equipment makes placing pulling lines or fibre cables into old or occupied conduits much easier and requires fewer operators.

The duct rod pushers are mounted on sturdy, anti corrosion treated tubular steel frame, and fitted with gel filled puncture proof tyres, with hydraulic controls mounted on the frame for ease of transportation. The rod pushers are fitted with a tilting extendable boom, and chamber clamp for use in underground structures.

Features

- Spring loaded self-centring fail safe operating lever.

- Measuring counter with reset lever.

- Front boom extending to 1 metre with angle facility dropping into underground chamber.

- Extendable chamber clamp for attaching to sidewalls. Range 400 – 800mm.

- Angle of operation 0-45º.

- Duct rod pushers feature integral lifting eye.

- Split pusher body which lifts and rotates to allow removal of duct rod.

- Anti crush control to prevent damage to rod.

- Disc spring controlled screw clamp to engage drive belts onto the rod.

- Cast aluminium body.

- Moulded profiled drive belts.

Contact Thorne & Derrick for competitive prices and delivery on the complete range of Duct Rods & Pushers for cable pulling applications.

Duct Rod Pushers

Specification: C-1270-0001-04-BT

| CBS Order Code | C-1270-0001-04-BT |

| Product Description | Duct Rod Pusher – 50cc motors |

| Diameter Range | 14mm |

| Installation speed | 0-30m/min* |

| Pushing/Pulling capacity | 220kgs at 60bar |

| Length | 1050mm |

| Width | 700mm |

| Height | 760mm |

| Weight | 53kg |

| * When used with the CBS C-1203-F power pack | |

➡ T&D offer the complete range of CBS Cable Blowing Machines for FTTH FTTP fibre optic blowing.

➡ T&D offer the complete range of CBS Cable Blowing Machines for FTTH FTTP fibre optic blowing.

- CBS Tornado Plus Cable Blowing Machine For Fibre Optic Cable Installations

- CBS Tornado Micro Tube Blowing Machine For Fibre Optic Cable Installations

- CBS BREEZE Cable Blowing Machine For Fibre Optic Cable Installations

- JetStream Cable Blowing Machine For Fibre Optic Cable Installations

- See also Fibre Optic Cable Pulling Lubricant

CBS Tornado Plus Cable Blowing Machine

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Roxtec | Record Sales Results 2020

December 18th, 2020NEWS | 2020 RECORD SALES RESULTS with Roxtec Group

Walloping back slaps and stinging high 5’s to the Superstar Team at Roxtec UK & Ireland.

For the technical training and field support from Rob Cullen + Ross Mannin – thanks for seeing, acting and realizing the business potential in Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment.

Seized the opportunity. Now smell the sales. Such proactivity. Distributor support unequalled. A blueprint for Manufacturer-Distributor relations. Thank you to Richard Keith for keeping us LinkedIn posted and updated on the Marine sector.

Special smiles and thanks to Abigail Yates DipM MCIM for encouraging and unleashing the digital and online possibilities – we got our most powerful campaign missiles readied on the launchpad for 2021. And just this morning our friend Jonas Lindblom I see we have further plans. Thanks for the email. See you soon.

It’s impossible to not mention Gav. Gav is Gav. Meteoric career trajectory, master strategist and “old-school” people person. Without doubt, the most product passionate and archetypal Company Man in our supply-chain. Inspirational. Committed. 3 cheers to Gavin Cornall.

Of course, 2020 is just a springboard for 2021.

Merry Christmas from me and our Team to you all – you can’t control the weather, but you can contain the flood.

INVITE | Nexans Industry Leading Technology Days

December 17th, 2020

With over a century of experience, Nexans is proud to be positioned as a world-leader in cable systems.

To showcase their environmental values and commitment to “Electrify The Future“, Nexans would like to invite you to join their state of the art HV Training Centre to enjoy the annual, industry leading, Technology Days.

Sign up to your preferred date below ⬇

| Wednesday 19th January | Thursday 20th January |

Featuring the exciting new technological, and innovative, range of Heat Shrink Medium Voltage Power Cable Accessories, alongside the full range of standardised and customised Joints, Terminations & Connectors for all LV, MV and HV power networks – Nexans technology days are recognised throughout the industry as providing some of the very best insight and technological advances in market including the Euromold brand of separable connectors for the termination and connection of medium voltage power cables into electrical switchgear.

With technical staff demonstrating the latest industry technology coupled with on hand, real time, practical working environments, a Nexans Technology Day is a must for anyone wanting to be at the forefront of the cable accessory installation market.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

A Photoblog: 138kV Southwire Cable Pull & Termination by Allteck Contractors

December 15th, 2020This Article was originally published in September 2015.

Andy O’Malley and Jimmy Nicklin have been jointing cables together for more than a decade.

Andy is a 420kV Cable Jointer and EHV Cable installation  Supervisor while Jimmy Nicklin is an HV/EHV Cable Jointer, Splicer and acknowledged oil cable expert up to 500kV.

Supervisor while Jimmy Nicklin is an HV/EHV Cable Jointer, Splicer and acknowledged oil cable expert up to 500kV.

Both are employed by Allteck, international leaders in the design, construction, maintenance and upgrade of overhead and underground high voltage electric power utilities.

The following sequence of site installation photographs demonstrate the high skill levels deployed by the Allteck team in the cable pulling, termination and installation of a Southwire Canada 138kV cable system.

Southwire Company is North America’s leading manufacturer of wire and cable used in the distribution transmission of electricity.

Together, Allteck and Southwire Canada deliver power 24-7-365.

We all take electric power, heat and light for granted. Until we suffer blackout.

Let us offer thanks to those who power our homes and businesses through the simple act of flicking a switch.

To the Splicers and Linemen who face sleepless nights, dizzying heights, atrocious weather and the constant threat of electric shock.

To the pioneering Cable Manufacturers striving to advance technology and improve the reliability of power systems, whether underground or overhead.

Thank you Allteck and Southwire Canada.

Images Courtesy : Andy O’Malley & Jimmy Nicklin

Installation Credit : Andy O’Malley, Jimmy Nicklin & Allteck Crew

Jetset Jointers – Head in the clouds but feet firmly on the ground. Flying into Ontario the Allteck Team will be talking through the “game plan” for the 138kV Southwire cable installation. Working at high voltage and high height is high risk. “Great Safety is Great Business” is Allteck’s maxim and No.1 core value.

Sub-Zero – Sharp chill in the air and a hard ground frost with the dawn sun reflecting on the frozen ice as the Allteck Team arrive at the job site.

Getting Started – cable jacket scraping is key stage of EHV cable preparation.

Lift-Off – cable pulling commences with completion of the cable chute.

Heave-Ho – cables pulled up monopole ready for scaffolding and then terminating.

Tools of the Trade – cable jointers must hold the correct cable jointing tools to strip and remove cable jacket, cable insulation and cable semi-conductive screens from high voltage cables.

Cable Jointing – high voltage cable stalk positioned and sealed.

If The Cap Fits – hard hat swapped out for baseball cap worn for critical parts of the job once the cable oversheath has been removed as it is critical to not damage the cable insulation.

Wiping Down – a highly skilled stage of cable termination

A Master Craftsman – Jimmy Nicklin (Allteck) showing the world how to “wipe”.

Stripping Off – removal of semi-con screen using Hivotec CP90 jointers tool.

No Cheating On Cleating – installing transmission cable cleats to retain the 138kV cable in the event of short-circuit condition (as if). Southwire cable supported by Southwire cable cleats installed by Allteck crew.

Mission Accomplished – completed NKT ODSE 138kV Cable Termination

Why Specify Southwire?

138kV Southwire Cable Specification & Benefits

- Compressed Round or Compacted Segmental Conductor

- Corrugated Metallic Sheath or Copper Laminate Sheath

- True Triple Extrusion

- Super Clean XLPE Cable Insulation

- Insulation Thickness 650 mils-850 mils

Conductor Material & Size

The choice of the conductor material, copper or aluminium, is a matter of customer preference and required current carrying capacity. For larger loads, copper is the most common option. When both copper and aluminium conductors can satisfy power system requirements, the more economical solution will be a function of the metal and the cable components costs in effect.

Insulation Thickness

Cables referred to by “Traditional Wall” insulation (850 mils) follow the traditional insulation wall practice referenced in ICEA standard S-108-720 appendix F as still specified by a number of customers and utilities. For cables with a radial moisture barrier, “Southwire(SW) Standard Wall” thicknesses of 650 mils in accordance with AEIC specification CS9 are recommended. For applications requiring smaller cable diameters, cables with reduced insulation thickness are available upon request within the stress limits in AEIC specification CS9.

Cable Sheath Material

Copper and aluminium corrugated sheaths offer the best mechanical and moisture protection for HV cable. In addition, copper will provide better short circuit performance and improved connectability. Another option is Southwire composite laminate sheaths in both copper and aluminium that offer excellent protection against moisture ingress.

Cable Jacket

Southwire standard outer jacket is extruded LLDPE with a co-extruded outer semi conductive polyethylene layer for jacket integrity testing. Halogen Free Fire Retardant (HFFR) compounds are available upon request for installations in cable trays and ventilated troughs.

Southwire is one of the world’s leading manufacturers of Wire and Cable, Tools, Components and Assembled Solutions.

“We Want To Produce The Best Wire Products”

Southwire is one of the world’s leading developers, manufacturers and suppliers of building wire and utility cable, as well as the cable tools used in their installation. As such, Southwire are continually improving their products, studying how they’re used in the field and assessing the needs of their customers to find new and better ways to solve the problems facing the industry.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.