Blog

Verifying MV Cable Sheath Integrity

August 18th, 2020Republished with the Kind Permission of Sam Soady |

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

Verifying MV Cable Sheath Integrity

As a cable jointer, most of the time I am called in to jobs at specific times during construction to complete high voltage cable terminations.

I usually only see the end stages of most projects, and the HV cables have already been installed by other contractors.

As the cable jointer and electrician certifying the cable installation, it is important to verify the cable has been installed appropriately. As the cables are generally buried direct underground or in conduit systems, it can be difficult to inspect the cable for physical damage that may have occurred during installation.

This is when a sheath integrity test should be performed. Eccentricity recommends testing the sheath integrity prior to installation (on the cable drum) and post installation (in the ground). This gives you a good baseline to compare to after the cable has been installed and whether damage has occurred during installation.

Potential hazards that can damage the MV cable sheath include:

- Binding machinery that wraps single core cables to tightly into trefoil

- Rocks / debris present in the underground trench

- Sharp edges along the route of installation

- Not using suitable aggregate material or sand when backfilling around cables

Image courtesy of Eland Cables

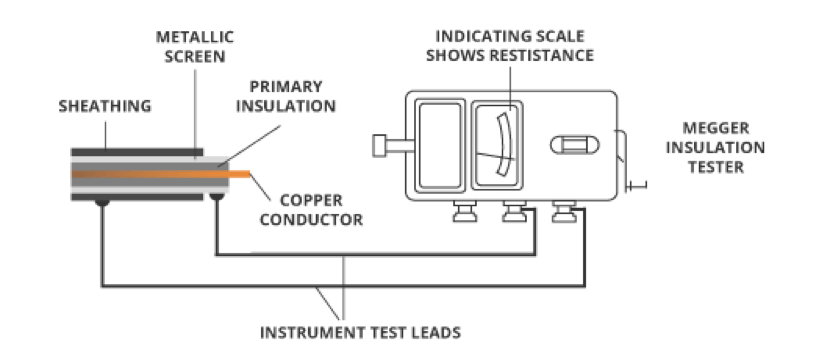

The sheath integrity test consists of a DC voltage injection on the screen wires of generally 1000V on MV cables to the general mass of earth. By proving the insulation resistance of the outer sheath is acceptable, it can be expected no damage to the outer sheath has occurred during installation.

Before Eccentricity completes any terminations for our clients, we complete this sheath integrity test to further ensure the baseline of the cable installed is adequate and the termination has not compromised the sheath in any way.

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

Preventing Cable Theft with Ander-Fin Rail Cable Anchoring Systems

August 18th, 2020Ander-Fin Cable Anchoring Systems

ANDERTON REDUCING CABLE THEFT

With cable theft costing the UK rail network millions of pounds each year, Anderton are tackling the issue with the launch of a new innovative-patented product, Ander-fin – this complements their market-leading range of cable trough systems specified extensively throughout the UK and international rail networks.

Ander-Fin Cable Theft Deterrent

Metal & Cable Theft

Theft of metal on the rails has been a prominent problem for many years, not only at the cost of taxpayers, but it also has the potential to bring the network to a standstill. As the leading manufacturer of precast concrete products, we have designed a system to make cable theft virtually impossible.

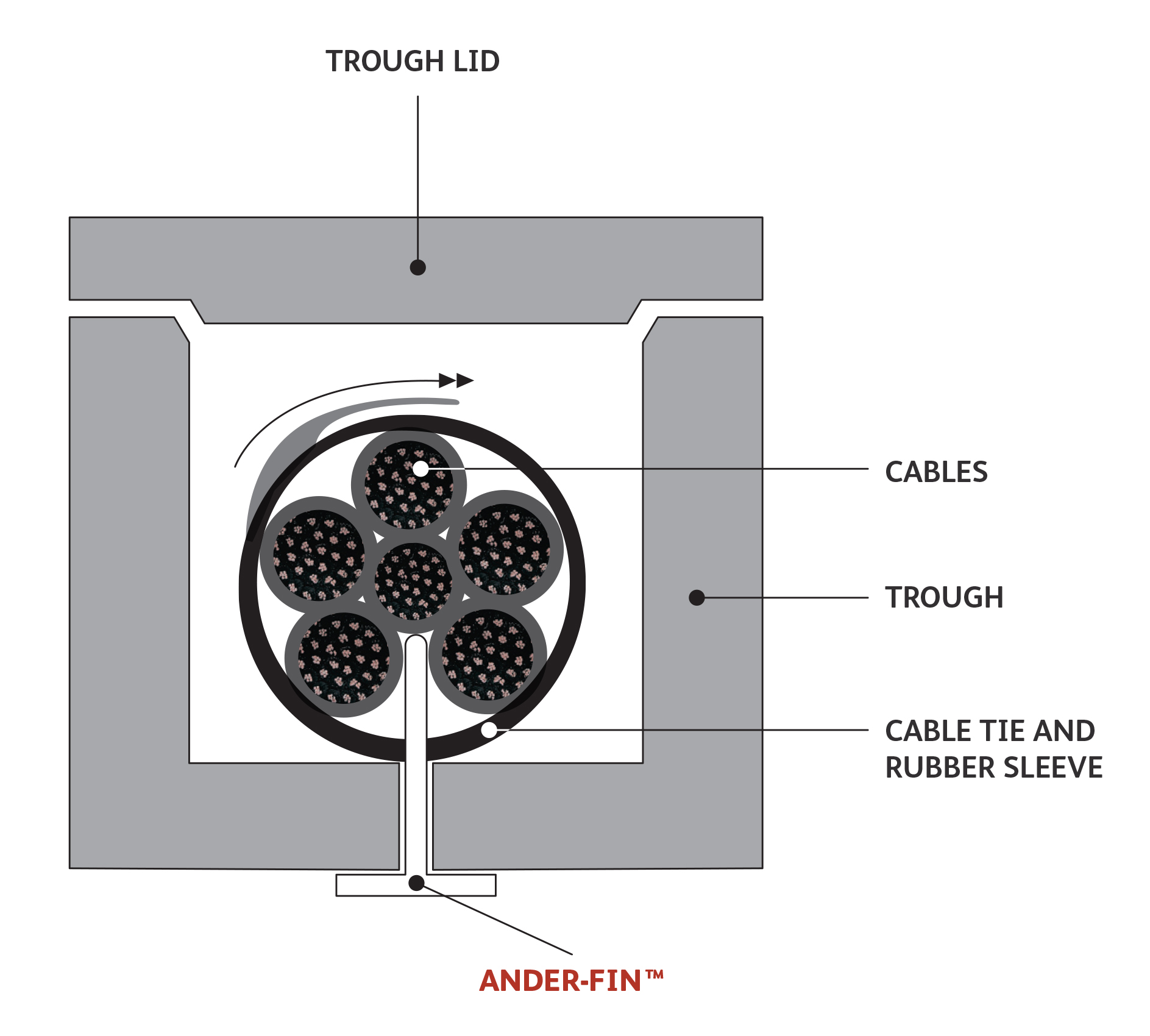

Ander-fin is a newly approved cable anchoring system, which is patent approved and can be used in conjunction with our cable troughs to protect from metal theft.

Every reduced weight trough, which we now manufacture, incorporates a slot in its base to allow Ander-fin to be fitted at the point of installation, which when used in unison creates a system that makes cable theft virtually impossible.

Shaun Forrester, Sales Director for Anderton Concrete commented: “We believe Ander-fin offers an extremely effective solution to a continuing problem within the rail network and its shocking to learn an estimated 50,000 minutes per year are lost on the rail system due to cable theft. The beauty of our patented system is that we have protected every aspect of the system; this includes the void in the trough and the fin itself to anchor down the cable, which prevents any other system replicating the anchoring of cable via a void in the trough.

“For any railway scheme designers who are working in high risk areas, we encourage to specify the patented system as early as possible within the process. This will mean that the trough route is protected against potential theft and therefore reduces the chance of costly delays once the network is operational.”

Ander-Fin Rail Cable Anchoring System

Anderfin Cable Anchoring Systems

Protect against cable theft with Ander-Fin – the newly approved cable anchoring system from Anderton.

Benefits Of The Ander-Fin

- Cable theft costs the rail industry thousands of delayed minutes each year and is costly to replace

- Cable theft causes safety hazards

- Ander-Fin helps to prevent cable theft by securing and tying the cables to the trough

- Ander-Fin secures long lengths of cable

- Can be used in conjunction with Anderton cable troughs

- Ander-Fin cable anchoring system is patent approved

How Does The Ander Fin Work?

How The Ander-Fin Works

The Ander-Fin is inserted into the Anderton trough from below. Then, a Network Rail approved cable tie with rubber sleeve is threaded through the Ander-Fin. Cables are then bundled and secured with a cable tie.

Specification

- The fin is compatible with a range of Network Rail approved clips and sleeves

- The fin is manufactured from glass filled nylon

- Strength depending on orientation of the fin has a failure load in excess of 2kN

- FIRE – The fin material has been tested to UL 94 and achieved V5A rating

- Limiting Oxygen Limit is 32.5 and the material contains no halogen

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

NEW MANUFACTURER – We have signed a new distributorship agreement and are now approved distributors of Cubis. Contact us for Access Chamber Systems, Cable Troughs and Cable Protection.

110kV Oil Filled Cable Joint With Cross Bonding Leads & Link Box

August 18th, 2020Image: Andrew Brezovszky (EHV Cable Jointer | Australia)

Pictured: 110kV Oil Filled Cable Joint (Screen Break) With Cross Bonding Leads & Link Box

110kV Fluid Cables On Flowboards Prepared For Cable Jointing

110kV Fluid Cables On Flowboards Prepared For Cable Jointing

The Final Three Cable Joints Fibreglassed

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

400kV 3200kVA AC Resonant Test System For Guangdong Nanyang Cable

August 18th, 2020Image Courtesy of : Jessica Chen (Yangzhou Power Electric Co.Ltd)

Pictured: 400kV 3200kVA AC Resonant Test System For Guangdong Nanyang Cable

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Offshore Cable Cleating | 33kV Single Core Cable Containment

August 18th, 2020Image Courtesy of : Stewart Cornelius (LV-HV Cable Jointer).

Pictured: Offshore Cable Cleating – 33kV Single Core Cable Containment. 185sqmm aluminium cables and 630sqmm copper cables out of the offshore hang-off using 316 stainless steel cable cleats.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.