Blog

20kV Ensto Cold Shrink Cable Terminations For High Voltage Substations

January 8th, 2020Pictured : Ensto Cold Shrink Cable Terminations installed in preference to heat shrink terminations due to limited working space in high voltage electrical panels.

Location : Roodaki Substation, Tehran, Iran.

Image via : Morteza Sobhani (Expert of Installation and after Sales Services-HV sales Engineer)

Cable Accessory Technology : Cold Shrink

Ensto develop MV HV Joints & Terminations for overhead and underground networks in close cooperation with their customers. Ensto offers a comprehensive solution for 1–42kV underground cable networks. The cable accessory products have been developed to endure the most varying and demanding conditions, and both their mechanical and electrical properties have been thoroughly type tested. Ensto cable joints and terminations exceed the requirements of international and national standards.

Ensto Cold Shrink (MV HV Indoor Termination) Single Core 300sqmm 24kV

Ensto Cold Shrink (MV HV Indoor Termination) Single Core 300sqmm 24kV

Cable stripping dimensions should be carefully observed by the MV cable jointers and the correct cable jointing tools used to remove sheath, insulation and semi-conductive screens.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Electrical Workforce | Are There Problems In The UK Electrical Industry?

January 8th, 2020

The Electrical Workforce Ratio Guidance And Composition

-

Republished with the kind permission of Derek Thompson from Electrical Training Trust

SparkSafe Ltp has emerged from the Electrical Training Trust.

Established in 1998 by employers, Electrical Training Trust has championed the development of employer-Led Level 3 electrical apprenticeship training and adult worker upskilling.

Electrical Workforce Composition

We analysed eleven recent UK Public Sector construction projects with a combined value of circa £200 million to ascertain the composition of the electrical workforce.

The projects ranged in value from £500K to £60 million. Each of the projects is considered to be complex in scope as they:

- require significant coordination and cooperation with others

- make use of industrial pattern materials and techniques

- have an impact on the public

- involve professional design services

- require compliance with exceptional standards

- require a high-level health and safety management

SparkSafe workforce ratio guidance recommends a 50% minimum cohort of Qualified Electricians (QE) where complex electrical work is to be undertaken. None of the projects in the sample meets the proposed recommendations. Eight of the eleven projects are reported with a QE worker percentage between nil and 25%.

Summary of electrical work

- Three projects operated without a QE worker

- Four projects operated with a QE cohort of 15% or less

- One project (circa £30 million) relied on a 47% cohort of Apprentice Electrician (AE)

- The most significant value project (circa £60 million) was contingent on 75% of the electrical workforce operating below a QE licence level

Quality improvement and control measures are likely to be undermined when the model becomes over-reliant on disproportionate use of semi-skilled, under-qualified, or apprentice workers to carry complex and skilled tasks. Exceptions do exist. High-quality, close supervision, and other control measures may off-set the accumulation of defective work, reoccurring snagging lists, and latent defects. However, the trend, if unchecked, in this and other building service sectors, will continue to wither, an already ailing construction industry.

Historical toleration of this model has progressively shifted the Client prerogative to one of necessity and acceptance in terms of workforce composition in parts of the UK. Skilled labour shortages, lack of CPD drivers, and other demographic factors point to an industry that presently struggles to field a match fit team for industrial and commercial projects.

Extended supply chains and health and safety checks at the gate, have blurred Client insight into the occupational identity and qualitative make-up of the contractor’s workforce.

Nevertheless, projects are completed, commissioned, and eventually handed over.

So, what are the problems?

- A decline in quality and standards is widely reported throughout the industry. Clients are often forced to contend or accept failing and inconsistent standards by the industry to gain timely possession of their project.

- Failure to correct the problem means that it will become worse. The virtuous loop of sustainable skill training is replaced by a vicious circle which depletes the industry with a feed of semi-skilled and under-qualified workers.

Photo : Electrical workers undertaking cable terminations by Hobi industri on Unsplash

Conclusion

The resolve of many responsible Electrical Contractors to maintain traditional standards has been eroded as other existing, and new enterprises adjust working practices to win contracts, build turnover and attempt to stay in business. Who could blame them! Discipline and restraint by the industry are poorly regulated. Insolvency and/or prosecution are the primary checks and balances for the UK electrical contracting industry.

Attempts at self-regulation have broken down as competitive instincts and market forces, compel the supply chain to find ways of getting around the national conventions of the industry. Industry-led, self-help efforts must continue. Responsible trade and industry bodies must be encouraged, supported and be subject to constructive criticism in their efforts to do the right thing. Nevertheless, the ultimate authority and influence over the behaviour and development of the industry is the Client.

The findings of our analysis flow from an absence of specification and scrutiny concerning the dynamics and composition of the contractor’s workforce ratio. A greater effort by specifiers and designers is usually placed on material specification. Whereas the competency of those who install those materials is often presumed and unchecked.

High spec materials and low-tech installers don’t make sense!

The striking imbalances across the sample projects are the immediate product of the industry, not the Client. However, by using their buying authority, responsible Clients can halt the decline, reinstate the virtuous loop, and help produce a much-needed win-win outcome for the UK going forward.

WORKFORCE RATIO GUIDANCE

Why was this developed?

Workforce ratio guidance aims to get the balance of manual electrical worker competencies right at site level. Client organisations and their professional representatives are often obliged to work on a trust basis regarding the flow and composition of an electrical contractor’s workforce. The issue of workforce composition and competency is often poorly defined or referenced in the specification and related documentation.

The number of “go-to” competent electrical workers in modern construction and maintenance contracts appears to have declined. Parts of the industry have become over dependant on under-qualified and unqualified electrical workers to meet tender budgets or overcome skills shortages. This shift means that the proportion of electrical competencies may not be matched to the requirements of the project.

We have produced the following ratio guidance as a quality improvement and social responsibility measure with the aim of stimulating productivity and performance. By including labour ratio competency requirements, specifiers will spur the industry towards sustainability in the construction industry.

Guidance on the Electrical Contractors Workforce Composition

Table 1 is aimed at addressing a typical complex multi-electrical service contract.

A Type Contract

| No. of Workers By Licence Type |

5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|

| QE | 2 | 5 | 7 | 10 | 12 | 15 |

| REW | 2 | 3 | 5 | 7 | 9 | 10 |

| AE | 1 | 2 | 3 | 3 | 4 | 5 |

We recommend that the electrical workforce should comprise of circa 50% Qualified Electricians (QE). A concession to make-up the balance of the required workforce by a mix and match approach from the Restricted and Apprentice Licence type should be made available. Note: A reasonable, contract-specific, pro-apprentice weighting should always be applied. We suggest that this should be not less than 20% of the required workforce.

Table 2 is offered in consideration of projects that are less complex regarding scope, value, coordination, risk and programme.

B Type Contract

| No. of Workers By Licence Type |

5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|

| QE | 2 | 3 | 5 | 6 | 8 | 9 |

| REW | 2 | 4 | 6 | 8 | 10 | 12 |

| AE | 1 | 3 | 4 | 6 | 7 | 9 |

This model indicates that circa one-third of the sub-contractors direct and indirect workforce should be fully qualified in line with the QE Licence type. A mix and match option similar to the A-Type concession is made available when it comes to determining the balance of the sub-contractors required workforce across the remaining Licence types.

Electrical EqUipment – Thorne & Derrick

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOGwith contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Electrical & Hybrid Vehicles | Improving Electrical Safety for the EV Industry

January 8th, 2020-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

According to Mckinsey & Company under the current growth trajectory, EV producers could almost quadruple production in 2020, moving 4.5 million units, around 5 percent of the overall global light electric vehicle market.

This rapid increase in the number of electric and hybrid vehicles has introduced and imposed specific electrical safety regulations upon the EV industry.

For example in France, the electrical safety regulations are now codified according to UTE C 18-550 (♦) to provide clear legislative guidance on the responsibilities of the EV industry to prevent electrocution and electrical injury to workers.

Thorne & Derrick can support the implementation of electrical safety precautions with automotive manufacturers, dealership networks and garage repair specialists – products specifically designed to prevent electrocution of mechanics:

EV Safety Products

- PPE | Electric Arc Face Shields, Insulating Gloves & Undergloves

- Floor Protection | Insulating Matting

- LV Test & Measurement | Voltage Detection & Testers (12V to 1200V DC)

- LV Live Working Tools

- Lock Out Tag out & Warning Signs

- EV Electrical Vehicle Safety Catalogue

♦ UTE C 18-550 (Electrical safety instructions for operations on vehicles and motor vehicles with thermal, electric or hybrid motorization having on-board electrical energy).

Electrical Risk Prevention & Safety Kits for EV Industry

Thorne & Derrick stock and supply EV Kits for electrical risk prevention – contact us for further information or to place an order.

- CATU KIT-VE-S1 Obstacle Safety EV Kit

- CATU KIT-VEH EV Safety Signage Kit

- CATU KIT-VE-D EV Car Servicing & Breakdown Kit

- CATU KIT-VE-BCL Instruction Kit

- More Information

Safe Working On Electrical & Hybrid Vehicles

Catu Electrical Safety Equipment Stockists

Do you know that by 2030 electrical vehicle sales will represent 40% of the total sales in Europe & China? This impacts the maintenance approach and safety equipment requirements to enable the industry to work safely. Therefore, CATU as specialist manufacturers of Safety Equipment for the prevention of electrical risks has designed some dedicated kits including insulated tools for live operations, PPE for providing comfort of use and voltage detectors. Discover our complete solution set in the e-mobility brochure.

CASE STUDY

West Midlands Police approached Thorne & Derrick with a requirement for Electrical Safety Kits for forensic collision investigation at life changing and predominantly fatal road collisions. Training has been upgraded with vehicle examinations of electric / hybrid vehicles but no safety equipment had ever been provided. Thorne & Derrick rectified this EV safety shortcoming when the risk was identified by a new member of staff and the CATU KIT-VE-BCL has been adopted by the police force.

Based in the UK, Thorne & Derrick International are the largest Stockist Distributor of CATU Electrical Safety Equipment protecting workers on underground cables, overhead powerlines, switchgear and substations at LV, MV and HV.

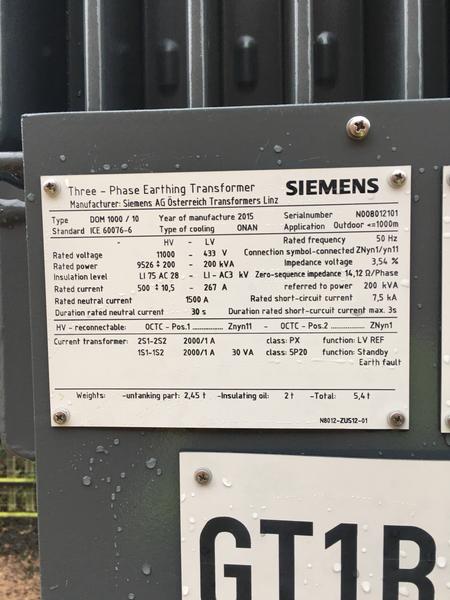

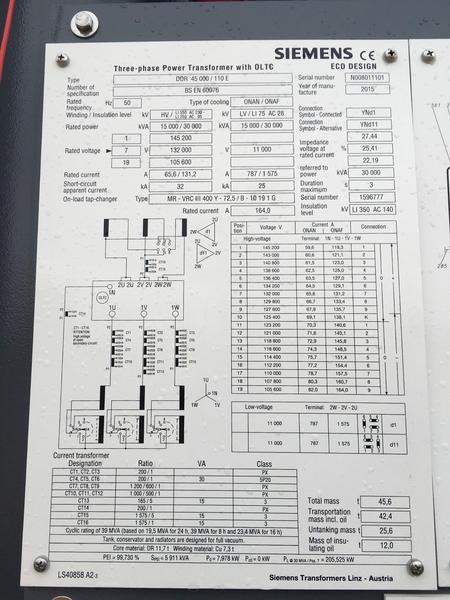

Nexans Euromold 11kV Tee Connectors Terminating EPR & XLPE Cables Into Siemens Transformers

January 8th, 2020Images Courtesy of: Euan Palmer – Cable Technician at Prysmian Cables.

Cable Jointers: Euan Palmer, Alex Hope, David Barnes.

Nexans Euromold are world leaders in the manufacture of Screened Separable Connectors to enable the termination of medium voltage power cables onto outer cone bushings of electrical equipment including switchgear, transformers and motors.

In this series of photographs, Nexans Euromold K440TB separable tee-connectors are shown terminating 11kV polymeric insulated cables into Siemens transformers – the 11kV single core cables include both Tratos (EPR) and Prysmian (XLPE) manufactured cables.

The medium voltage installation is located on Western Power Distribution (WPD) network, the electricity distribution network operator for the Midlands, South West and Wales.

Pictured : 12 x 11kV Nexans Euromold Separable T Connectors Terminating 11kV Single Core Power Cables (9x630sqmm XLPE & 3x630sqmm EPR cable).

Siemens Three Phase Earthing Transformers , 11kV Outdoor

Manufacturer : STL – Siemens Aktiengesellschaft Österreich Transformers Linz

Since 1920, power utilities and industry have relied upon Siemens (STL) power transformers, reactors and earth-fault protection devices.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

/div><

Thorne & Derrick Working With JDR Cables | MV Jointers Tool Sets

January 7th, 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

Thorne and Derrick, the UK’s Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt have provided customised MV Jointers Tool Kits to JDR Cable Systems – JDR based in the UK are world leading cable manufacturers for high performance subsea and power cables for the renewable energy sector.

The Jointers Tool Kits are designed to provide their jointers with the specialist  tools needed to prepare inter array cables prior to the installation of joints, terminations or connectors to the highest standard – included in the customised tool sets are tools to enable the removal of the cable outersheath, insulation (XLPE) and semicon screens.

tools needed to prepare inter array cables prior to the installation of joints, terminations or connectors to the highest standard – included in the customised tool sets are tools to enable the removal of the cable outersheath, insulation (XLPE) and semicon screens.

Housed in Peli Protector Cases – these are rugged crushproof and waterproof cases to provide protection to the tool sets when in transit.

JDR Cables has an impressive portfolio of Inter Array Cable Termination and Test work up to 66kV.

Using their own Approved Tools & Equipment to complete all aspects of the work scope allows JDR to guarantee  the quality and consistency of tooling.

the quality and consistency of tooling.

Expertise comes from their in-house MV Jointers and Fibre Optic Technicians.

Field Services, part of JDR’s Renewable Energy Product and Installation Services group, supports the renewables industry; from project installation consultancy, to pre-commissioning, with full product life cycle support including repair and maintenance.

Market Leading Precision Engineered Cable Preparation Tools for Medium & High Voltage Power & IAC Cables

https://www.jdrcables.com/product-and-installation-services-4/

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

THORNE & DERRICK | LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Nexans Euromold | 3M Cold Shrink | Pfisterer Connex | Alroc Tools Stockists