Blog

Basics of Cable Design and Engineering for Power Systems

January 29th, 2024

Guest Article : Authored by Ryan Smith MSc MIET | Owner of EasyCableSizing.com

As an Electrical Engineer, I’ve always been fascinated by the “hows and whys” in the design and engineering of power cables. In this Article, I delve into the essential aspects from the core components of a power cable to the considerations in choosing the right materials.

components of a power cable to the considerations in choosing the right materials.

Key highlights include:

- the critical roles of conductors, insulation, and sheathing

- a comparative look at copper and aluminium in cable applications

- insights into the evolving world of eco-friendly materials in cable design

- importance of understanding electrical properties like conductance, resistance, capacitance, and inductance

I also discuss the significance of standards like IEC 60287 and IEC 60502 in cable sizing, essential for anyone working with MV and HV power cables. Whether you’re a fellow engineer, a student, or just curious about the field, I believe there’s something valuable for everyone in this piece.

→ See original article here!

Table Of Contents

1.Introduction to Cable Engineering

1.1 Definition and Scope

2. Cable Construction Basics

2.1 Core Components of a Power Cable

2.1.1 Conductors

2.1.2 Insulation

2.1.3 Sheathing and Jacketing

2.2 Types of Power Cables

2.2.1 Low Voltage Cables

2.2.2 Medium and High Voltage Cables

3 Material Selection in Cable Design

3.1 Conductive Materials: Copper vs. Aluminium

3.2 Insulation Materials: XLPE, PVC, and Others

3.3 Advances in Eco-friendly Materials

4 Electrical Properties of Cables

4.1 Conductance and Resistance

4.2 Capacitance and Inductance

4.3 Impedance Considerations

5 Cable Sizing and Capacity Considerations

5.1 Calculating Current Carrying Capacity

5.2 Factors Influencing Cable Sizing

5.3 Utilizing Standards for Sizing

5.3.1 IEC 60287 Standard

5.3.2 IEC 60502 Standard

6 Key Takeaways

Introduction to Cable Engineering

Definition and Scope

Cable engineering is a specialised domain focusing on the design, implementation, and optimisation of electrical power cables. This field encompasses a range of activities from material selection to performance testing, ensuring that cables meet the demands of modern electrical networks.

Cable construction Basics

Core components of A POWER CABLE

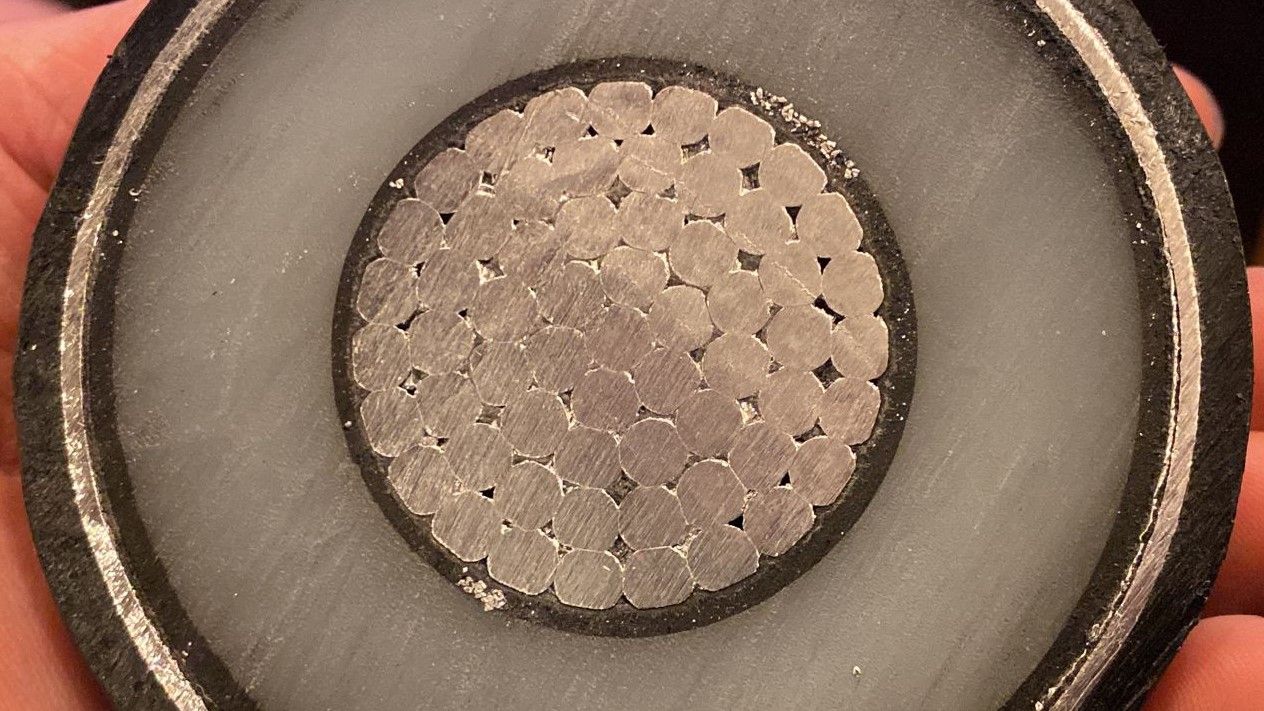

Underground power cables consist of a minimum of two components, a conductor and insulation, however these are usually accompanied by other elements, each playing a critical role in overall functionality:

cONDUCTORS

Conductors are the principal element of a power cables, responsible for transmitting electricity. They are typically made of materials like copper or aluminium, chosen for their excellent conductivity and durability. In other applications where conductors are required, other materials are often used, like gold, but these aren’t feasible for power applications due to their high cost.

iNSULATION

Insulation in power cables primarily provides segregation from a conductor and other conductive materials, whether they’re intended to be conductors or not, but also protects it from environmental factors.

Sheathing and Jacketing

Sheathing and jacketing provide an additional layer of protection to cables, safeguarding against physical damage and environmental factors. This layer is crucial for cable longevity and reliability.

Types of Power Cables

Power cables are categorised based on their voltage capacity:

Low voltage Cables

Low voltage cables are designed for applications with voltage requirements commonly up to 1000V. They are commonly used in residential and commercial settings for everyday electrical needs, and in industrial settings for smaller loads. Learn more about low voltage, heavy-duty industrial cables like the H07RN‑F rubber cable in our detailed selection guide.

Medium and High Voltage Cables

Medium and high voltage cables cater to more demanding applications, such as industrial plants, generation, and power transmission lines. They are able to handle higher voltages and are key in large-scale power distribution.

Material Selection in cable design

Conductive materials: Copper vs. aluminium

The two main materials used for conductors are copper and aluminium, due to their wide availability and relatively low cost.

- Copper, known for its superior conductivity and durability, is often preferred for certain applications, despite its higher cost.

- Aluminium, being lighter and more cost-effective, is a viable alternative, especially for large-scale power transmission.

Insulation Materials: XLPE, PVC, and Others

Different insulation materials like XLPE, PVC, and EPR play a crucial role in cable performance:

- XLPE (Cross-Linked Polyethylene): Known for high temperature resistance and excellent electrical properties, ideal for high voltage applications.

- PVC (Polyvinyl Chloride): Offers flexibility and durability, used in a wide range of cable types.

- EPR (Ethylene Propylene Rubber): Notable for dielectric strength, flexibility, thermal stability, suitable for high stress environments.

- Others: Includes materials like Teflon and Rubber, chosen for specific applications based on properties like fire resistance, low toxicity, or extreme environmental conditions.

Advances in Eco-friendly Materials

The cable industry is evolving towards eco-friendly materials like polypropylene (PP) to minimize environmental impact. PP stands out for its excellent insulating properties and recyclability, making it a promising material for next-generation power cables. However, its application in cable insulation still faces challenges, such as optimising its mechanical and electrical properties. This drive towards sustainable materials is redefining cable technology, balancing environmental considerations with performance requirements. For an in-depth understanding, read more about the potential of PP in power cable insulation in this research article.

Electrical properties of cables

Conductance and resistance

Understanding the conductance (G) and resistance ® of power cables is essential for evaluating their performance. These properties are inversely related, where G=1⁄R. Conductance represents a cable’s ability to allow electric current flow, while resistance quantifies the opposition to current flow. This affects cable efficiency, with lower resistance implying less energy loss as heat. Factors such as material type, cross-sectional area, and temperature influence these properties.

To learn more about the impact of resistance in power systems, consider reading this comprehensive guide on resistance and its effects.

Capacitance and Inductance

Capacitance © and inductance (L) are key factors in cable design, affecting how cables react to different electrical loads and frequencies. Capacitance in cables arises from the electric field between conductors, typically calculated using where is the permittivity of the insulating material, the area of the conductor, and the distance between conductors. Inductance, on the other hand, is influenced by the magnetic field around the conductor and is given by , where is the permeability of the material, the number of turns in the coil, the area, and the length of the coil.

Impedance Considerations

Impedance (Z) in cables, a combination of resistance, inductance, and capacitance, is crucial in AC power systems. It can be represented as , where is the inductive reactance and the capacitive reactance. Impedance affects signal quality and power loss in cables, and its proper management is vital for maintaining the integrity and efficiency of electrical systems.

For an in-depth understanding of impedance and its impact on power systems, you might find this resource on impedance in AC circuits useful.

Cable sizing and capacity considerations

Calculating current carrying capacity

There are various methods used to calculate the current carrying capacity of cables (or ampacity), although the two methods predominantly referenced and used are IEC 60287 and Neher-McGrath. Both IEC 60287 and Neher-McGrath methods consider the heating of a conductor, and the cable’s and surrounding mediums’ ability to dissipate the heat until thermal equilibrium is met. An increase in current results in an increase in temperature, and the less thermal resistivity the cable and surrounding medium have, the more current can be carried.

Factors Influencing Cable Sizing

A principal consideration in cable sizing is the insulation selected for the conductor, as this determines the maximum temperature that can be reached before causing overheating and unnecessary stress or damage to the cable. Beyond that, it is primarily the surrounding medium and installation conditions that influence the thermal resistivity.

For cables installed underground, the soil itself has a thermal resistivity value to be considered. If sand, bentonite, or concrete are used, their own thermal resistivity values and geometry are incorporated into the formulas to determine the cable’s ampacity. If a cable is installed in a duct, the geometry, thermal resistivity of the duct itself, and the filling medium (such as air or bentonite) must also be considered.

Another major factor affecting the ampacity of cables is their proximity to other heat sources, such as other circuits (which are assumed to reach 90°C if insulated with XLPE), hot water pipes, steam pipes, etc. This mutual heating significantly impacts the ampacity calculations, especially in shared trenches or when cables are installed in ladders or trays.

Utilizing Standards for Sizing

When determining the appropriate size for power cables, adhering to established standards is crucial. These standards provide a comprehensive framework for evaluating various factors, ensuring that the chosen cable meets both current and future demands of electrical networks while adhering to safety and efficiency guidelines.

IEC 60287 Standard

The IEC 60287 standard is renowned for its systematic approach to cable sizing. It accounts for numerous factors, including conductor temperature, load pattern, cable laying conditions, and the thermal resistivity of the surrounding environment. This standard is particularly valued for its detailed thermal model, essential in accurately predicting cable behaviour under varying operational conditions.

EasyCableSizing.com plans to integrate this model into its platform, enhancing its cable sizing capabilities.

IEC 60502 Standard

IEC 60502 covers the requirements for the manufacture and testing of cables ranging from 1kV to 30kV. It includes tables of multipliers used against standard cable ampacity tables to determine adjusted ampacities based on specific conditions. These tables are derived from methodologies in IEC 60287, offering a practical guide for cable system development.

EasyCableSizing.com utilizes the IEC 60502 methodology in a user-friendly manner, helping users quickly and efficiently determine cable ampacities. This approach simplifies the complex process of cable sizing, making it accessible to a wider range of professionals and ensuring compliance with international standards. In Understanding the IEC 60502 Sizing System: A Double-Edged Sword this standard in particular is discussed in more detail.

Key Takeaways

- Cable Engineering’s Core Focus: Emphasizes the design, implementation, and optimization of electrical power cables, highlighting its crucial role in modern electrical networks.

- Components of Power Cables: Details the significance of conductors, insulation, and sheathing in cable construction, and their impact on cable functionality and durability.

- Conductive Material Choices: Discusses the use of copper and aluminium in power cables, outlining their advantages based on conductivity, durability, and cost-effectiveness.

- Insulation Material Varieties: Explores different insulation materials like XLPE, PVC, EPR, and their roles in high voltage applications, flexibility, and thermal stability.

- Eco-friendly Material Trends: Addresses the shift towards sustainable materials like polypropylene in the cable industry, balancing environmental considerations with performance requirements.

- Electrical Properties in Cables: Analyses essential properties such as conductance, resistance, capacitance, and inductance, crucial for cable efficiency and performance.

- Impedance in AC Power Systems: Highlights the importance of impedance, combining resistance, inductance, and capacitance, and its effect on signal quality and power loss.

- Current Carrying Capacity Methods: Compares IEC 60287 and Neher-McGrath methods for calculating ampacity, focusing on thermal equilibrium and thermal resistivity.

- Influences on Cable Sizing: Discusses how insulation, installation conditions, and surrounding medium impact cable sizing and thermal resistivity.

- Standards for Cable Sizing: Underlines the importance of adhering to standards like IEC 60287 and IEC 60502 for accurate and safe cable sizing, integrating these standards into EasyCableSizing.com for user-friendly access.

ib vogt – company

ib vogt is firmly committed to supporting the decarbonisation of the global electricity sector. The company focuses on the global development of turnkey PV plants and battery storage projects as well as the expansion of its IPP portfolio. In these areas, the company performs all integral services of the value chain from development, financing, and EPC, to O&M and asset management.

Headquartered in Berlin, Germany, ib vogt has established various offices across Europe, Asia Pacific, the Americas, and Africa as part of its presence in over 30 countries. The company works together with numerous partners globally, augmenting its in-house team of over 700 staff. ib vogt has built or has in construction more than 3.1 GW of PV power plants globally with a project pipeline of more than 45 GWp.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

T&D hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.

So, You Want To Be An Electrician? | Your Complete Guide To The Electrical Industry By Gary Alder

January 29th, 2024

Sparking An Interest & Powering Up Careers – Buy Now

So, You Want To Be An Electrician?

Your Complete Guide To The Electrical Industry

By Gary Alder

Introducing “So, You Want to be an Electrician?” – a comprehensive guide for aspiring electricians. This illuminating book sheds light on the intricacies of the trade, empowering readers to master the art of electrical work. Get electrified with knowledge at our bookstore.

Buy Now – £9.99 Presale Ends 29th February 2024

Gary has spent the last 18 months putting together a book. It’s a guide to everything associated with the electrical industry for those outside of it and even those within it.

He likes to think of it as the information you should have gotten from the career advisor at school! The book will walk you through entry, qualifications, businesses, who’s who, and more!

⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️⚡️

Interested in becoming an electrician?

Many of us toy with the idea of entering the trades. Becoming an electrician is a viable option for many. This book gives you the opportunity to learn all about the industry, whether you’re already in it or not!

Currently on pre-sale until 29th February 2024 with a competition to win a Veto Tech Back Pack! – Buy Now

This book explains what to expect from an electrical career, including everything from apprenticeships to business and daily life as a spark! Not only does it cover your potential career path but it also touches on memberships, safety considerations and the potential future of the industry.

It gives a bird’s-eye view of the key factors you need to consider when looking to ignite your career in the electrical industry.

There’s never been a better time to become an electrician!

Buy Now – £9.99 Presale Ends 29th February 2024

CONTENTS

Below is an overview of all the chapters in the book:

Introduction

Chapter 1 – Apprenticeships

Employers

Attitude

All the Gear, No Idea

Colleges

End Point

Chapter 2 – Late Entrants

Are Short Courses Good?

Wages

The Job Market

The Skills Gap

Chapter 3 – Qualifying

The Moment After

Other Qualifications

Supervising Others

Chapter 4 – Inspection and Testing

Inspection and Testing Qualification

Test Kits

Codebreaking

Testing

Chapter 5 Pick a Sector

Domestic

Commercial

Industrial

Chapter 6 – The Regulations

BS 7671

The Electricity at Work Regulations 1989

More Regulations

The Gap

Chapter 7- The Business Mindset

The Dark Art of Quotations and Tenders

Risk

Profit

The Race to the Bottom

Agency Work

Directors and Shareholders

Programme

Chapter 8 – The Only Certainties in Life Are Death and Taxes

Limited Companies

Inside or Outside?

Chapter 9 – Competent Person Schemes

The Misconception

Qualified Supervisors

Chapter 10 – Other Memberships

Trade Associations

Joint Industry Board (JIB)

Institution of Engineering and Technology (IET)

Trade Unions

Chapter 11 – Continuous Professional Development (CPD)

What’s Continuous Professional Development (CPD)?

Chapter 12 – Safety

Mental Health

Banter

Risk Assessment Method Statements (RAMSS)

Personal Protective Equipment (PPE)

Electrical Safety First

Asbestos

Chapter 13 Challenges

Quality

Advertising

Community Engagement

Chapter 14 – The Future The Environment and Sustainability

Electric Vehicles (EVS)

The Prosumer

Smart Homes

Conclusion

Electricity Kills. Take It Seriously

Abbreviations

References

About the Author

Author – Gary Alder CEng FIET CMgr FCMI

With nearly 20 years experience in the electrical industry, Gary Alder is a Chartered Engineer & Fellow of the IET. After completing his apprenticeship, he has gone on to lead multiple electrical contracting businesses as well as the national infrastructure super sewer “Tideway” in London.

The Podcast

Before writing this book, Gary hosted the electrical industry podcast “Hit the Lights”. Where people from all aspects of the industry have shared their journey and experiences. Become an electrician’s apprentice.

Listen HERE – Hit the Lights (Electrical) Podcast

Horizon Utility Supplies Introducing Cable Safety Improvements to UK DNO’s

January 25th, 2024

Press Release | 26.1.2024

Thorne & Derrick, the Specialist Distributor of LV HV Cable Accessories, Tooling & Substation Equipment, are delighted to announce a Partnership Agreement with Horizon Utility Supplies Ltd, one of the largest suppliers of Tools & Equipment to the UK DNO’s.

“Our Partnership Agreement is focussed on the introduction of the Vicera APU2.0 Cable Jointers Stand to the UK DNO’s and National Grid. Initial interest and sales uptake has been outstanding with immediate acceptance by several utility clients of Horizon and field trials ongoing with others. The APU2.0 is now available from stock at Horizon – please do hesitate contact them for further information, site demonstration or sales enquiries.”

“Thorne & Derrick introduced the Vicera range into the UK early last year and the product has been adopted by many High Voltage Power Contractors, ICP’s, Cable & Accessory Manufacturers including Nexans, 3M, Hellenic, NKT, Tyco and Pfisterer. Working alongside the team at Horizon we look forward to improving cable safety and working practices within the UK DNO’s,” comments Chris Dodds (Thorne & Derrick Sales & Marketing Manager).

“Horizon Utility Supplies are excited to announce our partnership with Thorne & Derrick, for promoting the Vicera APU2.0 Cable Jointer Stand into the major utilities in the Electricity Supply Industry. This collaboration allows us to use the strengths of both companies to deliver workplace solutions to our customers and reflects our shared dedication to meet the evolving needs of our industry.”

“The Vicera range of products offers a great opportunity to kick-start our Partnership, fitting perfectly into our portfolio of products for the supply of equipment for the care and maintenance of the utility network within UK DNO’s. We are very much looking forward to working with our partners at Thorne & Derrick,” comments Richard Casey (Horizon Utility Supplies, Managing Director).

APU2.0 | Cable Stability & Support for MV HV Cable Jointing & Termination

The Vicera APU2.0 Jointers Stand for both field or training centre use provides safe and stable support of Low, Medium & High Voltage Cables – the cable stands are suitable for cable diameters 18-90mm with adjustable height for substation, joint bays or trench use.

The Cable Joint Stands feature step-less lateral and tilt adjustment and high strength clamps to prevent cable slippage or movement while jointing – secure and balanced cables when Jointers are undertaking highly skill-sensitive cable preparation prevents inadvertent damage to cables and future potential O&M reliability.

The cable support stands are rugged and durable for outdoor use in joint bays and trenches in all ground terrain conditions – this includes the support of 11kV/33kV/66kV cables to enable precise cable preparation by the Jointer prior to installation of joints, terminations or connectors on medium/high voltage power cables.

Stability & Security of Power Cables

Horizon Utility Suppliers were established in 1996 specialising in the distribution of equipment and PPE for working live on overhead power lines and underground cables – Horizon hold a reputation for engineering custom-solutions to provide problem solving and innovative products for Linesmen, Jointers, Substation Fitters & Utility Engineers.

Tel: +44 (0)1275 342700 | [email protected]

The POWER Connected | Thorne & Derrick and PFISTERER Training Day

January 24th, 2024Earlier today at PFISTERER Sheffield the Thorne & Derrick Team benefitted incredibly from a Practical Training Day covering the benefits, specification and installation of CONNEX & SICON brands of MV Cable Accessories. The world-class standard of Cable Preparation Skills demonstrated by Dan & Jon using PENTA FRANCE (Alroc) & Ripley Tools assists our ability to provide technical support to customers.

Commercially, we are now further increasing both the levels and extending the lines of our PFISTERER stocks at Thorne & Derrick.

Thanks so much to Daniel Leech, Jon Reed, Mark Hanlon, Bethany Dodson, Tracey Stevenson, Cathy Longstone & Paul Tuckwood.

THORNE & DERRICK LV-HV Cable Accessories, Jointing, Tooling, Substation & Electrical Safety Eqpt | Approved PFISTERER UK Stockists.

PFISTERER with Thorne & Derrick

Ripley US02 Tool – The “Red Ripley”

Pfisterer Cable Training School for Jointers

Alroc CWB – The “Blue Tool”

Stripping MV Medium Voltage Cables 33kV

MV HV Cable Jointers Tools Sets

Supporting Cables Using Vicera Jointers Stands for MV HV Cables

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

When Are Arc Flash Switching Suits Required?

January 22nd, 2024

STRATA Workwear Arc Flash Protective Clothing Range

Arc Flash Switching Suits

Thorne & Derrick are the UK’s Leading Specialist Distributor of Electrical Safety Equipment to clients working in the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – we supply arc flash clothing from a range of brands including STRATA® Protection.

STRATA® Protection a the leading Arc & Flame Protective Clothing brand in the Energy Sector including arc flash switching suits for the protection of workers.

Arc flash switching suits are required in situations where electrical systems pose a risk and are specially designed suits that are used in situations where electrical systems have the potential to release intense energy in the form of an arc flash event. These suits are commonly worn by professionals working in electrical, utility, and industrial sectors.

Switching suits are specifically designed to provide multiple levels of protection against the hazards associated with arc flash events. These suits are categorised based on their ability to shield the wearer from thermal energy, flames, and other hazardous elements.

Wearing the proper arc flash suit is essential in high-risk work environments, where electrical equipment or systems may be subject to faults or malfunctions that could result in an arc flash event. These environments include power plants, substations, electrical maintenance and repair, and other industrial settings – protecting utility workers against arc flash dangers posed during maintenance on underground electric cables, overhead line conductors or electrical equipment.

What garments does an arc flash suit comprise of?

Thorne & Derrick understand how critical it is to have reliable, highest quality personal protection equipment (PPE), clothing and arc workwear available from stock at competitive prices

The arc flash kit typically consists of:

- Arc Flash Hood: A hood designed to cover the head and neck, often featuring a built-in face shield and integrated hard hat. Designed to be used alongside your existing clothing systems to provide specialist protection when working with high incident energy levels

- Arc Flash Jacket: A flame-resistant jacket is tailored to cover the upper body completely, including the torso, arms, and neck, providing a reliable barrier against extreme temperatures and potential burns. Available in a range of different size, including ‘extra small’ (XS) all the way through to 4XL

- Arc Flash Trousers: Specially designed trousers or dungarees that offer protection for the lower body. These garments help guard against thermal hazards and electrical risks arising from arc flash events. Available in a range of different size, including ‘extra small’ (XS) all the way through to 4XL (size 8 to 18 for women)

- Arc Flash Gloves: Insulated gloves made from arc-rated materials, intended to safeguard the hands against the cuts, abrasions, and burns that are possible during an arc flash incident while maintaining dexterity. Available in a range of different sizes

- Storage Bag: A dedicated bag for storing and transporting the components of the arc flash switching suit kit.

All these components work together to provide comprehensive protection against the hazards associated with arc flashes and electrical incidents. It is crucial to select items that meet relevant safety standards and are tested and certified for arc flash protection. Regular training on the proper use and maintenance of these components is also essential to ensure workers’ safety.

When do I need to wear my arc flash Switching suit?

You are required to wear your arc flash switching suit whenever you are working on or near electrical systems or equipment that pose a potential arc flash hazard. This includes situations where there is a risk of electrical faults or when you are working with energised electrical systems.

It is essential to wear arc flash suits to protect yourself from the thermal and electrical hazards associated with arc flashes.

The specific requirements for wearing arc flash suits may vary depending on your local regulations, employer policies, and the level of hazard present. It is crucial to follow industry standards and guidelines to ensure your safety.

Here are some examples of situations you would consider wearing one:

- Switchgear Operations: When interacting with electrical equipment like switchgear, arc flash suits provide indispensable protection against arc flash incidents during maintenance, inspections, or troubleshooting

- Electrical Panel Work: Wiring, repairing, or maintaining electrical panels pose inherent risks, demanding the use of arc flash suits to mitigate potential dangers

- Circuit Breaker Maintenance: Activities involving circuit breaker maintenance and repair require the full-body coverage offered by arc flash suits to prevent severe injuries

- Panel Inspections: During inspections, repairs, or maintenance of electrical panels and distribution boards

Arc Flash Clothing Kit 40 Cal

How often do arc flash suits need to be tested?

It’s important to note that while periodic non-destructive testing is not required for arc flash suits, it is still crucial to adhere to industry standards, guidelines, and manufacturer recommendations to ensure the safety and effectiveness of the suits.

However, the frequency of testing may vary depending on the usage, condition, manufacturer’s recommendations, and relevant industry standards or regulations. Additionally, suits should be inspected prior to each use for any signs of damage or wear and should be replaced if necessary.

However, there are recommendations out there for maintenance:

- Consider replacing the clothing for the suit every 10 years (this will depend on how often you are using the suit, less frequent usage may result in the kit lasting longer)

- Keep your arc suit clothing free of oil, grease, dust or – carefully read the laundering instructions to maintain the integrity of the garment.

- Refresh your face shield every 5 years. Should the face shield show substantial scratches or discolouration, take immediate action to replace it.

- Audit your full kit – take the time to look for scratches on your helmet, rips or snags in your clothing and take the safest course of actions after the audit and replace where necessary.

Alternatives to Arc Flash Suits

It is important to note that the effectiveness of arc flash clothing and personal protective equipment (PPE) depends on various factors such as the level of risk, the specific tasks involved, and the hazard analysis conducted.

While layering other items of arc flash clothing and PPE can provide adequate protection, it is crucial to ensure that each layer is properly selected and compliant with relevant safety standards. The layering should also not compromise mobility or restrict the wearer’s ability to perform their tasks safely.

Providing a variety of options for engineers to choose from can certainly contribute to their comfort and well-being. It is important, however, to prioritise safety and effectiveness in selecting the appropriate arc flash clothing and PPE. Regular maintenance and inspection of these items should also be carried out to ensure continued protection.

Further Reading: STRATA Workwear | Skanwear Arc Flash Clothing & Protection

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.