Blog

Flooding & Underground Cables: Myth or Reality?

September 6th, 2021

Protecting Underground Cables

This Article was originally published by T&D World.

From Superstorm Sandy to Hurricanes Harvey, Irma, Maria, Florence and Michael – the volume of rain and storm surge has and can cause unprecedented flooding.

Flooding negatively impacts power systems – but not for the reasons you might think. Power Delivery Intelligence Initiative (PDi²) is taking on the myth that flooding compromises underground cables.

Medium and high voltage cables are designed to be direct buried, often in areas where they will be below the water table and permanently in a wet environment. Under normal weather conditions, manholes and vaults are often full of water and need to be pumped out for even routine inspections.

Outer jackets for these cables, made of polymeric materials, resist moisture permeation to prevent water incursion into the cable over the life of the system.

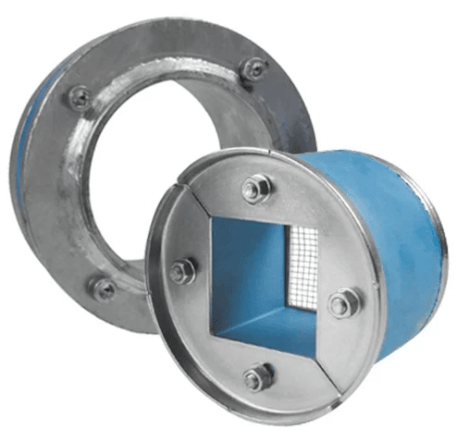

Roxtec Cable Transits provide effective protection to LV HV substation cables against flood damage and water penetration be it in dry or wet conditions.

In the rare instances that water permeates a cable jacket, certain insulations, including tree-retardant crosslinked polyethylene, are designed to resist growth of water trees that could cause premature cable failure. In addition, cable also can be manufactured using moisture-blocked conductor, water-swellable tapes and powders and corrugated sheath to make them more moisture impervious.

Underground cables are expected to meet rigorous standards specifically addressing operation under adverse weather conditions like flooding. These standards take into consideration both moisture and chemical resistance as there can be significant differences between rain and flood water. ICEA, ANSI and AEIC require adherence to a variety of test procedures that address moisture barriers, water-blocking components, water-resistance tests and other sealing components and technologies.

CSD RISE Duct Seals – combining ease of installation with cable duct sealing and protection against water, gas and fire.

Cables are rarely at fault for failures related to flooding.

The biggest concern for flooded underground systems are the open-air terminations at ground level where external or internal contamination has occurred due to poor sealing. However, technology is improving here as well.

Certain elbow and T-bodies are typically submersible and have not shown any significant negative impact after flooding. Joints and other accessories like link boxes are used in manholes and vaults and can be designed and installed in such a way that they can operate submerged in water without compromising cable insulation integrity.

Areas known for periodic flooding can take additional measures for outer protection of cable joints like metal housings moulded with epoxy coatings or fibreglass boxes filled with water sealants.

These designs are typically electrically screened with electrical fields that are fully contained within the solid insulation of the cable.

Myth – flooding and underground cables

busted.

Cables are made to resist water under both normal and extreme operating conditions. As long as water does not extend to the exposed terminations, there is little risk of failure due to flooding.

Where terminations are at ground level, technology and products exist to mitigate the chance of failure. These solutions should be part of storm hardening efforts and decisions regarding choices for new and rehabilitated power infrastructure.

Joint | Terminate | Connect Medium & High Voltage Cables MV HV

Further Reading

- Sealing Underground Cables & Pipes Under Constant Water Pressure

- Submersible Switch Applications By G&W Electric

- 21st Century Costs of Underground Distribution

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Onshore Cable Pulling Starts At Seagreen Offshore Wind Farm

September 6th, 2021

Cable Pulling & Laying

Work is underway to pull cabling through 19.5 kilometres of underground ducts which will connect the GBP 3 billion Seagreen Wind Farm to the Scottish National Grid.

The cable pulling is the latest stage in the cable installation process and another milestone in the construction of the 1,075MW 114-turbine development 27 kilometres off the coast of the county, which when operational, will power up to 1.6m homes throughout the country.

Once finished, the cabling will reach from where the project makes landfall in Carnoustie to a new dedicated substation currently under construction in Tealing.

Onshore Electrical Infrastructure Project Manager, Steven Reid from SSE Renewables is responsible for the cable installation project.

”The start of the cable pulling process marks an important achievement in the delivery of the onshore electrical transmission infrastructure following significant efforts from the Project Team and the support of various stakeholders,” Reid said.

”Again, I‘d like to express our thanks to all who live along the route for their co-operation and understanding as the project has progressed up to this stage of delivery. Working with our Contractor Nexans, we now look forward to continue to deliver the installation of the 19km of cabling safely and with the least amount of disruption possible to the surrounding community.”

Electrical Arc Flash Protection for Offshore Wind Farm WorkersSeagreen is a joint venture between SSE Renewables and Total.

First power at the wind farm is expected by early 2022 with full power coming on stream in 2022/23.

Seagreen selected Montrose Port as the home for the operations and maintenance base for the 114-turbine development in October 2019.

See how T&D support, supply and service the Renewable Energy industry.

Cable Pulling & Cable Laying Equipment

Cable and Pipe Transits For Naval Vessels

September 3rd, 2021

Cable Transits & Duct Seals

Increased Safety & Security

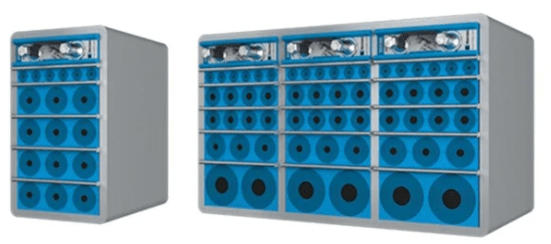

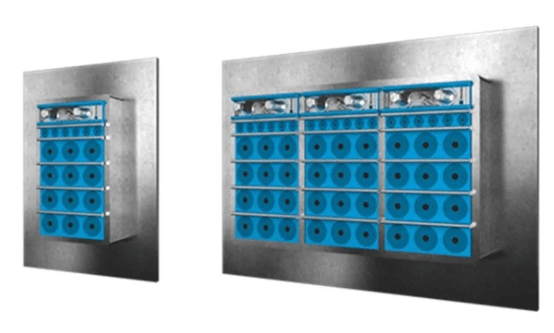

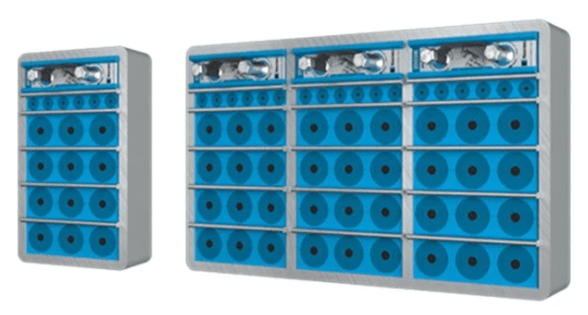

With world class cable transits protecting against multiple risks, you pave the way for maximum survivability. Cable transits and duct seals from Roxtec are your solution for safety, EMI/EMP protection and blast load resistance.

The vibration damping, the area efficiency and the light-weight nature of the pipe seals contribute to a more silent operation and more free space onboard. Roxtec solutions simplify everything – from planning to future upgrades.

Application areas

Explore the multitude of applications where you can benefit from Roxtec’s solutions.

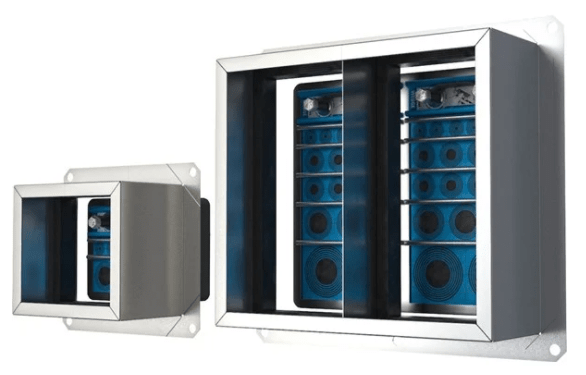

Cabinets & enclosures

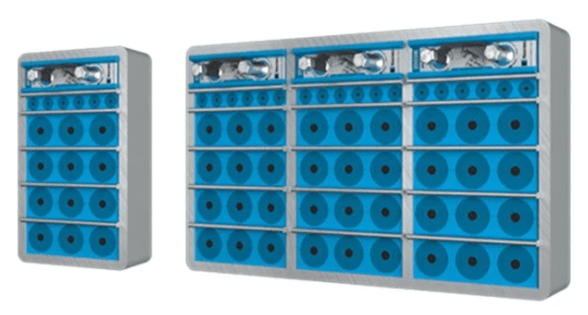

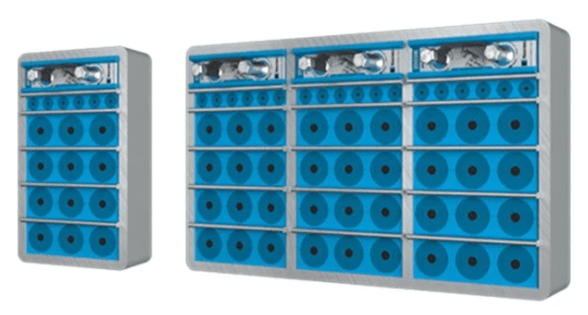

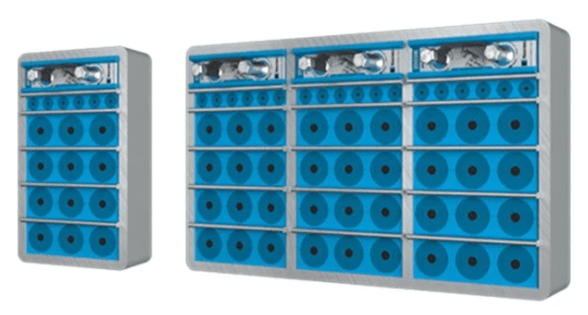

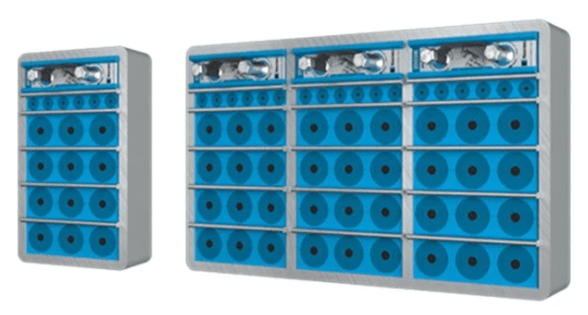

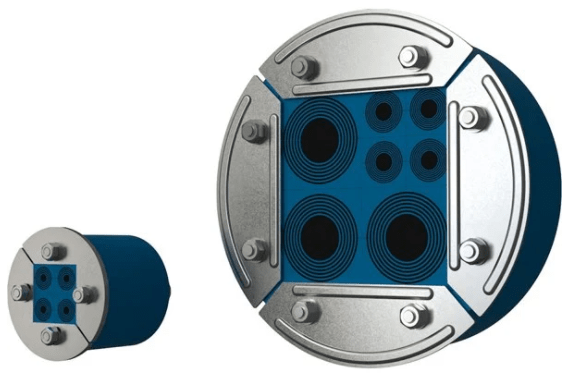

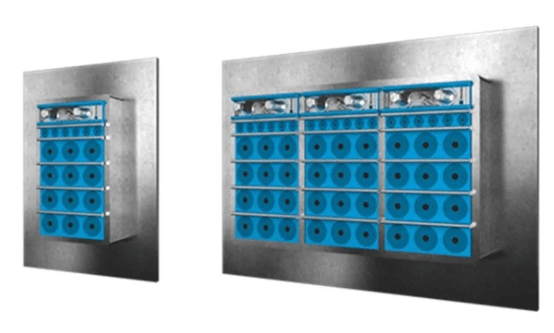

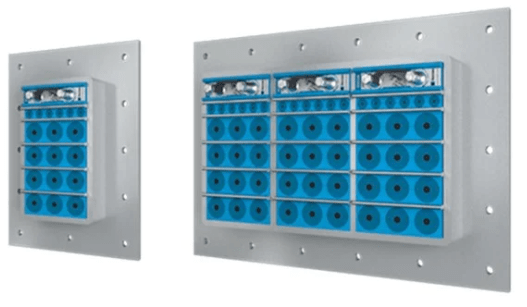

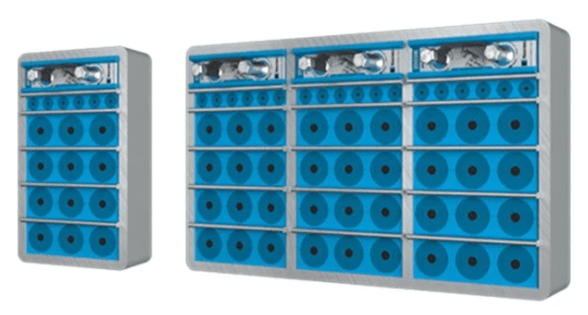

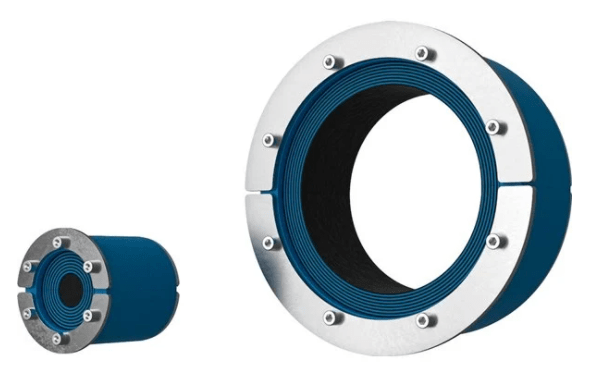

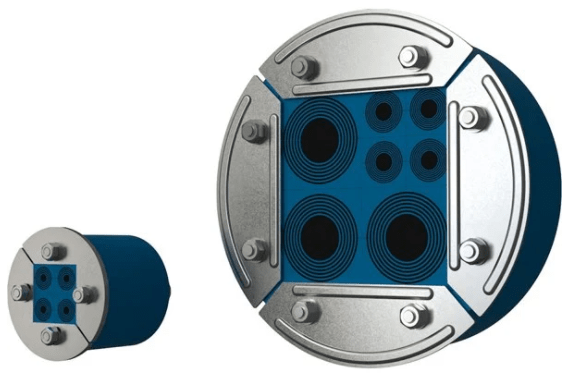

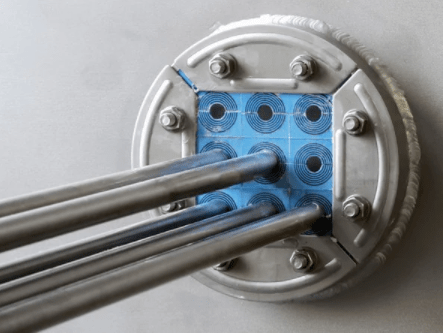

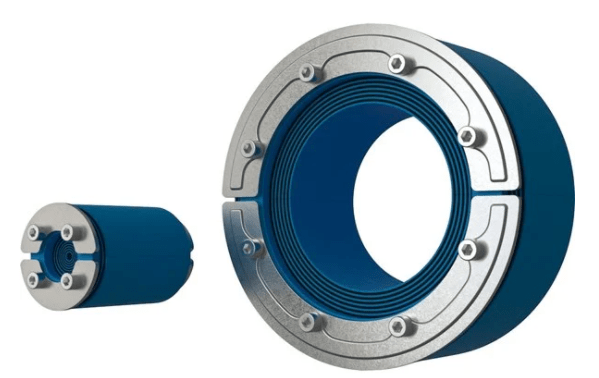

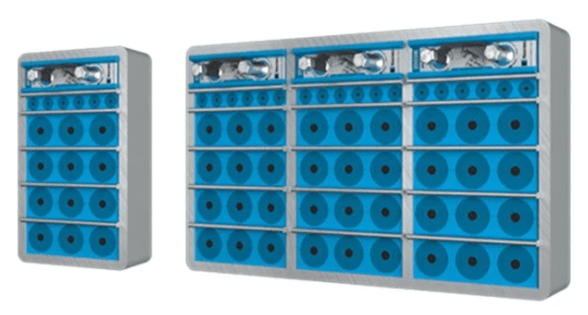

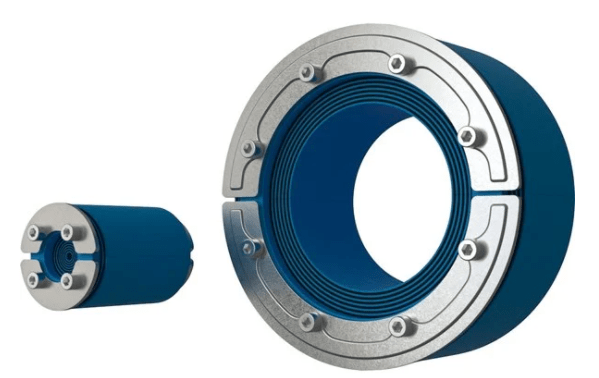

Roxtec CF 8/32 Transit

Roxtec multi-cable transits offer several additional customer benefits and can entirely replace cable glands. Use Roxtec’s compact, area efficient seals to ensure EMI/EMP protection and to be able to reduce the size of your cabinets, junction boxes and enclosures as well as to reduce engineering hours spent on cable data and cable gland configurations.

Why use Roxtec?

- Watertight

- Gas-tight

- Dust-tight

- One cut-out for dozens of pre-terminated cables which may vary in size

- Built-in spare capacity for upgrades and retrofits

- Solutions for armoured cables

- EMC solutions for electrical safety

- Ex solutions for hazardous locations

Recommended Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec HD Transits High cable density transit device with frame in 316L. For harsh environments. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec HD Ex Transits High cable density transit devices for Ex environments with frame in 316L. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 Ex e/ Ex tb |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Command control room

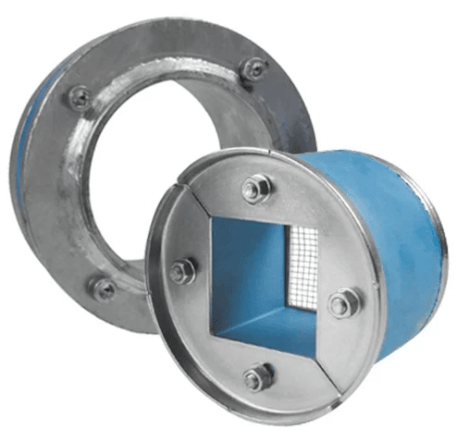

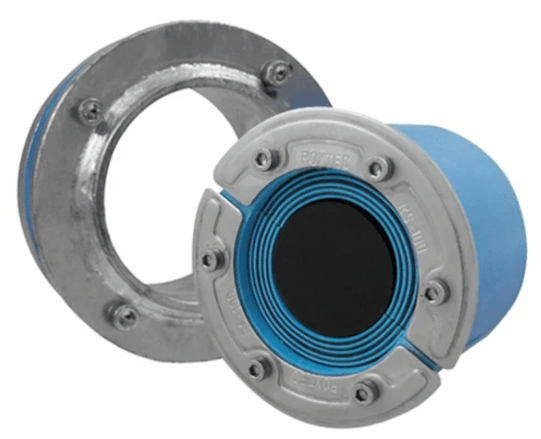

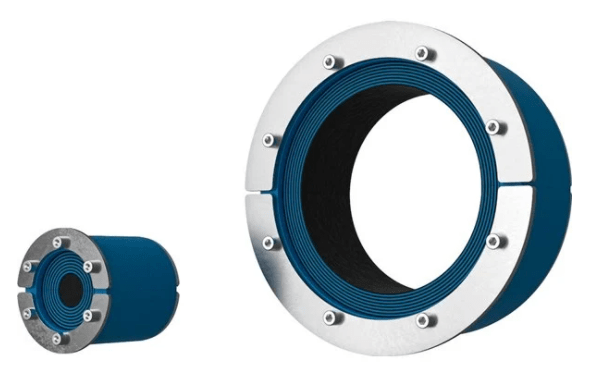

Roxtec S Transit

Roxtec cable transits ensure electromagnetic shielding and protect equipment both inside, and around the command control room. Use Roxtec EMC solutions to secure data, communication and high-precision operation in order to improve survivability.

Why use Roxtec?

- EMI/EMP protection

- Watertight

- Firestop

- Gas-tight

- Dust-tight

- Blast load resistant

- Flexibility for cables of different sizes

- Built-in spare capacity for upgrades and retrofits

- EMC solutions for electrical safety

Recommended Cable & Pipe Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

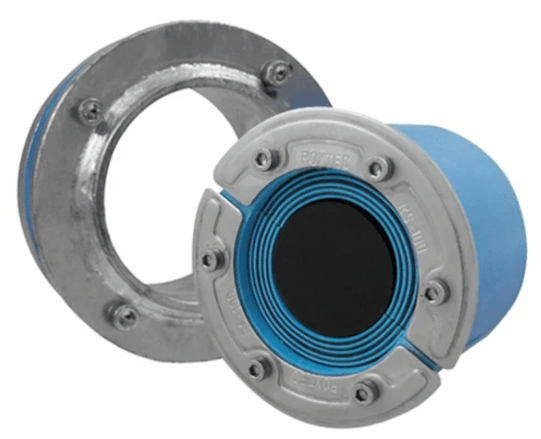

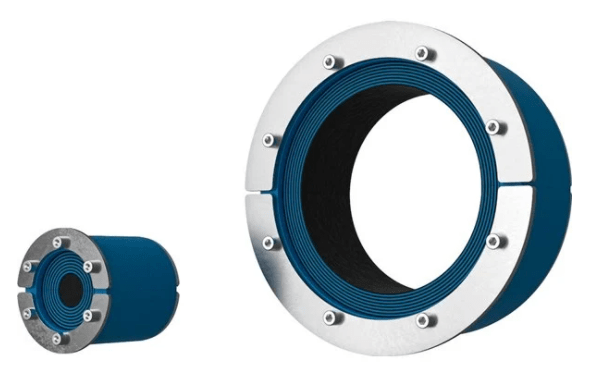

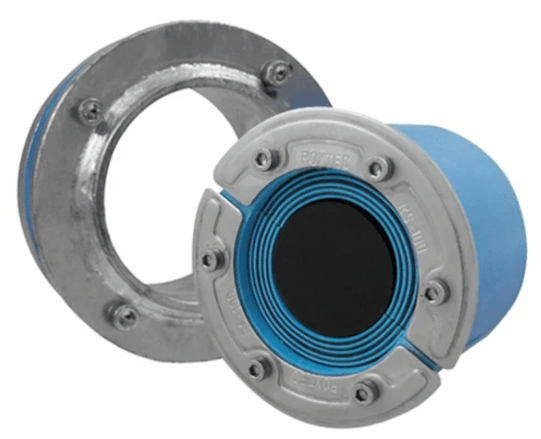

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Communication area – Crypto & Sonar

Roxtec cable and pipe transits ensure electromagnetic shielding both inside, and around the sonar and crypto rooms. Use EMC solutions to protect equipment and create an internal barrier for sensitive information. Stop RFI, optimize communication security and ensure safety and survivability.

Roxtec RS Cable Transit Frame

Why use Roxtec?

- EMI/EMP protection

- Watertight

- Firestop

- Gas-tight

- Dust-tight

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits

- EMC solutions for electrical safety

Recommended Cable & Pipe Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

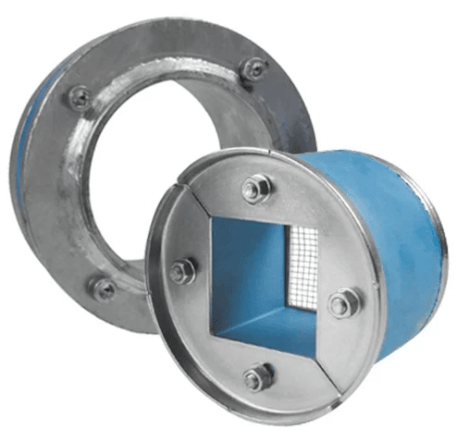

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Engine room

Roxtec cable and pipe penetration seals are perfectly suited for large cables and pipes entering the engine room through decks and bulkheads. Use Roxtec transits to ensure the best possible protection for the heart of the ship.

Roxtec S Transit for Engine Rooms

Why use Roxtec?

- Watertight

- Gas-tight

- Firestop

- EMI/EMP protection

- One opening for dozens of cables and pipes

- Flexibility for cables and pipes of different sizes

- EMC solutions for electrical safety

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

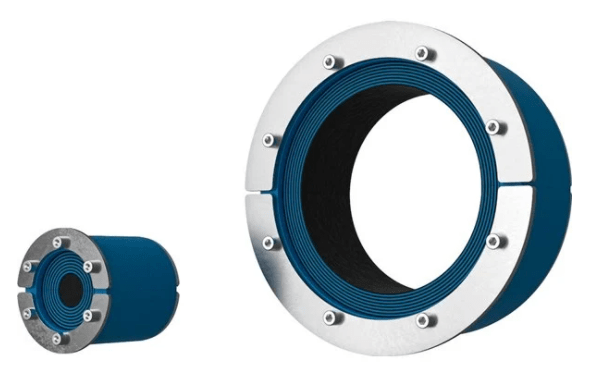

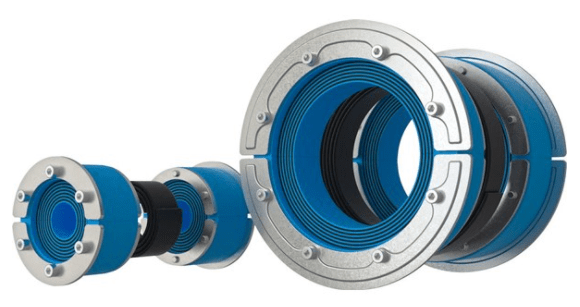

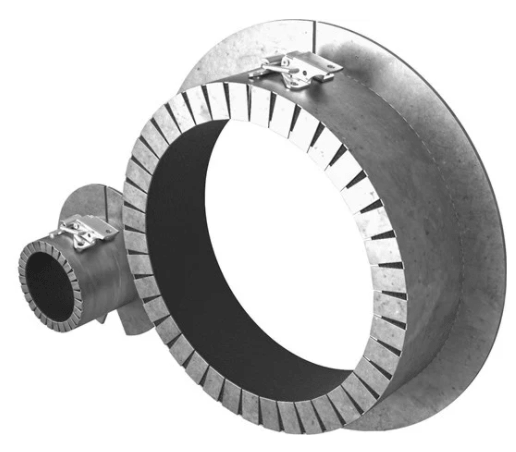

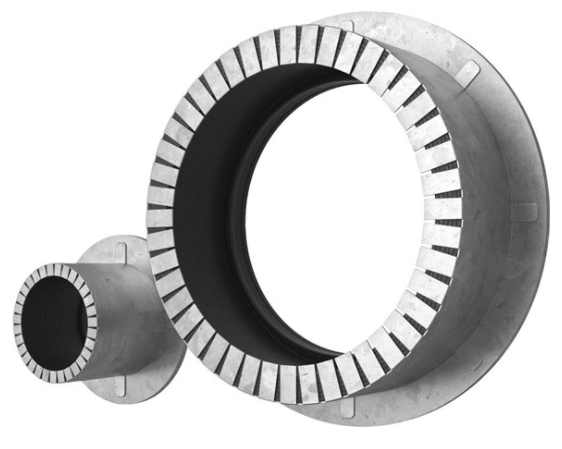

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited are without welding or bolting. For attachment through expansion. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SBTB Transit Transit with metal frame for an extra level of fire protection. For high fire demands. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SF Transit Cable and pipe transit with metal frame and flange for welding to the structure. For wide aperture tolerance when welding. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SFHM Transit with metal frame and flange for bolting to the structure. |

A-CLASS H-CLASS |

Water: 4 bar (catastrophic) |

|

Roxtec SRC r20 Transit Transit with metal frame for load-bearing structures. Corner radius 20mm. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Gas-tight areas

Roxtec seals are not only your solution for safety, they provide EMI/EMP protection and excellent blast load resistance. Additionally, the transits reduce vibration and are area efficient in order to allow more free space onboard.

Roxtec SBTB Transit for Gas-Tight Area

Why use Roxtec?

- Watertight

- Firestop

- Gas-tight

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits

- Back-to-back solutions for increased protection

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SBTB Transit Transit with metal frame for an extra level of fire protection. For high fire demands. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SF Transit Cable and pipe transit with metal frame and flange for welding to the structure. For wide aperture tolerance when welding. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Hydraulic and compressed air systems

Roxtec’s round cable transits and rectangular penetration seals are ideal for single or multiple cables, pipes and tubes. Use Roxtec transits to ensure certified fire protection in A-0 to A-60 rated areas and maintain the ability to reopen the seals whenever you need.

Roxtec R Transit for Hydraulic & Compressed Air Systems

Why use Roxtec?

- Watertight

- Firestop

- Vibration damping

- Noise reduction

- One opening for dozens of cables and pipes

- Flexibility for cables and pipes of different sizes

- Ex solutions for hazardous locations

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited area without welding or bolting. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS OMD Seal Flexible transit with adaptable outside to fit non-standard sleeve sizes. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Power Generators, Motors and Thrusters

Roxtec cable seals are perfect for large cables entering the engine room through decks and bulkheads. Use Roxtec transits to achieve well-organized pipe penetrations and cable entries both inside, and around machine areas and engine control rooms. Also, benefit from savings resulting from the reduced space requirements of cabinets and enclosures.

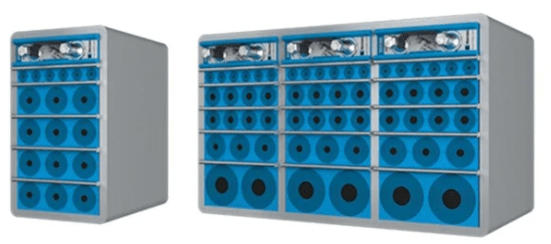

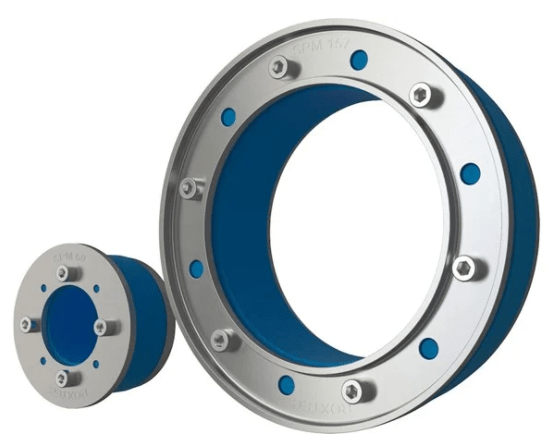

Roxtec ComSeal

Why use Roxtec?

- Watertight

- Firestop

- EMI protection

- Dust-tight

- One opening for dozens of cables

- Flexibility for cables and pipes of different sizes

- EMC solutions for electrical safety

| Description | Fire | Tightness | |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec ComSeal IP55 rated entry seals with aluminium frame |

N/A | IP55 UL/NEMA 3, 12, 12K |

|

Roxtec C RS T Seal Round seal for single cable entries |

N/A | IP66/67 IP69K UL/NEMA 4, 4X, 12, 13 |

Water pipes

Regardless of your preferred pipe material, Roxtec has the sealing solution. Roxtec pipe seals are A-0 and A-60 approved for all metal and most plastic pipes.

Use them to ensure watertight deck and bulkhead penetrations, to avoid the risk of water spreading from any leaking pipes and to be able to reopen the transits whenever you need.

Roxtec RS Seal for Water Pipes

Why use Roxtec?

- Watertight

- Firestop

- Vibration damping

- Certified solution

- Easy and safe installation of pipes

- Can be used for fresh, chilled and waste water

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited area without welding or bolting. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SPM Seal Seal for metal pipes for use when welding is not allowed, recommended or desired. Easy to install without welding. |

A-CLASS | Gas: 0.67 bar (catastrophic) Water: 1 bar (catastrophic) |

|

Roxtec RS OMD Seal Flexible transit with adaptable outside to fit non-standard sleeve sizes. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS PPS Penetration seal for large single plastic pipes. For installation in existing sleeve. |

A-CLASS | Gas: 2 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec S with SE PPS Transit for multiple plastic pipes. For welding into precise openings. |

A-CLASS | Gas: 2.5 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec Sleev-it Fire Penetration Seal Fire penetration seal for single plastic pipes. For fire rated divisions. |

A-CLASS B-CLASS |

N/A |

|

Roxtec Sleev-it Waterproof Penetration Seal Penetration seal for plastic pipes for basic protection against fire, gas & water. Waterproof seal for exact/fixed pipe diameters. |

A-CLASS B-CLASS |

Water: 1 bar (catastrophic) |

Further Reading

- Flexible Cable Seals for Gas Insulated Substations

- Data Centres | Safely Sealing LV HV Cables & Electrical Equipment

- Roxtec Pipe & Cable Seals | Offshore & Onshore Windfarm Product Spotlight

- Sealing Cables & Pipes Using Roxtec | Battery Storage Applications

Cable Sealing Using Roxtec

Roxtec cable seals are used in cable vaults, duct banks, electrical substations, trenches and M&E building services protecting low, medium and high voltage power systems against numerous external risk factors:

- Fire – A60, H120 Class bulkhead sealing for offshore classification against jet-fire or spray and prevention of suffocating smoke spread

- Gas – ensure complete tightness against air and gas pressure or migration through cable ducts with DSEAR compliance

- Water – prevent flood and water penetration into substations and buildings – avoid humidity and partial discharge conditions

- Cables – withstand cable bending load in heavy power and high voltage cable seal applications

- Pressure – protect against catastrophic sudden or constant pressure

- Electrical – protect cables and electrical infrastructure against EMI, EMP and lightning strike effects

- Particles – control levels of of dirt, dust, chemical and fumigants from entering buildings, cable ducts and substations

- Blast – protect against vibration, shock-waves and the risk of explosion in industrial and hazardous area locations

Cable Transits – Sealing Cables & Pipes

Cable Transits

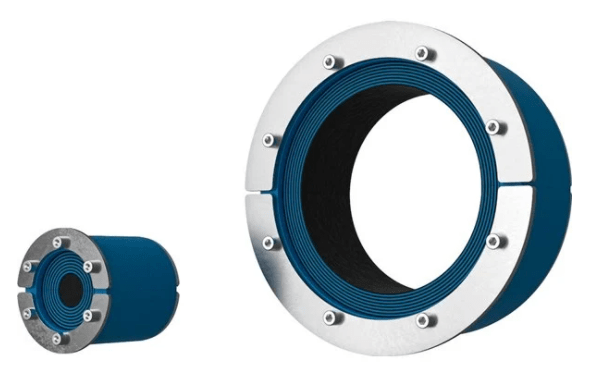

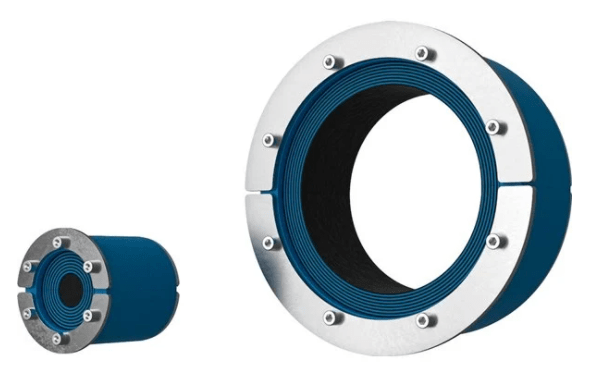

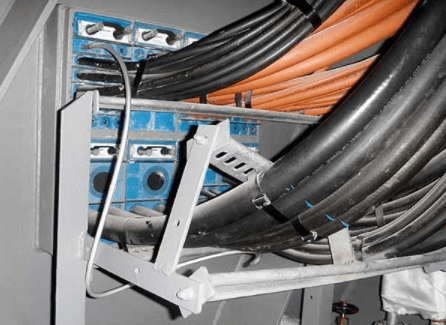

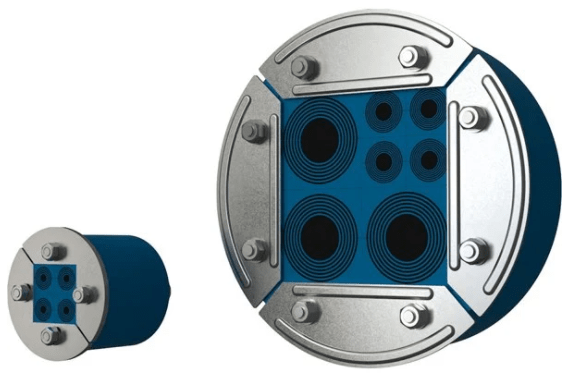

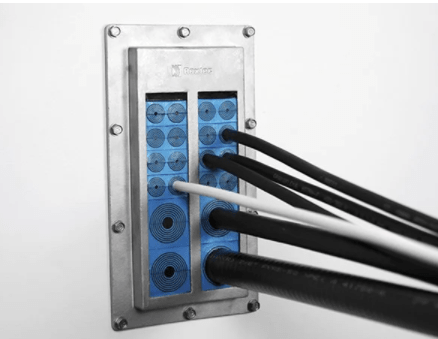

Roxtec cable transits are used to prevent water, gas, fire, dust and rodents from entering cable duct openings and potentially causing damage to cables and other electrical infrastructure.

Cable transit systems can be designed for sealing medium/high voltage substations including 11kV/33kV and “triplex” type cables in single, multiple or trefoil configuration.

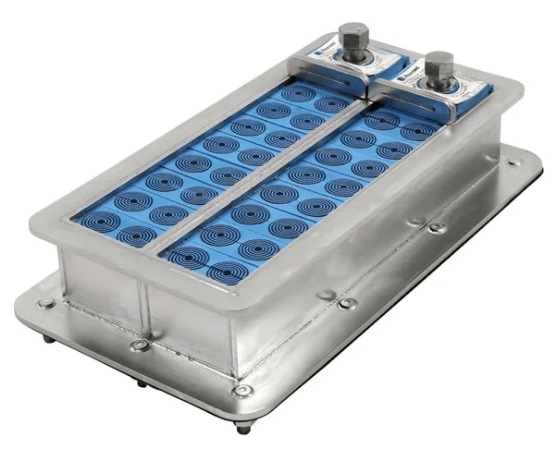

Roxtec modular cable transit seals are based upon a rubber design with seals that are constructed of a number of removable layers to secure a watertight, gas tight and fire proof seal around the cable or pipe – the range includes rectangular transits and round transits to fit a variety of pipes and cable sizes.

Cable transit products ensure safety, reliability and efficiency by providing an effective, dependable seal around cables and pipes through an opening, penetration or duct.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Providing Electrical Safety & PPE to Offshore Wind Farm Workers

August 24th, 2021

Thorne & Derrick | LV HV Electrical Safety & PPE Stockists & Specialists

Thorne & Derrick have recently supplied Electrical Safety Equipment to a renewable energy company working on the construction of the worlds largest offshore windfarm project in UK waters. The Personal Protective Equipment (PPE) will provide mitigation against the hazards of impressed/induced voltages prior to and during the pull-in of subsea cables.

Liasing with the Works Manager (Subsea Cables & Flexibles) and the Quality, Health, Safety and Environmental (QHSE) management team a minimum level of PPE and electrical protection was ascertained to protect workers carrying out maintenance and construction tasks in and around exposed cables. Essentially this included robust dielectric footwear, commonly referred to as insulating boots, and hand protection to protect against electrical hazards. The PPE delivered from stock will protect both crews and technicians working at landfall location and onboard the offshore cable laying vessel.

Critical to the project was our rapid response delivery from stock in a mixture of sizes to suit the individual requirements of the offshore workers, engineers and technicians.

Gloves & Boots

For hand protection gauntlet type Class 1 electrical insulating gloves were specified in accordance with Standard EN 60903:2003 – additional mechanical outer protection and cotton inner gloves were supplied. Footwear for electrical protection in accordance with the Standard EN 50321-1:2018 (tested to 20kV) was selected and specified.

-

BS EN 60903:2003 | Live Working. Gloves of Insulating Material -

BS EN 50321-1:2018 | Footwear Electrical Protection - Insulating Footwear & Overboots

Boots CATU MV-137 | these insulating boots are designed to protect offshore workers against the risks of step voltage on the ground, or against current circulating between the feet and the ground. The dielectric safety boots provide worker protection against electrical shock up to 20kV across the entire boot and up to 35kV on the sole. CATU’s MV-137 boots are made from high voltage-resistant dielectric compounds with slip-resistant vulcanised blue rubber sole and are available from stock at Thorne & Derrick.

Gloves CATU CG-1 | Class 1 insulating gloves to provide electrical protection for live voltages up to 7,500V and are fully compliant with IEC 60903 and EN 60903 standards.

Offshore Electrical Safety

Further Reading Arc flash accidents are not nearly as rare as you would think and the hazards they create are severe. In wind turbines, these hazards are magnified. Read our Electrical Safety Blog about safe wind turbine working.

- MV HV Cable Laying, Installation & Support Products | Offshore Windfarms

- Pipe & Cable Seals for Onshore Windfarm, Enclosures, Foundation & Stations

- Pipe & Cable Seals for Offshore Windfarm Substations, Enclosures & Foundation

- Cable Cleats & Safe Cable Installations for the Wind Energy Industry

- 33kV v 66kV | A Wind Farm Collection Grid Technical Comparison

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

Electrical Safety & Arc Flash Protection for Offshore Wind Farm Workers

Concrete Trough for Rail Industry Cables | A Case Study

August 20th, 2021

Concrete Cable Trough

As part of Network Rail’s substantial Railway Upgrade Plan to increase capacity across the Great Western Main Line, the significant re-signalling project between Paddington and Reading is continuing to make significant progress.

New cabling is currently being installed as part of a variety of infrastructure projects between Paddington and Heathrow junction. These infrastructure projects include Crossrail works on the Elizabeth Line, the upgrading of the signalling infrastructure from track circuits to axle counters and the safer faster isolation works.

➡ See our range of Insulated Rail Track Tools

Upgrading Cable Routes

Colas Rail is supporting the signalling infrastructure upgrade works through telecoms, civils, electrification and power support. The project aims to deliver a more reliable railway for London and all passengers travelling to the West and Wales, ultimately putting the passenger first. Many of the cable routes on this section of the infrastructure are reaching capacity and therefore are being upgraded by Colas Rail to accommodate the extra cable required.

As part of the cable installation process, Colas Rail has commissioned Anderton Concrete, market leader in the supply of cable protection products to the UK’s rail industry, to supply over 6000 metres of precast concrete troughing to successfully increase cabling capacity.

Facilitating the seamless transition from existing ground routes to new routes, the Anderlite straight concrete troughs have been manufactured in half lengths of 500mm to increase on-site efficiencies. The troughing lids have been manufactured at a standard length of 1metre to provide further cost and resource benefits.

Over 3000 metres of troughing has already been installed by Colas Rail’s engineers, with the project predicted to be finalised by this summer.

Anderlite 500 Concrete Trough

Daniel Clouth, Project Manager at Colas Rail Ltd., said: “A project of this scale and nature requires optimum communication and collaboration from all parties to ensure its successful delivery. It is therefore crucial that the level of materials we require are on site at the key access points, when we need them.

“Having worked with Anderton Concrete across previous rail projects, we were confident that the team could deliver the volume of troughing we required, whilst also taking a bespoke approach to the specification of the product to ensure on-site efficiencies were increased.”

With the UK’s railway network experiencing a doubling of passenger levels over the last 20 years, Network Rail’s Railway Upgrade Plan will deliver a more reliable railway that ensures new trains can run alongside existing rail services to deliver quicker and easier journeys for passengers.

Neil Cross, National Sales Manager for Anderton Concrete, said: “As a longstanding partner of Colas Rail, it has been fantastic to collaborate with them for the re-signalling of the Great Western Main Line.

“With this project, it was imperative we could meet tight deadlines and supply high volumes of product with just a few days’ notice. As Anderton Concrete is at the heart of building for the UK, our extensive range of precast concrete products are manufactured at our headquarters in Cheshire, which places us in a strong position to guarantee that our troughing solutions can be on site in the shortest lead times, without compromising on quality.”

Anderton Concrete’s extensive portfolio of troughing, signal bases and complementary rail products are designed to comply with Network Rail standards and as a result, have full Network Rail Approval status, Certificate No. PA05/00318 & PA05/05810 and RISQS accreditation.

As the durable Anderlite concrete cable trough range is up to 30% lighter than traditional materials, it offers increased installation and sustainability benefits to reduce manual handling concerns, associated cost and resource implications and the overall environmental impact of the project.

Colas Rail

A subsidiary of the Colas Group, Colas Rail are part of over a hundred years of experience in delivering major innovations across our sector. Every day, thousands of trains run on tracks built or maintained by Colas Rail.

Colas Rail is a leading provider of railway infrastructure services – providing design, engineering, project management, construction and maintenance solutions for the light rail, metro, mainline and high-speed markets.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry. Low, Medium & High Voltages

Power Products ♦ Cables & Accessories ♦ Electrical Equipment