Blog

June 15th, 2021

Thorne & Derrick | Elcon Megarad Distributed from Stock | Approved Supplier

UK & Export Sales

Elcon Megarad

Thorne & Derrick can provide expert technical support, customer service and competitive prices with delivery from extensive stocks for the complete range of Elcon Megarad products.

Elcon Megarad is an Italian company which designs, manufactures, tests and markets cable accessories and components for medium/high voltage power grids around the world. Research and Development is constantly engaged in developing new materials and technologies, with particular attention to the different market demands.

Their chemical-physical characterisation laboratory and high voltage (HV) test room enable the design and development of a wide range of cable terminations and junctions for all types of cables on the market, according to CENELEC standards, to be performed with maximum reliability.

LV Cable Joints & Cable Terminations

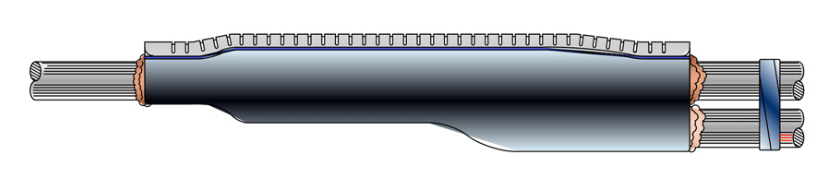

LV Heat Shrink Branch Cable Joints | Elcon Megarad

Elcon Megarad offer a wide range of high performance low voltage cable accessories, including resin cable joints, re-enterable straight/branch gel joints, heat shrink cable joints and heat shrink cable terminations. Each Elcon Megarad LV cable joint and cable termination includes a robust and easy to assemble components kit.

The complete range of LV cable joints and terminations are compliant with CENELEC HD 623 & CEI EN 50393 standards, which both require a low voltage cable power distribution of 0.6kV/1.0kV.

MV CABLE JOINTS & CABLE TERMINATIONS

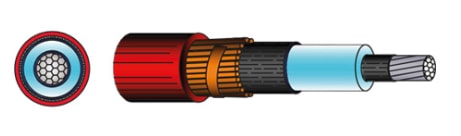

MV Heat Shrink Cable Terminations | Elcon Megarad

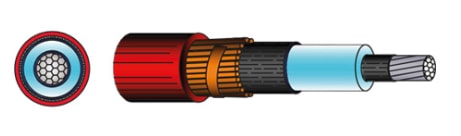

The extensive Elcon Megarad collection of high performance medium voltage cable accessories offer wide variation of products. Medium voltage cable terminations range from, both indoor and outdoor cold shrink/heat shrink cable terminations, heat shrink trifurcation kits, porcelain cable terminations and cable connectors. Elcon Megarad’s MV power cable joints include, cold shrink cable joints, heat shrink cable joints and resin cable joints.

Additionally, MV stock extras include medium voltage single core cable connections pre-assembled with cable terminations, as well as MV cable joints and cable terminations designed for renewable energy and wind farm applications, available in both heat shrink and cold shrink variants.

All MV cable accessory stocks are compliant with CENELEC HD 629.1 S2 & CEI 20-62/1 or CEI 20-62/2 standards, meeting the test requirements of rated voltage from 3.6kV/6kV up to 20.8kV/36kV.

HV CABLE JOINTS & CABLE TERMINATIONS

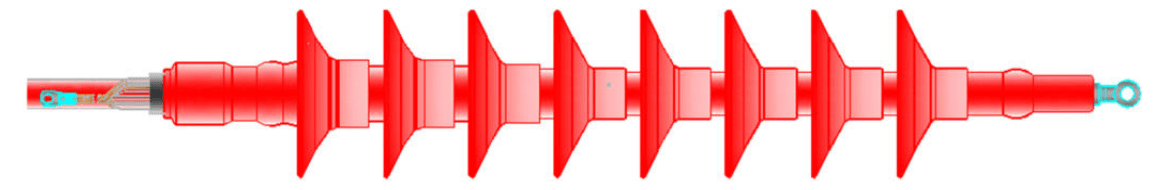

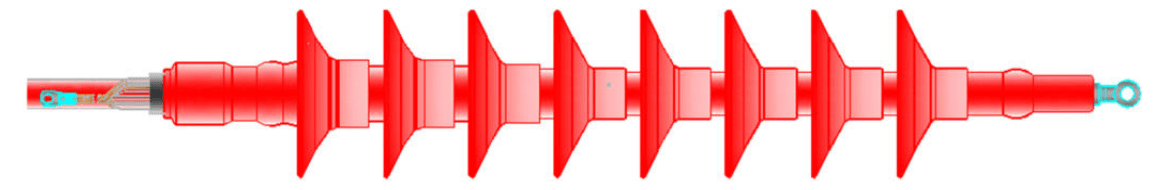

HV Heat Shrink Cable Terminations | Elcon Megarad

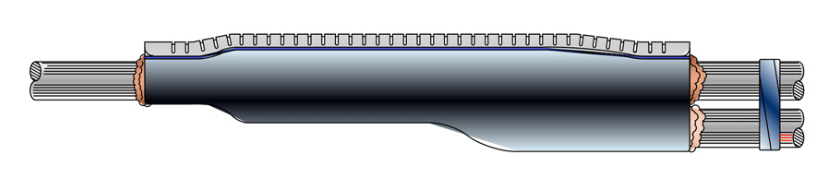

Offering an uncommon stock of high performance HV heat shrink cable joints and cable terminations. Elcon Megarad’s High Voltage Heat Shrink Cable Termination 66kV/72.5kV & High Voltage Heat Shrink Cable Joint 66kV/72.5kV are available with an extensive heat shrink cable termination and cable joint selection guide, including details on product application and kit components.

The Elcon Megarad range of HV heat shrink cable joints and cable terminations are compliant with IEC 60840 & IEEE 404 standards, making them suitable for direct burial and underground cables located in cable trenches up to 72.5kV.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

June 14th, 2021

Data Centres

Safely Sealing LV HV Cables & Electrical Equipment

Due to the ever-changing data centre environment Roxtec seals were installed on several centres built for a multi-national technology company throughout the USA.

With service continuity as a top priority, the company selected Roxtec system of cable transits as a cable sealing solution.

Roxtec seals would both protect their equipment and provide flexibility for continued growth. Site superintendents, project managers and installers of contractors Structure Tone, IES and Hunt Electric also consider Roxtec a best-fit solution for the industry. Jim Wagner, Senior Project Manager at Hunt Electric coments, “Roxtec is a great product, the best I have seen in the market based on flexibility.”

Roxtec Project facts

Project Description – Construction of data centre in multiple locations in the USA

Owner – Multinational technology company

Installations – Structure Tone, IES, and Hunt Electric

Applications – Walls, trenches and cable trays

Sealing Requirements – Fire-proof, watertight and air-tight

Future Capacity Included

The HVAC systems, power equipment and communications equipment must be updated continuously. Our openable and adaptable seals make it possible to leave room for future capacity. You can easily make changes and upgrades without cutting a new hole. This allows for a dustless re-entry into your contained sensitive environment. Roxtec offers a long-term partnership to protect your data centres and server halls against multiple risks such as fire, flooding and air leakage.

Unbeatable Sealing & Protection of Cables

Roxtec provided sealing solutions for both exterior and interior penetrations keeping water and fire from causing damage and downtime all while providing airtightness and increasing the efficiency of the data centre.

Contractor Approved

Roxtec seals are easy to install, adapt and reseal. Ross Catlett of IES states:

“It is significantly easier to install Roxtec than using solutions like foam and the bags that you have to pack and fill in.”

After participating in Roxtec’s training and becoming an approved installer he can now train new employees as they come onsite or continue on to future projects.

Why use Roxtec?

- Watertight firestop

- Air-flow management

- Easy to use and install

- Flexibility for changes

- Built-in spare capacity

- Dustless re-entry

Roxtec cable seals are used in cable vaults, duct banks, electrical substations, trenches and M&E building services protecting low, medium and high voltage power systems against numerous external risk factors:

- Fire – A60, H120 Class bulkhead sealing for offshore classification against jet-fire or spray and prevention of suffocating smoke spread

- Gas – ensure complete tightness against air and gas pressure or migration through cable ducts with DSEAR compliance

- Water – prevent flood and water penetration into substations and buildings – avoid humidity and partial discharge conditions

- Cables – withstand cable bending load in heavy power and high voltage cable seal applications

- Pressure – protect against catastrophic sudden or constant pressure

- Electrical – protect cables and electrical infrastructure against EMI, EMP and lightning strike effects

- Particles – control levels of of dirt, dust, chemical and fumigants from entering buildings, cable ducts and substations

- Blast – protect against vibration, shock-waves and the risk of explosion in industrial and hazardous area location

➡ Further Reading | Connecting High Voltages & Energising Data Centres

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

June 14th, 2021

Conference Name: Subsea Power Transmission & Cabling 2021

Dates: 16-17 September 2021

Start: September 16, 2021 13:00

End: September 17, 2021 17:00

Location: Virtual Event – Find out more here

Email: [email protected] Prospero Events Group helps decision-makers in the European energy industry benchmark best practices by organizing peer-to-peer conferences.

➡ 50% discount if booked before 30th June 2021 – BOOK NOW!

Virtual Conference

Subsea Power Transmission & Cabling 2021

With the growth of offshore power production and in order to meet net-zero, it is important to ensure high quality and reliable offshore grid infrastructure to integrate the growing offshore power production. Infrastructure development is also important to ensure the security of supply and to ensure cross-border energy trading. Talking about infrastructure development, new challenges in cable technology, design, installation and maintenance needs to be addressed as well.

Subsea Power Transmission & Cabling 2021 will bring together the most prominent European energy industry leaders in an exclusive closed-group and business-friendly environment for peer-to-peer networking to discuss challenges and opportunities of the strategic role of submarine power cable infrastructure, subsea power transmission and infrastructure development to support the expansion of offshore wind production and to secure the stability of power supply by sharing their business models and latest studies.

Bringing together decision-makers responsible for subsea power cables and offshore power transmission to discuss challenges and opportunities of the strategic role of submarine power cable infrastructure, subsea power transmission and infrastructure development.

TOPICS

- Expanding Offshore Production: Challenges for Grid Integration

- Case Study: The Belgian Offshore Grid from a Developer’s Perspective

- Business Models for Future Interconnectors

- Offshore Wind Integration: Status and way forward from Elia Group’s perspective

- Cable Repairment: Project Planning & Project Finance

- BritNed Cable: Operational Challenges & Project Updates

sPEAKERS

|

Bart Goethals CCO, Nemo Link, Belgium

Bart is in charge of the commercial aspects of the Nemo Link interconnector between Belgium and England which is the first ‘cap and floor’ interconnector.

Over the last ten year he has been working on multiple interconnector and offshore grid investment files.

|

|

Dr. Lorenz Müller, Head of Regulatory Affairs, 50Hertz, Germany

Lorenz Müller was born in 1972 in Dortmund, Germany. He studied electrical engineering and received a PhD at the Technical University of Dortmund, Germany.

In his professional career, he has executed different management positions in the company, e.g. responsible for grid usage and connection contracts, energy market development and the whole energy business of the company. |

|

Dennis Stufkens, Operations Directors, BritNed, The Netherlands

BritNed Development Limited is an international organisation with sites based in Great Britain and the Netherlands. They own and operate the electricity interconnector between Great Britain and the Netherlands and deliver world class asset reliability, vital to the energy needs of Great Britain and the Netherlands, and they do with it with a key focus on safety. |

|

Margot Van Nuffel, Project Finance Manager, Otary, Belgium

Since 2017 with Otary (Belgian knowledge centre for offshore wind energy that develops, finances, constructs and operates offshore wind parks) as the project finance manager. Leading the negotiations with Elia in 2019 on an asset sale to complement the Modular Offshore Grid, and assisting in the financing of SeaMade in 2018, the largest Belgian offshore windfarm. Responsible for the PPAs and the regulatory/market aspects of 800 MW of offshore wind assets. |

|

Luke Wainwright, Offshore Coordination Manager, National Grid ESO, UK

Luke Wainwright is an experienced leader in the Electricity System Operator for Great Britain, National Grid ESO. He has worked for National Grid for 20 years in a variety of Commercial, Project and Operational Leadership roles, including the leading the New Connections team for England and Wales and being Chief of Staff to the Director of Operations. At present he leads on Offshore Coordination, specifically the change programme to ensure the System Operator can achieve 40GW by 2030 whilst also balancing the needs and interests of coastal communities and

consumers.

|

|

Aoife Wixted, Senior Lead Engineer, Eirgrid, Ireland

EirGrid develop and operate the national electricity grid, so that everyone has power when and where they need it. The grid takes electricity from where it is generated and delivers it to the distribution network, operated by ESB, which powers every home, business, school, hospital, factory and farm on the island. They also supply power directly to some of Ireland’s largest energy users.

|

Prospero Events

Prospero Events help decision-makers in the European energy industry benchmark best practices by organizing peer-to-peer conferences.

Their promise is to offer the longest average minutes (at least 4 minutes per participant within two days of a virtual event) of direct peer-to-peer networking with the most senior, relevant, committed, innovative, and open-minded European professionals about specific energy industry-related topics.

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground and subsea cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to and EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

June 11th, 2021

Cable basement KW Schattenhalb, Switzerland (c) 2014 Damian Aegerter

Cable Pulling

In this 3rd article about cable pulling we discuss the usage of the weight correction and sidewall bearing pressure factors plus the conduit jamming ratio.

Transportation, handling, and installation of cables causes often more mechanical stress than what is actually experienced during operation. Therefore, it is important to carefully plan the cable installation, which can be done in Cableizers updated cable pulling module.

General considerations

For Cable Pulling

The conductors of the cable are generally the only members that can bear the pulling forces without damage. Do not use metallic shielding wires, tapes, braids or armor not designed for the purpose in pulling tension calculations.

Pulling different conductor sizes at the same time is not recommended if the conductor size or other cable characteristics are significantly different. If you must pull different size conductors, it must be done with care.

Pulling additional cables into an existing conduit system is generally not recommended. If this must be done, extreme caution must be taken. Of special concern is the cutting action of the tensioned pulling rope.

Some factors and ratios

Usage of weight correction factor

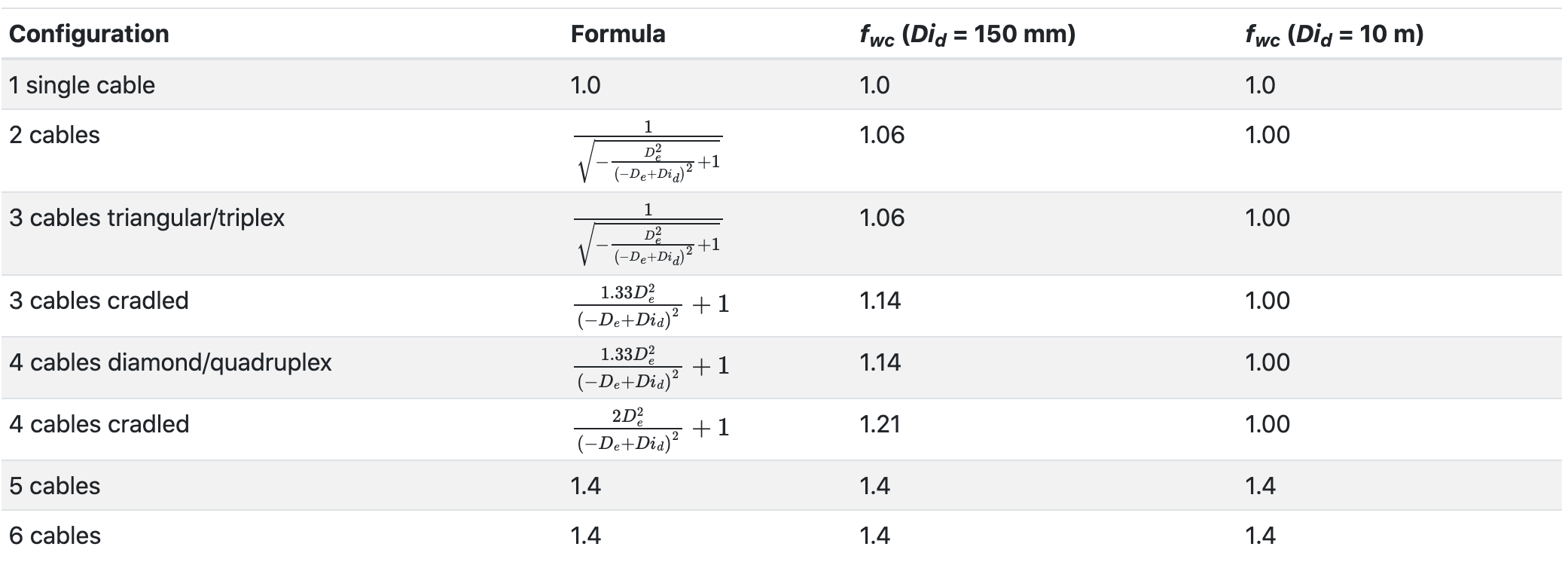

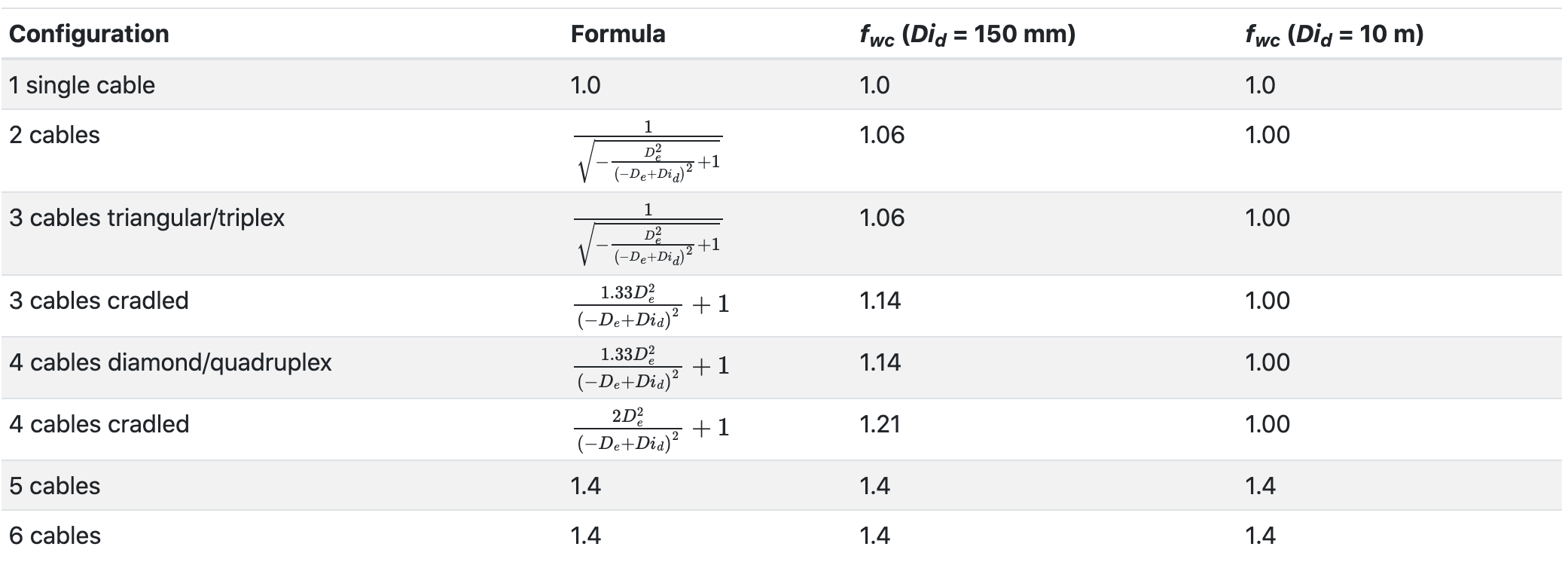

When multiple cables are pulled together, their mechanical configuration in the conduit is changing along the route which exposes them to uneven forces, an imbalance that is causing additional frictional drag. The weight correction factor f_wc is taking this into account by increasing the weight of cable assemblies consisting of more than one single cable.

Formulas for weight correction factors are mostly limited for pulling of up to 3 cables. Some formulas exist for pulling cable assemblies of 4 cables, but they were not leading to consistent results. Cableizer has extended the formulas for cable assemblies of up to 6 cables.

The following examples are calculated with a cable with an outer diameter D_e of 37 mm and a conduit with an inner diameter D_id of 150 mm. In addition, all calculations are also done on the example of a very large conduit (Di_d = 10 m) for validation reasons.

In this case, the cables lie next to each other and do not rub against each other, and the weight correction factor should be negligible (i.e. equal to 1.0).

As can bee seen in the following table, this is the case except for 5/6 cables which have a constant weight correction factor independent of the cable and conduit dimensions. As a consequence, the pulling force calculation in Cableizer for large conduits is rather conservative (i.e. on the safe side).

The above figures show that the weight correction factor is as expected incrasing with an incrasing number of cables pulled together.

Cradled configurations do have higher weight correction factors than when the cables are more organized (3 cables triangular/triplex or 4 cables diamond/quadruplex). If you are close to or exceeding the pulling force limits, it can therefore be of interest to investigate if binding the cables together can be an option.

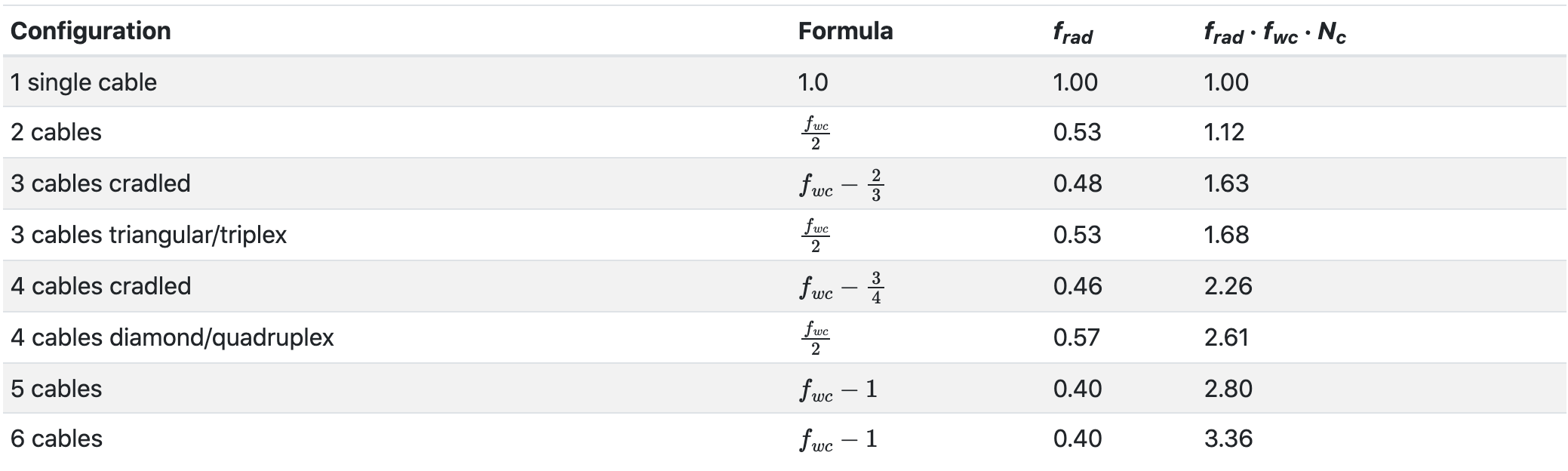

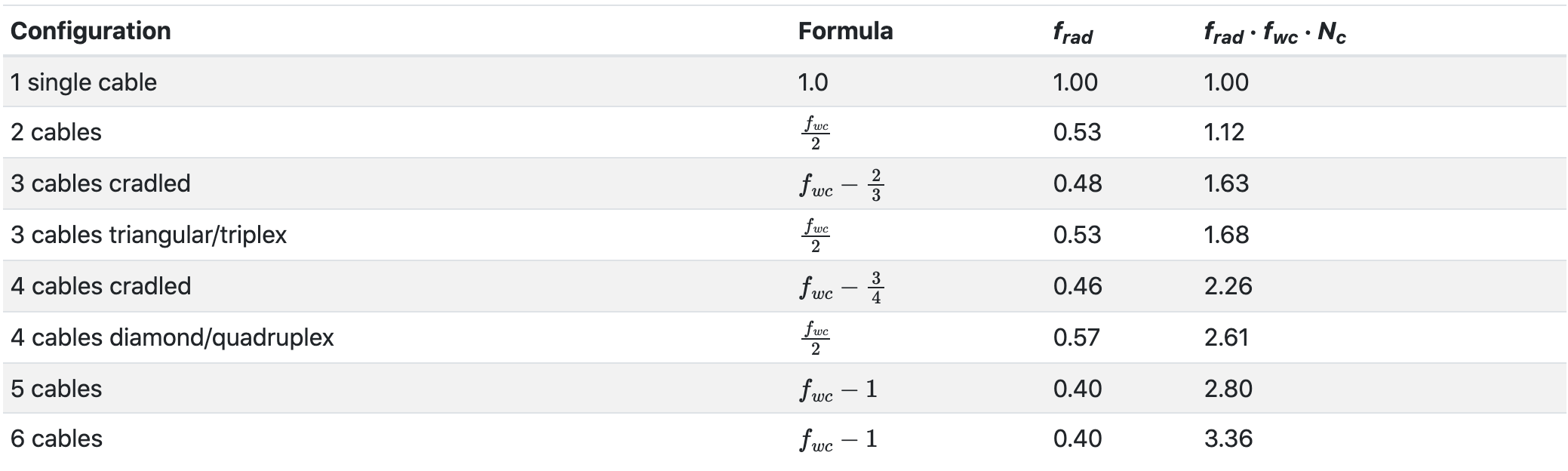

Usage of sidewall bearing pressure factor

Generally, manufacturers do also consider the influence of the weight correction factor when calculating the sidewall bearing pressure.

In Cableizer, this is considered with the sidewall bearing pressure factor f_rad, which can be optionally selected. Its calculations is always dependent on the weight correction factor, but it can be applied to the calculations independently of the weight correction factor. A normal use case is to either apply both f_wc and f_rad or none of them.

The following examples are calculated with a cable with an outer diameter of 37 mm and a conduit with an inner diameter of 150 mm.

The sidewall bearing pressure F_rad is proportional to the sidewall bearing pressure factor and the pulling force. The pulling force F_pull itself is proportional to the weight correction factor and the gravitational force. The gravitational force F_g itself is proportional to the number of cables N_c being pulled together.

As a consequence, the factor f_rad⋅f_wc⋅N_c indicates to what extent the sidewall bearing pressure is increased as compared to the case where a single cable is being pulled.

The above figures show that the sidewall bearing pressure on the most exposed cable is increasing steadily with an increasing number of cables being pulled. As expected, cradled configurations do have lower sidewall bearing pressures than when the cables are more organized (3 cables triangular/triplex or 4 cables diamond/quadruplex).

Conduit jamming ratio

Jamming is the wedging of three unbound cables when pulled into a conduit. This usually occurs because of crossovers when the cables twist or are pulled around bends. The conduit jamming ratio is the ratio of the conduit inner diameter Di_d and the cable outside diameter D_e. When calculating jamming probabilities, a 5% factor is used to account for the oval cross-section of conduit bends. The cable diameters should be measured, since actual diameters may vary from the published nominal values.

Cableizer indicates the risk for jamming according to the following table. As shown, different references use different ranges for quantifying the jamming risk. Cableizer does only indicate the jamming ratio for Three cables unbound because even while jamming can occur when pulling four or more cables into a conduit, the probability is very low.

Disclaimer

Always follow the instructions from the cable manufacturer when preparing your cable pull. While some manufacturers disregard the use of the weight correction factor (example I from Brugg Cables), others include it in their calculations (example II from Southwire). In Cableizer, both options can conveniently be calculated.

Cableizer specifically disclaims any warranties, including, but not limited to, the implied warranties of merchantability, accuracy, or fitness for any particular purpose of its calculation results.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

June 11th, 2021

Cable Pulling Example from Southwire Manual in Cableizer

Cable Pulling

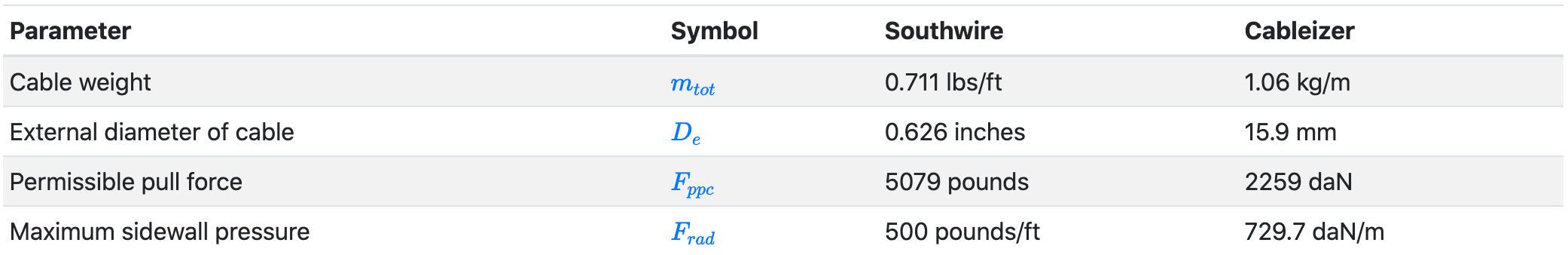

The 2nd of this blog series features the following cable pulling example from Southwire is an extract from their public document titled ‘Power Cable Installation Guide’, published in 2005. The cable pulling calculation example is found on pages 23ff in the section ‘Typical calculation for cables in conduit‘.

This example validates our cable pulling module and has been added to our test cases, ensuring that the cable pulling calculation won’t unexpectedly and unnoticeably change.

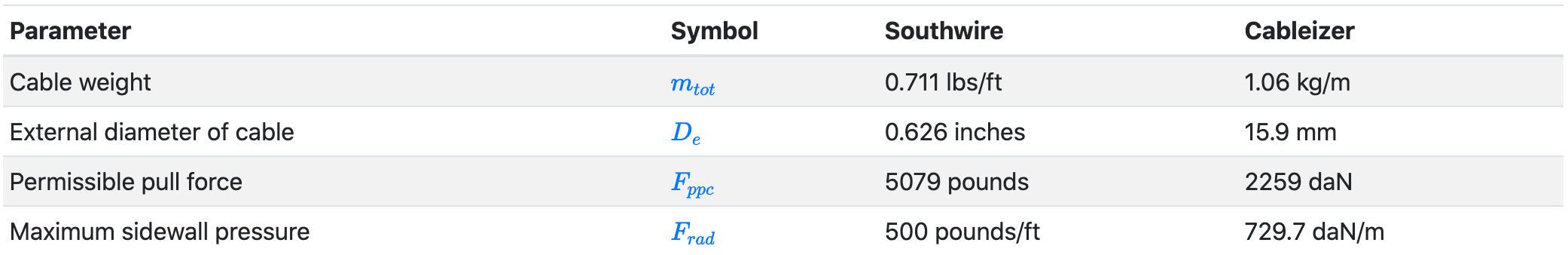

Cable selection

In the Cable tab of the cable pulling module the cable is selected, which in the example is a THHN single-conductor 4/0 AWG copper cable. In the Cableizer cable editor, standard conductor cross-sections A_c can be selected either in mm2 or in AWG/kcmil. Typical values of conductor diameters d_c for this cross section can conveniently be selected for AWG sizes up to 2000 kcmil from UL 1581 and beyond from ASTM B8-11 standards.

In Cableizer, all inputs/outputs are currently only supported in metric units so we converted them for this example. The following table shows the corresponding inputs regarding the cable selection for the Southwire example with cable weight m_tot and external diameter of cable D_e, which covers the case where three identical unbound cables are pulled together. Permissible pull force F_ppc and maximum sidewall pressure F_rad have been manually set to the same values as in the Southwire installation guide.

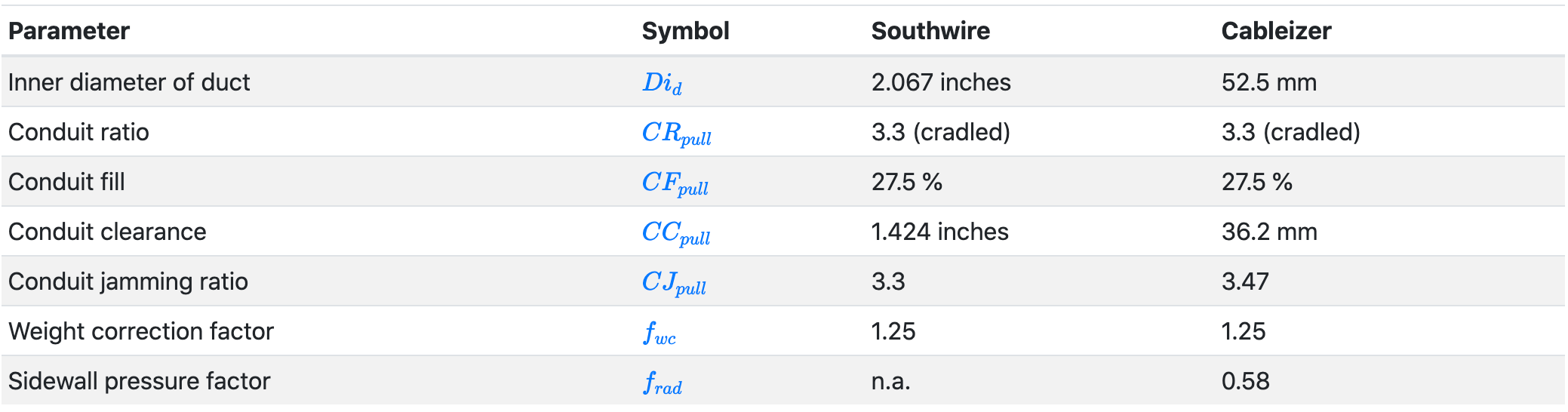

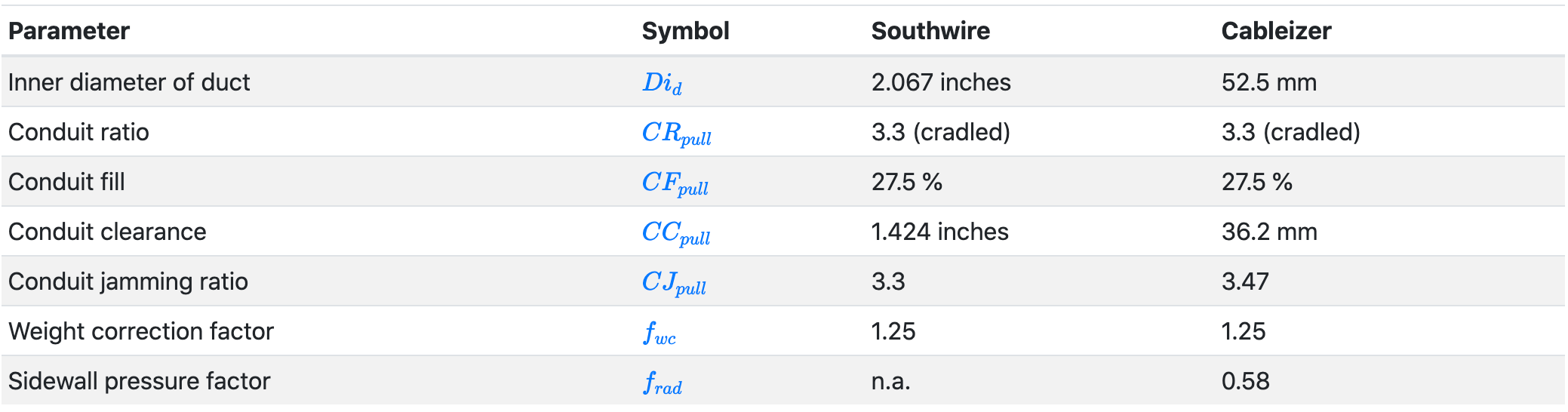

Conduit selection

In the Conduit tab of the cable pulling module the conduit (EMT trade size 2 inch) is defined. The parameters include the inner diameter of duct Di_d, the conduit ratio CR, the conduit fill CF in percent, the conduit clearance CC in percent and the conduit jamming ratio CJ.

Cableizer does then verify if the installation is feasible and calculates the weight correction factor f_wc and the sidewall pressure factor f_rad as shown in the following table:

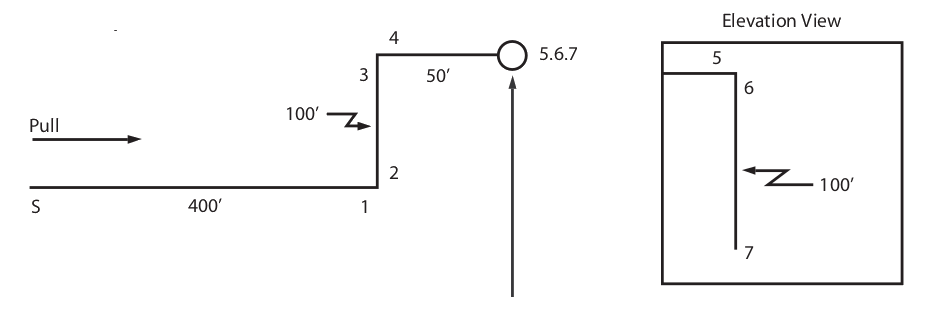

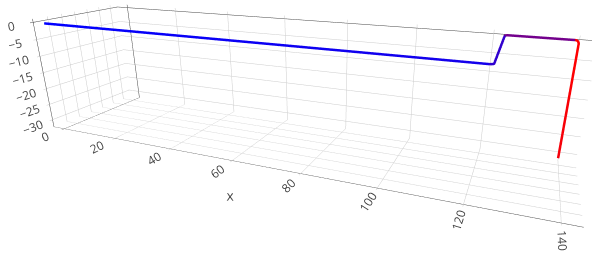

Route editor

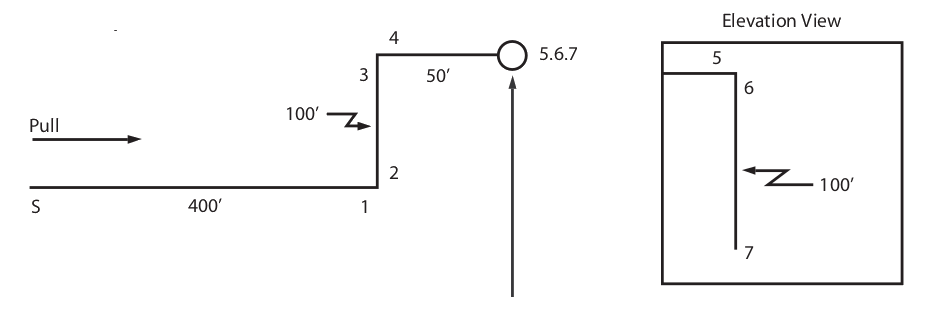

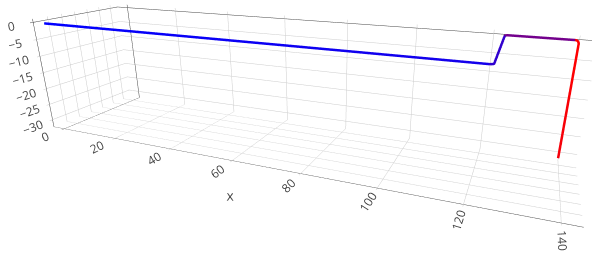

In the Routing tab of the cable pulling module the example route is composed of sections and bends. Bends have an angle ϕ_arc of 90° and a radius r_arc of 914.4 mm (36-inch sweep elbows with an inside radius of 2.91 feet). The friction coefficient μ_dyn is 0.4 all along the route. The following images show the Southwire conduit layout and the Cableizer cable route (in 3D):

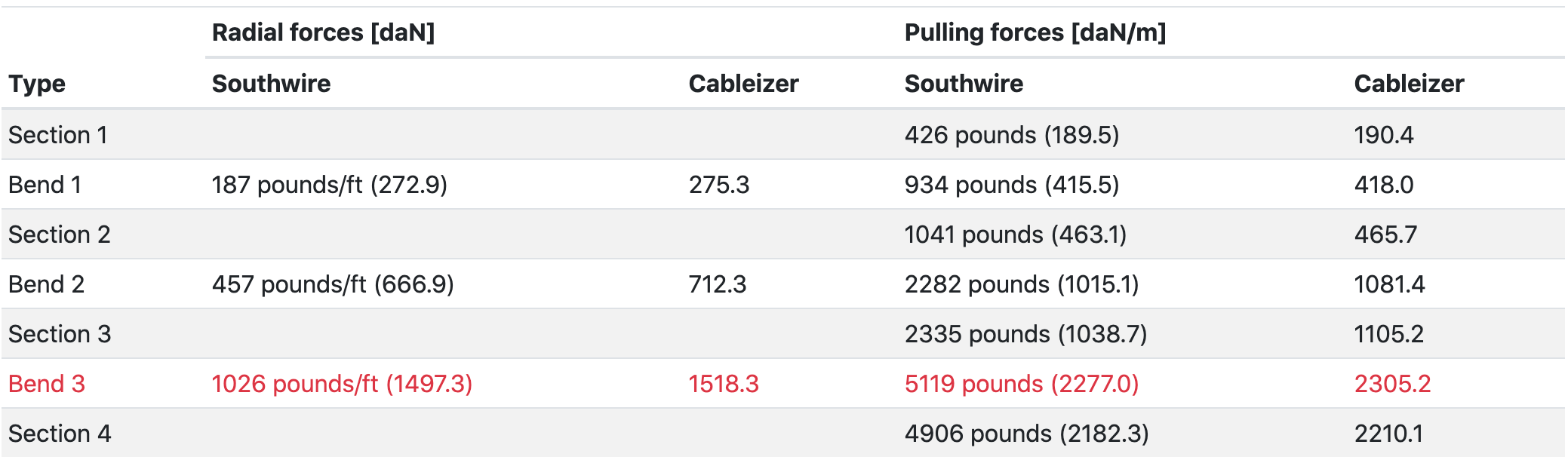

Results

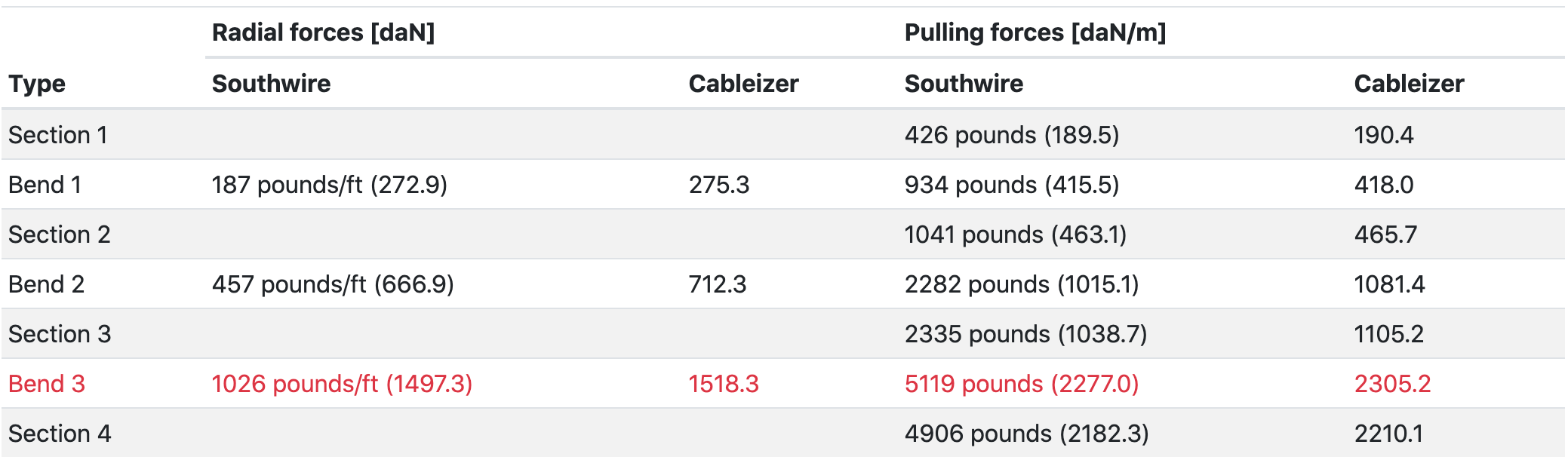

The results show a good agreement with the Southwire installation guide figures, both regarding the pulling force F_pull and the sidewall bearing pressure F_rad. In bend 3, both forces exceed the respective limits:

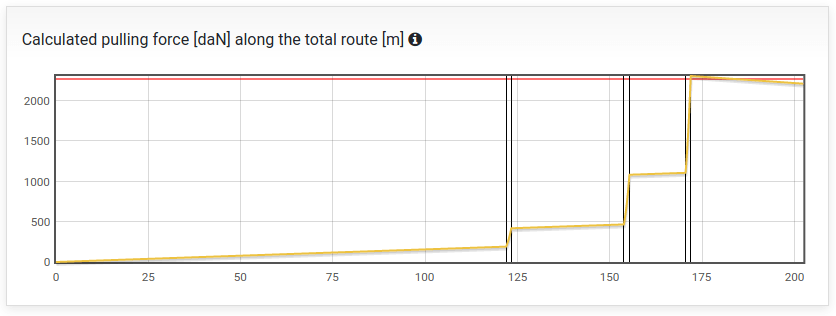

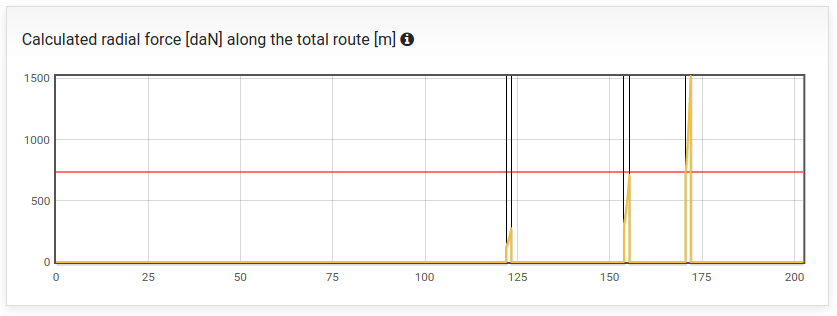

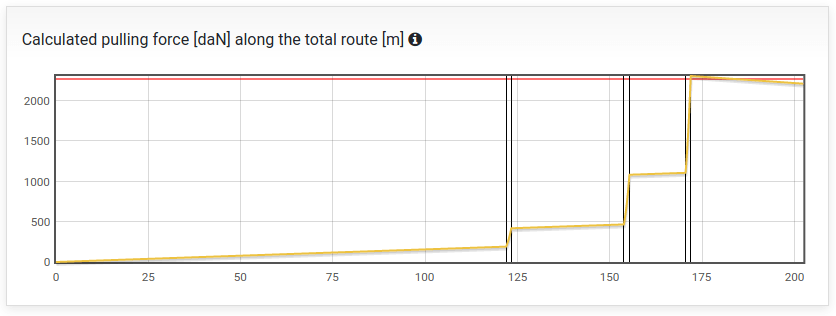

Part of the small differences in the above table can be explained by the fact that Southwire is using approximate equations for both horizontal bends and the vertical concave downwards bend (bend 3). The following figure shows the pulling forces along the cable route for the forward pulling direction. The red line shows the applicable force limits.

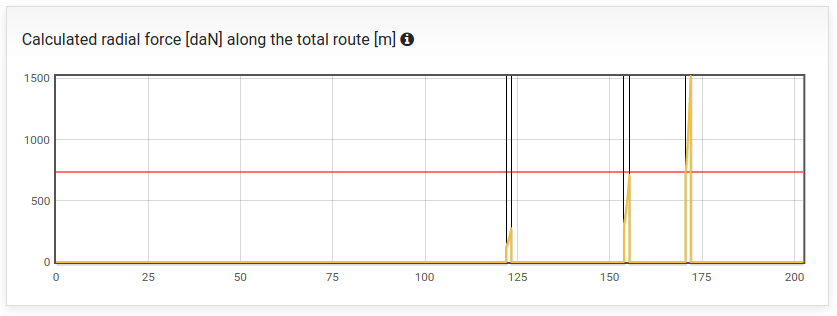

A figure showing the radial forces along the cable route is likewise generated.

Backwards pulling direction

In Cableizer, you can also simulate a pull in backward direction. In this case the maximum pulling force is reduced to 1443.7 daN and does not exceed the force limit anymore. The radial force is also considerably reduced to a maximum value of 825.5 daN/m, which is only slightly above the limit.

The forces are reduced despite the fact that the cable has to be pulled up the vertical shaft at the start of the cable route! But having the bends close to the start of the route instead of close to the end of the route significantly reduces the overall pulling forces.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations