Cable Joints & Terminations HV

Nexans Power Cable Accessories & The Innovative JTS Joint for Medium Voltage Cable

February 8th, 2022

MV Cable Joint – JTS

Improved Reliability & Safety at Reduced Cost

Nexans Power Cable Accessories is the UK’s leading cable and accessories company that has recently announced the launch of a new innovative product range that will ensure safer, easier and time efficient installations.

With their UK base in Castleford Nexans Power Cable Accessories has launched the new JTS Heat Shrinkable MV Joints range which boasts unique design features developed to reduce installation time, minimize risk of failure and simplify installation.

Launched at ENERGYX2021 event in Chester, the new JTS Heat Shrinkable Joints Range feature a range of design innovations that will deliver cleaner, quicker and simpler jointing installations. These features include:

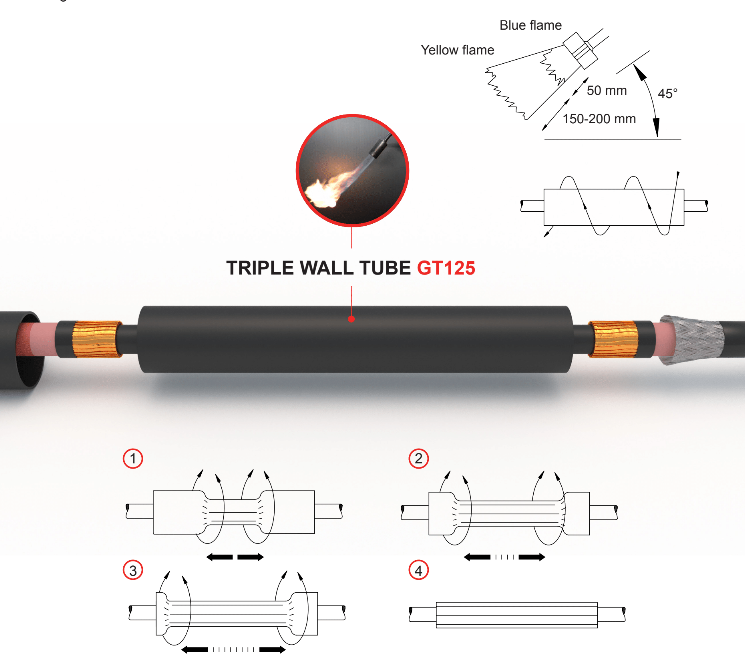

- Innovative triple wall technology where three inner tubes have been extruded as one, and as such, requiring only one heat shrinking activity instead of three

- The use of this triple wall tube meaning the chance of misalignment is reduced by a factor of 3 to 1 and;

- The inclusion of a revolutionary integrated faraday cage section within the connectors mastic patch minimizes misalignment in critical areas.

MV | Robust Outer Sealing & Protection & Advanced Electrical Stress Control

latest innovation to MV cable joint range

Speaking about the new product range Joe Roberts, UK & Ireland Sales Manager at Nexans Power Cable Accessories UK said: “We are delighted to be launching this product range to market and with what we consider to be some of the most innovative technology available to date”.

“As a business we pride ourselves on pioneering new ways of working and new technologies that ultimately make cable installations slicker, quicker and easier whilst consistently delivering products that meet the very highest standards of health and safety. We are immensely proud of our new JTS Heat Shrinkable Joints range and are very much looking forward to launching it, not only at ENERGYX, but over the coming months as we introduce these products to the marketplace.”

Alongside the range of unique design innovations, the new MV Cable Joint JTS Heat Shrinkable Joints Range also offers a host of additional installation benefits designed to speed up, simplify and improve safety across the install process. These include:

- A compact, slim design with sizes ranging from 95mm² to 1000mm²

- Market leading insulating properties for safer installations

- Advanced screen connection and armour continuity for maximum control of fault currents

- Thick walled outer tubing for high mechanical strength and impact resistance

- Resistance to water penetration & chemical aggression

- Stabilized UV protection for external longevity

- Halogen free material content with outer LSOH jacket for safer use in enclosed spaces

- Fitting single core and three core MV cables up to 42kV

- Quick and Easy to install – saving labour time, with no additional retraining required

- Excellent Insulating Properties – for safer installations

- Plus Premium Technical Support from our UK based technical staff

M

MV Heat Shrink Cable Joint Development

After engaging with Europe’s major MV installation companies to find out their thoughts on how to improve standard MV heat shrink cable joints. The main features were found to be – reduce the installation time, minimise the failure risks and simplify the installation.

Reduce Installation Time

This was achieved by the innovative design featuring “triple wall” technology, where the three inner tubes for semi conductive conductor screen, insulation, and semi conductive insulation screen have been extruded into one simple triple wall tube. This requires only one heat shrinking activity instead of the usual three, and the new design of roll on mastic pad to go over the connector eliminates the requirement for additional mastic tapes as in previous designs which can tend to stick to each and become very messy. The new design results in a much quicker and cleaner installation.

Minimise The Failure Risks

By the application of the triple wall extruded tube, this has effectively reduced the problem of misaligning the over tubes by a factor of 3 to 1 and maximizes coverage of the screen cut area – this, together with a new design of roll on mastic patch over the conductor area featuring a revolutionary “Faraday Cage” built in inner semi conductive layer also minimizes potential for misalignment in these critical areas.

Simplify the installation

By the application of these new and innovative design features, together with improved jointing instructions featuring high resolution images and easy to read step by step text, the whole process of installation has been simplified and no additional jointer training will be required to install the JTS.

TRIPLE WALL HEAT SHRINK CABLE JOINTS

Single Tube with Triple Function

The below video shows the Triple Wall design of the JTS Joint reducing installation times with corresponding labour savings.

Traditionally, heat shrink joints required several separate stages for the installation of the complete cable joint with multiple layers of heat shrink tubes needed to provide stress control, insulation and conductive functions – the labour intensive jointing procedure introduced increased risks of jointer error including tube misalignment and flamework deficiencies (scorching of tubes by overheating).

Nexans

Nexans is a global player in energy transition. The Group designs solutions and services in these main business areas: Building and Territories, High Voltage Projects, Rail and Mass Transit, Renewables, Data Centres and Industry Solutions.

In the UK, Nexans Power Cable Accessories provides complete solutions including cables, accessories and training services for energy transmission and distribution networks. As the leading European specialised innovator, manufacturer and distributor of low- medium- and high-voltage accessories, as well as connection technology, Nexans Power Cable Accessories has been a leader in pre-assembled cable accessories for over 60 years.

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold brand of separable connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

The joints and terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.

Thorne & Derrick International, based in the UK, are the Specialist Distributor for the Nexans Power Cable Accessory range of Screened Separable Connectors (Euromold), Cold-Applied (AIN AFN) & Heat Shrink Joints (JTS) & Cable Terminations (MONO) for Medium Voltage Power Systems up to 66kV; we hold extensive stocks and provide the most competitive commercial and technical levels of customer service in the UK.

Record Business Growth for Thorne & Derrick & Nexans Power Accessories (UK) Ltd

February 8th, 2022

By Chris Dodds | Sales & Marketing Manager at Thorne & Derrick International

In 2018, Thorne & Derrick signed a UK Distribution Agreement with Nexans Power Accessories – this united the leading UK based Specialist Electrical Distributor with a global driver of the world’s transition to a more connected and sustainable energy future.

Since inception our contracted agreement has delivered consecutive annual business growth, last year including a 65% year-on-year leap in sales.

This success is due to our shared commitment to increasing stock holding, customer service levels, technical training and product innovation. Despite acknowledged supply chain and logistical challenges, due to politics and pandemics, we have worked hard together to overcome and mitigate impacts on the customer.

Our dynamic agreement supports existing customers and develops new market-share for the Nexans range of cable joints, terminations and connectors for use with medium voltage power systems up to 66kV.

No Time for Downtime | Resilient & Reliable Power Systems

Thorne & Derrick have been at the forefront of many critical national infrastructure projects supplying customers with world-class cable accessory products to build new medium voltage electrical systems; powering the renewable energy revolution and the digitalization of the world economy.

A combination of multiple major project wins by Thorne & Derrick during 2021 within the wind and data-centre sectors coupled with buoyant substation projects across other sectors has fuelled our impressive sales results.

“We look forward to our shared future together with Nexans and thank our customers for their business – 2021 was a record sales year for us in 36 years of trading. Our project experience and approved vendor status with key clients has enabled us to build a solid reputation for the reliable supply of Nexans products – we have a multi-million pound stock capacity at our Bristol location where orders can be supplied on next day delivery. This includes a complete offering for both the JTS & MONO heat shrink ranges of 11/33kV joints and terminations and the market-leading brand of Euromold connectors,” comments Chris Dodds (Sales & Marketing Manager at Thorne & Derrick).

“Congratulations to all our distribution network for a successful 2021 even in the face of adversity. Let’s hope we can further strengthen our relationships in 2022 and continue these record breaking years!” enthuses Joe Roberts (UK & Ireland Sales Manager at Nexans Power Accessories).

Innovation | New product launches including the JTS MV Joint have enabled Thorne & Derrick to increase market-share with power contractors. JTS provides unique design features developed to reduce installation time, minimise risk of failure and simplify installation by the cable jointer.

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Cold Shrink Joints From 3M Electrical – MV HV Ranges

February 1st, 2022

Cold Shrink Cable Joints By 3M

MV HV Cold Shrink Joints

Stocked & Supplied by Thorne & Derrick | Technical Support | Competitive Prices | UK & International Projects

Thorne & Derrick distribute 3M Cold Shrink Cable Joints suitable for jointing, connecting and splicing medium and high voltage (MV-HV) cables including 11kV, 33kV, 66kV and 132kV – we provide competitive prices for cold shrink cable joints from extensive stocks to UK and international destinations.

3M Cold Shrink Cable Joints include built in components to ensure sound insulation, stress control and adequate earth potential over the screens of medium voltage cables. The 3M Cold Shrink Technology ensures constant radial pressure is exerted over the cable for the duration of the cable joint’s life.

The Simple Application Of A 3M Cold Shrink Cable Joint

|

|

|

|

| 1. Place the 3M Cold Shrink splice body onto the prepared cable, connect the cores and clean cables thoroughly. | 2. Thoroughly grease the connected cable in preparation for the cable splice body. | 3. Once in position, begin to remove the inner coil from the cable joint body. | 4. For extra peace of mind, take advantage of the fact that cable splice body position is easily checked. |

|

|

|

|

| 5. Place the earth stocking over the splice body. Ground and secure with 3M Constant Force Springs. | 6. Insulate the constant force springs with Scotch 23 Rubber Splicing Tape and then overlay with Scotch Rubber Mastic Tape 2228. | 7. Position the pre-parked 3M Cold Shrink Outer Protection Tube over the stocking and beginning to remove the inner supporting core. | 8. Continue to remove the inner core until the outer tube is fully shrink, completing the cable joint. |

3M Cold Shrink cable joints are available in a Standard cost-effective range or Premium options for medium/high voltage (MV HV) power systems.

The Standard range covers many of the most common cable configurations and size ranges unique to the UK market but requires the electrode to be built up by the cable jointer using Scotch 13 electrical semi-conductive tape.

3M Standard Cold Shrink Cable Joints

The Standard 3M Cold Shrink Cable Joints are available for both single core and 3 core cable connections for medium/high voltage cables including 11kV 33kV 66kV and 132kV.

3M premium Cold Shrink Cable Joints

The Premium 3M Cold Shrink Cable Joints are available for both single and 3 core cable connection for medium/high voltage cables including 11kV 33kV 66kV and 132kV.

3M Super Premium Cold Shrink Cable Joints

The Super Premium 3M Cold Shrink Cable Joints are available for both single and 3 core cable connections or medium/high voltage cables including 11kV 33kV 66kV and 132kV.

Cold Shrink Joints Features

- Prefabricated one-piece Cold Shrink splice body with integrated semi‑conductive electrode forms a faraday cage over the connector and eliminates the use of tapes or additional moulded or metallic electrodes

- Fast and easy installation at temperatures ranging from -20°C to +50°C

- Suitable for a broad range of cable type and sizes

- Permanent radial contact pressure

- Simple assembly by pulling out the spiral core

- Meets exceeds the requirements of European Standard CENELEC HD 629.1 and IEC 60502-4

| QS1000 | QS2000 | QSIII | QS200 | |

| Splice Body Type | Moulded | Moulded | Moulded | Extruded |

| Range Coverage | 50sqmm to 400sqmm | 50sqmm to 400sqmm | 300sqmm to 630sqmm | 50sqmm to 1000sqm |

| Voltage Class | 6.6/11(12)kV | 20/22(24)kV to 19/33(36)kV | 19/33(36)kV | 6.6/11(12)kV to 19/33(36)kV |

| 100% Factory Tested Splice Body | Yes | Yes | Yes | No |

More from 3M Electrical

- Continuous Shearhead Bolt vs. Crimp Compression Technologies By 3M Electrical

- 3M Electrical Tapes Guide | The Tape For Every Task

- 3M Terminations | Surface Tracking on Medium Voltage Cable Terminations by 3M

- 66kV Terminations | NEW Stock Introduction for 3M Cold Shrink Cable Terminations

- Stress Control | MV Cable Terminations by 3M Electrical

- Q/ Can 3M Electrical Offer MV Cable Joints For Hazardous Areas?

- MV Cable Jointing & Some Jointers Tips Using 3M Scotch Tapes

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Nexans Supply Cables For The World’s First Floating Wind Farm

February 1st, 2022

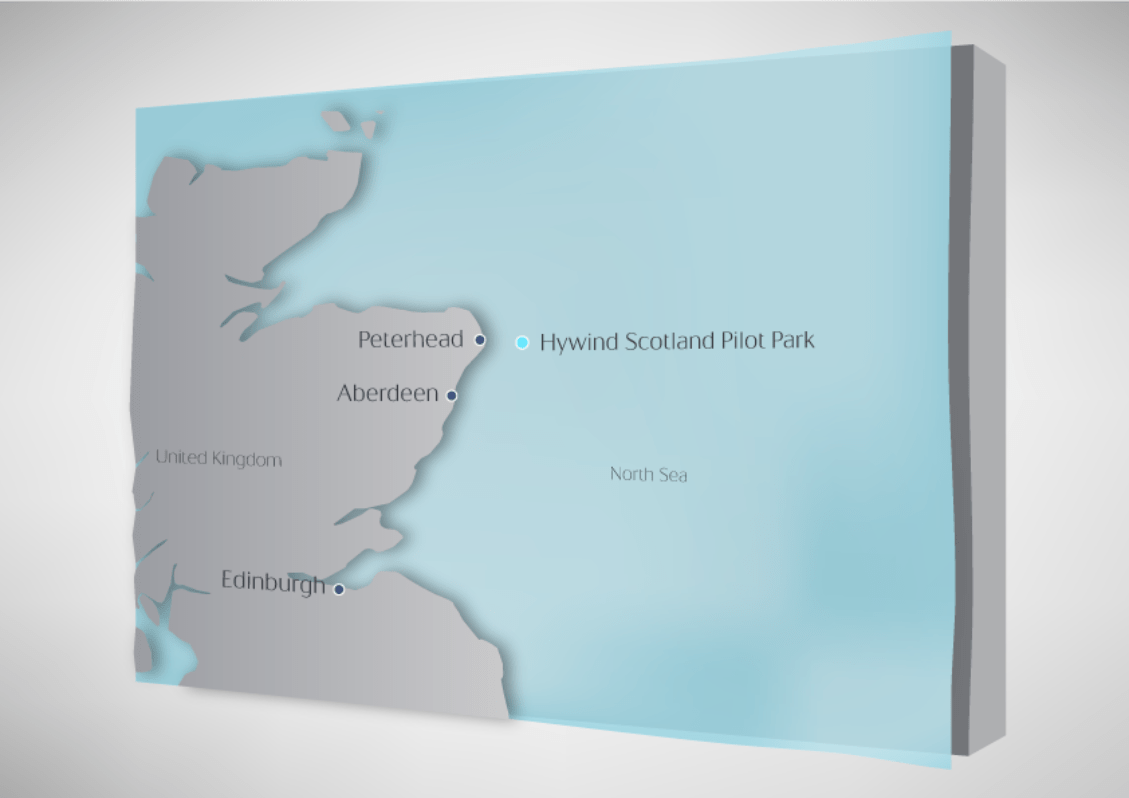

Hywind Scotland Pilot Park Offshore Wind Farm

Offshore Export Cables

Hywind Scotland Pilot Park Offshore Wind Farm

Location: Scotland

Partnership: Equinor

Market: Wind Farms-Offshore

Equinor (former Statoil) awarded Nexans the contract to supply static and dynamic cabling and associated accessories for the world’s first floating wind farm, following a successful demo facilitated by Nexans’ cables which have been in operation since 2009.

Following the initial Norway demo, Equinor awarded Nexans a new contract worth approximately 10.2 million Euro to service the Hywind Scotland Pilot Park wind farm. Nexans delivered offshore export cables to the site, located 30 km off the coast of Aberdeenshire.

The offshore cable systems was tested, sealed off, prepared for pull-in and delivered in individual lengths ready for installation. The cables were tested and manufactured at Nexans’ specialized facility in Halden, Norway.

The pilot 30MW floating farm is made up of five wind turbine generators connected through an inter-array cable network before feeding into a single offshore export cables carrying energy back to land in Peterhead, Scotland. Following the successful Norway demo, the project, assisted by Nexans, will demonstrate technological improvements, installation and operation of multiple floating wind turbines, as well as examine the cost efficiency of the park configuration.

Hywind Project – Copyright STATOIL – Wind Farms Offshore

The Hywind project will generate energy to power roughly 20,000 homes, and will lead the way to developing larger floating wind farms in other areas after an initial two-year testing period.

Vincent Desale, Nexans SEVP for the Subsea and Land System Business Group commented “ This project is a great example of Nexans pioneering alternative offshore wind design, extending the options for renewable energy generation. The contract establishes Nexans as leaders in offshore wind innovation by designing specialist cables for both the initial pilot project and the Hywind Pilot Park. ”

Hywind Project – Floating Farm – Copyright Statoil

FURTHER READING

- Nexans Offshore & Onshore Export Cables | Seagreen The Largest Windfarm Project In Scotland

- Onshore Wind Farms: Nexans Awarded Underground Power Cable Contract for Viking Wind Farm

- Nexans Windlink® Cables To Electrify The Future Of Onshore Wind Turbines

- Nexans OJC Offshore Medium Voltage Junction Cabinets For Wind Power Projects

- Nexans Power Cable Accessories For Wind Energy Projects – MV & HV Cables

See how T&D support, supply and service the Renewable Energy industry.

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Nexans Offshore & Onshore Export Cables | Seagreen The Largest Windfarm Project In Scotland

January 31st, 2022

Nexans Power Export Cable Supplier For The Seagreen Offshore Wind Farm Project

Offshore & Onshore Power Export Cables

Seagreen Offshore Wind Farm Project

Location: Scotland

Partnership: SSE Renewables

Market: Wind Farms-Offshore

Nexans is SSE’s preferred supplier for the design, manufacture and installation of the onshore and offshore export cables for the 1,075MW Seagreen wind farm project. Nexans will supply and install three 65 km offshore export cables and three 20 km onshore export cables.

About the project

Phase 1 development, comprising the Seagreen Alpha and Bravo wind farms. It will have combined capacity of 1,075MW. When complete it will form the largest windfarm project in Scotland when they come online in 2024. To promote contract opportunities for local companies, SSE Renewables organises ‘Meet the Buyer’ events, where they can discuss their service offerings with members of the supply chain.

Seagreen Project Director John Hill said: “We are pleased to announce Nexans as our preferred supplier to design, supply and install the onshore and offshore export cable. Nexans is one world leaders in this field and this agreement is a major step forward for the Seagreen project.”

Seagreen Offshore Wind Farm project

The Seagreen Offshore Wind Farm project is located 27km off the coast of Angus in the North Sea.

A joint venture between TotalEnergies (51%) and SSE Renewables (49%), Seagreen will be Scotland’s largest and the world’s deepest offshore wind farm when complete.

The Seagreen offshore wind farm was consented with permission granted to install 150 offshore wind turbines.

114 offshore wind turbines are currently under construction with an installed capacity of 1,075MW and will be fully operational by early 2023. The power generated will be exported to the grid via a new substation at Tealing near Dundee.

The 114 Seagreen wind turbines will provide enough green energy to power more than 1.6 million homes, equivalent to two-thirds of all Scottish homes. They will also displace over 2 million tonnes of carbon dioxide from electricity generated by fossil fuels every year – similar to removing more than a third of all of Scotland’s annual car emissions and making a significant contribution to Scotland’s net-zero ambition by 2045*.

The remaining 36 offshore wind turbines are consented but not yet constructed. The power will be exported to the grid via Cockenzie, East Lothian.

In January 2022 Seagreen submitted a Screening Report to Marine Scotland to increase the size of the 36 consented turbines.

FURTHER READING

- Onshore Wind Farms: Nexans Awarded Underground Power Cable Contract for Viking Wind Farm

- Nexans Windlink® Cables To Electrify The Future Of Onshore Wind Turbines

- Nexans OJC Offshore Medium Voltage Junction Cabinets For Wind Power Projects

- Nexans Power Cable Accessories For Wind Energy Projects – MV & HV Cables

See how T&D support, supply and service the Renewable Energy industry.

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV