Earthing

HV System Earthing Design – A Case Study

March 27th, 2020

- Republished with Permission of Matthew Taylor – Principal Engineer & Managing Director at Earthing Risk Management Ltd

HV System Earthing Design – A Case Study

Project Brief

An effective earthing system is vital for large installations such as power stations.

ERM was asked to verify the proposed earthing design against UK standards, including ERM’s previous experience designing the earthing system for the new 400kV connection substation and verifying the designs for the existing 400kV and 275kV substations.

The scale of the site, its varying elevation and the proposed use of a backfill material made this a challenging project.

Challenges

Sheer size; with a site almost a kilometre across, the amount of electrode involved in calculations is taxing for even modern computing with the latest CDEGS software.

Varying surface elevation presented a technical challenge and required the use of specialised functions within CDEGS as well as top-end hardware to process the model and keep calculation times to an acceptable level.

Lateral variation in soil resistivity and significant depths of imported backfill material to be represented in the model. Staged construction of the earthing system in the vicinity of live 400kV and 275kV substations and the provision of 11kV construction supplies present particular safety hazards. ERM was asked to analyse the construction programme and design out any safety hazards associated with the 11kV power network.

Working with multiple companies to progress the project, including international involvement

OUR APPROACH

The size of the power station earthing system, along with the adjacent interconnected sites and requirement to represent a multi layer soil model including backfill representation made the construction and processing of a CDEGS model difficult.

ERM built a bespoke top-end PC to give sufficient processing power to run this model in a timely manner.

Regular liaison with the client throughout the project allowed ERM to understand the breadth of the project including associated areas such as construction techniques and installation methods proposed.

The range of practical and technical experience at ERM allowed us to not only deliver the customer’s requirements but to provide advice value engineering advice, which subsequently provided significant safety improvements and savings in excess of £1M.

PROJECT OUTCOME / DELIVERABLES

The earthing design was approved from a safety viewpoint and significant cost savings were identified during value engineering both for the design itself and for its construction. The saving exceeded £1M.

Safety hazards with 11kV construction supplies were identified and designed out with a pragmatic solution that required little ongoing management.

The finished product was a detailed model with the functionality required to examine, calculate and draw the above conclusions.

Earthing & Lightning Protection | Earth Tapes | Earth Rods | Earth Bars

meet the company – erm ltd

Earthing Risk Management Ltd (ERM) was established in 2002 to address the needs of the Electricity Supply Industry to manage safety hazards associated with HV earthing systems.

Since then, the company has grown to be an established, well respected consultancy serving a broad range of clients.

Employing an experienced engineering team as well as full time site testing teams, they are able to manage, assess and evaluate safety hazards associated with all aspects of HV earthing and lightning protection systems.

ERM’s experts from around the world provide their clients with the highest quality services in earthing design and verification, earth testing and measurements, earthing/lightening protection systems commissioning and test pit reconfiguration, pipeline interference studies, high frequency and transient studies, lightening protection design and upgrade, industry training, quantified risk assessment and fault investigation.

Earthing Risk Management has many years of experience in working with many companies throughout the electricity, gas, rail, and renewables industries trust ERM to deliver solutions for critical infrastructure such as National Grid, DNOs, Mitsubishi and Siemens.

Other Case Studies from ERM Ltd

Fall of Potential Measurement

➡An onshore substation which was constructed as a part of the new extension for an offshore wind farm project, located in the Irish Sea has a capacity of approximately 750MW.

The power from the offshore wind farm is to be exported by undersea high voltage cables to the 400kV onshore substation where the power is fed into the transmission network.

ERM was asked to test the new, onshore substation earthing system to verify the earthing installation and the CDEGS (Current Distribution, Electromagnetic Interference, Grounding and Soil Structure Analysis) model.

Lightning Risk Assessment

➡ ERM was asked by Uniper Energy to carry out a lightning protection site survey and risk assessment for one of their sites.

Their approach was to attend the site to obtain all relevant information needed to complete the lightning protection risk assessments (LP RA). This information was then passed over to the engineer who could then check that all of the required information was obtained.

This information was entered into specialist software to calculate the lightning risks in accordance with BS EN 62305. Any structures that were above the risk limits were then reassessed with additional lightning protection to reduce the risks to tolerable levels.

The client was provided with a report which detailed the results of these risk assessments and any improvements that they should make to bring the lightning risk levels down.

Accurate lightning risk assessment results were obtained for each of the structures, taking account of existing lightning and surge protection.

Soil Resistivity Measurement

➡ A new overhead line (OHL) was being built between two EHV substations.

The new planned route was in a difficult location compared to the existing route with Earth Potential Rise (EPR) impacts being likely along the strings. As there is potential for significant impacts ERM were brought in to examine the impact of EPR on towers along the routes.

Their experience and information gathering expertise allowed for the identification of Often Frequented Towers (OFT’s) as points of interest along a significant number of tower spans.

This prioritisation allowed for the planning of Soil Resistivity test routes in proximity to these points of interest only and therefore reduce the number of tests that had to be carried out. This allowed for savings on project costs and time taken to produce results.

The project was delivered to the customer outlining the findings of the study in a timely manner. The report made recommendations to the customer for not only the results but for the possible improvement of this, and any subsequent, studies with regards to the information used and alternative approaches to the study.

Contact ERM

Britannia House, Caerphilly Business Park, Caerphilly, South Wales, CF83 3GG

+44 (0)2920 850 444

[email protected]

further reading

- Earth Bars | High Specification Copper Earth Bars for Lightning Protection Systems

- Substation Earthing

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Lightning | An Introduction To Lightning Protection | Networks, Strategy & Systems | Part Two

October 23rd, 2019

An Introduction To Lightning Protection

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Earthing

Lightning Protection

AN Wallis

In the second part of the series AN Wallis gives an introduction to lightning protection focusing on systems, strategies and earth terminations and networks.

➡ Earthing | An Introduction To Earthing & Earthing Designs | Part One

Structural Lightning Protection

Structural Lightning Protection systems are installed to minimise the risk of damage to the external & internal parts of the structure, including the electrical and electronic equipment from a lightning strike and reducing the risk of injury to humans by safely discharging the high voltage to the earth system.

The external lightning protection attracts the lightning discharge and conducts it safely to earth and the internal lightning protection, with use of transient surge protectors, minimises the damage to sensitive equipment and bonding of conductive services ensure a safe path to earth.

A complete Lightning Protection System (LPS) can only be achieved when both safety measures of Internal & External LPS are employed to the structure based on the Risk Assessment.

Lightning Protection System (LPS) JG253 – In-Situ

Lightning Protection Strategy

The normal strategy in achieving protection is to capture the lightning at a preferred point by the use of air terminations and conducting it via low impedance down conductors and earth electrodes to a low resistance earth of less than ten ohms.

Air terminations and down conductors are spaced at regular intervals to form a mesh of conductors around the perimeter of the building and roof, known as a Faraday cage, and are joined together by specially produced damps and fixings or welding.

Lightning Protection System Design Considerations

A LPS is designed according to geographical location, local terrain, soil conditions, size and height of building, type of material used in construction, type of material stored in the building, use of building and is based on established standards for risk assessment.

The Risk Assessment needs to be carried out prior to the design of the structural LPS to determine the Class of LPL required based on the IEC / BS EN 62305 standards or internationally accepted standards.

Air Termination Networks

Based on the determined Class of LPL conductor spacing’s can be selected as identified below:

| Class of LPS | Roof Mesh Conductors W (Width – Metres) | Rolling Sphere Radius r (Radius – Metres) | Protection Angle a (Degree) | Down Conductor Spacing (Metres) |

| I | 5 x 5 | 20 | Refer to chart | 10 |

| II | 10 x10 | 30 | 15 | |

| III | 15 x 15 | 45 | 15 | |

| IV | 20 x 20 | 60 | 20 |

To calculate the areas of protection the Rolling Sphere technique can be employed. The zone of protection determined by the methods requires protection through the Roof Mesh method and Protective Angle Methods.

Roof Mesh Method — Simple and direct implementation of conductor spacing’s based on the Class of LPS, e.g. Class I LPS — Roof conductors are to be spaced in a grid of 5 x 5 metres throughout the flat roof plane.

The Protective Angle Method is based on the relativity between the height of protection required to the prescribed angle of protection in conjecture with the height to be protected which can be obtained from the chart below. Key areas or strike points need to be determined before employing the protection measure.

Class of LPS Graph

Down Conductors

Down conductor spacing has to be in accordance with the Class of LPS which is determined and to be adopted based on the table. E.g. Class I LPS — Down conductors to be spaced at every 10 metres of the structure around the periphery of the structure.

The spacing should be carried out as evenly as possible on the periphery starting at the corners and at the shortest distance to earth.

Sufficient separation distance ‘s’ need to be maintained when down conductors are placed in overhangs and care to be taken to avoid re-entrant loops.

Earth Terminations & Networks

The information contained in this section is primarily for LPS earthing.

For Earth Termination systems two basic types of earth electrode arrangements are applied. Type A earthing arrangement is suitable for low structures and existing structures. Type B earthing arrangement is usually followed throughout.

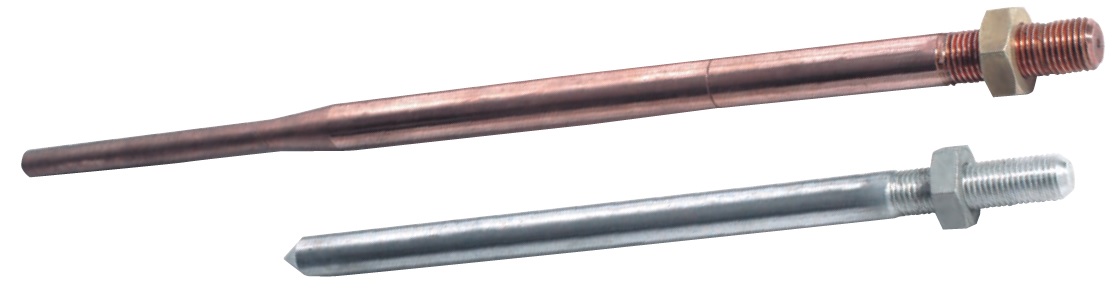

Each down conductor needs to be connected to an earth electrode to form the earthing with a minimum of two. The minimum length of earth rods that are required to be driven into ground is 2.4 metres. Earthing system contains of horizontal earth electrodes and vertical earth electrodes. Earth rods may need an earth inspection housing for periodic testing of earth resistance.

Resistance to Earth

To maintain a safe earth system, it is recommended that the earth rods to ground resistance values are less than 10 ohms. Earth resistance values are measured at low frequency.

A single earth rod may not achieve the required resistance figure and several may need to be fitted to achieve this; their combined resistance is proportional to the reciprocal of the individual rod resistances to earth.

This rule holds true as long as each rod is situated outside the resistance area of any other. To ensure this is the case, it is generally accepted that the minimum spacing between rods should not be less than their driven length.

The expected number of rods required to obtain a particular resistance value, e.g. ten ohms, can be roughly calculated.

To do this the soil resistivity needs to be taken into consideration. A soil resistivity test will need to be performed.

There are several methods used to obtain a lower resistance value:

- More rods can be driven. Rods can be driven deeper

- Rods of a larger diameter can be used

- Ring conductors connecting rods together underground can be used

- Where deep driving is not possible shorter rods with a larger diameter can be used; copper earth mats and earth plates can be used in place of earth rods

- A “crows foot” configuration can be used where a parallel connection is not possible

Where high resistance soil conditions are a problem soil conditioning agents can be used to backfill rod holes. Conductive concrete can be used to backfill an earth mat. Both effectively increase an electrodes cross sectional area and therefore reduce its resistance to earth.

The international standards also specify the recommended materials used for all earthing conductors and their dimensions.

Equipotential Bonding

It is common practice to use the buildings natural structural steelwork and bonding it to the LPS to further improve its ability to conduct lightning and fault currents to earth; prior permission may be required.

Joints

Joints should be mechanically effective, all joints other than welded ones are a potential discontinuity, and care should be taken to ensure contact surfaces are clean and that fixing clamps are tight and well protected from corrosion, which can occur if dissimilar metals are joined. Ideally there should be as few joints as possible in an LPS design.

Maintenance & Life of an LPS

It is important to properly maintain an LPS to ensure it retains its ability to conduct the same current carrying capacity as it did when it was originally installed. Earth rod resistances should be regularly checked.

Corrosion and fault currents can cause high resistance joints leading to overheating. However, if an LPS is correctly installed and maintained it should last for many years.

The information contained in this section is intended as a guide and should not be used to perform designs. AN Wallis does not accept responsibility for errors or omissions. Detailed information on LPS design is contained in internationally recognised European and British LPS standards.

Earthing – Copper Earth Tapes | Bars | Clamps | Rods

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Furseweld | The Furse System of Exothermic Welding

October 9th, 2019

Furseweld | The Furse System of Exothermic Welding

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Furseweld

The Furse System of Exothermic Welding

Since 1893, Furse has provided world leading Earthing, Lightning and Electronic Systems protection solutions for electrical infrastructure, building services and LV MV HV substations.

FurseWELD exothermic welding is a cost efficient method of achieving high quality electrical connections.

FurseWELD is a simple, self-contained exothermic welding system that uses the high temperature reaction of powdered copper oxide and aluminium, within a mould, to form permanent electrical connections.

Exothermic welded connections are accepted according to the 11kV and 33kV substation earthing design and construction manuals by most UK DNO’s, including UK Power Networks (UKPN) – for instance earth welding copper to copper tape connections and copper tape to stranded cable earthing connections.

Typical Exothermic Welding Applications

- Earthing for power plants and high voltage substations (11kV-33kV)

- Telecommunications

- Transmission and power distribution lines

- Cathodic protection

- Rail connections

Exothermic Wedling Using the FurseWELD System

FurseWELD Earth System Benefits

- Requires no external power or heat source

- Creates high quality electrical connections

- Completely portable

- Can be used safely with minimum training

- Cost effective exothermic welding

- Can be used for over 45 standard connection configurations

FurseWELD Earth Connection Advantages

- Tolerant to repeated fault currents

- Highly conductive

- Does not loosen

- Excellent corrosion resistance

FurseWELD Exothermic Welding – contact T&D for Training & Certification Courses

FurseWELD connections have at least twice the cross-sectional area of the copper conductors being joined or welded, and an equivalent or greater current carrying capacity. Corrosion resistance is exceptional due to the very high copper content (> 90%) of the alloy.

Typical FurseWELD Applications

- Bar to Bar

- Bar to Earth Rod

- Cable to Bar

- Cable to Cable

- Cable to Earth Rod

- Exothermic Moulds & Joints

FurseWELD is suitable for earth rod connections to copperbond, solid copper and stainless steel earth rods – threaded porttion of copperbond earth rods must be removed prior to FurseWELD application.

Welding procedure

- Position the cleaned conductors in the mould after ensuring the mould is dry by pre-heating or making a test joint.

- Lock the mould with the handle clamp; if the mould does not close properly adjust the tension by removing the split pin and turning the eye bolt accordingly. Insert the steel disc into the mould crucible, ensuring it is centred over the tap hole.

- Pour the welding powder into the crucible; the starting powder is retained in the underside of the cartridge and identified by a red cap.

- Spread the starting powder evenly over the welding powder, placing a small amount on the top edge of the mould for easy ignition.

- Close the cover and ignite the starting powder with the flint gun; pull the gun away immediately to prevent fouling the flint. Wait a few seconds to allow the metal to solidify before opening the mould. Remove all slag and dust before making the next weld.

FurseWELD Exothermic Welding Moulds

FurseWELD system of exothermic welding uses moulds to contain the exothermic reaction that creates safe and robust connections. Different types of FurseWELD moulds are available, whose use depends on the requirements of the project.

- Graphite Moulds – Marketleading FurseWELD graphite moulds are extremely robust and capable of creating over 75 connections each.

- Mini-Moulds – FurseWELD mini-moulds are a cost effective alternative to full sized moulds, especially where lower numbers of connections are required. They are smaller overall, less robust and therefore lower priced. Care is required in order to achieve similar service lives to full sized moulds.

- Sureshot – the FurseWELD Sureshot system is a single use ceramic mould supplied complete with retaining disc and powders – It has been designed for use in applications where only a few exothermic welding connections are required.

FurseWELD – How to make a FurseWELD Joint Connection

1. Locate the copper conductors to be joined in the FurseWELD cavity and close the mould.

2. Locate the steel retaining disc in the base of the crucible, pour in the weld powder followed by the starting powder. Ignite starting powder with a spark gun.

3. The exothermic reaction reduces the weld powder to molten copper alloy which melts the retaining disc and flows into the weld cavity where it partially melts the conductors

4. The molten copper allow cools to leave a fusion weld of great mechanical and electrical integrity.

FURSEWELD TOOLS / ACCESSORIES

Furseweld Exothermic Welding Tools & Accessories

- Handle Clamp

- Flint Gun

- Toolkits including cable or tape cleaning brush, mould cleaning brush & mould scraping tool

- Gas torch (to preheat the mould)

- Optional toolbox & heat resistant mould jacket

Potential Hazards

As with all forms of welding the potential hazards are:

- Accidental contact with hot work.

- Spatter of molten metal.

- Eye irritation.

- Throat/chest irritation.

Frequently Asked Questions About Exothermic Welding

Could you tell me how many welds can be completed before replacement of the mould is required?

With regards to the Exothermic Welding Mould, the mould should be good for 40-50 joints at a minimum (they could easily do a lot more if they are maintained and used correctly).

Are the earth welding products classed or recognised as “explosives”, and should they be stored in a secure metal box and labelled as explosives?

- FurseWELD materials must be stored in a dry and secure place

- Only take onto site, sufficient materials to give continuity of work

- Fully discuss the operation with the client including site fire precautions. Note: A permit to work system may be required before work can be done

- Wear all of the above listed personal protective equipment and any other equipment which may be required for the job in hand

- Do not use flame or heat near flammable substances or atmospheres; this will include the following: paints, solvents, oils, petroleum, diesel, gasses, paper, rags

What are the training and competency assessments requirements and how often should this training be reviewed, refreshed or renewed?

Furse can offer Exothermic Welding Training and will supply a certificate at the end to show that the user has successfully completed a course of instruction and demonstrated competence in the process. This certificate will last for 4 years – contact Thorne & Derrick for further information.

PPE Requirements?

Safety Goggles & Heat Resistant Gloves

The following should always be worn:

- Safety Goggles

- Heat Resistant Gloves (welders gloves)

- Safety Boots (for site use)

- Safety Helmet (for site use)

- Fire Bucket or Extinguisher (if working near flammable materials)

In addition to the above, other equipment may be required dependent upon the location of and the nature of the job. This may include:

- Fire bucket/extinguisher (if working near flammable materials).

- Heat resistant board (to contain spillage or protect surfaces).

Further Reading

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Furse | Earthing & Lightning Protection Design Services & Solutions

September 11th, 2019

Thorne & Derrick: Stockists & Suppliers of Furse Products

Furse

Thorne and Derrick are stockists and suppliers of Furse Earthing and Lightning Protection products. Acquired by the ABB Group, Furse is established as the world leader for earthing and lightning protection.

Lightning is a real and significant threat – which is why there is a need for a total solution (for more, see Furse).

💡 Experience

Furse has over 125 years of experience to provide the optimum design; using minimal material to save you money.

💡 Expertise

Specialist advice is provided from fully qualified technical engineers – focusing on earthing and lightning protection concerns.

💡 Knowledge

The most appropriate and up to date products are used due to exceptional knowledge of the latest materials

💡 Compliance

Furse designs comply with all national and international standards, ensuring they remain at the forefront of new developments.

- NFPA 780 Standard for the installation of lightning protection systems

- IEEE Std 80:2013 IEEE Guide for safety in AC substation grounding

- ENA TS 41-24 Guidelines for the design, installation, testing & maintenance of main earthing systems in substations

- BS EN 50522:2010 – Earthing of power installations exceeding 1.k Vac • SS 555

- BS EN/IEC 62305 Protection against lightning

Technical Earthing Solutions

Lightning Protection Solutions – Furse have a team of experienced engineers: engineering designs to meet client specifications and conducting risk assessment, complying to the latest standards.

Experienced Surveyors – Accurate surveys are the key to creating effective earthing systems. Multiple readings are taken to ensure safe and accurate designs.

Analysis & Earthing Design – The latest CDEGS software is used to optimise designs. A range of detailed reports are produced to meet clients’ requirements.

Earth Resistance Testing – The verification of earthing design is validated through measurement. An experienced team of engineers with a full understanding of electrode testing will conduct this.

💡 NEWS: Researchers map timing and location of rare lightning “superbolts.”

Superbolts release a thousand times more energy (at least) than the average lightning strike and tend to occur mostly over oceans and seas. Forrest Moreland via Unsplash

Furse Design services, site surveys & analysis

Earthing & Lightning Protection experts Furse provide Focused Technical Design Services | Image: Voltimum.co.uk

Earthing & Lightning Protection Solutions

Why choose Furse?

There are many benefits to choosing Furse for earthing and lightning protection analysis. They offer specialist advice from a fully qualified technical team, focusing on earthing and lightning protection. European and International standards are followed, which ensures that engineers remain at the focus of new developments.

Furse recognises that it is their responsibility to provide safe designs – and they always ensure to provide an optimum design, using minimal material and saving you money. By Utilising product knowledge and experience, designs are tailored and installed using the most appropriate products.

Soil Resistivity Surveys

A comprehensive soil resistivity survey is key to creating an effective earthing system; as opposed to inadequate or erroneous soil resistivity readings, which are likely to result in a flawed design.

Furse site surveys take multiple accurate soil resistivity readings at various depths across the site. As these results form the basis of the whole earthing design, the experience of engineers is critical in ensuring the correct implementation of the test data.

Analysis & Earthing Design

Furse can produce detailed earth electrode and lightning protection system designs. These are created through the use of the latest computer-aided design and modelling software and comply with recognised standards. Designs are also created to any complexity requirement or budgetary need. State-of-the-art software is used for full earthing analysis to determine step and touch voltages, potential rise and hot/cold classification of the site.

Earth Resistance Measurement

Earth resistance measurement is essential to accurately determine that the installed earthing system meets the criteria from initial design.

Furse technicians ensure all measurements are correctly taken and interpreted so that the true resistance of the earthing system can be accurately determined.

the total Furse solution

As the world leader in lightning protection services, Furse is committed to providing a good quality total solution.

Structural Lightning Protection Structural Lightning Protection

Furse offers a range of air termination systems, including strike plates and air rods to capture lightning strikes. They also offer an extensive range of down conductors and lightning protection components which channel lightning energy safely to a Furse earth termination network.

|

Earthing Earthing

A combination of earth electrodes, as well as FurseCEM soil conductive back-fills and conductors, are offered from Furse. Equipotential bonding bars are also supplied to provide effective, low resistance dissipation from the lightning protection systems to earth.

|

Electronic Systems Protection Electronic Systems Protection

Furse has an exhaustive range of equipotential bonding and transient overvoltage SPDs. These provide fully coordinated protection against transient overvoltages, on all incoming and outgoing metallic service lines – including power, data, signal and telecoms.

|

FurseWELD – Exothermic Welding FurseWELD – Exothermic Welding

FurseWELD exothermic welding is a cost-efficient and self-contained system. It uses the high-temperature reaction of powdered copper oxide and aluminium, within a mould, to form permanent electrical connections.

|

Industries

Furse has shared its expertise with the following industries.

- Oil & Gas / Petrochemical

- Utilities

- Rail & Infrastructure

- High Tech & Industrial

- Commercial Construction

- Ports & Recreation

- Government & Public Sector

For the full case study, visit the PDF in Further Reading.

Further Reading

FurseCEM Earthing Conductive Aggregate Concrete

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Furse

September 9th, 2019

Thorne & Derrick: Stockists & Suppliers of Furse Products

Earthing & Lightning Protection

A Supplier Overview

Since 1893, Furse has provided world leading Earthing, Lightning and Electronic Systems protection solutions.

Furse have over 125 years of experience, and design and manufacture their own products. From design and manufacture, through to risk assessment and systems design advice, Furse offers an acclaimed total solution for earthing and lightning protection.

Furse has remained a constant force in an unpredictable world; even throughout a century that has seen such remarkable social and technological change. Acquired by ABB Group in 2012, the Furse brand is established as a world leader in earthing and lightning protection, with products specified and installed in many distinguished projects globally.

The combined expertise of Furse and the experience within the electrical sector that ABB provides, allows them to share the knowledge they hold in key industry sectors with customers. This results in properly informed decision making on the best earthing and lightning protection solutions. Furse earthing analysis uses state-of-the-art software to determine the step and touch voltages, earth potential rise and fall, and hot/cold site classification of the site generated by the initial design.

Photo by David Moum on Unsplash

Services include:

- Lightning Protection Solutions

- Soil Resistivity Surveys

- Analysis & Earthing Design

- Earth Resistance Testing

The expertise and experience of which Furse have attained has constructed and helped to develop their exceptional service; offering specialist advice from fully qualified engineers, as well as solutions that save money and use minimal material. Furse also offer design solutions: using the latest computer aided design and modelling software to produce detailed system designs for any complexity.

This produces high quality earth electrode and lightning protection designs, in compliance with globally recognised standards. Designs are tailored and installed using the most appropriate and up-to-date products. Knowledge of the latest standards ensures designs and products comply with the latest IEC/BS EN/NFPA/UL standards.

why do we need lightning protection?

Lightning is a real and significant threat. Containing astonishing amounts of electrical energy. Lightning discharges have been measured from several thousand to over 200,000 Amps (enough to light half a million 100 Watt bulbs). Although very short in duration, a lightning strike can cause tremendous damage and destruction.

Devastating consequences:

- Direct lightning strikes damage structures, and create fire, explosion and electric shock hazards.

- Indirect lightning (up to a kilometre away) creates transient over voltages which degrade electronic systems and disrupt essential services.

While the effects of a direct lightning strike are immediately obvious, secondary effects of lightning can be less visible; which can lead to equally catastrophic devastation, and damage to electronic systems within structures.

These frightening photos of lightning from a hurricane above Miami, Florida in the USA were taken after the storm left a trail of destruction in the Caribbean. Credit: Chad Weisser | Caters News

The need for a total solution

Lightning protection throughout the world is now governed by National and International standards which stress the need for a comprehensive solution. A structural lightning protection system cannot and will not protect electronic systems from lightning currents and transient over voltages. This is why a total solution to earthing and lightning protection is encouraged. This approach to lightning protection is now fully endorsed by the IEC/BS EN 62305, as well as NFPA 780 standards.

Buy A Copy Of The NFPA 780 Lightning Protection Systems Standards.

Furse delivers an approach demonstrating effective life safety, as well as long lasting and reliable protection of a structure and the electronic systems within. This solution is tailored and covers a wide range of sectors; providing dependable, long term lightning protection and earthing.

Furse Products

Contact Thorne & Derrick for competitive prices on the complete range of Furse products.

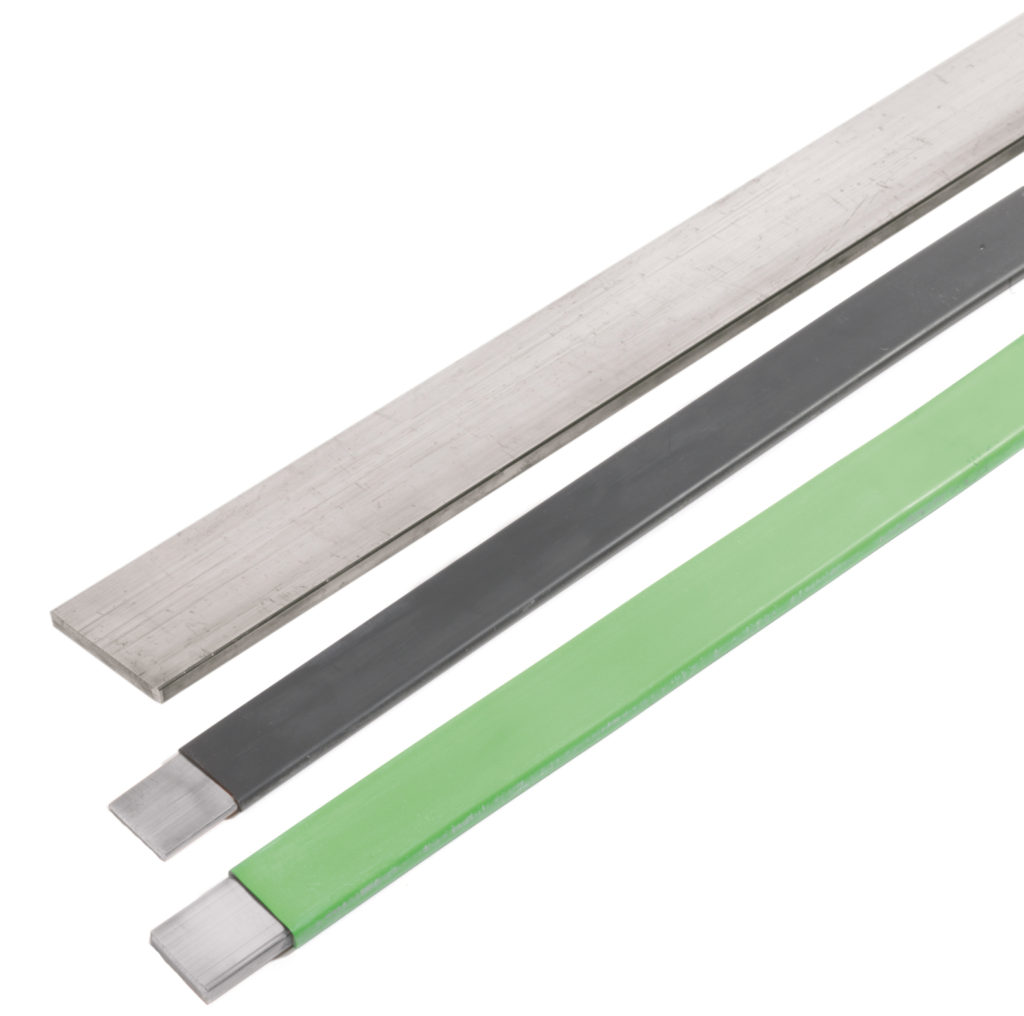

- Conductors

- Bare conductors, bare stranded & tinned conductors

- Hard drawn bar & PVC covered conductors

- PVC covered conductors & guards

- Air Termination

- Air terminals, bases, brackets & couplings

- Multiple point, strike pad & free-standing air termination

- Conductor Network

- Conductor clips

- Standing seam roof fixings, puddle flange and holdfasts

- Trapezoidal holdfasts and conductor clamps

- Earth Electrodes

- Earth rods & seal

- Inspection pits, plate, lattice & backfill materials

- Earth Bonds & Clamps

- Mechanical clamps

- Earth boss & bonds

- Earth points & splitbolt connectors

- Static earth connection points, flexible braid bonds & static earth clamps

- Earth Bars

- Earth bar & earth bars with single disconnecting link

- Earth bar with twin disconnecting link & accessories

- FurseWELD

- FurseWELD exothermic welding

- Electronic Systems Supplies

- Surge protection devices (SPDs) for mains power supplies

- Surge protection devices (SPDs) for data, signal and telephone lines

- Surge protection devices (SPDs) for computer and telephone lines

- Surge protection devices (SPDs) for specific systems

over 125 years of history

Furse has remained a constant force in an unpredictable world, through all the century could throw at it.

Further Reading

FurseCEM Earthing Conductive Aggregate Concrete

Furse Earthing & Lightning Protection Design Services & Solutions

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV