Cable Pulling Equipment – A Cable Laying, Duct & Installation Guide From SSE

Published 01 Feb 2018

Thorne & Derrick | Cable Pulling & Laying Equipment Stockists and Suppliers

-

by Chris Dodds T&D - estimated reading time 2 minutes

Cable Pulling

The following information based upon a document produced by UK DNO, Scottish & Southern Electricity Networks, provides information and guidance on New Connections and best practise for cable pulling and laying and when installing LV (Wavecon | Concentric), 11kV (3 Core | Single Core) and 33kV (Single Core) cables into underground cable trenches.

The cable pulling equipment for ensuring safe and compliant installation of LV-HV cables up to 33kV is briefly outlined – should you require any further information or technical support please contact us.

All work carried out and cable pulling equipment used must be compliant with SSE technical guidance (TG-PS-881) available from the SSEN website.

It is also recommended that contractors and clients review the ‘Practical Guide to Streetworks’ before undertaking any excavations prior to installing LV-HV cables to form part of new connections.

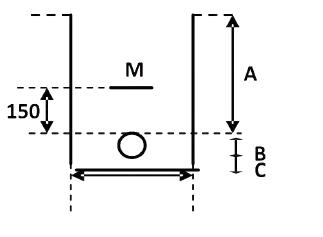

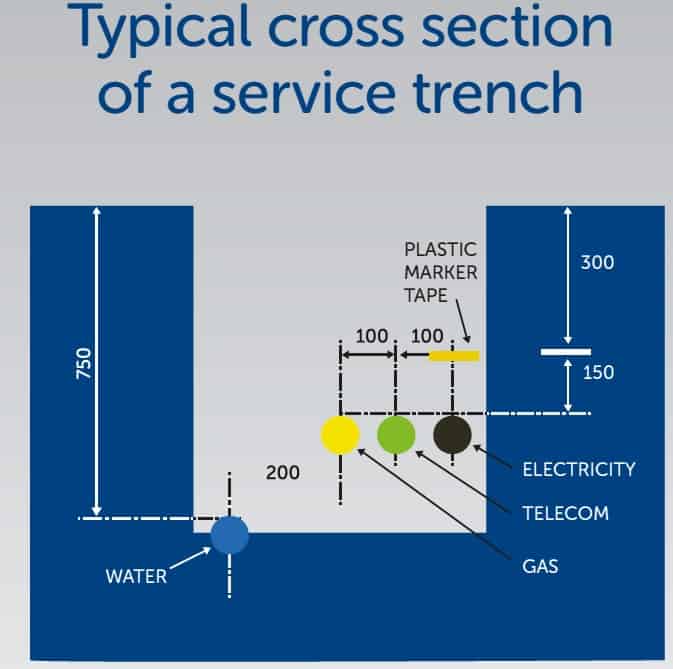

The following cable trench section shows the position of cable and the cable duct in the ground – it is important that the top of any apparatus is at these depths as a minimum, this includes the top of the cable duct. In addition to the cable or duct there is a requirement for 75mm finefill material on all sides. Cable marker tape or cable tiles/covers must be installed 150mm above the top of the apparatus, this needs to have SSEN branding on.

This table shows the minimum depths to top of apparatus (A within the diagram above)

| Minimum Apparatus Depth | Unmade Ground, Verges & Footway (mm) | Carriage (Road) (mm) | Agricultural (mm) |

| Cables LV | 450mm | 600mm | 1000mm |

| 11kV Cables HV | 600mm | 750mm | 1000mm |

| 33kV Cables HV | 800mm | 900mm | 1100mm |

Minimum Excavation depth required = (A) minimum depth of apparatus + (B) outside duct/cable size + (C) 75mm of sand bedding.

Please note that (M) represents the cable marker tile (for 33kV cables use Stokbord covers) or cable protection tape for all other installations including 11kV cables and cable joint protection.

Please note: Where there are sudden changes in surface type (e.g footway to carriageway), excavations should always be at the greater of the depths required.

New Housing Service Cable Installation Guide

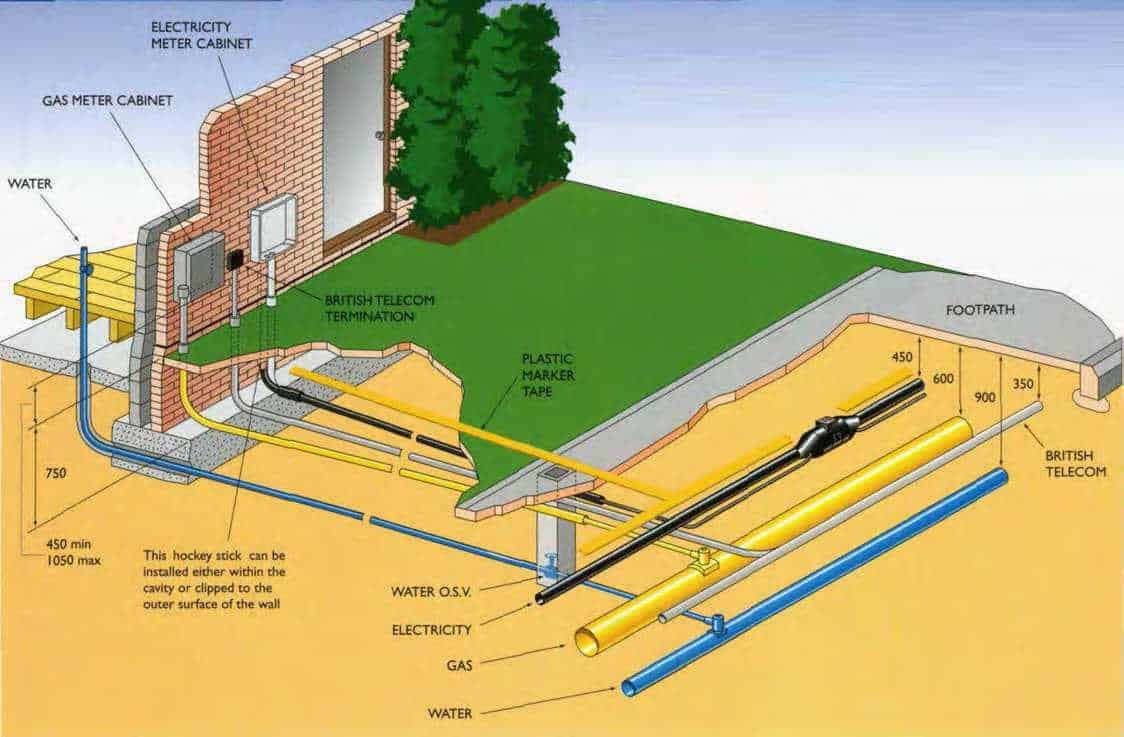

Experience has shown that by using a service tube the disturbance to the site is reduced when the electricity supply is connected.

The service tube can be laid in the same cable trench as the other services are shown, with an identifying plastic cable marker tape installed above to give advanced warning of service cable location on private property.

External meter cabinets

The external meter cabinets must be positioned in agreement with SSE to provide unrestricted access.

The preformed ‘hockey sticks’ can be installed either within the cavity or clipped to the outer surface of the wall below the meter cabinet.

White ‘hockey sticks’ must be used on the outer surface of walls. The service tubing must be securely coupled to the ‘hockey sticks’. The cabinets are only large enough to house SSE service and connection equipment.

Clients must fit own main switches on an inside wall so that the length of interconnecting cable does not exceed 3 metres.

This cable must only enter through the bottom of the cabinet, using the right hand hole, when viewed from the front.

Typical Cross Section of A Service Trench

Duct Seals – contact us for duct sealing solutions and products to provide sealing against water (flood prevention) to copper and ducted low, medium and high voltage power cables.

Installation of Cable ducts

For the installation of ducted schemes the use of Black electric cable ducts only (see table below for approved suppliers) are permitted for use.

Clients should consider the type of cable ducts intended to use before ordering as excavations will be different depending on which cable duct supplier you use – the minimum cable bending radius must also be considered by referring to the manufacturers specification and selecting the appropriate cable pulling equipment to include cable rollers, socks, drum jacks and cable winches.

Emtelle cable duct range includes a smooth bore type of ducts which have rigid preformed bends at differing angles. When pulling and laying cables it is important that angles or bends should not be placed too close together otherwise cable pulling tensions will become greater than the manufacturers guidelines during the installation process.

Winch Cable installation

All cable must be installed not exceeding the manufacturers recommended cable pulling tensions – this applies to low, medium and high voltage power cables. Contractors must familiarise themselves with these cable pulling loads before hiring the equipment to ensure that these loads are not exceeded.

For all Cable Pulling applications contractors should use the following cable laying equipment and products:

- Cable winch

- A display of the cable pulling tension on the winch (calibrated)

- A free moving cable pulling swivel link

- Cable rollers located typically every 4 metres and/or where LV-HV cable would come into contact with ground

- Cable socks to ensure excellent grip and support of LV-HV cables

In addition to cable trench installations, for ducted cable schemes you will also need;

- Bell mouth roller

- Cable lubricants

- Cable drum trailers for each cable drum

For 33kV single core cables it is recommended that the contractor put colour indicators on each cable for identification – the cable installer must securely anchor the cable drums and the cable winch at either end and ensure that the LV-HV cable does not come into contact that could inflict cable sheath damage.

Cable Socks – high tensile strength galvanised steel cable socks provide support and grip for LV-HV cable pulling into duct or laying into trench.

Cable Pulling Equipment

Cables, Duct, Duct Seals & Cable Tiles Approved Equipment

| Item | Manufacturer | Manufacturing Location | Notes |

| LV Concentric Cables | Tratos | UK | |

| Cabelte | Portugal | ||

| LV Wavecon Cables | Prysmian | Wrexham UK | |

| Hellenic | Greece | ||

| 11kV Three Core Cables | Nexans | Hannover, Germany | Aluminium stranded & solid conductors 11kV |

| Prysmian | Wrexham UK | ||

| 11kV Single Core Cables | Tele-Fonica Kable | Poland | Copper or aluminium stranded for all conductor sizes Solid aluminium up to and including 300sqmm conductors 11kV |

| Prysmian | Wrexham UK | ||

| Nexans | Hanover, Germany | ||

| 33kV Single Core Cables | NKT | Cologne, Germany | Copper or aluminium stranded for all conductor sizes 11kV or

Aluminum stranded for all sizes or solid aluminium up to and including 300sqmm |

| Tele-Fonica Kable | Poland | ||

| Prysmian | Wrexham UK | ||

| Nexans | Hanover, Germany | ||

| Cable Duct | Polypipe Civil Ltd | UK | |

| Emtelle UK Ltd | UK | ||

| Cable Tile | Centriforce | UK | |

| Cable Warning Tape | Centriforce | UK | |

| Plastic Tape Tile | Centriforce | UK | |

| Duct Seals | TE Connectivity | UK | Rayflate Inflatable Cable Duct Seals |

| WT Henley | UK | Services Ducts (Green Plastic Compound) | |

| Winn & Coates (Denso) | UK | Denso Mastic Denso Tape |

|

| CSD Cable Sealing System | UK | CSD RISE Cable Duct Sealant System |

Joints | Terminations | Glands | Cleats | Cables | Tools | LV MV HV 11kV 33kV

Cable Laying & Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Laying & Pulling Equipment to enable the safe installation of utility power cables including LV Waveform and MV-HV Power Cables 11kV/33kV – full range of cable spiking tools available to ensure LV-HV power cables are dead prior to jointing or cable termination works.

➡ Further reading: Cable Pulling Equipment – A Cable Duct Laying Guide From BT Openreach

Further Reading

-

Cable Laying – A Cable Pulling, Duct & Installation Guide From SSE

Size: 387.98 KB

Cable Laying – A Cable Pulling, Duct & Installation Guide From SSE

Size: 387.98 KB

-

SEB Cable Pulling & Cable Laying Equipment LV MV HV

Size: 5.12 MB

SEB Cable Pulling & Cable Laying Equipment LV MV HV

Size: 5.12 MB