Arc Flash Protection

When Are Arc Flash Switching Suits Required?

January 22nd, 2024

STRATA Workwear Arc Flash Protective Clothing Range

Arc Flash Switching Suits

Thorne & Derrick are the UK’s Leading Specialist Distributor of Electrical Safety Equipment to clients working in the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – we supply arc flash clothing from a range of brands including STRATA® Protection.

STRATA® Protection a the leading Arc & Flame Protective Clothing brand in the Energy Sector including arc flash switching suits for the protection of workers.

Arc flash switching suits are required in situations where electrical systems pose a risk and are specially designed suits that are used in situations where electrical systems have the potential to release intense energy in the form of an arc flash event. These suits are commonly worn by professionals working in electrical, utility, and industrial sectors.

Switching suits are specifically designed to provide multiple levels of protection against the hazards associated with arc flash events. These suits are categorised based on their ability to shield the wearer from thermal energy, flames, and other hazardous elements.

Wearing the proper arc flash suit is essential in high-risk work environments, where electrical equipment or systems may be subject to faults or malfunctions that could result in an arc flash event. These environments include power plants, substations, electrical maintenance and repair, and other industrial settings – protecting utility workers against arc flash dangers posed during maintenance on underground electric cables, overhead line conductors or electrical equipment.

What garments does an arc flash suit comprise of?

Thorne & Derrick understand how critical it is to have reliable, highest quality personal protection equipment (PPE), clothing and arc workwear available from stock at competitive prices

The arc flash kit typically consists of:

- Arc Flash Hood: A hood designed to cover the head and neck, often featuring a built-in face shield and integrated hard hat. Designed to be used alongside your existing clothing systems to provide specialist protection when working with high incident energy levels

- Arc Flash Jacket: A flame-resistant jacket is tailored to cover the upper body completely, including the torso, arms, and neck, providing a reliable barrier against extreme temperatures and potential burns. Available in a range of different size, including ‘extra small’ (XS) all the way through to 4XL

- Arc Flash Trousers: Specially designed trousers or dungarees that offer protection for the lower body. These garments help guard against thermal hazards and electrical risks arising from arc flash events. Available in a range of different size, including ‘extra small’ (XS) all the way through to 4XL (size 8 to 18 for women)

- Arc Flash Gloves: Insulated gloves made from arc-rated materials, intended to safeguard the hands against the cuts, abrasions, and burns that are possible during an arc flash incident while maintaining dexterity. Available in a range of different sizes

- Storage Bag: A dedicated bag for storing and transporting the components of the arc flash switching suit kit.

All these components work together to provide comprehensive protection against the hazards associated with arc flashes and electrical incidents. It is crucial to select items that meet relevant safety standards and are tested and certified for arc flash protection. Regular training on the proper use and maintenance of these components is also essential to ensure workers’ safety.

When do I need to wear my arc flash Switching suit?

You are required to wear your arc flash switching suit whenever you are working on or near electrical systems or equipment that pose a potential arc flash hazard. This includes situations where there is a risk of electrical faults or when you are working with energised electrical systems.

It is essential to wear arc flash suits to protect yourself from the thermal and electrical hazards associated with arc flashes.

The specific requirements for wearing arc flash suits may vary depending on your local regulations, employer policies, and the level of hazard present. It is crucial to follow industry standards and guidelines to ensure your safety.

Here are some examples of situations you would consider wearing one:

- Switchgear Operations: When interacting with electrical equipment like switchgear, arc flash suits provide indispensable protection against arc flash incidents during maintenance, inspections, or troubleshooting

- Electrical Panel Work: Wiring, repairing, or maintaining electrical panels pose inherent risks, demanding the use of arc flash suits to mitigate potential dangers

- Circuit Breaker Maintenance: Activities involving circuit breaker maintenance and repair require the full-body coverage offered by arc flash suits to prevent severe injuries

- Panel Inspections: During inspections, repairs, or maintenance of electrical panels and distribution boards

Arc Flash Clothing Kit 40 Cal

How often do arc flash suits need to be tested?

It’s important to note that while periodic non-destructive testing is not required for arc flash suits, it is still crucial to adhere to industry standards, guidelines, and manufacturer recommendations to ensure the safety and effectiveness of the suits.

However, the frequency of testing may vary depending on the usage, condition, manufacturer’s recommendations, and relevant industry standards or regulations. Additionally, suits should be inspected prior to each use for any signs of damage or wear and should be replaced if necessary.

However, there are recommendations out there for maintenance:

- Consider replacing the clothing for the suit every 10 years (this will depend on how often you are using the suit, less frequent usage may result in the kit lasting longer)

- Keep your arc suit clothing free of oil, grease, dust or – carefully read the laundering instructions to maintain the integrity of the garment.

- Refresh your face shield every 5 years. Should the face shield show substantial scratches or discolouration, take immediate action to replace it.

- Audit your full kit – take the time to look for scratches on your helmet, rips or snags in your clothing and take the safest course of actions after the audit and replace where necessary.

Alternatives to Arc Flash Suits

It is important to note that the effectiveness of arc flash clothing and personal protective equipment (PPE) depends on various factors such as the level of risk, the specific tasks involved, and the hazard analysis conducted.

While layering other items of arc flash clothing and PPE can provide adequate protection, it is crucial to ensure that each layer is properly selected and compliant with relevant safety standards. The layering should also not compromise mobility or restrict the wearer’s ability to perform their tasks safely.

Providing a variety of options for engineers to choose from can certainly contribute to their comfort and well-being. It is important, however, to prioritise safety and effectiveness in selecting the appropriate arc flash clothing and PPE. Regular maintenance and inspection of these items should also be carried out to ensure continued protection.

Further Reading: STRATA Workwear | Skanwear Arc Flash Clothing & Protection

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

ProGARM 4690 Coveralls | Arc Flash Protection for Rail Trackside & Substation Engineers

January 2nd, 2024

ProGARM | 4690 Coveralls

Progarm 4690

RIS-3279-tom tested arc flash cOVERALLS

ProGARM’S Mission is to Lead with Innovation

Introducing a new addition to the ProGARM range of Arc Flash Clothing – the ProGARM 4690 is a lightweight and comfortable high vis orange coveralls Tested to RIS 3279 Standard to protect workers in the rail industry.

These arc flash coveralls feature the improved lighter and more comfortable fabric.

Features and Benefits of ProGARM 4690 Coveralls

- Arc flash protection and flame resistant fabric

- Mandarin collar // Maximum neck protection

- Kneepad pockets // Wear with kneepacks for extra comfort

- Chest Pockets with zippers // Secure storage

- Gas monitor loop // Secure fixing point

- SafetyICON on arm // Visual EN Standards icon system

- 5cm FR AS Reflective Tape // Double Stitched for longer life

- Phone Pocket on sleeve with flap // Safe and Secure

- Cuff tabs with VELCRO Brand fasteners // Close fit around wrist or gloves

- Side access pockets with flaps // With entry inside coverall

- ThermSAFE plastic FR zippers // CE Certified

- Internal elastic 2 Point adjustable waistband // Ensures close fit

- Double stitched side seams // Lifetime quality assurance

- Easy-Stretch side panels // Maximum wear comfort

RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4690

Arc Flash Coveralls 4690

SPECIFICATION

- Sizes: Small Regular leg, Medium Regular leg, Medium Tall leg, Large Regular leg, Large Tall leg, XLarge Regular leg, XLarge Tall leg, 2XLarge Regular leg, 2XLarge Tall leg, 3XLarge Regular leg, 4XLarge Regular leg

- Colour: HI-Viz Orange

- Open ARC Test: ARC 2

- Box Test: 4KA // Class 1

- LOI: Not applicable

- Protection Type: Antistatic // ARC Flash // Heat & Flame // Hi-visibility // Railway

- Fabric: ProGARM VXS + inherent Woven weave // 290

- Industry Sector: Industrial Electrical // Petrochemical // Rail // Utilities & Power protection

- Type: ARC Flash Coveralls

- Collection: Hi-Visibility Orange Collection

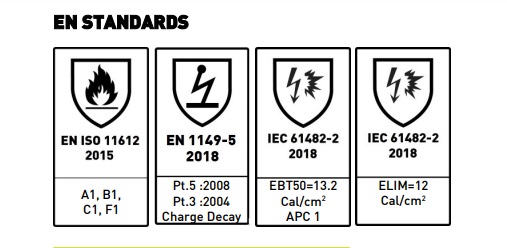

Arc Flash Clothing EN STANDARDS

ProGARM 4690 arc flash coveralls are garment Tested to the following European Standards;

- EN 1149-5:2018: Pt. 5:2008 // Pt.3:2004 // Charge Decay

- EN ISO 11611:2015:Class 1 // A1

- EN ISO 11612:2015: A1 // B1 // C1 // F1

- EN ISO 20471: 2013: Class 3

- IEC 61482-2:2018: APC 1 // ATPV=8 cal/cm² // ARC 2

- RIS 3279 : Issue 1

ProGARM for the Rail Industry | RIS-3279-TOM

What is RIS-3279-TOM?

RIS-3279-TOM (formerly known as GO-RT 3279) is a high visibility standard that only applies to the rail industry in the UK, as opposed to the EU-Wide nature of other EN standards. The aim is to ensure that rail workers on or near the trackside are sufficiently visible to trains approaching at speed or any other traffic.

High visibility clothing is the fundamental principle behind the UK Rail Industry Standard. This is based on the European Norm EN 20471:2013, and garments must comply to Class 2 High Visibility, the middle of a three class range. The standard states the following: ‘high visibility clothing worn by people on the lineside or on or near the line should conform to a single standard for the colour and luminance of background material and that this standard will accord with the detail contained within BS EN 20471:2013 high visibility clothing – Test methods and requirements (ISO 20471:2013).’

cOLOUR rEQUIREMENT sTANDARDS

However It is stated in the standard that: ‘the colour specific requirements within this standard conform to the range specified within BS EN 20471 clause 5.1.2.’ In order to confine this to a specific orange colour, and to prevent the selection of a colour at the red end of the spectrum, the precise chromaticity co-ordinates for the colour are specified as: Fluorescent orange, X:0.588, Y:0.371. with a luminance factor of at least 0.4. The accepted tolerance in colour is as laid out in EN 20471. However, there is no tolerance for the luminance factor.

Also stipulated in RIS-3279-TOM is the need of retro-reflective materials, with photometric and physical performance aligned with EN 20471.

ARC Flash Coverall Range

Mentioned in RIS-3279-TOM is the accepted use of a mini vest where the nature of the work being carried out will not obscure the high visibility clothing, and thus reduce the surface area’ that is visible. The same applies to company logos; these are permitted where they do not compromise the surface area of background colour, and compensation may have to be made for this.

ProGARM 4690 Arc Flash Coveralls

Arc Flash Coveralls, from the ProGARM range of Arc Rated garments and clothing are used to protect against arc flash accidents as the last line of defence. Arc Flash PPE will not prevent incidents, and it is therefore vital that a comprehensive electrical safety plan for maintenance, repair and diagnostic procedures (involving energised LV, MV or HV electrical equipment) is also implemented.

Thorne & Derrick distribute a range of arc flash coveralls to suit a range of requirements. Variations include ladies coveralls, designs for overhead linesmen, orange and yellow hi vis options and a wide range of sizes. Contact Thorne & Derrick with your specific PPE requirements and we will be happy to help.

The ProGARM range of Flame Resistant protective garments are designed for every-day wear and protection – the highly breathable clothing ranges are designed for comfort and safety without compromising the ability of the wearer to work productively, safely and unhampered by cumbersome garments prone to overheating.

Other garments and protection products include Arc Flash Gloves, Arc Clothing, Arc Flash Suits and Arc Flash Helmets & Visors.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Arc Flash Protection Covers for Worker Protection Against Underground Cable Strikes

January 2nd, 2024

Arc Flash Covers | Protection Against Underground Strikes

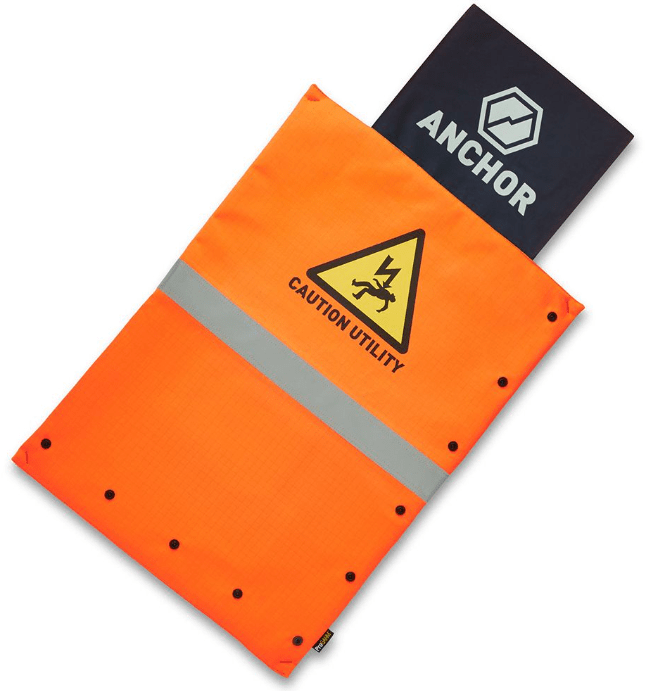

2800 Arc Flash Protection

The ProGARM range of protective garments deliver ultimate Arc Flash clothing and protection, conforming with the relevant industry and EN standards ensuring protection from Arc Flash incidents.

The Range of ProGARM 2800 are specially engineered to provide an extra protective layer against the risk of underground cable strikes, whilst at the same time providing an important visual hazard warning for those in the vicinity.

When to use the Arc Flash Covers

The Arc Cover is used as a warning not to dig near a cable and helping prevent the cable being hit, they provide you with additional protection against the risk of underground service strikes during the core activities you carry out on a daily basis.

- When digging near a cable and it is not exposed

- Once a cable is exposed but not damaged to the side of an excavation

- When digging near an exposed cable

- To support the handover for awareness of an exposed cable or when in excavation is in close proximity to a cable

Arc Flash Covers – Features and Benefits

- Two Layer Construction featuring padding

- 50cm FR industrial wash reflective tape

- FR studs for attaching multiple covers

- Includes anchor point to hold cover in place

- Water resistance fabric layer

- Machine Washable

- Size: 68.5cm x 50cm

Arc Flash Protection – EN Standards

Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Further Reading

- IEC 61482-2 2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

- IEC 61482-2 | Arc Flash Protective Clothing Standards

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

The First Sustainable Arc Flash Range Of PPE From ProGARM

June 5th, 2023

ProGARM launches first sustainable range of Arc Flash Protective Clothing

Sustainable Arc Flash PPE

Introducing ProGARM’s new sustainable arc flash protective clothing range; which meets both sustainability and safety obligations.

The ProGARM range of protective garments deliver ultimate Arc Flash protection, conforming with the relevant industry and EN standards ensuring protection from Arc Flash incidents.

Thorne & Derrick provide competitive prices and fast delivery for the complete range of ProGarm arc flash clothing and accessories designed to protect people and save lives.

ProGARM are known for being arc flash specialists, and in a world-first they have launched a range which looks and performs just like their regular arc flash garments – but with a few key differences making it a truly sustainable option.

After extensive research and development working with fabric specialists across Europe, ProGARM’s new range features the maximum amount of recycled content possible while still creating a fabric and garments that meet the stringent safety standards required for arc flash protection. It uses 20% recycled fabric content, taken from off-cuts from making ProGARM’s regular range – the first arc flash range in the world to achieve this.

The first to use recycled

content in arc flash PPE

Until now it’s been difficult to use recycled content in life-saving PPE garments because of the need to guarantee protection and understand the origin of any recycled material. Using off-cuts from ProGARM’s own production and putting them back into the production process removes question marks over quality and protection levels of other recycled content which may have suffered degradation to the protection it offers.

Using this unworn fabric enables this range to have some recycled content and the same life-saving protection.

Other sustainable features include:

- Sustainable, carbon neutral packaging, made from a plant-based polymer which is a waste product from the sugar industry

- Manufactured in mainland Europe and transported by sea and land in consolidated loads. No ProGARM product travels more than 1900 miles to reach its UK destination (up to 60% less than other suppliers), with deliveries carefully planned to minimise mileage, reducing the number of deliveries by 10% in 2021/22

All of this supports organisations in minimising their impact, contributing to achieving their sustainability goals.

The sustainable arc flash protective clothing range

Meeting High Standards

Five coveralls, one jacket, and four pairs of trousers in men’s and women’s cuts make up the new range. Available in three colourways – including high-vis yellow, navy blue, and a combination of navy and high-vis yellow – the range has been designed to offer the most popular and useful garments for anyone requiring arc flash protection, while passing all relevant tests and standards.

See an overview of the range below ➡

|

|

|

|

|

| ProGARM CV170F Sustainable Ladies Are Coverall | ProGARM CV170M Sustainable Arc Coverall | ProGARM TR170F Sustainability Ladies Arc Trouser | ProGARM TR170M Sustainable Arc Trouser | ProGARM CV155M Sustainable Linesman Arc Coverall |

|

|

|

|

|

| ProGARM CV100F Sustainable Ladies Coverall | ProGARM CV100M Sustainable Arc Coverall | ProGARM TR120F Sustainable Arc Ladies Trouser | ProGARM TR120M Sustainable Arc Trouser | ProGARM JK128M Sustainable Arc Jacket |

Contact Thorne & Derrick to order

The range is certified for standards covering arc flash (APC1, ELIM 8cal), flame resistance (EN11612, A1 + A2), welding (EN11611), anti-static (EN1149-5), and high visibility. So it not only performs the way other arc flash garments do, but has materially less impact.

The arc flash protection is inherent, meaning it can’t be washed out and helping the workwear provide protection for longer.

ProGARM, renowned for making protective workwear which lasts up to 70% longer than the industry average, is the first company to launch a certified arc flash range containing recycled fabric.

Arc flash sustainability initiatives

The new range comes after ProGARM created the first repair programme for arc flash PPE in 2021, which helps with sustainability by making minor repairs to garment components such as zips and fastenings to extend the life of the clothing.

With arc flash clothing, even a small rip which happens during the rigorous workday of the wearer would mean it no longer offered the life-saving protection needed, and would mean it had to be thrown away. The combination of ProGARM’s focus on durability and the option for small repairs to fastenings means their range can last up to 70% longer than competitor options.

The company has also partnered with a leading textile recycler to offer end-of-life recycling for all its products so they can be recycled, making sure ProGARM products don’t become part of the 350,000 tonnes of textile waste send to landfill in the UK every year.

ProGARM aims to be carbon neutral throughout all its operations and the whole supply chain (scopes 1, 2 and 3) by the end of 2025.

ARC FLASH LEARNING & RESOURCES

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Protection Against Arc Flash, Faults & Electric Shock | 5 Safety Rules

March 24th, 2023Protect employees from electric shock and arc faults

In industries working around high and low voltage electricity, the importance of Electrical PPE and arc flash protection is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike.

It is imperative that the 5 safety rules are complied with to prevent accidents when working on electrical systems. By using insulating tools and equipment, electric arcs are prevented from forming and the working distance is made bigger.

DEHN are committed to the protection of workers and material assets. The energy and the spirit of innovation of more than 1,400 employees are reflected in their developments and innovative products in the field of lightning protection, surge protection and safety equipment.

DEHN protection at a glance:

Effective – The probability of an arc fault occurring is reduced and the PPE protection level increased.

Protective – The employee is further removed from the system, increasing his/her safety during work.

Competent – DEHN offers the right products for complying with the 5 safety rules.

Foresighted – A large range of services ensures that electrical equipment is kept safe permanently.

ARC FLASH Protection | Five safety rules

| 1. Disconnect completely |  |

Operating poles are used for safe hot stick working when switching and insulating live equipment. | ||

| 2. Secure against reconnection | Locking devices secure the work location against re-powering. | |||

| 3. Verify that the installation is dead | Voltage detectors are available for verifying a dead condition on all poles at the work location. | |||

| 4. Earthing and short-circuiting | Earthing and short-circuiting devices for earthing and short-circuiting electrical systems. | |||

| 5. Provide protection against adjacent live parts | Insulating protective shutters for protecting against accidental contact with live parts of an installation. |

reducing Arc Flash risk

The use of tested insulating tools and operating sticks reduces the probability of occurrence of an arc fault and thus also the risk involved. Furthermore, the individual is distanced further away from the system (working distance) due to the lengths of the insulating sticks, meaning the PPE protection level is increased.

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.