Blog

Offshore Substation High Voltage Cable Re-alignment

March 26th, 2021

HV Cable Re-alignment

High Voltage Cable Re-alignment

Offshore Substations

- Special thanks to Geoff Briggs MIET from MGL Cable Services for the kind permission to republish this short case study in Wind Energy Network

When substation high voltage cable routing design and installation specifications do not align, MGL Cable Services bring expertise and professionalism to maintain cable integrity during the re-alignment process.

One of MGL Cable services teams recently stepped up to this challenge by demonstrating those qualities, they successfully delivered a project to re-align previously installed cables on offshore windfarm substations.

Process Preparation

As the cables were required to be removed from the high voltage switchgear this required the removal of the terminations from the switchgear, the terminations were then cleaned and protected from exposure to the harsh offshore elements.

Following the termination protection, the cables protective cable transit blocks and cable cleats were removed, this enabled the team to expertly manoeuvre the cables from the switchgear and safely suspend the cables away from the existing cable containment structure, paying careful attention to keep the cable within the manufacturer bend radius limit and protecting the cable from any sheath damage when manoeuvring to maintain cable integrity.

High Voltage Cable Re-alignment

Once the cable was safely suspended, the cables and containment structure were then modified to re-align the cable routing design and installation specifications.

The process involved manipulating the cable into the realigned cable containment structure whilst maintaining cable integrity and ensuring all terminations aligned with their respective switch gear bushings.

Once the team had effectively accomplished the re-alignment, the terminations were re-greased and re-attached to the switchgear and all fastening torque tightened to required specification. The cables were cleated into final position.

Each cable was the sheath tested to verify the cables integrity had been maintained throughout the process. The team delivered progress reports on a daily basis and sheath testing reports to ensure the client was confident MGL were delivering the high standard and workmanship required to execute the re-alignment process.

Client Feedback

Feedback from client’s representative commented on ‘genuine experts, real professionals and they were impressed with how the team handled the extreme pressures effortlessly. The team earned my highest recommendations.’

ABOUT MGL Cable Services

MGL Cable Services is a cabling focused electrical engineering company based in the North East of England. Part of the MGL Group of Companies, we have the expertise to fulfil the full scope of a large project or deliver a single service as part of a smaller scope within a large project. Our processes and procedures enable us to deliver consistent outcomes and we share our knowledge and lessons learned with clients and delivery partners.

MGL Cable Services work to high quality standards embodied within our SHEQ management systems, endorsing our Zero Harm policy to provide every client with complete peace of mind. We ensure that customer service and satisfaction are our priority and as a service provider, we work closely with the client to ensure the smooth delivery of services and projects, to specification, on time, and on budget.

Specific expertise includes High Voltage Cable Jointing up to 400kV, High Voltage Cable Testing, Fibre Optic Cable Splicing, Fibre Optic Cable Testing, Offshore Termination & Testing, Project Management, Project Support, Technical Documentation Drafting, Client Witnessing, Civil Construction and Plant, High Voltage Cable Fitters and Specialist Engineering Consultancy.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable

LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV Cables 11kV 33kV 66kV | Cable Joints, Terminations & Connections

Transformer Hi-Side PILC Cable Termination Chamber With Stress Cones

March 26th, 2021Image Courtesy of: John McGaughan, Safety Manager/U.G. Cable Systems Operation Specialist-NCCER/FACTE Certified Training Instructor at Barrow Power LLC.

Pictured: Transformer Hi-Side PILC Cable Termination Chamber With Stress Cones

TECO & PILC Cable

“We only replace PILC cable that goes bad. We have about 95% in our Network system downtown. About 75% in our UCD system downtown. And about 60% at our UCD system at TIA our airport. We use P&C transition modules for take offs to our switchgears. The cable box is filled using G&W 219 insulating oil heated to 250 degrees Celsius,” John clarifies.

TECO utilise a mix of traditional PILC cable jointing accessories including varnished cambric tape from Mac Products.

Mac Products: America’s Largest Inventory of HV Cable Splicing Products

Cable Splicing Accessories

- Lead Sleeves

- Varnished Polyester Tapes

- Crepe Paper Tape

- PPC Tape

- Kraft Paper Tape

- Silicone Rubber Tape

- Compression Connectors

- Solder connectors

- Insulating Compounds

- Dielectric Fluid

- Flushing Oil

- Shielding Braid

- Live End Caps

- Cotton Tape

- Cotton Yarn

- Arc and Fireproofing Tape

- Glass Tape

- Solvent Cable Wipes

- Paper Pasters

- Abrasive Cloth

- Bar Solder

- Wire Solder

- Stearine Flux

- Rosin Flux

- Wiping Pads

- Flexible Copper Ground Strap

- Solid Copper Ground Strap

- Splicing Cement

- P & B Paint

- Lead Crotch Pieces

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

0.3 Square Inch PILC STA To 3 Core 300sqmm Wavecon Mains Transitional Straight Cable Joint

March 26th, 2021Image Courtesy of: Daniel Betts (33KV 11KV LV Cable Jointer at Western Power Distribution).

Pictured: 0.3 Square Inch PILC STA To 3 Core 300sqmm Wavecon Mains Transitional Straight Cable Joint

Wavecon Cable

Wavecon cable is the typical replacement for paper/lead cables in the LV distribution network.

Wavecon cable is available as “CNE” and also “SNE” – the construction is (usually) aluminium conductors (three for CNE with a fourth for a neutral in the SNE variant). The outer armouring is a copper tape/copper wire armour, providing either just the earth (SNE) or a combined neutral/earth (CNE).

Jointing Tools

“The cable jointing tools I used to strip down the cable were a depth gauge saw to take the steel tape amours off the imperial paper insulation lead cable. Once the bitumen layers were removed with the gas torch and premane wipes I then used a hammer and insulated hack knife to remove the lead sheath down to the belt papers and the paper cores,” comments Daniel.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cable Jointing – An Art or Science?

March 26th, 2021Both.

Whether lashing in a Straight 6 resin joint to power a domestic shower or jointing 110kV cables to energise Brisbane, the cable jointer must concentrate during all stages of cable stripping, measurement and joint installation.

Make an error with your measure, flirt with failure.

Of course cable failures keep cable jointers busy.

But self-inflicted cable failures caused by bad jointing and the “jointer” will soon be hanging up his crimper.

Quick joke. What’s the difference between a Jointer and a Doctor? A Doctor buries his mistakes – a jointer digs his up! Tumbleweed rolls through Blog.

Cable failures caused by poor jointing are costly.

Reputation damage plus consequential losses incurred by a power cut then multiplied by cost of the supply restoration as a formula is simply incalculable.

However, the ability to understand and apply complex mathematical formulae is a required staple of an EHV jointers skill-set.

Andrew Brezovsky is amongst many other things an EHV jointing legend and social media megastar. I suggest you Connect with Andrew on LinkedIn now – but don’t forget to hit the back button and rejoin us for a lesson in advanced cable jointing.

Cable Jointing Science

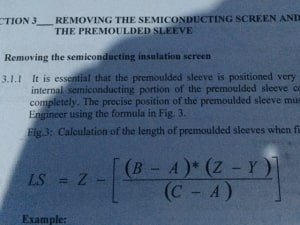

In todays lesson, Andrew considers the importance of the theoretical formula and the practical skill required in calculating and installing premoulded sleeves when jointing 110kV cable.

Removing the semi-conducting screen and installing the premoulded cable joint sleeve is a critical stage of jointing 110kV cables.

“So the calculation of the length of the premoulded sleeves when fitted is relying on the length of the mould, inner bore diameter of the tube, insulation diameter and the inner bore of the mould,” says Andrew.

Therefore, referring to the featured image above the calculation for the length of the premoulded sleeves is as follows:

- LS = length of cable joint mould when landed

- Z = overall length of mould as supplied

- A = inner bore diameter

- C = diameter of PVC tube

- Y = diameter of sleeve on PVC tube

- B = cable insulation diameter

Cable Jointing Art

“Here are a few shots from the mould loading process. The mould is being forced onto that PVC tube with the machine and silicone oil used as cable lubricant. The landing position is calculated individually for every cable joint to the point of a millimetre. You have to be good with your maths as the formula as you now know is complicated,” informs Andrew.

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

3M QS1000 Joint & 3M QTIII Termination – 11kV Triplex Cold Shrink Joints & Terminations

March 26th, 2021Images Courtesy of: Danny Williamson (LV HV Cable Jointer).

Danny is pictured below, jointing and terminating 11kV Triplex cables into medium voltage Schneider Ringmaster RN2c (RMU).

Schneider Ringmaster is a compact highly reliable solution for both indoor and outdoor MV distribution networks up to 13.8kV.

The 11kV joints and terminations were completed using Northern Power Grid (NPG) specification 3M QS1000 and 3M QTIII Cold Shrink kits – terminations include Sicame mechanical shearbolt cable lugs.

Alroc cable strippers are pictured removing the red XLPE cable outer sheath which is the stage before the HV jointer must bend back the copper screen wires and remove the bonded semi-con layer.

Danny is also Pfisterer Connex size 1,2,3 3/S 3XL trained and authorised for live LV cable jointing on GTC networks and we look forward to featuring more examples of his work soon.

➡ Should you wish to feature and showcase your cable jointing skills on our Photoblog simply submit images with accompanying description to [email protected].

Good Housekeeping, Best Cable Jointing

“Some people tend to forget to treat all cables with same respect, whether they’re 11kV or 400kV. Any cable jointing area should be clean, neat and tidy – cable jointing tools handy and kept clean. Cables off the floor, away from dirt, dust etc. Danny Williamson has done that, he even has a tarpaulin over his head, sometimes you can only cook with what you’ve got, he has made an effort which is absolutely commendable,” commends Andrew Brezovszky.

3M QS1000 Cable Joint – 11kV. Cold Shrink tubes parked up the cable in the trench as the jointer uses connector holding tools to steady the mechanical connector as the shear-off bolts are installed. Copper wire screens secured with constant force springs are over-wrapped with 3M tape.

NPG specification Tapetile Cable Tile awaits roll-out to provide effective protection to the underground 11kV power cables.

Jointing Tools. Perfect 11kV cable preparation using appropriate cable jointing tools. Cold Shrinking. The inner spiral from the 3M QTIII cable termination is unwound and the Cold Shrink tube with in-built stress control collapses onto the 11kV cable. Cold shrink jointing technology has virtually replaced heat-shrink material on UK DNO 11kV-33kV networks.

Cold Shrinking. The inner spiral from the 3M QTIII cable termination is unwound and the Cold Shrink tube with in-built stress control collapses onto the 11kV cable. Cold shrink jointing technology has virtually replaced heat-shrink material on UK DNO 11kV-33kV networks.

Connecting the 3M QTIII cable terminations onto the 11kV RMU bushings.

3M QTIII Cold Shrink Terminations Complete – 3M 92EE717 type universal bushing boots insulate the termination and protect against flashover. Copper wire screen entwined, identified with PVC insulation tape and bonded to earth stud. Heat shrink cable glands used to provide mechanical retention to the 11kV cables.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.