Blog

132kV Prysmian Cable Terminations

August 18th, 2020Pictured: 132kV Prysmian Terminations – completed with Chris Barker (EHV Jointer)

Images Courtesy of: David Gorski (EHV Jointer at Wootton and Wootton Ltd)

Thorne & Derrick International are distributors for Prysmian Cable Components which includes their range of Bicon cable joints, cable cleats, cable glands and jointer tooling for LV, MV and HV cables.

Further Reading

- Masterclass: 110kV Cable Preparation & Termination Using Prysmian Outdoor Sealing Ends

- ATEX | Electrical Power, Light & Heat For 132kV Substations & Battery Rooms

- Pirelli Joint | 132kV Oil Filled Cable Joint with Wipe & Chamfer

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Installing 132kV Prysmian Cable Joints Using Prysmian Multi Ram Crimping Tool

August 18th, 2020Pictured : Installing 132kV Prysmian Cable Joints Using Prysmian (Pirelli) Multi Ram Crimping Tool – the EHV cable jointer is shown wrestling with a 132kV XLPE insulated single core 1000sqmm copper cable prior to jointing using Prysmian straight joints.

132kV mechanical shearbolt connectors are currently undergoing type testing which will eventually negate the need for traditional style cable crimping by the jointer.

Thorne & Derrick International, based in the UK, are distributors for Prysmian Cable Components which includes their range of cable joints, cable cleats, cable glands and jointer tooling for LV, MV and HV cables.

Installer : Chris Barker (EHV Cable Jointer).

For almost 100 years Prysmian cables and systems (formally known as Pirelli Cables) have been designing, manufacturing, installing and maintaining High Voltage (HV) and Extra High Voltage Cable (EHV) Systems throughout the world.

Chris Barker is also experienced and certified to carry out the installation of the following HV and EHV cable joints and terminations :

- Pirelli/Prysmian

- Prysmian Click-Fit

- Ericsson

- ABB

- Silec Cable

- Nexans

- Pfisterer/Ixosil

- Raychem

- Tyco TE Connectivity

- LS Cable

- 3M Electrical

Silec 220kV Straight Joints. Installed by Chris Barker (CB Jointing Ltd)

Further Reading

- Masterclass – 132kV ABB Cable Termination

- 3M Cold Shrink HV Joints Splicing 66kV XLPE Cable

- Hivotec Tools For 66kV Cable Jointing, Stripping & Peeling High Voltage Cables

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Brugg Straight Joint 132kV

August 18th, 2020Image Courtesy : Necdi Cetin (Bachelor of Technology Akhisar Endüstri Meslek Lisesi)

Pictured: Brugg 132kV Joint – Saudi Arabia Riyadh Project

Further Reading

- Masterclass – 132kV ABB Cable Termination

- ATEX | Electrical Power, Light & Heat For 132kV Substations & Battery Rooms

- Sanding 132kV High Voltage Brugg Cable Joint

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

33kV Shunt Reactor | A TRV Study for a UK Offshore Windfarm

August 18th, 2020

33kV Shunt Reactor

A TRV Study for a UK Offshore Windfarm

Enspec Power have released a case study of a TRV assessment for a UK Wind Farm.

This assessment was done to ensure the 33kV Circuit Breaker was sufficiently rated for the sites 2.5MVAr shunt reactor.

Enepec Power carried out full modelling of the medium voltage network, site and shunt reactor to investigate the peak TRV and RRRV values and compared these against the breaker ratings.

The full case study can be found via download. The full redacted paper is available on request from Thorne & Derrick.

This report was produced by Enspec Power Ltd – it details a Temporary Recovery Voltage (TRV) study carried out for ABC Wind Farm in order to assess TRV ratings of the shunt reactor circuit breaker.

The following events have been investigated: De-energisations of the shunt reactor, credible single phase-to-ground and three phase-to-ground faults, simulations of the worst case TRV peak and Rate of Rise Recovery Voltage (RRRV) values of the vacuum circuit breaker (VCB), with a comparison of the results with the switching capability of the VCB according to IEC 62271-100, and finally a discussion of the possible solutions in order to reduce the TRV to below VCB ratings.

In conclusion, the investigations found that the TRV values for the de-energisation of the shunt reactor and the fault interruption of a three phase-to-ground and single phase-to ground fault at the reactor terminals were not compliant with the corresponding envelopes described in IEC 62271-100 (T10 / T60).

The probability of a fault between the VCB and shunt reactor terminal is low. Nevertheless, the de-energisation of the shunt reactor would be considered as frequent. Thus, a TRV / Overvoltage suppression / mitigation method should be considered. It is essential not only for the TRV requirement, but also for protecting the reactor against over voltages.

An RC snubber with appropriately sized SAs, or controlled switching with appropriately sized SAs are considered to be the best solutions to suppress the TRV to below the breaker ratings, minimise/eliminate probability of reignition phenomena and reduce the overvoltage stress at the reactor terminals. Note that independent pole operation is required for the solution of controlled switching.

About Enspec Power

Enspec Power help organisations to make money and to save money – professional engineers can do this! They’ve been making businesses more profitable since 1998 when their sibling founders, fed up with the bureaucracy of larger organisations, decided to go it alone and set up Enspec as a friendly, flexible engineering company.

Two decades on, they’re still a friendly bunch and one of the UK’s leading independent specialists in power quality engineering. They really understand electrical power systems and are passionate about what we do and what’s happening in the wider world of technology.

They are progressive members of The Institution of Engineering and Technology (IET) with links to academia – so if they don’t have the immediate answers, chances are they know somebody that does. They offer specialist engineered products and services such as Power System Studies, Power Factor Correction, Harmonic Filters, Reactive Compensation, Point-on-Wave Switching and Site Services. They’re here to help all manner of heavy electricity users such as utilities and renewables, oil and gas, manufacturing and other industries.

Company News

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

How to Protect HV Underground Cables

August 18th, 2020

Republished with the Kind Permission of Sam Soady |

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

How to Protect HV Underground Cables

Underground high voltage cables have been a great innovation to the electrical distribution industry. While they make an installation look more visually pleasing than the overhead conductor systems currently being utilised, they are often exposed to scenarios which are overlooked by electrical designers and engineers.

It is common practice to protect your cables from mechanical damage via installation methods and manufacturing mechanical protection systems, however in some areas, cables have an environmental issue leading to a shortened lifespan and failure. Termites!

Even though electrical cables are not considered food for the termites it is well known they can attack underground cables damaging the integrity of the installation, which eventually leads to failures.

Some areas in Australia have a higher risk of termites such as the northern part of Queensland and the Northern Territory requiring underground cables to have an added protective layer during manufacturing.

Methods for termite protection on underground systems include hard physical barriers such as:

- Rigid HD PVC conduit systems.

- Added layer of plastic Nnlon sheath (must maintain a smooth surface).

- Metal barriers such as brass, copper or steel tapes.

- Chemical infused High Density Polyethylene with Cypermethrin.

While all systems are highly effective at providing termite protection, the most common method utilized for modern installations is option 4 – chemical infused High Density Polyethylene.

This solution provides the most cost-effective choice as additional layers are not required to be added to the normal specification/design of the cable. Some companies however have moved away from this method due to Health and Safety concerns which have arisen from the use of these chemicals.

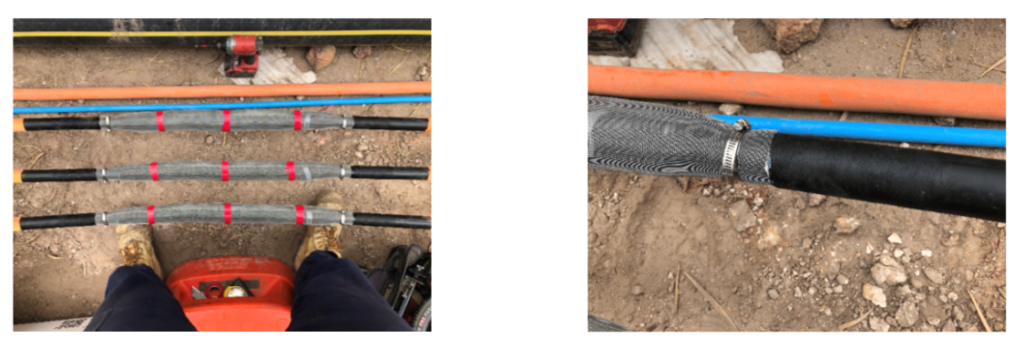

When performing joints/terminations on the cable, it is imperative to continue the termite protection all the way through the cable joint. This is generally achieved using stainless steel mesh being installed as a protective layer over the joined cable (refer image). The use of roll springs or hose clamps ensures termites cannot enter the joint body.

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex