Blog

A Lesson in Transition Jointing Cables by A Competent Jointer

March 20th, 2020

A Lesson in Transition Jointing Cables by A Competent Jointer

HEATSHRINK TRANSITION JOINT 6.35/11(12kV)

Featured Jointer: Stuart Duncan from BELAC

Shrink Polymer Systems heatshrink cable joints and terminations suit all types of standard and non-standard MV-HV Electrical Power Cables (single or multi-core) with or without armour or lead sheaths up to 33/36kV – zero halogen and fire resistant cable joints are also available.

➡ Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Shrink Polymer Systems heat shrink cable joints and terminations.

Below shows the installation of a heatshrink transition joint by Stuart Duncan from Belac.

Stuart Duncan at Belac commented, “The cable joints were spot on. Quite enjoyed doing them to be honest. It’s a bit different from the normal so it was a nice change from the usual cold shrink. Jointing instructions were clear and well laid out. Some cable joint kits can get a bit confusing and with irrelevant info in them. I did notice that each separate component was clearly labelled with a name matching the instruction which was a nice touch and helped a lot in the trench. Some kits we use have just numbers and some kits are not labelled at all. Everything fitted well and I was happy with the way everything went together. Good joints, would definitely use them again.”

Picture 1: Stress relief mastic tape had been applied on the step down from lead to paper insulation to eliminate the air void and went on to fit the clear oil barrier sleeve (PILC side).

Picture 2: The semi conductive sleeve and stress control tube have been shrunk into place (PILC side) using a jointer gas torch kit.

Picture 3: Semi-conductive screen has been treated on the XLPE side as well as the application of the yellow stress relief mastic to assist with removing any potentially harmful amounts of electrical stresses. The cable MUST be thoroughly cleaned using a solvent, prior to applying the yellow stress relief mastic. Stress relief mastic should be applied under tension, to ensure void free application.

Picture 4: Connector is in place. Important to note that the connector insulation tubes and outer heatshrink sleeve have been parked down the core before connecting the two conductors together.

Picture 5: Stress relief mastic tape had been applied over the connector and onto the insulation at both sides to eliminate any air voids in the medium voltage cable joint.

Picture 6: CWS and earth braids connecting from the lead are joined. Copper mesh is then wrapped for the length of the cable joint.

Picture 7: Outer adhesive heat shrink sleeves are positioned and fitted to provide moisture and mechanical protection to the 11kV joint.

Thorne & Derrick

Specialist Electrical Distributor

Established since 1985, Thorne & Derrick International based in the UK distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Access Chambers, Cable Cleats, Duct Seals, Cable Transits, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

Distributors for : 3M, Pfisterer CONNEX, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Cembre, Prysmian, Ellis Patents, ABB & Furse.

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

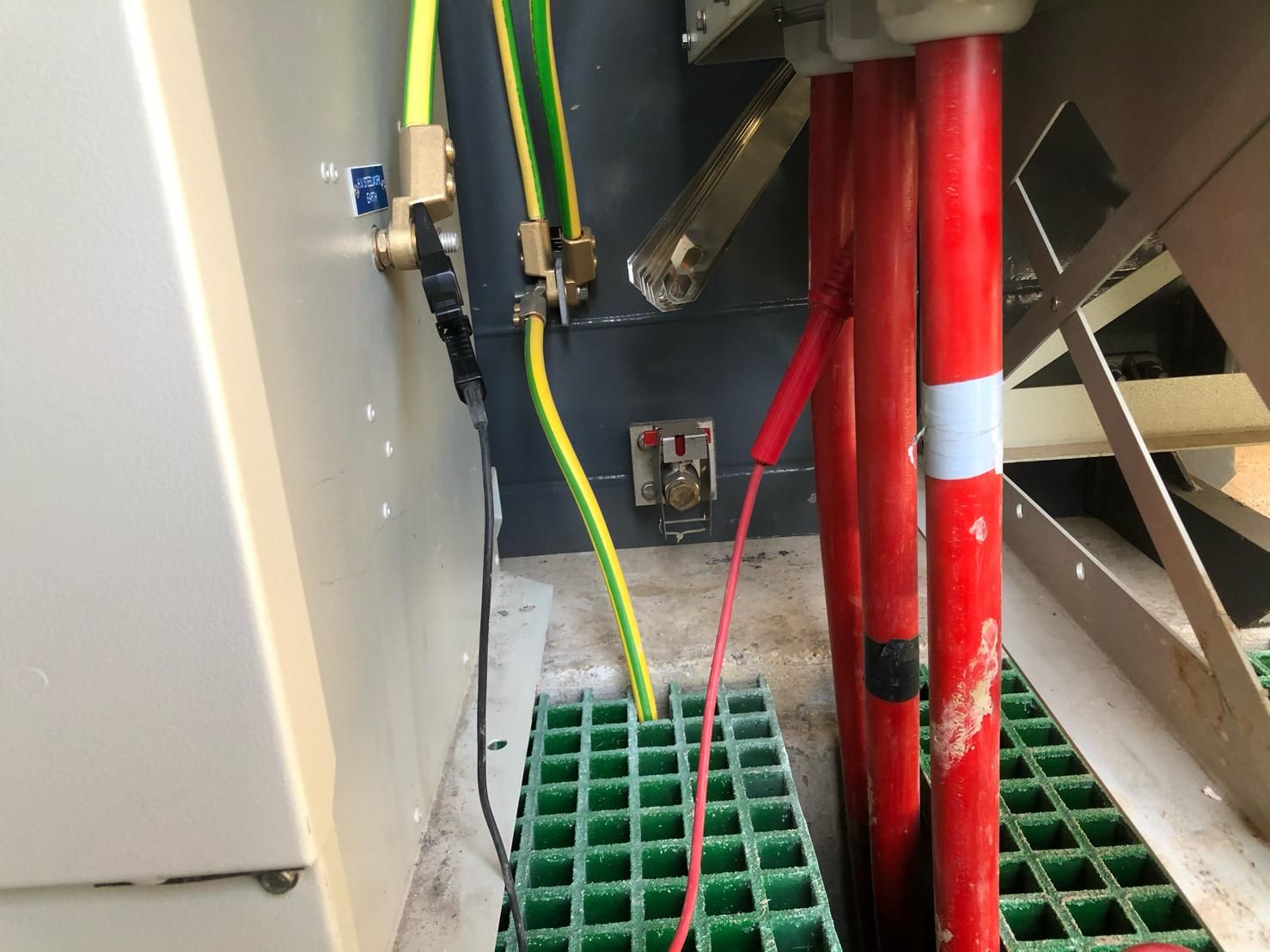

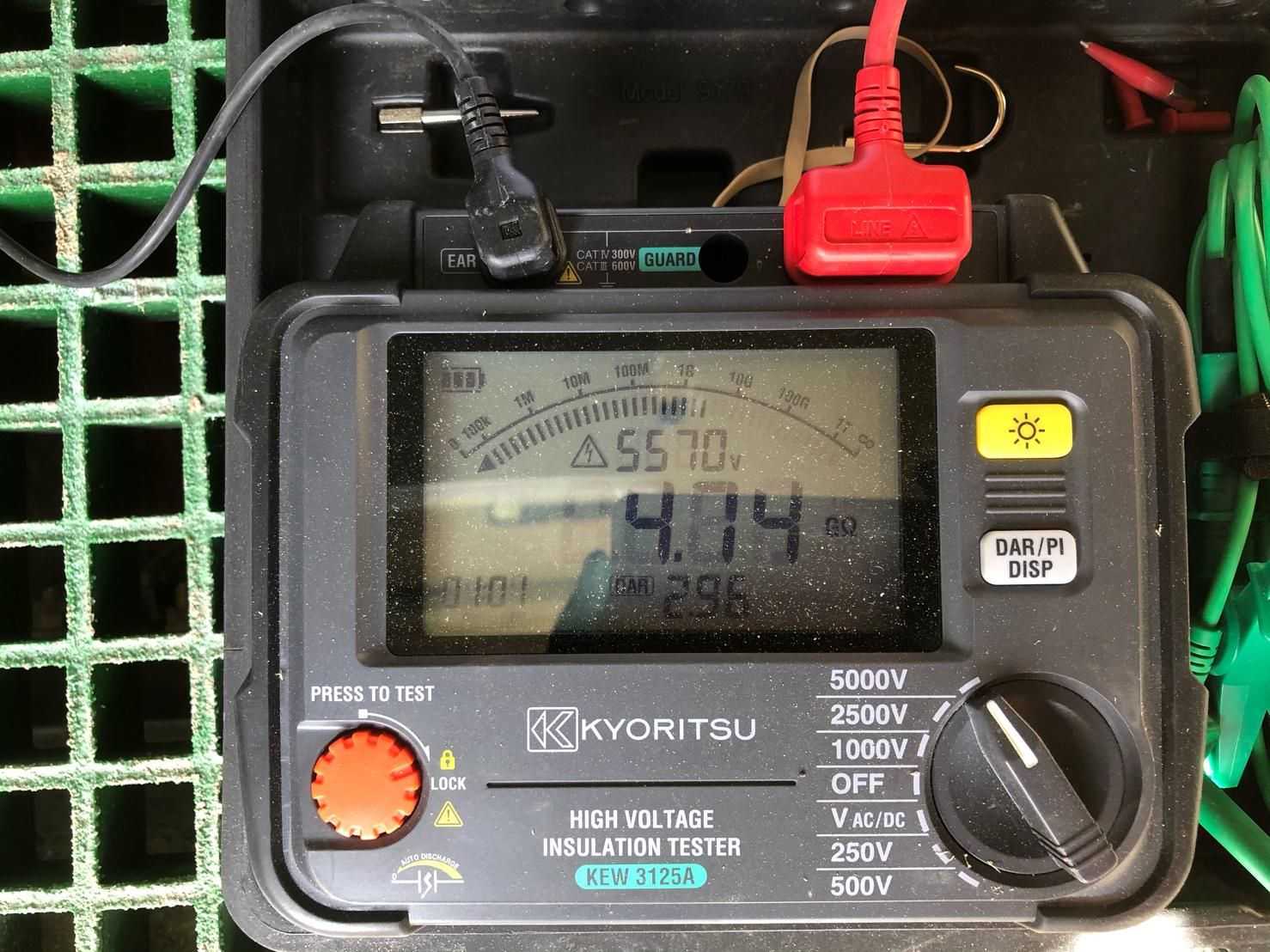

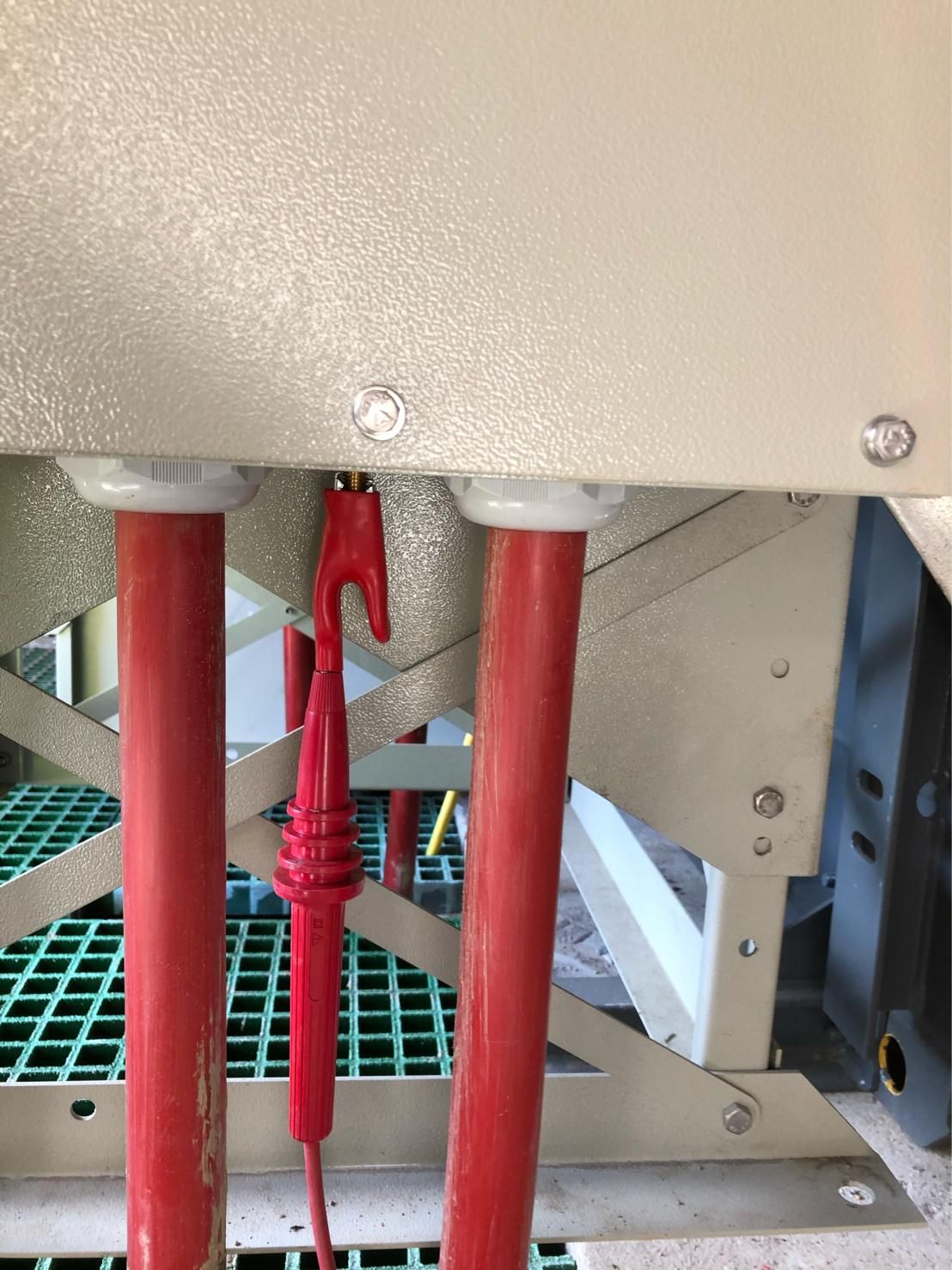

Sheath Testing 11kV Cables Prior to Substation Connection

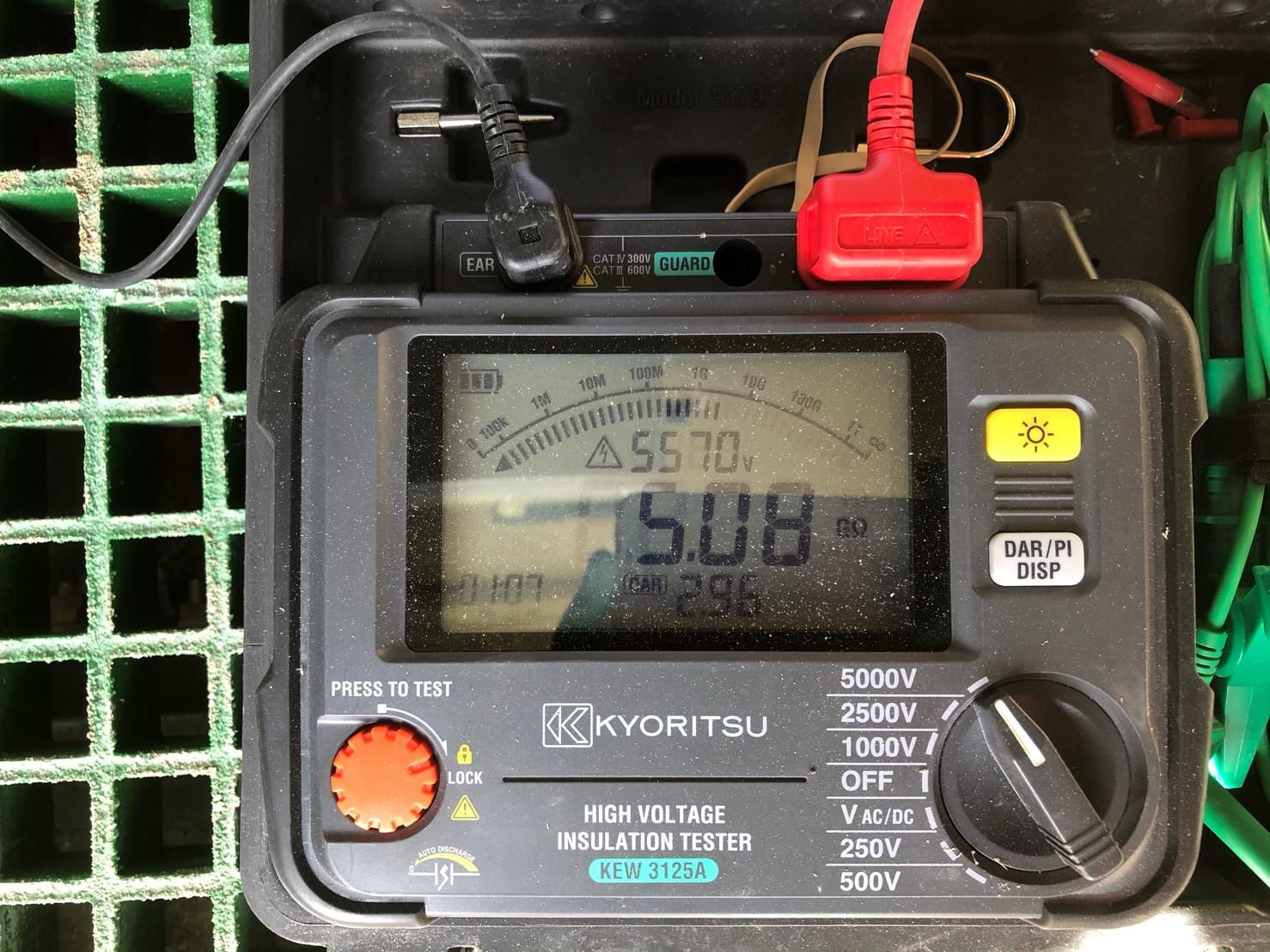

March 19th, 2020Pictured: Sheath Testing 11kV Cables Prior to Substation Connection

Images Courtesy of: Andy Dresser GCGI IEng MIET – Director at ASD Power Services Ltd

11kV Cable Sheath Testing

With the weather nice and dry outside ASD Power Services were out doing some cable sheath testing for a customer.

A pre-connection witness test for a new 11kV substation connection. All went nice and smooth with a good test on each cable run. Another satisfied customer.

asd power services ltd

ASD Power Services Ltd, established July 2016, are based in Newbury, Berkshire and offer the following services:

- (SAP) Senior Authorised Person (11KV)

- Auditing of Electrical Distribution Networks both LV and HV

- Maintenance inspections on electrical installations, including none intrusive IR Inspections

Director Andy Dresser is a Senior Authorised Person (SAP) and has over 25 years of experience in the Electricity Distribution business including network design, project management, auditing, people management, operational engineering, network construction, control engineering and procedure development.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Silver Fox Cable Labels – Salt Mist Spray Testing For Offshore & Marine Cable Labelling

March 16th, 2020 Silver Fox, a leading UK manufacturer of cable labelling solutions, has reported positive results from the most recent tests carried out on its labels – for salt mist spray.

Silver Fox, a leading UK manufacturer of cable labelling solutions, has reported positive results from the most recent tests carried out on its labels – for salt mist spray.

T&D supply the complete range of Silver Fox Cable Labels – this includes thermal and laser cable labels.

According to the resulting certificate, which relates to the complete range of coloured cable labels produced by Silver Fox: ‘Environmental Test Service (ETS) performed visual inspections of the cable labels by comparing them with control samples provided by Silver Fox Ltd.

None of the cable labels had been affected visually in any way and were perfectly legible at the end of the test.’

The tests – carried out by the UKAS-certified ETS, of Woodley in Berkshire – conformed to the Lloyds Register Type Approval Test Specification No1, July 2013, Section 16, generally known as IEC600068-2-52 Test Kb Salt Mist (Cyclic).

It involved replicating a marine environment and subjecting Silver Fox labels to four cycles of a two hour exposure to salt mist, followed by subjecting the labels to a temperature of 35 degrees Celsius and between 90 per cent and 95 per cent humidity for seven days.

“Silver Fox labels are routinely used in the Energy, Power, Rail and Data & Telecoms industries worldwide,” said Nick Michaelson, CEO of Silver Fox, which regularly tests its labels at MoD, UKAS-certified and independent recognised test laboratories in compliance with a number of different MIL and other standards.

“These labels are used in demanding conditions – where they can experience both high and low temperatures and, sometimes, are exposed to dangerous gases and other hazards.

So, it’s important that the labels are tested thoroughly to ensure that they’ll perform well under ‘real world’ conditions – and, indeed, out-perform their rivals.”

In all tests carried out on its labels, Silver Fox tests the finished, printed label – and not just the material on which it is printed.

“These tests are expensive but, at Silver Fox, the commitment to offer the very best materials and back these up by independent tests is relentless,” said Nick Michaelson. “It’s part of our on-going resolve to do all we can to enable and empower our customers to turn time into profit.

“Over the past 30 years, Silver Fox has been at the forefront of the development of innovative durable and time-saving labelling solutions. This is driven by a passion for excellence and a determination to be the best in our field.

“Today, our solutions more than hold their own against products from some of the largest companies in our business – and we’re still improving our solutions,” he added.

“Our goals are to design, develop and supply complete labelling solutions including software, hardware and label material ensuring a highly time saving and durable solution for all our customers.”

- Further reading

The Case For Low Smoke Zero Halogen Cable Labels & Public Safety

Offshore Cable Labelling Solutions From Silver Fox (IMO Approved)

How to Label Cables Safely In Zone 1 & Zone 2 Hazardous Areas

Offshore Cable Labelling Solutions From Silver Fox (IMO Approved)

March 16th, 2020Fox-Flo LS0H Tie-on Cable Labels

Offshore Cable Labelling Solutions

The offshore industry operates under extreme conditions, therefore cables and cable accessories must demonstrate advanced technical specification performance. Endurance and reliability cannot be compromised. Under-specified or sub-standard electrical equipment and cable accessories can pose serious threat to the safety of people and plant.

Silver Fox “Fox-Flo” Tie-On cable labels are tested to International Maritime Organisation (IMO) standards for labelling power, control, instrumentation and signal cables for use in the offshore oil and gas, shipbuilding and marine industries. The tests include the ISO 5659-2, Part 2 “Smoke & Toxicity” test and the IMO Fire Test Procedure Code Part 5 Appendix 1 : “Fire test procedures for surface flammability of bulkhead, ceiling, deck finish materials and primary deck coverings”.

Other cable labelling applications include : communication, LAN, bus, CCTV camera, coaxial cables.

Silver Fox “Fox-Flo” cable labels demonstrate the highest levels of performance – Low Smoke Zero Halogen Cable Labels

- Low Smoke emission in the event of a fire to enable personnel to escape and evacuate safely

- Low Toxicity in the event of a fire to ensure personnel are not overcome during their escape or evacuation

- Zero Halogen eliminates halogen acid (flourine, chlorine, bromine, iodine) gas emissions which can destroy sensitive electronic equipment

Halogen Gas Effects On Electronic Equipment

Acidic smoke and gas emissions inflict corrosion damage to all types of substrates – the heat generated by fire opens the substrate pores and drives soot particles deeply into outer layers of the substrates of electrical equipment or cables.

Soot when combined with water or high humidity conditions exponentially increases the acidic strength and exacerbates aggressive damage to equipment. Smoke damage to electronic equipment can be significantly more extensive than the actual fire.

The Aftermath

Electronic, electrical and cabling equipment can occasionally be repaired for re-use. Electrical gear, power distribution and generation equipment should only be serviced by properly trained electrical engineers using correct tools, testing and recertification methods for working with OEM consent and approvals prior to being put back into use or re-commissioning.

Flame Test : Low Smoke & Fume v Low Smoke Zero Halogen. There Is A Difference.

LSF cable emits black smoke containing toxic and corrosive gases which pose choking dangers to personnel and catastrophic damage to sensitive electronic equipment in fire situations.

Toxic smoke generated by combustion would cause serious disruption and safety risks where poisonous gas accumulates in poorly ventilated areas.

YouTube Video Playlist : Silver Fox Cable Labels – Watch, Listen & Learn

Silver Fox “Fox-Flo” Cable Labels Are Low Smoke, Zero Halogen.

Silver Fox “Fox-Flo” cable labels are ideal for low smoke, zero halogen and flame retardant cable labelling – Silver Fox can also provide high specification cable labelling solutions to suit a complete range of marine, offshore oil and gas power, control and instrumentation cables for use on oil platforms and floating oil production units (FPSO) including BS, NEK, UL, IEEE, UKOOA and IEC specification. Visit www.oilvoice.com

Silver Fox Tie-on Cable Labels are ideal for larger cables and cable bundles and for use with nylon or stainless steel cable ties.

Silver Fox “Fox-Flo” Tie-on cable labels are low-smoke, zero-halogen and UV-stable. Produced using the highest quality materials offering long-term endurance and reliability of zero halogen cable labels.

The Silver Fox “Fox-Flo” labels are both strong and flexible and can be attached using either nylon or stainless steel cable ties. Print quickly and easily using the Silver Fox Plug’N’Play thermal printer and Silver Fox Labacus Innovator Advanced or Professional labelling software.

Silver Fox Cable Labels

T&D are distributors for Silver Fox the market leading manufacturer of Cable Labels and Marking Systems – fast and efficient identification of cables, wires, optical fibres, panels, valves and equipment in safe and hazardous areas.

Silver Fox cable labels comprise Laser, Tie-On and Thermal Heat Shrink solutions for utilities, telecoms, power, construction, rail, mining, subsea, offshore, oil, gas and petrochemical industries.

Silver Fox cable labels are manufactured for long-term performance, endurance and reliability Turning Time Into Profit. 60 Labels in 15 Seconds.

YouTube Video : North Sea Oil & Gas Installations are subjected to extreme electrical and mechanical conditions. Silver Fox Cable Labels are designed, manufactured and tested to highest level of material performance and technical specification. Specify & Buy Silver Fox Labels for offshore cable label projects.

Further Reading:

Silver Fox Labacus Innovator Software Update

The Most Efficient & Simplest Cable Labelling System In the World

Nexans Euromold | Where the Difference is Material

March 16th, 2020-

Uploaded by Chris Dodds - Sales & Marketing Manager with Thorne & Derrick International

EPDM

No Time for Downtime | Resilient & Reliable MV CONNECTORS

Grids are under increasing electrical stress today as our planets insatiable hunger for power goes unabated.

The energy transition to a net-zero carbon economy pressures our electricity networks to carry increasing demands, therefore superior materials technology and product performance is essential to the prevention of premature cable system failure.

The need to electrify power from renewable energy harnessed from the Sun and the wind, the hyper-scale drive to datacentre digitisation and the EV boom means cable systems must provide both resilience and reliability – to Electrify the Future both cables and cable accessories must be robust, safe and provide longevity of service.

Cable accessories should not be weak links in the network.

Screened separable connectors manufactured by Nexans Euromold have been designed for at least 40 years of field service when installed correctly and functioning in normal environmental conditions. For 50+ years Euromold has been formulating and moulding rubber compounds – their Connector products manufactured using EPDM rubber are trusted by utilities and asset managers globally.

EUROMOLD is approved and used by medium voltage OEM’s including ABB, Siemens, Schneider, Lucy Electric and Toshiba.

EPDM Connectors demonstrate the highest quality electrical insulation, superior tracking resistance and a proven field performance with an unrivalled service life cycle expectation.

The difference is material. That material difference is EPDM. Trust Euromold.

Customer Service

Thorne & Derrick, the UK Distributor for Nexans, can support the technical specification of Medium Voltage Cable Accessories to ensure that correct and compliant products are used to connect cable to electrical equipment with Interface A to F bushings up to 72kV.

EPDM Benefits

Ozone & Corona Resistance

The outstanding resistance to corona is due to the ability of the EPDM rubber to withstand ozone and other chemical compounds formed by discharges and its resistance to heat.

Chemical Resistance

Products made from EPDM rubber resist attacks made by many acids, alkalis, detergents, phosphates, esters, ketones, alcohols and glycols. They give particularly outstanding service in the presence of hot water and high pressure steam.

Resistance To The Environment

EPDM rubber has properties comparable with the best speciality elastomers in resistance to weather. Accelerated life and salt spray tests suggest excellent properties which have been field proven by 50+ years experience in widely varied applications across the world.

Resistance To Water

Water has little effect on the properties of EPDM hydrocarbon rubber. Even long immersion in hot water results in minimal loss of tensile strength. Tests also show a very low degree of water absorption. By design, Euromold connectors are protecting live elements of the connection against ingress of dust and water. The protection class per IEC 60529 is IP67.

Resistance To Mechanical Abuse

EPDM rubber has good resistance to compression, cutting, impact, tearing and abrasion over a wide temperature range.

eUROMOLD

- Fully screened, touchproof and safe MV cable connections

- Fully watertight, fully submersible connectors

- Compatible with equipment bushing interfaces A-F

- Designed to terminate MV cables up to 72kV

- ATEX Certification options for potentially explosive atmospheres

- Smart Technology options with integral voltage sensor

EUROMOLD with optional Smart Sensor Technology which integrates voltage measurement and Partial Discharge monitoring and detection functionalities in transformers and switchgear up to 33kV.

More | Facilitating Sensor Installation In MV Power Networks By Nexans

💡 72.5kV | Nexans Euromold | New Catalogue Download

Nexans Power Cable Accessories

Main UK Stockist & Distributor

Thorne & Derrick distribute the most extensive range of Medium Voltage Cable Joints, Terminations & Connectors – EPDM, heat shrink and cold applied Slip-on cable accessories enable the jointing, terminating and connection of cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity up to 72kV.