Blog

66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

December 8th, 2022

Power Cable Accessories

Nexans Power Accessories is the leading European innovator and manufacturer of Low, Medium & High Voltage Cable Accessories as well as connection technology for energy transmission and distribution networks, including both onshore and offshore renewable projects. The Nexans range of Medium Voltage Power Cable Accessories ranged is stocked and supplied in the UK by Thorne & Derrick, contact us for commercial quotations, specification support, product training or to discuss your requirements.

The standard product range of GPH® compression or mechanical connectors and cable lugs is developed and produced as well as customised solutions.

Nexans also manufactures ready-to-install pre-assembled cable lengths and factory tested cable bridges for industrial applications.

Power Cable Accessories for High Voltage Power & IAC Cables 66kV 72.5kV

Catalogue Contents | ↓ Catalogue Download ↓

Nexans

With the brand name EUROMOLD® Nexans Power Accessories is a European market leader for medium voltage cable accessories. T&D offer the entire portfolio of separable connectors for Interfaces A to F in proven EPDM technology with at least 3mm conductive jacket. In this scope, longtime know-how and technological advance was successfully transferred into high voltage applications.

Nexans provide a complete range of cold-shrinkable and slip-on accessories, e.g. pre-moulded terminations and joints for cables and epoxy bushings for transformers and switchgears, up to 170kV.

An extensive range of additional equipment and a variety of dedicated installation training and jointer tooling make Nexans a strong partner in the transmission and distribution of energy.

|

R909TB/G – EUROMOLD® Tee connector

Interface F Separable tee shape connector designed to connect designed to connect polymeric insulated cable to equipment (transformers, switchgears, ……). Also connects cable to cable when using the appropriate mating parts. -Thick conductive EPDM jacket The R909TB/G separable tee connector is type tested acc. to IEC 60840 |

| AFN72 – EUROMOLD® Slip-on Termination For indoor and outdoor use up to 72.5kV U (Um) 60-69 (72.5) kVDry type, non size sensitive terminations for use indoors, outdoors and exposed to prolonged sunshine and other weather conditions.To connect polymeric insulated cable to equipment and for the outdoor terminating onto overhead lines or bus bars-Its compact and modular design supports the suitability for different pollution levels-All termination housings are tested for AC withstand and partial discharge prior to leaving the factory The AFN72 slip-on termination is type tested acc. to IEC 60840, and meets the requirements of IEC/TS 60815-3; SPS class d and e. According to IEC 60112: CTI>600 |

|

|

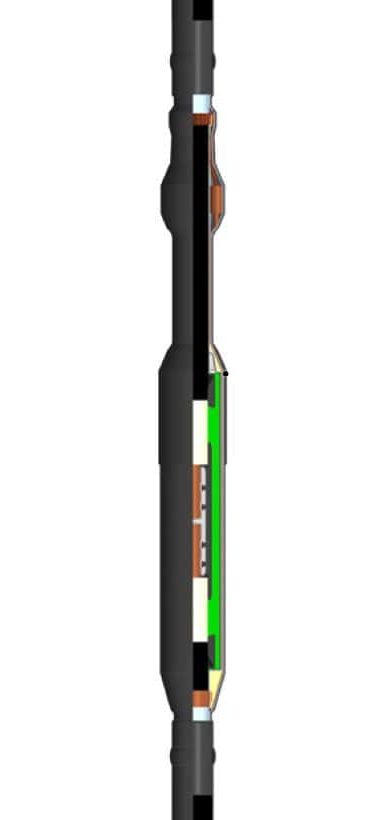

72MSJ Single Core Straight Joint

Slip-on technology up to 72.5kV Non size sensitive slip-on single core straight joint made of silicone, optimised for mechanical connectors. For jointing coper wire screened polymeric cable to be laid in air or directly buried. The product is fully screened and fully submersible. -All joint bodies are tested for AC withstand and partial discharge prior to leaving the factory The slip-on single core straight joint 72MSJ is type tested acc. to IEC 60840. |

Euromold

R909TB/G – EUROMOLD® Tee connector, Interface F

R909PB/G – EUROMOLD® Coupling connector

900SA-CD – EUROMOLD® Surge arrester, Interface F

R900BE/G – EUROMOLD® Bushing extender, Interface F

R900DR-B/G – EUROMOLD® Dead-end receptacle, Interface F

900GP-SBT – EUROMOLD® Grounding plug, Interface F

Possible arrangements Interface F

R900AR-8 / R900AR-12 – EUROMOLD® Equipment bushing, Interface F

Fixings for equipment bushings

AFN72 – EUROMOLD® Slip-on termination for indoor and outdoor use

AFNS72 – EUROMOLD® Slip-on termination with support

FEV72.5 – Outdoor termination with composite insulator

ESC – EUROMOLD® Premoulded EPDM stress cone

Ready to install, pre-assembled cables

72MSJ – Slip-on single core straight joint

72MSJ-x-SB – Sectionalizing slip-on single core straight joint for cross-bonding application

LHV1 – Multitool for cable preparation and installation

➡ See Also | Heat Shrink MONO Terminations MV HV | Heat Shrink JTS Joints MV HV

DOWNLOAD | Distributed in the UK by Thorne & Derrick International

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

See how T&D support, supply and service the Renewable Energy industry.

Stockists & Suppliers | UK & International Projects

Next Generation Data Centres Need Medium Voltage UPSs & Fuel Cells

December 8th, 2022

Data Centres

Medium Voltage UPSs & Fuel Cells

Original Article By Danel Turk, ABB Global Data Centre Segment Leader

As data centres grow larger, a move from LV to MV is a natural step. Medium voltage (MV) uninterruptible power supply (UPS) and fuel cell technologies have the potential to protect the availability of and provide power to the grid, while saving energy and carbon emissions.

Why are data centre operators embracing green trends?

Increased environmental legislation, coupled with record-high energy prices, puts European operators under pressure. With energy experiencing a supply crisis at a time of high demand, energy-intensive businesses like data centres are eager to take more control over their energy usage. This will help them meet new legislation, maintain power continuity, and earn income from energy markets.

New UPS and fuel cell technologies can provide both power continuity and power to the grid. The technologies also allow the data centre to integrate renewable energy and even generate income by participating in demand and frequency response schemes. Using low-carbon technologies also help to build your reputation as a sustainable business.

Why is the medium-voltage level beneficial for a UPS system?

Data centre UPS systems traditionally operate alongside servers and HVAC equipment at the low-voltage level. However, data centre facilities are becoming larger and demanding more power to gain economies of scale. As power requirements increase, moving to medium voltage is a natural step for UPS systems.

Aside from offering the two primary benefits of increased reliability and reduced costs, medium-voltage systems provide other benefits too.

Operating at 24kV, medium-voltage equipment is significantly more robust than comparable low-voltage systems. A data centre would also require fewer units to meet its power needs. As individual modules, these units are easier to install, operate, and maintain than multiple low-voltage systems spread around the facility. This reduces downtime because more equipment automatically means more risks.

Since the MV UPS operates at a medium-voltage level at the grid connection point, it’s flexible enough to support any data centre loads.

Medium Voltage MV Data Centres

Thorne & Derrick Stockists for Medium Voltage Cable Accessories | Joints | Terminations | Connectors | Tools

MV Approach

The medium-voltage approach also has energy efficiency advantages as it runs lower currents, reducing electrical losses. The latest systems boast efficiency of up to 98 percent because of power conversion equipment that supports power quality continuously without requiring batteries. Evaluated against a rotary UPS, the higher medium voltage efficiency can save up to 4.2 GWh. This saving equates to 1,245 tonnes of CO2 emissions over a 15-year life for a large site.

Added benefits are achievable by using a scalable and modular MV UPS.

For instance, operators can deploy up to ten ABB HiPerGuard units of 2,250 kVA in parallel to handle 22.5 MVA power. In an N+1 configuration, it’s possible to take one system offline while leaving the others in service for ease of maintenance.

Since the MV UPS operates at a medium-voltage level at the grid connection point, it’s flexible enough to support any data centre loads. This flexibility ensures power continuity for servers to remain stable throughout the center by overcoming short outages and power quality concerns.

In contrast, low-voltage UPS capacity can potentially become stranded when power can’t be reassigned elsewhere. This may require additional capital outlay to ensure full coverage of backup power.

Furthermore, operating at the MV level saves on additional capex, as the UPS units can be installed in an electrical room or substation rather than occupying high-value server room space. Such a location makes it ideal for feeding power back into the grid if necessary.

How can fuel cells play a role?

Many of the largest data centre providers actively pursue strategies to reduce or eliminate reliance on diesel generators. For example, Microsoft has committed to ending diesel use by the end of 2030 and is already trialling fuel cells as an alternative.

In 2020, Google announced a commitment to use large batteries instead of diesel gensets at a new site in Belgium. The appeal of fuel cells lies in their potential to provide local backup power and even inject power into the grid during peak demand periods. Fuel cell technology combines materials and chemical science with automation, and protection and control systems, therefore its application requires specialist knowledge from each field.

Importance of Fuel Cells

Fuel cells can be integrated into power systems, for instance deploying 200kW installations to power electric vehicle charging stations where grid power is unavailable. Furthermore, fuel cells provide emergency backup in microgrids and power for telecoms sites at other remote locations.

As a component of microgrids, fuel cells can be combined with other technologies to meet any off-grid or prosumer need

However, for data centres, further investigation needs to take place at the multi-megawatt level. This requires sophisticated development and testing of the interfaces between fuel cells, energy storage systems, electrical switchgear, and control infrastructure. We need an integrated approach to data centre requirements.

As a component of microgrids, fuel cells can be combined with other technologies to meet any off-grid or prosumer need. The latest offerings are available as modular 1 and 3 MW solutions, which are fast to deliver and deploy.

Fuel Cell Station

How can operators use backup capacity to generate income?

Operators with robust infrastructure can earn additional income and offset their costs by selling their excess power back to the grid during peak demand. This can take place through demand response schemes or using a battery energy storage system to support the integration of renewables like wind and solar.

At the end of the day, the data centres own power needs must remain the top priority. Therefore, operators can use MV UPS systems and fuel cells to support their own servers and HVAC systems in the first instance. Only when these needs have been met can spare capacity be used for grid support.

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, substation battery rooms and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

Introducing the new HoldIt Hand Safety Tool for Push-Pull Working

December 7th, 2022

Hand Finger Injury Prevention

Thorne & Derrick | UK Partners & Stockists for the Push-Pull Tool range manufactured by Hand Safety Tool Company

| The Hand Safety Tool Company is pleased to announce the launch of an upgraded version of the HoldIt Hand Safety Tool. |

Hand & Finger Injury Prevention

HoldIt Tools

The Hand Safety Tool Company have made significant design changes to the original HoldIt Tool based upon feedback from the field and end-users – the key difference is that the new version utilizes a cam buckle trigger to tighten the loop around an object, versus twisting the end handle.

NEW Innovation | HOLDIT Tool by Hand Safety Tool Co | Distributed by Thorne & Derrick

HOLDIT Tool Improvements

|

Introducing the new HoldIt Hand Safety Tool

| Hand Safety Tool Part Number | Tube Length | Loop Range | Tool Weight | Part Dimensions |

| HOLDIT12 | 12″ | 0.75″-4.00″ | 1.4 lbs | 19″ X 4″ X 4″ |

| HOLDIT24 | 24″ | 0.75″-6.00″ | 1.8 lbs | 31″ X 4″ X 4″ |

| HOLDIT36 | 36″ | 0.75″-6.00″ | 2.2 lbs | 43″ X 4″ X 4″ |

Push Pull Tools

The range of Push Pull Tools manufactured by the Hand Safety Tool Company and distributed by Thorne & Derrick provide significant Health & Safety Improvements around site where “pushing and pulling” operations such as handling deliveries or loading/unloading in yards is commonplace. This download produced by the UK HSE enables the Risk Assessment according to Load Weight, Operation Frequency, Push/Pull Distances and other impacting factors – the range of tools to keep hands off loads, enable “hands-free” lifting, mitigate risk of load handing and prevent hand or finger injury are available in the UK from Thorne & Derrick.

The ShoveIt Hand Safety Tool is manufactured by Hand Safety Tools and stocked and distributed by Thorne & Derrick.

ShoveIt tools are designed to help users avoid hand injuries while working with suspended loads or manoeuvring objects. The tool ensures correct ergonomic body positioning for safe handling out of the line of fire, while enabling users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

Thorne & Derrick distribute a range of Safety Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Over a quarter of a million people suffer serious hand injuries each year. The Hand Safety Tool Company works hard to help to reverse that trend by creating No Touch Hand Safety Tools that keep hands off and away from potential injury areas. The range of Safety Products are the result of numerous conversations and in-field encounters over the last decade with key Health & Safety Officers and “boots-on-the-ground personnel” to ensure each tool produced does the most important job of all – helps every user to keep their hands.

Hand Safety Tools for Prevention of Pinch-Point Injury During Push – Pull Working

December 6th, 2022uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick International

ShoveIt® Tools

Prevention of Pinch-Point Injury

The ShoveIt® no touch hand safety tool manufactured by the Hand Safety Tool Company helps avoid hand injuries while working with suspended loads or manoeuvring objects, maintaining proper body positioning for safe handling out of the line of fire.

The Push Pull Tool allows users to guide loads, move and position pipes and tubulars, as well as grab slings and taglines without physically placing hands on the item.

The SnareIt™ no touch hand safety tool eliminates finger and hand exposure to the danger zone while safely manoeuvring pipe or other like cylindrical-shaped equipment. The hand tool makes it easy to quickly tighten or loosen the cable around the item to be maneuvered, mitigating risk by minimizing exposure to potential hazards.

The HookIt Tool acts as an extension of the worker’s body to move, push or reposition the item keeping hands and fingers out of the danger zone, avoiding crush and pinch points while at the same time sustaining control of the object being positioned.

While initially designed specifically for lifting grating, the HookIt can be used for a multitude of jobs including, as an extension to move, push or reposition items and equipment, as a rigid tagline to grab wire cables or slings and when used with the Magna-Grab magnetic tagline, closing engine cowling doors, retrieving product out of box making machines, or even for manoeuvring suspended equipment like valves as well as other items with flange holes or openings.

The GrabIt™ hand safety tool helps enable hands-off operations by firmly closing around a pipe or other like object, ensuring a solid grasp when working with suspended tubulars. The Quick Tool Holder enables easy storage of and access to Hand Safety Tool Company tools.

Safe-T-Stik is the ultimate hands-off magnetic load control and positioning safety tool for moving road plate, trench plate, poles, pipe, I-beams, shipping containers, valves, fittings and any other heavy steel objects or large parts being lifted or hoisted into or out of position. The Magna-Grab is a multi- purpose, hands-off magnetic tool. It can serve as a portable magnetic tag line and tether anchor point or may be used as a long-reach, magnetic-retrieval tool.

Thorne & Derrick’s mission is to provide tangible solutions to reduce the impact of potential hand and finger injuries in all industries where hazardous conditions exist. We truly envision a world where hand injuries are no longer the number one recordable incident.

Push Pull Tools

Prevention of Pinch-Point Injury

The range of Push Pull Tools manufactured by the Hand Safety Tool Company and distributed by Thorne & Derrick provide significant Health & Safety Improvements around site where “pushing and pulling” operations such as handling deliveries or loading/unloading in yards is commonplace. This download produced by the UK HSE enables the Risk Assessment according to Load Weight, Operation Frequency, Push/Pull Distances and other impacting factors – the range of tools to keep hands off loads, enable “hands-free” lifting, mitigate risk of load handing and prevent hand or finger injury are available in the UK from Thorne & Derrick.

The ShoveIt Hand Safety Tool is manufactured by Hand Safety Tools and stocked and distributed by Thorne & Derrick.

ShoveIt tools are designed to help users avoid hand injuries while working with suspended loads or manoeuvring objects. The tool ensures correct ergonomic body positioning for safe handling out of the line of fire, while enabling users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

Thorne & Derrick distribute a range of Safety Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Over a quarter of a million people suffer serious hand injuries each year. The Hand Safety Tool Company works hard to help to reverse that trend by creating No Touch Hand Safety Tools that keep hands off and away from potential injury areas. The range of Safety Products are the result of numerous conversations and in-field encounters over the last decade with key Health & Safety Officers and “boots-on-the-ground personnel” to ensure each tool produced does the most important job of all – helps every user to keep their hands.

Manual Handling Push & Pull Tool Developed By The HSE

December 6th, 2022The HSE has developed a new tool to assist organisations in reducing risks from manual handling pushing and pulling activities.

The guidance, entitled ‘Risk assessment of pushing and pulling’ (RAPP) provides a simple method for evaluating the levels of risk associated to your activities. By following the guidance, you will be able to identify your high-risk activities and check the effectiveness of your control measures.

The tool covers two distinct types of operation:

- Moving a load which is mounted on wheels

- Moving loads without wheels which involves dragging/sliding, rolling, or churning (for example, manoeuvring a tilted barrel)

Each type of operation is then broken down further by the typical equipment which may be used, or the manual handling method applied for movement.

There are flow charts to follow for both types of operation; leading you through a number of factors which affect the risk of injury. These include:

- Weight

- Posture

- Grip

- Work pattern

- Travel distance

- Floor surface

- Obstacles

Each factor receives a score based the level of risk, highlighting which create the greatest risk e.g. certain tasks may require poor posture, or require a number of obstacles to be negotiated whilst moving from A to B.

You’ll also now have a cumulative risk score for the overall task.

When assessing a number of different push/pull activities within your organisation, the cumulative scores can be used to compare tasks against each other. This enables you to prioritise your focus on those which carry the highest risk scores.

The results should mean that you can evaluate the effectiveness of your control measures quantitatively, thus giving you a firm grounding on which to base your risk assessments and safe working practices.

Manual Handling Push & Pull Tool Developed By The HSE

Push Pull Tools

The range of Push Pull Tools manufactured by the Hand Safety Tool Company and distributed by Thorne & Derrick provide significant Health & Safety Improvements around site where “pushing and pulling” operations such as handling deliveries or loading/unloading in yards is commonplace. This download produced by the UK HSE enables the Risk Assessment according to Load Weight, Operation Frequency, Push/Pull Distances and other impacting factors – the range of tools to keep hands off loads, enable “hands-free” lifting, mitigate risk of load handing and prevent hand or finger injury are available in the UK from Thorne & Derrick.

The ShoveIt Hand Safety Tool is manufactured by Hand Safety Tools and stocked and distributed by Thorne & Derrick.

ShoveIt tools are designed to help users avoid hand injuries while working with suspended loads or manoeuvring objects. The tool ensures correct ergonomic body positioning for safe handling out of the line of fire, while enabling users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

Thorne & Derrick distribute a range of Safety Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Over a quarter of a million people suffer serious hand injuries each year. The Hand Safety Tool Company works hard to help to reverse that trend by creating No Touch Hand Safety Tools that keep hands off and away from potential injury areas. The range of Safety Products are the result of numerous conversations and in-field encounters over the last decade with key Health & Safety Officers and “boots-on-the-ground personnel” to ensure each tool produced does the most important job of all – helps every user to keep their hands.