Cable Pulling & Laying

Cable Drum Handling | Jack Towers for LV to EHV Power Cable Lifting & Site Handling

July 5th, 2021

Cable Drum Handling

Cable Jack Towers

Pictured: Despatched last week 5 sets of cable jack towers – the JT20 Cable Drum Jack Towers to support the safe on-site handling of LV-EHV cable drums at Western Power Distribution. Robust engineered construction with hydraulic jacks and adjustable height spindle support blocks.

Drum Lifting Jack Specification | JT20 20 Tonne Capacity SWL Per Pair, Minimum Drum Dia 1480mm, Maximum Drum Dia 3400mm, Base Area 1830x285mm, Weight Per Pair 370Kgs.

Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment and SEB service the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors. For over a decade, we have provided competitive prices and technical support for the SEB range of exceptional quality, British manufactured Cable Pulling & Laying Equipment – this includes rollers, socks, jacks, winches and trailers to enable cables, umbilicals or pipes to be installed into ducts, trenches and tunnels up to 400kV.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

July 2nd, 2021

Pictured | Singco Cable Grips – we produce cable socks for Boskalis, NKT, Nexans, DEME and other major cable laying contractors for the connection of wind farm projects globally.

-

Thank you to NnG Offshore Wind for their kind permission to republish this article

Offshore to Onshore

Cable Pulling

The first of two export cables, each 37 kilometres in length, has been installed at the nearshore of Thorntonloch Beach as part of construction of the Neart na Gaoithe (NnG) Offshore Wind Farm.

These electricity transmission cables will connect NnG’s two offshore platforms to its onshore substation located in the Lammermuir Hills.

The offshore cable was transported to the nearshore area of Thorntonloch Beach by Prysmian Group’s cable-laying vessel, the 124 metre long Cable Enterprise.

➡ Go to cable grips to learn about how Thorne & Derrick provide safe installation, support and pulling of cable in the wind energy sector.

Cable Enterprise is Prysmian Group DP2 cable laying vessel that has been designed with almost 8 MW of power, allowing her to autonomously maintain position in harsh weather conditions. The vessel has the capability to undertake simultaneous lay and burial operations with any type of plough, including HD3 ploughs with up to 180 tons tensions. The vessel maintains her ability to ground out and to operate in very shallow waters with 7-point independent mooring system allowing her to meet stringent operational requirements. Wärtsilä NOx reducing system fitted to all 4 Wärtsilä engines to achieve 75% NOx reduction from base levels.

The onshore winch cable was pulled through a 650m long horizontal directional drill duct and connected to the offshore cable situated on the deck of the vessel, 1km from shore. The offshore cable was then directed back through the cable duct towards onshore where it will be connected to the onshore cables behind Thorntonloch Beach.

The Cable Enterprise will lay the offshore cable from the nearshore of Thorntonloch Beach to the site of NnG. The cables will be buried to protect them from damage. Prysmian, one of NnG’s tier one contractors, expect the second offshore cable to be installed in July.

NnG Offshore Wind

NnG, jointly owned by EDF Renewables and ESB, will supply enough low carbon electricity for around 375,000 homes and has a capacity of c. 450MW of low carbon energy and will offset over 400,000 tonnes of Co2 emissions each year.

Matthias Haag, NnG Project Director, said: “The installation of the first of our two offshore cables is a significant milestone in the construction of NnG.

“These two 37km cables will play a pivotal role in connecting our two offshore platforms to the onshore substation over in the Lammermuir Hills.

“We’re grateful to all our neighbours in and around the Throntonloch area for their patience as we carry out these vital construction works nearshore.”

Massimo Galletta, Project Director (NnG) at Prysmian Group, said: “We are proud of being selected for such a strategic project, proving our state-of-the-art cable technology, know-how and project execution expertise to support the growing renewable energy industry.”

Further reading

- How Do Cable Socks React To Salt Water?

- Cable Winch | Customised & Refurbished 5 Tonne Cable Pulling Winch

- Cable Socks – Technical Guide for Safe Cable Pulling Using Cable Socks

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

➡ See Also Cable Laying, Installation & Support Products | MV HV Windfarm

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

Neptco’s Trace-Safe at The Roundtable Live! (2019)

June 16th, 2021

Neptco provided all of the Trace-Safe tracer wire for The Roundtable Live, and now because of that all new utilities that are installed will be located in the future. Quality tracer wire is something that often gets overlooked, and its important for contractors to make sure it stays intact when pulling back a utility. Thanks again Neptco, for truly contributing to a day in which damage prevention was demonstrated.

The video transcript can be found below:

Jonathon Jones Western Utility

“We are here at the Roundtable as a presenting sponsor for the second year in a row. This year we have finished up where we left off last year with a bore shot across the road behind me into a hand hole for some facilities that already existed in a place so we drilled out avoiding any existing utilities – pulling back a piece of two inch HDPE polypipe attached to the tracer wire prescribed by the manufacturer using their methods. We brought it back and it stays outside of the existing pipe follows the same path as the pipe itself. The gentlemen are going to do some proofing on it right now but everything is set up. The product pulls back very easily.”

Doug Moore Subsite Electronics

“One of the major reasons that it is important to have an inspection of tracer wire after the installation is too many times during or after the pull back of the product in the tracer wire there will be a fault or the wire will pull apart. So that’s an area the contractor leaves and then it can be impossible to track them down. It is subsequently impossible to locate that utility after so a doing a bore and post bore inspection of the quality of the tracer wire is critical.”

Joe Sylvia Neptco

“Joe Sylvia Business Unit Manager for Neptco, manufacturers of Trace Safe. The gentlemen in the video are pulling in trace safe with a 2 inch HDPE pipe pulling it around 150ft. Generally speaking when you are dealing with a plastic pipe you are going to require some kind of tracer with it so you can find it as once it is buried you have to be able to find it n the future and essentially that is what this product is for.

The way the connectors are designed you can have one end to end which allows you to daisy chain all along the way until you get to a far end of the ground that’s absolutely fine or you could connect them laterally and have a ground some place else. They are a universal connector so they can do end to end or lateral. One that was installed last year in direct sunlight the whole time, then this year we put a UV inhibitor in it and the plastic is still very strong after a year in direct sunlight. The USP about this particular product is its strength – 1800 pounds of pulling strength the strongest wire on the market (possibly the world).

So with that you only have to have one wire. The other good thing about the wire is that if there is any damage to the jacket the yarn itself that gives it the tenacity is woven with a super absorbent powder and if there’s any damage to the jacket it swells up almost like a baby diaper and keeps the water away from the conductor and that is what gives it a long life. How check to the wire is related to what the contractor is required to do. However in general you need a ground at least at the far end and you can do that with a temporary solution such as a long screwdriver that is pound that into the earth and a jumper can be created with a 12 gauge wire and connect that into a trace safe connector alongside the trace safe wire. Once closed you could energise the stud and walk the line to the far end.

So if we want to connect to a gas service essentially we have a 12 gauge wire and an adapter sleeve that goes on to it. It is split so it could easily wrap around the main line added to the connector alongside a piece of trace safe. This is then closed down with a pair of channel locks. Now we have a connection.

One of the tools the company has as an accessory item is a temporary locate tool. Basically if there is no connector in place a locator with this tool can be put the trace safe in and squeeze it down and what happens is a contact is made with the connector underneath. It simply attaches to the top and energises the wire. They can remove it, a little mark maybe left but the super absorbent powder will absorb any water that can get inside and will not harm the conductor. The tool will save you so much time as it just clicks in, closes and locates no stripping is required. It is simple to put it back to its normal condition as all you have to do is take it off and move onto the next job.”

Further Reading

- How to Trace & Locate Non-Metallic Underground Gas, Water Sewer Pipelines

- Trace Safe | Which Trace Safe is Best for Your Application?

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cable Pulling Considerations

June 11th, 2021

Cable basement KW Schattenhalb, Switzerland (c) 2014 Damian Aegerter

-

Special thanks to Damian Aegerter at Braavos GmbH / cableizer.com

for the kind permission to republish

Cable Pulling

In this 3rd article about cable pulling we discuss the usage of the weight correction and sidewall bearing pressure factors plus the conduit jamming ratio.

Transportation, handling, and installation of cables causes often more mechanical stress than what is actually experienced during operation. Therefore, it is important to carefully plan the cable installation, which can be done in Cableizers updated cable pulling module.

General considerations

For Cable Pulling

The conductors of the cable are generally the only members that can bear the pulling forces without damage. Do not use metallic shielding wires, tapes, braids or armor not designed for the purpose in pulling tension calculations.

Pulling different conductor sizes at the same time is not recommended if the conductor size or other cable characteristics are significantly different. If you must pull different size conductors, it must be done with care.

Pulling additional cables into an existing conduit system is generally not recommended. If this must be done, extreme caution must be taken. Of special concern is the cutting action of the tensioned pulling rope.

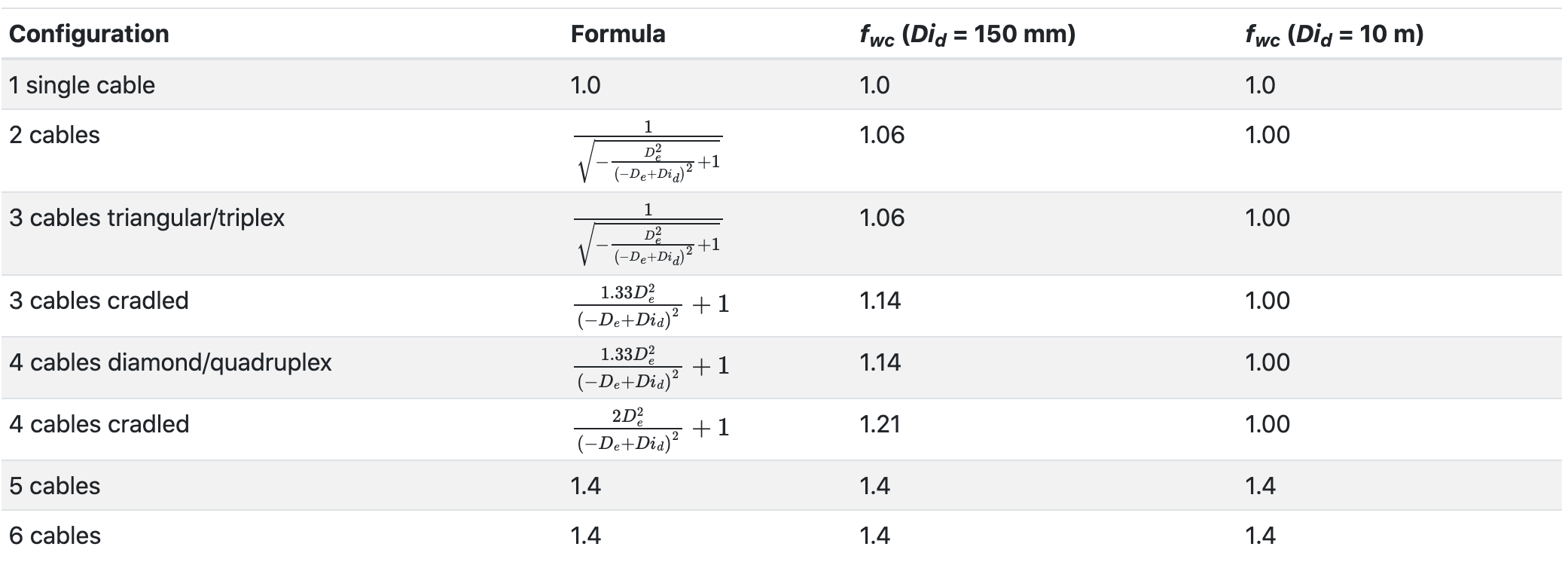

Some factors and ratios

Usage of weight correction factor

When multiple cables are pulled together, their mechanical configuration in the conduit is changing along the route which exposes them to uneven forces, an imbalance that is causing additional frictional drag. The weight correction factor f_wc is taking this into account by increasing the weight of cable assemblies consisting of more than one single cable.

Formulas for weight correction factors are mostly limited for pulling of up to 3 cables. Some formulas exist for pulling cable assemblies of 4 cables, but they were not leading to consistent results. Cableizer has extended the formulas for cable assemblies of up to 6 cables.

The following examples are calculated with a cable with an outer diameter D_e of 37 mm and a conduit with an inner diameter D_id of 150 mm. In addition, all calculations are also done on the example of a very large conduit (Di_d = 10 m) for validation reasons.

In this case, the cables lie next to each other and do not rub against each other, and the weight correction factor should be negligible (i.e. equal to 1.0).

As can bee seen in the following table, this is the case except for 5/6 cables which have a constant weight correction factor independent of the cable and conduit dimensions. As a consequence, the pulling force calculation in Cableizer for large conduits is rather conservative (i.e. on the safe side).

The above figures show that the weight correction factor is as expected incrasing with an incrasing number of cables pulled together.

Cradled configurations do have higher weight correction factors than when the cables are more organized (3 cables triangular/triplex or 4 cables diamond/quadruplex). If you are close to or exceeding the pulling force limits, it can therefore be of interest to investigate if binding the cables together can be an option.

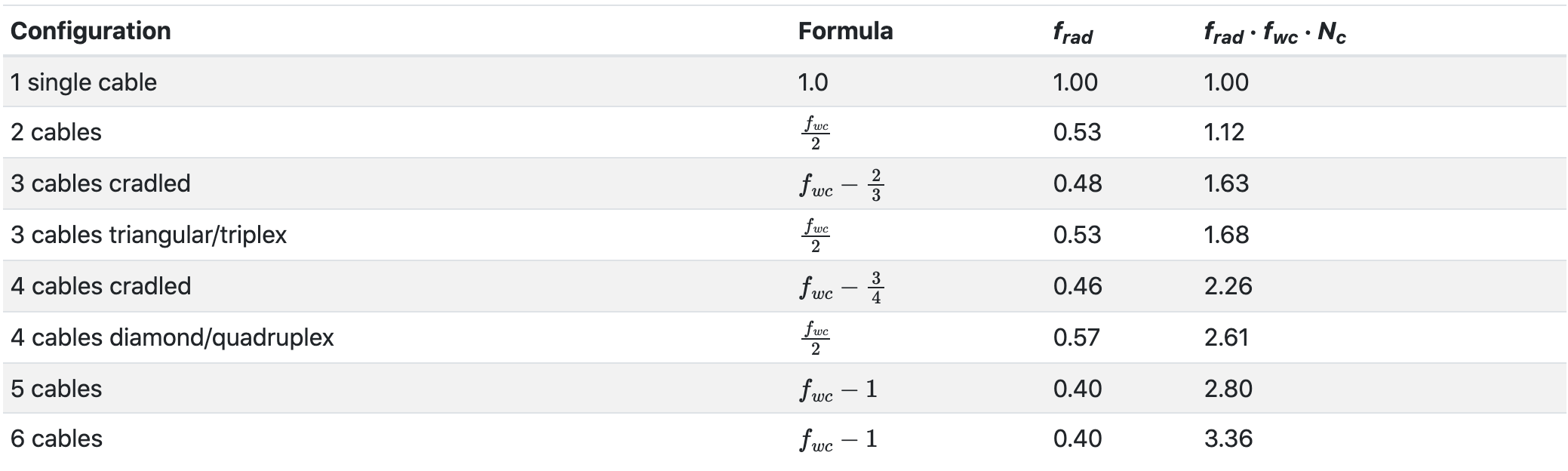

Usage of sidewall bearing pressure factor

Generally, manufacturers do also consider the influence of the weight correction factor when calculating the sidewall bearing pressure.

In Cableizer, this is considered with the sidewall bearing pressure factor f_rad, which can be optionally selected. Its calculations is always dependent on the weight correction factor, but it can be applied to the calculations independently of the weight correction factor. A normal use case is to either apply both f_wc and f_rad or none of them.

The following examples are calculated with a cable with an outer diameter of 37 mm and a conduit with an inner diameter of 150 mm.

The sidewall bearing pressure F_rad is proportional to the sidewall bearing pressure factor and the pulling force. The pulling force F_pull itself is proportional to the weight correction factor and the gravitational force. The gravitational force F_g itself is proportional to the number of cables N_c being pulled together.

As a consequence, the factor f_rad⋅f_wc⋅N_c indicates to what extent the sidewall bearing pressure is increased as compared to the case where a single cable is being pulled.

The above figures show that the sidewall bearing pressure on the most exposed cable is increasing steadily with an increasing number of cables being pulled. As expected, cradled configurations do have lower sidewall bearing pressures than when the cables are more organized (3 cables triangular/triplex or 4 cables diamond/quadruplex).

Conduit jamming ratio

Jamming is the wedging of three unbound cables when pulled into a conduit. This usually occurs because of crossovers when the cables twist or are pulled around bends. The conduit jamming ratio is the ratio of the conduit inner diameter Di_d and the cable outside diameter D_e. When calculating jamming probabilities, a 5% factor is used to account for the oval cross-section of conduit bends. The cable diameters should be measured, since actual diameters may vary from the published nominal values.

Cableizer indicates the risk for jamming according to the following table. As shown, different references use different ranges for quantifying the jamming risk. Cableizer does only indicate the jamming ratio for Three cables unbound because even while jamming can occur when pulling four or more cables into a conduit, the probability is very low.

Disclaimer

Always follow the instructions from the cable manufacturer when preparing your cable pull. While some manufacturers disregard the use of the weight correction factor (example I from Brugg Cables), others include it in their calculations (example II from Southwire). In Cableizer, both options can conveniently be calculated.

Cableizer specifically disclaims any warranties, including, but not limited to, the implied warranties of merchantability, accuracy, or fitness for any particular purpose of its calculation results.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

- Cable Pulling Calculation Example From Brugg Cables

- Cable Pulling Calculation Example From Southwire

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.

Cable Pulling Calculation Example From Southwire

June 11th, 2021

Cable Pulling Example from Southwire Manual in Cableizer

-

Special thanks to Damian Aegerter at Braavos GmbH / cableizer.com

for the kind permission to republish

Cable Pulling

The 2nd of this blog series features the following cable pulling example from Southwire is an extract from their public document titled ‘Power Cable Installation Guide’, published in 2005. The cable pulling calculation example is found on pages 23ff in the section ‘Typical calculation for cables in conduit‘.

This example validates our cable pulling module and has been added to our test cases, ensuring that the cable pulling calculation won’t unexpectedly and unnoticeably change.

Cable selection

In the Cable tab of the cable pulling module the cable is selected, which in the example is a THHN single-conductor 4/0 AWG copper cable. In the Cableizer cable editor, standard conductor cross-sections A_c can be selected either in mm2 or in AWG/kcmil. Typical values of conductor diameters d_c for this cross section can conveniently be selected for AWG sizes up to 2000 kcmil from UL 1581 and beyond from ASTM B8-11 standards.

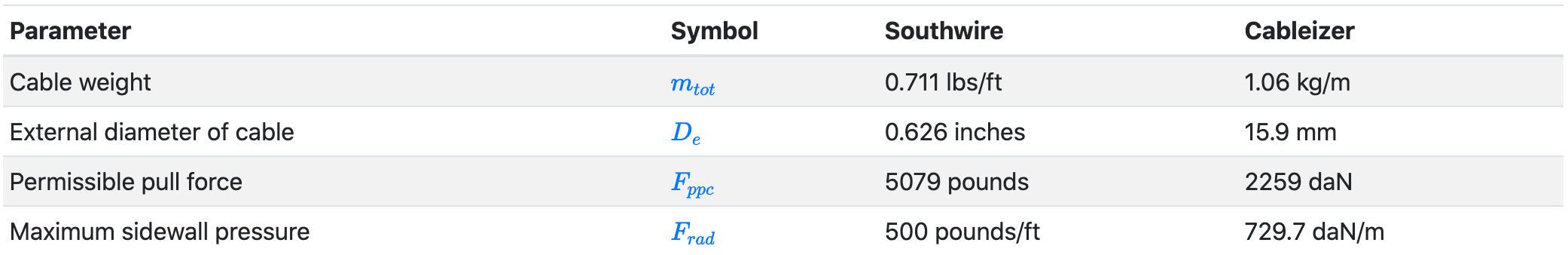

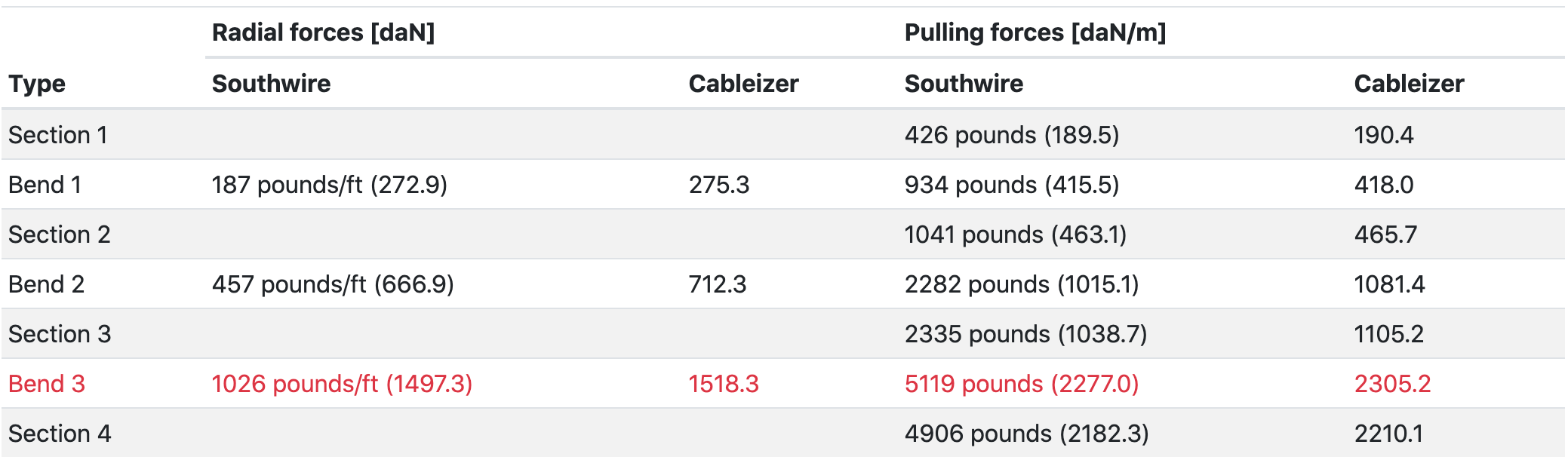

In Cableizer, all inputs/outputs are currently only supported in metric units so we converted them for this example. The following table shows the corresponding inputs regarding the cable selection for the Southwire example with cable weight m_tot and external diameter of cable D_e, which covers the case where three identical unbound cables are pulled together. Permissible pull force F_ppc and maximum sidewall pressure F_rad have been manually set to the same values as in the Southwire installation guide.

Conduit selection

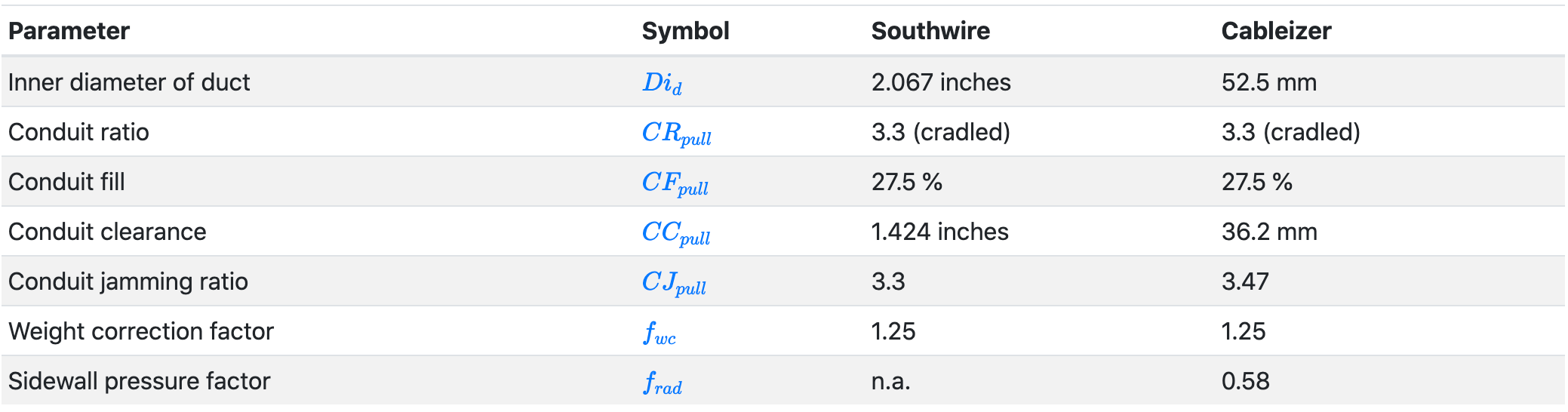

In the Conduit tab of the cable pulling module the conduit (EMT trade size 2 inch) is defined. The parameters include the inner diameter of duct Di_d, the conduit ratio CR, the conduit fill CF in percent, the conduit clearance CC in percent and the conduit jamming ratio CJ.

Cableizer does then verify if the installation is feasible and calculates the weight correction factor f_wc and the sidewall pressure factor f_rad as shown in the following table:

Route editor

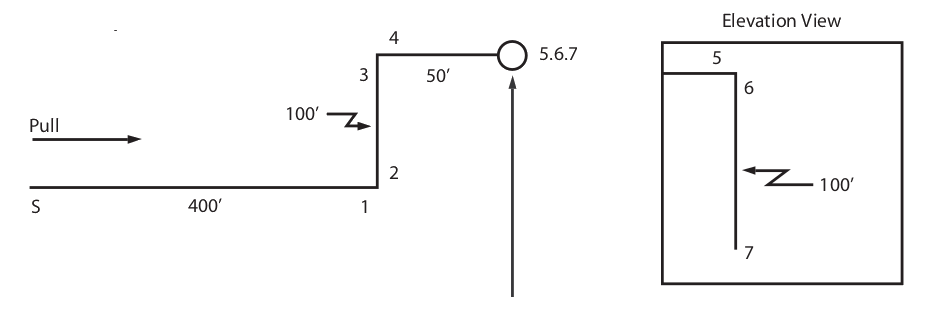

In the Routing tab of the cable pulling module the example route is composed of sections and bends. Bends have an angle ϕ_arc of 90° and a radius r_arc of 914.4 mm (36-inch sweep elbows with an inside radius of 2.91 feet). The friction coefficient μ_dyn is 0.4 all along the route. The following images show the Southwire conduit layout and the Cableizer cable route (in 3D):

Results

The results show a good agreement with the Southwire installation guide figures, both regarding the pulling force F_pull and the sidewall bearing pressure F_rad. In bend 3, both forces exceed the respective limits:

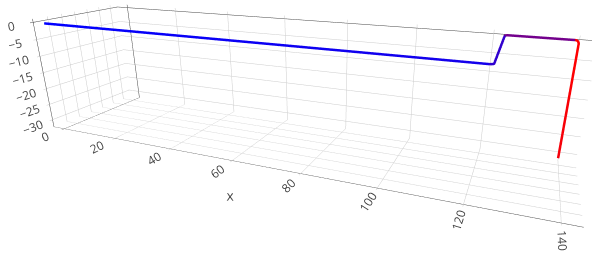

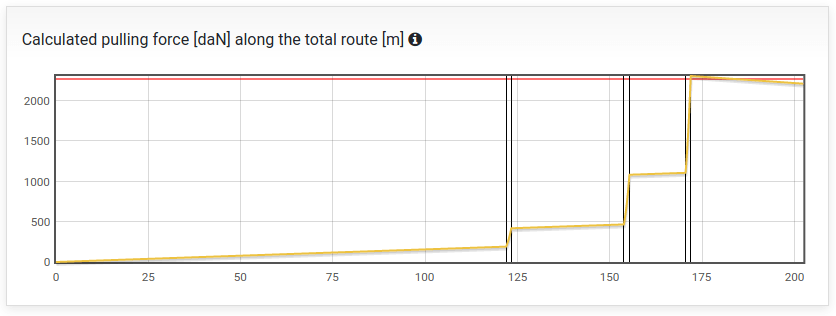

Part of the small differences in the above table can be explained by the fact that Southwire is using approximate equations for both horizontal bends and the vertical concave downwards bend (bend 3). The following figure shows the pulling forces along the cable route for the forward pulling direction. The red line shows the applicable force limits.

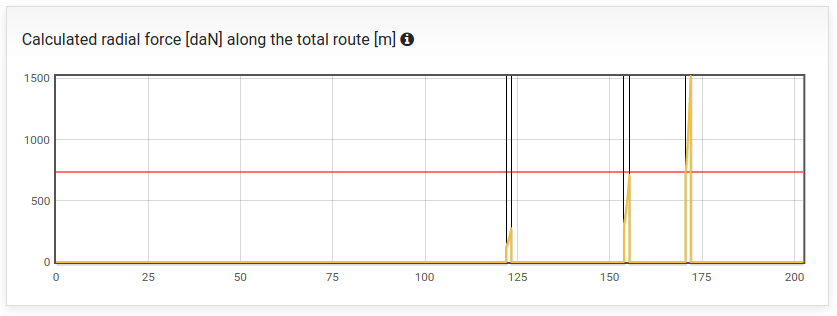

A figure showing the radial forces along the cable route is likewise generated.

Backwards pulling direction

In Cableizer, you can also simulate a pull in backward direction. In this case the maximum pulling force is reduced to 1443.7 daN and does not exceed the force limit anymore. The radial force is also considerably reduced to a maximum value of 825.5 daN/m, which is only slightly above the limit.

The forces are reduced despite the fact that the cable has to be pulled up the vertical shaft at the start of the cable route! But having the bends close to the start of the route instead of close to the end of the route significantly reduces the overall pulling forces.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.