Earthing

Earth Tape – The Manufacture of Copper Earthing Tapes

May 31st, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick, are UK distributors, stockists and suppliers for AN Wallis Copper Earthing & Lightning Protection Systems – we were recently invited to visit their UK based location in Nottingham to understand and learn more about the manufacturing processes for copper earth tapes.

In this post we provide a selection of photographs taken during the AN Wallis factory tour – all copper earthing products are manufactured according to BSI ISO 9001:2008 and BSI OHSAS 18001:2007.

Since 1946 AN Wallis earthing products including earth tapes, earth rods, earth bars and earth mats manufactured from high conductivity copper have provided Earthing & Lightning Protection to LV MV HV Network Assets including primary/secondary substations, overhead line towers and power cable systems from 11kV/33kV up to 400kV.

Copper is a chemical element with symbol Cu (from Latin: cuprum) and atomic number 29 – a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a reddish-orange colour.

Earth Tape

A panoramic photograph of the AN Wallis production facility and factory where the earth tapes are manufactured from raw material into finished product – earthing tapes in bare copper form or with optional PVC covering and coloured are manufactured in a range of tape thicknesses and widths to achieve the required cross sectional area.

AN Wallis extensive copper feed stocks enable fast turnaround of major earthing project requirements for the global electrical power and utility industry – the 17,000 square feet manufacturing facility and extensive raw material copper holding ensures short lead times with “off the shelf” deliveries or quick turnaround manufacturing of all earth tapes.

1 Earth Tape Manufacturing

2 Raw Material Copper Feed Stocks

The raw material is supplied in solid copper conductor form – note the circular form of the feed stock which must be processed via the manufacturing machinery into the flat tape copper configuration. The Conform machine processes the copper into flat tape form and can be pre-set to optional dimensions. Weekly maintenance checks of the Conform machine include a general clean down, gearbox oil level check, hub cooling oil check, hub cooling water check and ensuring no water or hydraulic pipes are leaking.

3 Copper Earth Tapes

The circular copper conductor is fed from coil into the Conform machine – the conductor is conformed from circular to flat configuration producing a range of flat copper earth tapes from 12.5mm to 50mm widths. Computer software, such as CDEGS, can be used to calculate the power system earthing and grounding. Asset managers must calculate the level of site protection required depending on the cross section area of conductor required to provide effective earthing and lightning protection.

Methods to improve high voltage substation earthing and grounding with supporting measurements of earth resistance and computational models to simulate the possible Ground Potential Rise (GPR) due to injected current surges are a key consideration in providing effective lightning and earthing protection.

4 Processing Circular Form Copper Into Flat Earth Tape

Here the circular copper conductor is shown entering the Conform machine – in the “On” mode the motors and pumps feed the copper conductor into the Conformer via the machine wheel. Adjustable settings enable the manufacture of an extensive range of widths and thicknesses of copper tape.

5 Copper Earth Tapes

From this angle the photograph shows the complete AN Wallis manufacturing process for copper earth tape. The finished copper earth tape has now been conformed by machine to a flat tape design from the circular copper feed stock – this production run is manufacturing 50mm wide x 6mm thick copper earth tape, a UK utility standard for medium/high voltage substation earthing. The copper earth tape is annealed and produced with radiused edges for safe site handling by installers.

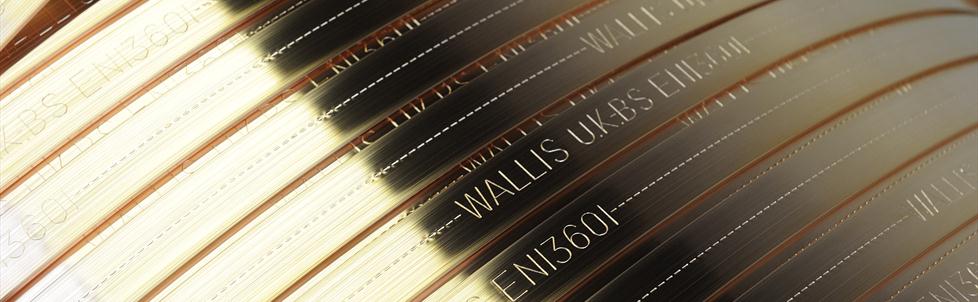

Wallis copper tapes are marked “Wallis U.K.- BS EN 13601”.

BS EN 13601 2013 is the current British standard covering Copper, Copper Alloys, Copper Rod, Bar & Wire for electrical purposes. The copper tapes are available embossed or inscribed with the client owners name as a copper theft deterrence measure.

6 Aluminium Earth Tapes

AN Wallis manufacture aluminium earth tape also at their Nottingham factory – lower cost than copper but with reduced conductivity the range of aluminium earth tapes are also available from stock.

7 Large UK Stocks Of Copper Earth Tapes

AN Wallis manufacture and hold the largest UK stocks of copper earth tapes – T&D, the UK’s largest supplier of AN Wallis products provide internationally competitive prices, delivery and technical support. A complete supporting range of copper clamps are available to secure and install the earth tapes to building infrastructures.

Full range of Earth Tapes

About AN Wallis

AN Wallis & Co Ltd has over 70 years experience in the design and manufacture of Lightning Protection, Earthing & Low Voltage Electronic Surge Protection products – a broad range of technical and earthing design services are provided including full design of structural lightning protection systems, design of substation earthing systems, soil resistivity tests, commissioning and project consultation.

AN Wallis has grown steadily and is a recognised world leader in the manufacture of quality Earthing, Lightning Protection, LV Surge Protection and Exothermic Welding products.

The Earthing Product range includes copper tape conductors, earth bars, copper earth plates, DC fixings clips, earth rods produced from solid copper, copper bond and stainless steel. Air terminals, earth rod clamps, inspection pits concrete and heavy duty polymer, earth rod seals, low resistance soil conditioning agents and also CU-NNECT exothermic welding products.

Thorne & Derrick distribute the complete range of Copper Earthing Products manufactured by AN Wallis to UK and overseas projects and competitive prices from extensive stocks – this includes earthing products for MV HV EHV substation projects including:

- Neasdon Depot Substation London Underground / Enterprise Rail

- Sleaford 132kV Substation EON / Enterprise

- Iver 132kV Substation/Windfarm SSE Scottish & Southern / Enterprise

- Swansea 400kV Substation National Grid / Electricity Alliance West

- Cardiff East 400kV Substation National Grid / Electricity Alliance West

- Sundon 400kV Substation National Grid / Electricity Alliance West

The products also provide Earthing & Lightning Protection for railway traction substations, distribution substations, overhead line towers, solar farms, STOR sites, data centres, hospitals and hazardous area sites.

-

Further Reading

Underground Cable Photo Album 1890-1940 – Western Power Distribution (WPD)

Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

Portable Earthing – Short Circuiting Kits For HV Substations & Overhead Lines

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

High Voltage Earthing & Grounding System Design Protecting Lives

February 21st, 2018

Special Thanks To Ian Griffiths - Earthing System Design HV

Below Ian discusses the successes of the last year at GreyMatters.

Lightning Strikes The Burj Khalifa

Well, 2017 was an exciting year for the team GreyMatters. So, at the end of 2016, we set goals on what we wanted to achieve in 2017. The biggest success story which is probably closest to my heart is smashing the previous year’s lives-protected by High Voltage Earthing/Grounding Design.

High Voltage Earthing

“Saving Lives” Explained

Above is a 2-minute explanation video on how we get to the lives protected numbers.

By-the-way, all rail sector work is ignored as this would add millions to the figures – which is great, but, for the purposes of catching the underlying trend for less populous work, it is not so helpful.

It’s an interesting dilemma, given that personally, my goal is to know that somewhere out there our work in Earthing/Grounding Design, has saved at least one person’s life.

Thorne & Derrick Largest UK Stocks Of Copper Earthing Tapes

And based on the HSE.gov.uk’s statistics for the UK, the rate of fatal injury per 100,000 workers is at 0.4 (2017); 6% (8) of those who sadly died last year (137) was as a result of electrocution, which means statistically in our population of 498,500 workers, we have still have got work to do! Given, we’ve influenced just under 1/8 of a worker’s life during 2017, we need to reach a figure closer to 4.16m workers to claim our first life saved.

Cumulatively, since we’ve been recording lives-protected, GreyMatters has recorded 1.4m which equates to a little over 1/3 of a life saved (statistically speaking of course).

Other Earthing News

Without wanting to sound too GreyMatters-centric – we upgraded the business systems to full UKAS accreditation for ISO9001, 14001 and OHSAS 18001. This is pretty unique as it makes GreyMatters the only independent specialist Earthing/Grounding Design Consultancy to be fully UKAS accredited – part of being a Top 1% specialist consultancy.

About GreyMatters

GreyMatters specialise in High Voltage Earthing System Design for earthing systems 1kV-765kV to meet EN 50522 and and international specifications, including 11kV, 33kV and 66kV power systems.

GreyMatters has been protecting critical assets and life from the harmful effects of high voltages and lightning strikes globally since 1995.

GreyMatters focus on high voltage electrical earthing system design, earthing measurement and surveys, lightning protection design, training and policy formulation.

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals.

Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

December 6th, 2017- Application: Using Copper Earthing Tapes, Rods & CADWELD To Earth 33kV Substation, Switchgear & Transformer

- Contractor: Power Jointing Services Ltd (Hampshire UK)

- Image Courtesy: Robert Coleman LV HV Cable Jointer at Power Jointing Services Ltd

- Featured Product: Earthing & Lightning Protection MV HV

Copper Earthing Tapes & Earth Rods

33kV substation earthing is provided around the transformer bund and new building structure using copper earthing tapes, electrode rods and exothermic welding (CADWELDing) of the earth rods to tape – 50mm x 4mm earth tapes are installed as a ring and cross earthing design with 40mm x 4mm copper tape braised for additional stairs and walkway earthing.

The 33kV switchgear housing within the high voltage substation is earthed and bonded to a new transformer ring and Neutral Earth Resistors (NER). The copper tapes and earthing cables are shown connected to the 10 way earth bar. To achieve the required earth resistivity reading 3 x 1.2 metre length coupled copper earth rods were driven into the ground.

Driven earth rods are used to exploit lower resistivity ground conditions where present to reduce the earth potential rise (EPR) on substation earthing and lightning protection projects from 11kV/33kV up to 400kV.

Substation Earthing

Earthing of low, medium and high voltage electrical networks is critical to ensure safe and correct operation preventing and minimising against the consequences of a direct lightning strike to equipment and buswork within substations. UK DNO’s publish primary and secondary substation earthing designs for the application of earthing systems to HV and LV underground cables and overhead line networks, typically operating at 33kV, 20kV, 11kV, 6.6kV, 3kV and 2kV.

Similarly, the National Grid publish an Earthing Technical Specification for the lightning protection of transmission and distribution systems located in the busbar protection zone of the electricity grid operating at nominal voltages of 400kV, 275kV 132kV and 66kV. The general requirements of the substation earthing systems are compliance with technical standard EA TS 41-24 and British Standards BS EN 50522 and BS7430.

➡ Read our Blog about Substation Earthing

Earthing Standards

- Energy Network Association (ENA) Technical Standard (TS) 41-24 (Substation Earthing) – the standard provides guidelines for the design, installation, testing and maintenance of main earthing systems in substations

- BS EN 50522:2010 – the British Standard provides guidance for Earthing of Power Installations Exceeding 1kV a.c

- BS 7430:2011+A1:2015 – the British Standard is a code of practice for Protective Earthing of Electrical Installations

Copper Earth Tape – the earthing tape 40mm x 4mm shown bonding to the existing medium/high voltage substation earth bar

Copper Earth Tape Dropper – 50mm x 4mm earth tape is shown earthing switch 1 of 3 on the 33kV distribution board

Earth Tapes – the 50mm x 4mm copper tapes are routed back to the rebar earths on the earth bar

Transformer Earthing – using 40mm x 4mm copper earthing tape on the 33kV high voltage transformer

Power Jointing Services Ltd

Power Jointing Services Ltd established in 2007 specialising in 33kV-400V electrical network construction, establishing industrial and commercial supplies, installing residential service connections and street lighting connections. Also: High voltage service alterations, cable fault finding and replacement of assets including transformers, low voltage distribution boards and link boxes.

Copper Earthing Tapes & Products

T&D provide competitive prices and fast delivery from stock for Earthing & Lightning Protection products including copper tapes, rods, electrodes, earth bars and ancillary items for low, medium and high voltage substations.

♦ Visit Substation Earthing for further information.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Exothermic Welding, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earth Tapes, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog

Substation Earthing

December 5th, 2017

Images: ABB

by Chris Dodds T&D - estimated reading time 6 minutes

Earthing Substations

Thorne & Derrick International are distributors for the ABB Furse and AN Wallis range of Earthing & Lightning Protection Systems – this includes earth rods, earth bars, earth tapes and a full supporting range of accessories to comprise the complete earthing system for electricity transmission and distribution systems.

The copper products are used typically to provide electricity substation earthing to medium/high voltage grids containing electrical infrastructure, cables, switchgear and transformers. Furthermore, it is usual for all exposed and normally un-energised metalwork inside the substation perimeter, including doors, staircases, ventilation ducts, cable supports etc to be be bonded to the main earth grid to avoid any potential differences between different items of metalwork.

Guidelines and policies vary according to the Distribution Network Operator – specialist contractors using modern earthing techniques compliant with relevant British and international standards, including BS 7430:2011+A1:2015 Code of Practice For Earthing and IEEE80-2000 Guide for Safety in AC Substation Grounding should be employed to calculate specific substation earthing requirements.

A final design of the earthing system can only be undertaken when sufficient knowledge is available of the proposed physical and electrical requirements of the substation – as an absolute minimum the earthing system desginer must have knowledge of:

- value of fault current and supply arrangements (overhead and/or underground cable)

- fault duration (or protection settings)

- soil resistivity

- substation dimensions

The specification for fixed earthing systems within EHV, HV, HV/MV and LV substations also applied to terminal towers adjacent to substations and cable sealing end compounds, pole mounted transformer or air-break switch disconnector installations and pole mounted reclosers with ground level control.

➡ View our complete range of Substation Earthing products including substation and overhead line earth clamps, telescopic sticks and portable earthing kits – see also Exothermic Welding.

Full range of bare copper, printed and covered earth tapes are available

Copper Earthing Products

Example – Substation Earthing 11kV. Image: SPE Electrical Ltd

For MV & HV Substations

Earthing products and systems can be supplied by T&D for all substation voltages:

- MV Medium Voltage 11kV 33kV

- High Voltage 66kV 132kV

- Extra High Voltage EHV 275kV 400kV

T&D provide expert technical support, competitive prices and delivery from stock for substation earthing projects – all earthing products are available to meet the design criteria and construction specification of the earthing systems for substations and equipment for 33kV and 132kV substations.

This include copper earth tapes with typical dimensions 32mm x 4, 40mm x 6mm, 50mm x 4mm and 50mm x 6mm.

With respect to high voltage earthing applications in the power utility sector the following items would normally be earthed or bonded to the main earth grid:

- Overhead line termination structures including towers, gantries and earthed wood pole structures adjacent to the substation

- Power cable sheaths and armours

- Transformer and reactor banks, cooler and radiators, tap changers, earthing resistors, earthing reactors, high voltage transformer neutral connections

- Metal clad switchgear assemblies and cases, isolators and earth switch bases

- Metal gantries and structures and metalwork mounted on wood structures

- Metallic structures including steel frames (bonded at each corner) rebars and piles

- Panels, cubicles, kiosks, LV AC equipment, lighting and security masts

It is usual for critical items such as medium/high voltage transformer tanks and terminal towers to have duplicate connections to the main earth grid.

11kV Substations

Pictured above is a diagram showing the typical layout of a high voltage GRP electricity substation distributing 11kV power – an outer ring of 70sqmm copper earthing conductor plus 4 earth rods of standard depth are shown with a 10 metre tail in the HV cable trench accompanied by a layout for the concrete rebar. Here, the HV substation is contained within a GRP enclosure with potential touch and step voltage risks.

Earth tapes are available stamped with the UK DNO ownership details to discourage copper metal theft – earth tapes printed “National Grid Property” are also available.

Full range of copperbond earth rods, couplings and driving studs are available for grid and primary substation earthing depending upon the calculated fault level.

- E – Earth electrode (copper earth rod)

- UE – Earth potential rise (EPR)

- S1, S2, S3 – Potential grading earth electrodes connected to the earth electrode E

- US Touch – Source voltage for touching (Touch Voltage)

- US Step – Source voltage for stepping (Step Voltage)

Touch Voltage

The potential on the surface of the soil near a copper earth rod during the time that fault current flows. If a person were to touch a rod (or any exposed metalwork connected to it), then the potential difference experienced between hands and feet is termed the touch voltage. Touch voltages are calculated assuming that the feet of the person are 1 metre away from the metalwork being touched. Touch voltages are normally reduced by using potential grading electrodes.

Step Voltage

Potential differences are established on the surface of the soil whilst fault current is flowing. Step voltage in a particular direction is defined as the potential difference between two points a metre part. Step potentials can be reduced by using potential grading copper electrodes or installation electrodes, such as copper earth rods, at a greater soil depth.

Transfer Potential

A potential rise of an earthing system caused by a current flowing to earth, transferred by means of a connected conductor (eg metallic sheath or pipe), which enters a substation area, with little or no potential rise relative to reference earth, and which is not connected to earth in that area. This results in a potential difference occurring between the conductor and its surroundings at the remote position.

Electrical Safety – Maintaining & Repair Of Earthing Systems

Substation earthing systems are the victim of operational and intentional damage – copper theft is rife and earthing maintenance work is often identified during routine site checks and inspection. Earth faults can be weekly occurrences on primary substations supplying extended high voltage rural overhead line networks. During these maintenance tasks there is serious risk of injury or even fatal electric shock when working on depleted or damaged earthing systems – specialist electrical safety equipment including insulated sticks, poles or rods, portable earth shorting leads, earthing clamps (substation or line-end), insulating footwear (shoes or boots) and insulating gloves depending on the voltage class of the substation earthing system.

T&D distribute a full range CATU Electrical Safety equipment including Arc Flash Kits, Insulating Boots & Safety Shoes and Voltage Detectors

High Voltage Substation Earthing 275kV

All images courtesy: Ian Forster (EHV Site Manager)

More Substation Earthing Applications

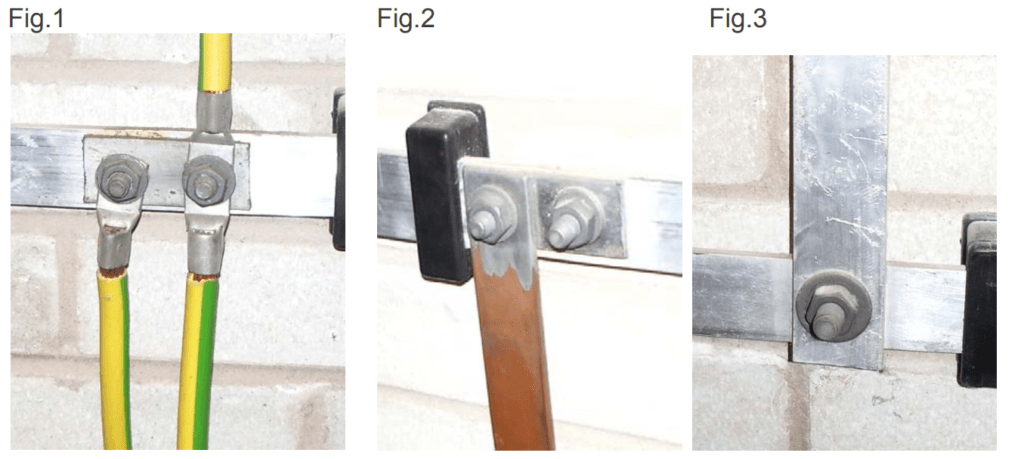

Fig.1 3 x Copper earth cables connected to main aluminium substation earth tape

Fig.2 Copper earth tape connected to main aluminium earth tape

Fig.3 Aluminium to aluminium tape connection

View the Earthing Products below for further information and technical details.