Electrical Safety

Pushing & Pulling Loads – RAPP Tools

December 6th, 2022

uploaded by Chris Dodds | Sales & Marketing Manage at Thorne & Derrick

All Content is Copyright of HSE & Original Information is here.

The HSE aims to reduce work-related death, injury and ill health.

Pushing and pulling of loads is a way to reduce or avoid manual lifting and carrying. Putting the load on a trolley and pushing it is one way of avoiding carrying.

So, when people push and pull instead of lifting and carrying, less effort is required, but there may still be a risk of musculoskeletal disorders (MSDs), which you need to assess and eliminate or reduce.

Although you may think that the Manual Handling Operations Regulations only apply to the lifting, lowering and carrying of loads, they also apply to pushing and pulling.

This ‘pushing and pulling’ guide should help you comply with the regulations and control the risks to your workers.

A risk assessment tool for pushing and pulling operations (the RAPP tool) is available:

- It is a simple tool designed to help assess the key risks in manual pushing and pulling operations involving whole body effort.

- It is similar to the MAC tool and uses colour-coding and numerical scoring, like the MAC.

- It will help identify high-risk pushing and pulling activities and help you evaluate the effectiveness of any risk-reduction measures.

- You can assess two types of pulling and pushing operations using the RAPP:

- moving loads using wheeled equipment, such as hand trolleys, pump trucks, carts or wheelbarrows;

- moving items without wheels, involving dragging/sliding, churning (pivoting and rolling) and rolling.

- For each type of assessment there is a flow chart, an assessment guide and a score sheet.

NOTE: Since the RAPP tool was launched, our experience, supported by further testing, has indicated that the tool is not sensitive to the level of risk in some tasks (or parts of tasks) involving moving loads with hand pallet trucks or similar, with small wheels.

In these tasks, small irregularities (including debris) and small gradients in the floor surfaces, which would otherwise be assessed as low risk (Good G/0) under the A-7 Floor surface and A-8 Obstacles along the route factors, can have a very significant effect on the manual forces required. In these situations, the RAPP will tend to underestimate the level of risk, although the need for high force should be identified from looking at worker posture in factor A-2 Posture.

Therefore, a full, site-specific, pushing and pulling risk assessment may be preferable when assessing tasks (or parts of tasks) in locations with varying floor and environmental conditions. This is particularly likely for tasks that occur outdoors or can be affected by the weather, such as deliveries or loading/unloading in yards. Worker involvement in the assessment process is important as they have valuable knowledge of the specific risks of the task, particularly, for example, drivers who are experienced in delivery operations.

HSE has produced a pushing and pulling risk assessment checklist and an example checklist to help with your full risk assessments – contact HSE for further information.

Push Pull Tools

The range of Push Pull Tools manufactured by the Hand Safety Tool Company and distributed by Thorne & Derrick provide significant Health & Safety Improvements around site where “pushing and pulling” operations such as handling deliveries or loading/unloading in yards is commonplace. This download produced by the UK HSE enables the Risk Assessment according to Load Weight, Operation Frequency, Push/Pull Distances and other impacting factors – the range of tools to keep hands off loads, enable “hands-free” lifting, mitigate risk of load handing and prevent hand or finger injury are available in the UK from Thorne & Derrick.

The ShoveIt Hand Safety Tool is manufactured by Hand Safety Tools and stocked and distributed by Thorne & Derrick.

ShoveIt tools are designed to help users avoid hand injuries while working with suspended loads or manoeuvring objects. The tool ensures correct ergonomic body positioning for safe handling out of the line of fire, while enabling users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

Thorne & Derrick distribute a range of Safety Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Over a quarter of a million people suffer serious hand injuries each year. The Hand Safety Tool Company works hard to help to reverse that trend by creating No Touch Hand Safety Tools that keep hands off and away from potential injury areas. The range of Safety Products are the result of numerous conversations and in-field encounters over the last decade with key Health & Safety Officers and “boots-on-the-ground personnel” to ensure each tool produced does the most important job of all – helps every user to keep their hands.

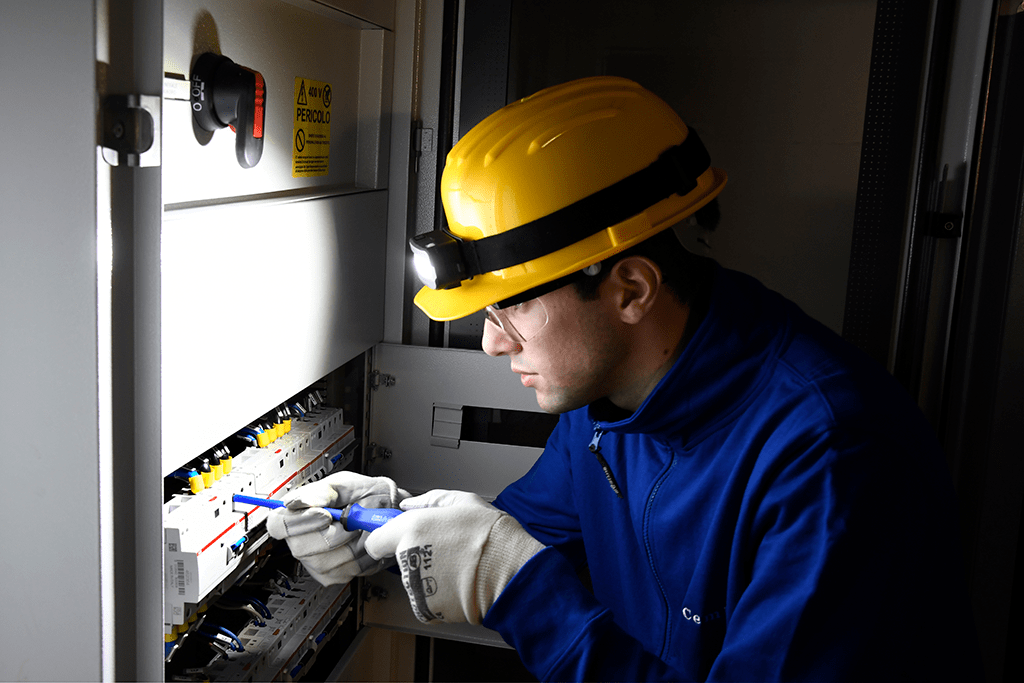

CEMBRE CBLIGHT | LED Portable Lighting for Electrical Contractors

October 25th, 2022

CEMBRE CBLIGHT

Cembre is a leading European manufacturer of electrical connectors, crimping tools, cutting tools and a variety of accessories for LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) power systems. Designed for switchgear and control panels, Cembre tools are ideal for installing low and medium voltage connectors.

The CEMBRE CBLIGHT (CBL) series offers a complete range of LED lights: highly practical and functional torches, lamps and portable spotlights.

Compact and easy to use, the CBLIGHT series lights, manufactured by Cembre, are a practical solution in any situation where quick and efficient wireless lighting is required.

The magnetic supports make CBLights useful for all outdoor activities, on construction sites and in emergency situations, ideal in the car, at home or in the office.

The built-in rechargeable battery guarantees durability and low consumption thanks to lithium polymer cells (Li-POLY), more advantageous than traditional lithium-ion (Li-ION) cells.

The high IP protection combined with the solid shockproof and non-slip rubber construction make the CBL series extremely robust and safe.

Min operating temperature range – 14 °F

Max operating temperature range – 104 °F

CEMBRE CBLIGHT (CBL) Range

WHY CHOOSE CEMBRE CBLIGHT?

The range consists of Compact, Portable, Floor & Table and Table Top devices.

- EFFICIENT, COB (chip on board) LED technology

- BRIGHT, 150-3000 lumens

- LOW CONSUMPTION, from 2.5-10h battery life and high energy rating

- ERGONOMIC and lightweight, bi-component plastic handles

- PRACTICAL, double light point, with adjustable magnetic support and built in suspension hook

- ALWAYS READY with wireless charging

- FUNCTIONAL as a power bank

CBL01 POCKET TORCH

|

The handy Cembre CBL01 torch is the size of a pen and is equipped with a double light point to illuminate small work areas. The side light allows you to illuminate the area while leaving it in your pocket, while the front light allows you to inspect less accessible areas. The clip is equipped with a magnet allowing it to be attached to any metal surface, freeing the operator’s hands. Supplied with USB charging cable. |

| Ideal for any indoor or outdoor activity requiring localised lighting and freedom of action, the Cembre CBL02-W head torch is equipped with a touch sensor allowing operation even whilst wearing gloves. The light intensity can be modulated via the dimmer function helping to preserve battery life. The CBL02-W is a versatile head torch adjustable by means of an elastic band to fit work helmets of various sizes. Supplied with USB charging cable and charger. |

CBL02-W HEAD TORCH

|

CBL03-W MULTIPURPOSE LAMP

|

The Cembre CBL03-W multi-purpose lamp is a mini-lamp that can be used on a table or hung on metal surfaces thanks to the handy magnet or the suspension hook. It is equipped with an ergonomic non-slip handle to make it easy to use. The 2 light points with dimmer function allow you to modulate the intensity and battery life as needed. The compact design makes it ideal as a pocket lamp for storage in a jacket pocket or work trousers. Supplied with USB charging cable and charger. |

| The most versatile of the family is the Cembre CBL04-W, which has a double light point, 2 dimmable light intensities, a rotatable and foldable stem and allows ideal lighting in all conditions. The double magnetic support and the suspension hook allow the lamp to be secured anywhere with ease. Designed to be easy to carry in a bag or trouser pocket whilst also offering excellent battery life and low weight portability. The compact design ensures the CBL04-W is the ideal solution for inspecting difficult to reach areas. Supplied with USB charging cable and charger. |

CBL04-W SPACE-SAVING FLOOR LAMP

|

CBL05-W PORTABLE LAMP

|

An ergonomic bi-component plastic handle makes the Cembre CBL05-W the most comfortable and robust lamp in the series, particularly suited to lengthy inspection work. Featuring two light points, dimmer function and a long battery life. Equipped with magnetic table support with retractable suspension hook. Supplied with USB charging cable and charger. |

| The Cembre CBL06 portable spotlight meets the requirement of those who need to illuminate small-medium work environments. The magnetic table mount allows the spotlight to be secured to metal surfaces. The power bank function allows small devices to be charged via the USB output, useful for emergency situations. Supplied with USB charging cable and charger. |

CBL06 PORTABLE SPOTLIGHT FOR SMALL-MEDIUM WORK ENVIRONMENTS

|

CBL07 PORTABLE SPOTLIGHT FOR LARGE WORK ENVIRONMENTS

|

The diffused light emitted by the Cembre CBL07 spotlight enables the illumination of large areas. Light, practical and sturdy, this spotlight is quick to install. The power bank function allows small devices to be charged via the USB output, useful for emergency situations. Supplied with charger. |

| The Cembre BCB1-W and BCB2-W charging bases make it possible to keep the lamps fully charged meaning they are always ready for use. The magnetic construction allows quick attachment to metal surfaces along with holding the lamps in place during charging. The BCB1-W single base is designed to recharge a single lamp. The BCB2-W allows 2 lamps to be charged at the same time. Supplied with USB charging cable and charger. |

BCB1-W / BCB2-W WIRELESS CHARGING BASES

|

Cembre CBLIGHT Technical Data

| Part Number | Lumen Front/ Flashlight | Duration Front/ Flashlight | Charging Method | Degree of Protection | Body Material | Lamp Material | Dimesions mm | Weight g |

| CBL01 | 150 / 70 | 2,5 / 3,5 h | USB | IP20 | ABS | PC | 160 x 15 x 20 | 38 |

| CBL02-W | 400 / 80 | 3 / 5 h | USB / Wireless | IP54 | ABS+PC | PC | 78 x 39 x 36 | 105 |

| CBL03-W | 300 / 100 | 3 / 6 h | USB / Wireless | IP65 | ABS | PC | 133 x 68 x 25 | 190 |

| CBL04-W | 600 / 100 | 2,5 / 8 h | USB / Wireless | IP54 | ABS | PC | 175 (325 max) x 44 x 38 |

246 |

| CBL05-W | 600 / 100 | 2.5 / 10 h | USB / Wireless | IP65 | PC | PC | 205 x 55 x 40 | 300 |

| CBL06 | 2000 | 3,5 / 7 h | USB | IP65 | ABS | PC | 195 x 125 x 48 | 800 |

| CBL07 | 3000 / 1500 | 3 / 6 h | Power Plug | IP65 | ABS | PC | 277 x 213 x 86 | 1400 |

| BCB1-W | – | – | USB / Wireless | IP20 | ABS | – | 105 x 106 x 18 (single) | 190 |

| BCB2-W | – | – | USB / Wireless | IP20 | ABS | – | 202 x 106 x 18 (double) | 270 |

Contact Thorne & Derrick for more information.

THORNE & DERRICK

T&D are Specialist Distributors of LV MV HV Cable Installation, Jointing, Substation & Electrical Equipment – we supply companies in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors with products to enable the energisation, operation and maintenance of underground cables and overhead lines.

Products | Surge Counters | Sealing Cable Ducts | Cleats, Clamps & Hangers | LV MV HV Electrical Safety | Arc Flash Clothing & PPE | Jointing, Termination & Stripping Tools | Cable Pulling & Laying | Feeder Pillars | Cold Shrink | Heat Shrink | Joints Terminations Connectors MV HV

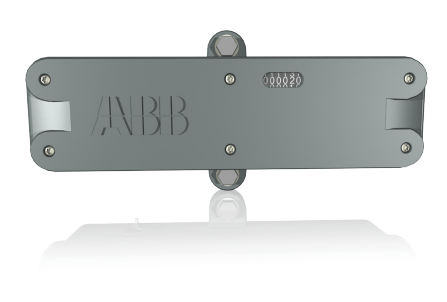

Surge Counters | Monitoring The Health Of Surge Arresters

September 15th, 2022

Surge Counters are used to monitor the health of Surge Arresters and protect against potentially damaging events which could lead to deterioration and ultimate overload. It is important to also schedule regular checks of surge arresters including visual inspection and diagnostics to detect and prevent a costly medium voltage power outage.

Well-designed and tested, ABB surge arresters are maintenance-free and can reasonably be expected to have a long service life. However, the condition of these surge arresters should also be monitored to ensure the most ultimate protection against a costly unplanned power outage. This can be achieved using the ABB EXCOUNT range of surge counters and monitors.

Surge Counters

Surge registration

The primary reason for the use of surge counters on modern gapless ZnO arresters is to check if a particular transmission line or phase suffers from an exceptionally high number of overvoltages leading to arrester operation — lightning faults on a line, for example. If this is the case, whilst it validates the need for the arresters, use of some preventative counter measures may be warranted to limit the number of surges. A sudden increase in the counting rate may also indicate an internal arrester fault, in which case the arrester should be investigated further.

However, simple surge counters tell only part of the story, as they only register the number of surges according to their operating characteristic. The user therefore has no way of telling the magnitude of the surge and if it was significant, nor when it occurred and if it was coincident with a system event.

Leakage current measurement

Surge counters can be complimented with the substation facility to measure leakage currents (total and/ or resistive), with the intention of monitoring and diagnosing the condition of the arrester and its state of fitness for continued service. However it is important to understand the validity of the information provided.

At continuous operating voltage (Uc), a metaloxide varistor acts as a capacitor, leading to a predominantly capacitive component of current and a significantly smaller resistive part. For a complete surge arrester, the capacitive current is further dependent on stray capacitances, pollution currents on the insulator surface, number of varistor columns in parallel and the actual operating voltage. Meanwhile the small resistive component of the leakage current is temperature and voltage dependant.

Since the capacitive component of the current dominates so greatly, the total leakage current measured on a basic mA-meter will be very sensitive to the installation; making interpretation of the readings difficult. Furthermore, the capacitive current does not change significantly due to deterioration of the voltage-current characteristic of the surge arrester. Consequently, measurement of capacitive current cannot reliably indicate the condition of metal-oxide arresters. Nevertheless, increasing values may be of some use in indicating that cleaning of the insulators is necessary.

Instead, it is generally recognized (IEC 60099-5) that the only reliable indicator for the condition of a gapless arrester that can be assessed during normal service is to measure the resistive component of the leakage current (or estimate it from the 3rd harmonic).

The obtained value may then be compared with the maximum allowable resistive current as given by the manufacturer under prevailing service conditions i.e. temperature and applied voltage.

If a metal-oxide varistor ages or is damaged by impulses etc, the arrester resistive leakage current, and hence power losses, increase permanently. This may result in an increase in temperature, which in turn, increases the leakage current and so on until a so-called thermal runway occurs. Early detection of a possible harmful increase may prevent a failure and subsequent unplanned shutdown. Hence, to provide true diagnostics, a good monitor must be able to detect the arrester leakage current and isolate and measure the resistive component flowing internally.

EXCOUNT Surge Counters | ABB

Diagnostic plan

A surge arrester does not contain any moving parts or items that can break.

Consequently there is nothing to maintain, adjust, correct or repair, which is why there is normally no need to perform any form of periodical checking or monitoring. In general, a correctly chosen and installed arrester is maintenance free during its entire lifetime. A correctly chosen arrester in this context means that its electrical and mechanical characteristics are matched to actual service conditions.

Nonetheless, since external factors can place stresses on the arrester, potentially leading to its deterioration and ultimate overload, it may be prudent to draw up a schedule for regular checks. Such consideration is all the more important if an unplanned outage is unacceptable for reasons of system stability or economics. The older the arrester, the more regular these checks may need to be, since the statistical risk for overload increases with age.

As a guide, the following strategy is proposed to be made at regular intervals as required and determined by site availability and importance:

- Visual inspection and possible cleaning

- Diagnostics in advance of the designated lighting season and thereafter following periods with bad weather conditions.

- Diagnostics after special fault conditions causing flashover in the network or TOV’s of high amplitude and/ or long duration.

Because of their nature, old-style gapped arresters should be removed as soon as possible as part of a scheduled replacement program. Their age and inherent design does not warrant detailed evaluation. Early models of gapless arresters may require additional visual checks to look for signs of mechanical or physical deterioration as well as monitoring of the internals. Newly purchased arresters can also benefit from diagnostic monitoring right from first installation since this permits easy trend analysis to detect potential deterioration later on in its service life.

EXCOUNT-C |

EXCOUNT-I |

EXCOUNT-II |

EXCOUNT-III |

|

|

|

|

Safety Comes First

Monitoring Surge Arresters

EXCOUNT draws upon over 80 years of experience by ABB in the development of arresters and associated accessories. Safety, functionality and longevity are key elements which are given priority in selection and design of components. The EXCOUNT range has not neglected short-circuit safety which lies inherent in the design concept.

The EXCOUNT family is characterized by:

Highest Personnel Safety

- Same electrical safety performance as ABB arresters

Negligible Residual Voltage

- Does not reduce protection margins

- Minimized risk for injury in case of accidental contact during surges

Maintenance Free

- Sealed components

- Requires no external power supply (except for EXCOUNT-III)

Long Life

- Moulded components, non-sensitive to humidity or temperature variations

Universal Application

- All makes and types of gapless surge arresters.

- All weather and temperature conditions.

Design

The use of an impulse current transformer with a single-turn primary ensures that the voltage drop across the counter is negligible, even at the highest impulse currents encountered in service. This leads to added personnel safety and no increase in the protection level of the arrester. Since no gaps or series impedance are used, there is no risk of internal arcing and consequent explosive failure in the event of a short-circuit following an arrester failure.

One further common feature with the entire EXCOUNT family is that all internal components are fully encapsulated in polymer. This provides sealing to IP67, which ensures no harmful ingress of dust or moisture as well as providing personal safety through complete protection against contact with the internals.

EXCOUNT is available in different variants, depending on the user’s needs: simple, basic or extensive. Contact Thorne & Derrick for more information.

T&D are Specialist Distributors of LV MV HV Cable Installation, Jointing, Substation & Electrical Equipment – we supply companies in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors with products to enable the energisation, operation and maintenance of underground cables and overhead lines.

Products | Surge Counters | Sealing Cable Ducts | Cleats, Clamps & Hangers | LV MV HV Electrical Safety | Arc Flash Clothing & PPE | Jointing, Termination & Stripping Tools | Cable Pulling & Laying | Feeder Pillars | Cold Shrink | Heat Shrink | Joints Terminations Connectors MV HV

HV Joints Terminations Connectors | 11kV/33kV up to 66kV Ex Stock

Testing Insulating Gloves | Guide to Safe Use & Care for Electrical Gloves

July 20th, 2022

Electrical Insulating Rubber Gloves

Testing Insulating Gloves

Guide To Safe Use of Classes 00, 0, 1, 2, 3 and 4 Electrical Gloves

Improper use of electrical rubber insulating gloves can be a matter of life and death.

Get them retested regularly to make sure that they are still electrically safe.

Treat your rubber insulating gloves well and they can last a long time. The testing of insulating gloves will help to prevent failure which could lead to electrical shock if the surface integrity has been comprised by “wear and tear”.

As Main UK Stockists for the CATU Electrical range of insulating gloves Thorne & Derrick regularly are requested to provide care and maintenance advice to ensure gloves provide adequate and ongoing electrical safety and protection to the wearer.

Any Brand of Insulating Glove can be tested. Here are some examples:

- CATU

- Regeltex

- Honeywell Salisbury

- Polyco

- Clydesdale (Novax)

Electrical Insulation Tests For Gloves

| Class Of Gloves | Maximum Voltage Use AC DC | Test Voltage AC Proof | Test Voltage AC Withstand |

| 00 | 500V ac | 750V dc | 2.5kV | 5kV |

| 0 | 1000V ac | 1500V dc | 5kV | 10kV |

| 1 | 7500V ac | 11250V dc | 10kV | 20kV |

| 2 | 17000V ac | 25500V dc | 20kV | 30kV |

| 3 | 26500V ac | 39750V dc | 30kV | 40kV |

| 4 | 36000V ac | 54000V dc | 40kV | 50kV |

Special Properties Of Gloves

| Special Property Of Insulating Glove | Category Marking Code |

| Acid Resistance | A |

| Oil Resistance | H |

| Ozone Resistance | Z |

| Acid, Oil & Ozone Resistance | R |

| Extreme Low Temperature | C |

1 – Expiration Date

Insulating rubber gloves have no expiry date and may be used as long as they comply with the periodic inspection.

2 – Periodic Inspection

Class 00 and Class 0 Gloves

- Verification regarding air leaks and a visual inspection

- However, a routine dielectric test may be performed at the owner’s request

Class 1, 2 , 3 and 4 Gloves

- Verification regarding air leaks and and a visual inspection

- Verification via a dielectric test to verify electric properties

- Every 6 months to be re-tested, since they were first worn

- Every 12 months, even those held in storage and not worn to be re-tested

Testing Insulating Gloves | Glove Markings

3 – Field inspection & Stock

Do not confuse the periodic inspection with the inspection before each use. Together with the periodic inspection, it is strongly recommended that a visual inspection of the gloves is carried out before each use.

It is important to store the gloves in their UV-Resistant polythene bag and keep the gloves away from light, heat, and ozone. Ideally, the user should use our pneumatic tester to inflate the gloves for a good visual inspection and keep the gloves in our polypropylene store box for both transportation and storage.

4 – Special Properties

Gloves that pass the special properties (acid, oïl, ozone, very low temperature) are not resistant to chemicals. The test is to guarantee electrical protection in case of accidental contacts. After completing the electrical work, it is recommended to replace the contaminated gloves.

A periodic dielectric inspection service

- On receipt of your gloves to our premises, the gloves and sleeves are documented and then washed and dried.

- They are then visually inspected by our technicians, using inflation equipment.

- The next stage is electrical testing. Test equipment is used and tests are carried out according to the correct voltage for the class of glove. After the electrical testing has been completed they are again inflated and visually inspected. The gloves are then stamped and packed for return.

- Documentation accompanies the gloves and sleeves through all stages of testing and any failures are recorded. Any glove that fails will be destroyed. If the customer wishes, failures can be replaced with new items from our stocks.

Arc Flash PPE & Electrical Safety

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

How To Save Lives In High Voltage Substations 11kV/33kV

July 18th, 2022

Thorne & Derrick | Distributed from Stock | Approved Supplier

CATU CZ kits are wall mounted substation life saving kits that can be used in the event of an electrical incident or accident in MV-HV substations up to 36kV – suitable for electrical intervention in substations up to 36kV and for assisting victims in the event of an electrical hazard or electrocution. Portable life saving kit options are also available for field service vans and engineers.

The installation of one of these Life Saving Rescue Kits can mean the difference between life and death for an electrocution victim and can save lives in high voltage substations. CATU substation life savings kits are in widespread use in the electrical industry – they provide vital protection and reduce the amount of fatalities and serious injuries caused by electrical incidents in and around substations and whilst working on medium voltage cables and electrical equipment installations.

The CZ range of Electrical Safety & Life Saving Intervention Kits are used throughout the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

CATU CZ kits

for Medium and High Voltage Substations

The CZ-54 is the most specified substation wall mounted life saving kit – the kit is suitable for up to 24kV and are widely installed during the construction and commissioning of 11kV high voltage substations. Other models are available from Thorne & Derrick and CATU Electrical, including the CATU CZ-55 for high voltage substations up to 36kV, and portable kits such as the CATU CZ-53.

Substation Kit Contents

Wall mounted board with a clear door and security straps to fix the below CATU Electrical components:

- 1 insulating platform 24 kV (phase/ground) CT-7-25/1

- 1 pair of insulating gloves 26,5kV, CG-3-10-NR, class 3 size 10 (IEC 60903:2014).

- 1 telescopic stick 45 kV with rescue hook

- 1 voltage detector (3 to 40kV) with flexible contact antenna fixed on the hook ref. M952170

- 1 pair of insulating boots to protect against the electrical risks of voltage when stepping on the ground MV-135/45 (size 45) or over boots class 3 MV-139-L (depending on ref)

- 1 cable cutter with insulated handles 25kV

Safety instructions on the plastic board, 1 instruction manual, 1 fixing kit with :

- 2 braces

- 6 TR 6×35 screws

- 6 pins

- 6 washers

- 2 plastic clips

How To Save Lives In High Voltage Substations 11kV 33kV | CATU CZ54

Medium & High Voltage Substation Life Saving Kits | CATU CZ53, CZ54 & CZ55

The components are within the plastic board which :

- Protects against dust and shocks

- Avoids borrowing of the electrical safety components

- Protects the safety equipment during transportation

- The substation kit is delivered with all the components already inside the board

- When the substation kit is fixed on the wall, the voltage detector shall be fixed on the stick, and the stick shall be unfolded and placed in the board

- Dimensions: 0,84 m x 0,75 m x 0,27 m

- Weight with components: 21 kg

CATU CZ Kit For HV Substations

Installing the Substation Kit

To protect this kit during transport, all components are placed inside the cabinet. To facilitate wall mounting, we recommend emptying it of its component parts.

- Mount the angle brackets on the wall taking care to match the precise distance of 600 mm between brackets (using two screws per bracket).

- Be sure to mount the cabinet 1510 mm from the floor.

- Place the cabinet onto the angle brackets and clip the two pressure mounted plastic clips into place.

- With the cabinet still on the wall, drill the wall through the two holes located in the base of the cabinet.

- Press the wall plugs in and screw in the two screws after inserting the washers.

- Stow the component parts in the cabinet using the Velcro strips for boots, cable cutter and stool.

- Extend the pole and mount the detector (so that this assembly is immediately operational).

- Clip the pole into the location provided.

- Check that the detector operates properly (by pressing the red button).

Offshore Wind Substations MV & HV Electrical Safety. Image Source: Daniel Paskell/Ørsted

The Risk & Electrical Switchgear Guide | Failure of electrical switchgear can cause death, serious injury and major damage. If you own or operate this type of equipment in industrial or commercial organisations, this book is mainly aimed at you. It should help you to select, use and maintain switchgear safely and reduce the risk of accidents. This guidance is aimed at owners and operators of electrical switchgear in industrial and commercial organisations. It may also be useful to others. It will help managers, engineers and others to understand their responsibilities and duties in the selection, use, operation and maintenance of high-voltage switchgear. Here you can download the HSE Guide to Keeping Electrical Switchgear Safe.

Warning

- To ensure optimum protection, all insulating components must be used (stool, gloves, pole).

- The detector only works with AC power (no detection is possible when using DC installations).

- Before use, always check equipment integrity (especially the gloves).

- Before and after checking to ensure that no voltage is present, always check correct installation operation.

- This check must be performed in contact with bare conductive parts.

- Never cut a number of phases at the same time using the cable cutters (this causes a short circuit hazard at blade level).

Selecting Your Substation Electrical Safety Kits

➡ The following table provides an overview of the operating voltages, ordering references and language versions available for the CATU Electrical range of MV HV Substation Kits:

| CATU Part Ref | Description | Maximum Voltage | Dimensions | Weight |

| CATU CZ-53-R | Life saving kit with instructions in English | 25kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-MR | Life saving kit with instructions in English / Arabic | 25kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-R/2 | Life saving kit with instructions in English | 36kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-MR/2 | Life saving kit with instructions in English / Arabic | 36kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-54-R | Wall mounted life saving kit with instructions in English | 24kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-54-RM | Wall mounted life saving kit with instructions in English / Arabic | 24kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-55-R | Wall mounted life saving kit with instructions in English | 36kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-55-RM | Wall mounted life saving kit with instructions in English / Arabic | 36kV | 840mm x 754mm x 270mm | 21kg |

Connecting High Voltages & Energising Data Centres | more info

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV