3M Scotchcast 5555 Resin | 3M Scotchcast Powder Resins

3M Scotchcast Powder Resins

3M Scotchcast 5555

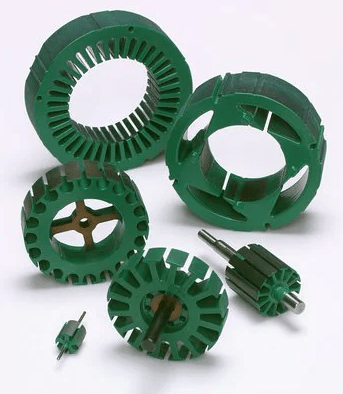

3M Scotchcast 5555 Resin is a 1-part, epoxy based powder electrical resin used to coat wire products by electrostatic fluid bed coating process. The high strength of the 3M Scotchcast resin exhibits excellent flexibility and elongation property even after curing. It is ideal for applications that require flexibility and resistance to cracking, when operating at high temperatures.

3M Electrical Resin 5555 is made from a fusion blend process and has a low gel point rating to ensure curing at room temperature. It provides a continuous, tough moisture and chemical resistant dielectric coating to a variety of substrates.

5555 resin is ideal for applications which need excellent thermal and mechanical shock resistance. Its high dielectric strength offers excellent electrical insulating property to the resin, thus making it a ideal insulator for creating a barrier between 2 conductors. UL Listed, EIS Approved and RoHS 2011/65/EU Compliant.

3M Scotchcast Electrical Powder Resins

Typical Property Data – Powder Resins

- 3M Electrical Powder Resin Product Number –5555 10G

- Temperature Class – H

- Cure Schedules (Temp/Time) – 177°C (350°F) 6 min. 204°C (400°F) 150 sec. 232°C (450°F) 90 sec.

- Specific Gravity – 1.7

- Cut-Through Resistance – 340°C (644°F)

- Edge Coverage (%) – >35%

- Impact Resistance (inch-lbs. Newton Meters) – 100 inch-lbs (11.3 J)

- Gel Time @ 193°C Hot Plate – 9-11 sec. @ 392°F (200°C)

- UL System 1446 Approved File Number E163090 – Yes

- UL 746B Comp. – E35075

- Dielectric Strength (volts/mil) – 1,300 V/mil (512V/micron) 12-15 mil (305 μm to 381 μm) film thickness)

- Volume Resistivity (Ohm-Cm at 23°C) – 10¹⁴

- Colour – Green

- 3M Electrical Powder Resin Product Number –5555 22G

- Temperature Class – H

- Cure Schedules (Temp/Time) – 177°C (350°F) 8 min. 204°C (400°F) 4 min. 232°C (450°F) 2 min.

- Specific Gravity – 1.7

- Cut-Through Resistance – 340°C (644°F)

- Edge Coverage (%) – >30%

- Impact Resistance (inch-lbs. Newton Meters) – 100 inch-lbs (11.3 J)

- Gel Time @ 193°C Hot Plate – 21-23 sec. @ 392°F (200°C)

- UL System 1446 Approved File Number E163090 – Yes

- UL 746B Comp. – E35075

- Dielectric Strength (volts/mil) – 1,300 V/mil (512V/micron) 12-15 mil (305 μm to 381 μm) film thickness)

- Volume Resistivity (Ohm-Cm at 23°C) – 10¹⁴

- Colour – Green

3M 5555 10G & 3M 5555 22G

3M Scotchcast Powder Resin Selection Process

The best way to select the proper 3M Scotchcast Powder Resin is to consider the needs of the application and the proposed application method.

Step 1: Define what needs to be coated

What is it that needs electrically insulated?

- Motor stator or armature core?

- Transformer wire?

- Coiled assembly?

- 3M offers a number of epoxy powder coatings suitable for use on a variety of applications.

Step 2: Determine the coating application method

How large or small is the component? Are there complex, hard-to-reach areas that need to be insulated? Will intricate masking be needed?

Knowing the size and geometry of the component helps determine the feasibility of powder coating as well as determining which application method is the most efficient. The most common application methods are:

- Fluid Bed Dip – Components are preheated and dipped into a powder fluid bed or powder hopper. The epoxy begins to gel immediately upon contact with the hot substrate.

- Venturi Spray – Components are preheated and powder is applied using venturi nozzles or powder spray guns. The epoxy begins to gel immediately upon contact with the hot substrate.

- Electrostatic Spray – Powder is sprayed using an electrostatic application gun. This is a common method used by powder coaters globally. Powder is positively charged either by a high-voltage corona or triboelectric friction. The charged particles adhere to grounded components. Parts can be coated at room temperature; however, thicker film builds are obtained when applying powder to preheated components.

- Electrostatic Fluid Bed – This is similar in construction to a standard powder fluid bed; however, the air feeding the powder chamber is electrostatically charged, creating a cloud of powder. The charged particles from the cloud adhere to grounded components. Parts are typically at room-temperature when coated using this method.

Step 3: Select the 3M Powder Resin that best fits the needs

What temperature will the coating be subject to? Is UL Recognition of importance? What dielectric strength is needed? What heating methods are available to cure the powder coating?

These are only a few of the questions that should be addressed prior to selecting a coating. The chart which begins on page 16 of the brochure will list a number of performance criteria that can help narrow down the product selection.

- The substrate to which the powder epoxy is being applied plays an important role in the adhesion performance of the coating.

- The 3M Scotchcast Powder Resins adhere well to carbon steel, aluminium and copper.

- Surface preparation, oxidation, existing insulation coatings and substrate alloy need to be taken into consideration.

- To obtain the best adhesion, substrate cleanliness is absolutely necessary.

- Alloy selection may have an impact on coating adhesion as well.

➡ More Electrical Insulation Products & Solutions from 3M Electrical | Fire Protection | Corrosion Protection | Repair Cables | Mastic Sealing Tapes | Shielding & Earthing | Cable Caps | Cable Breakouts | Re-enterable Resins | Cold Shrink Tubes & Products

Cable Joints | Scotchcast Resin Electrical Cable Joints by 3M Electrical