Heat Shrink Cable Joints & Cable Terminations | Manufacturers & Assemblers

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Although modern cable manufacturing technologies evolve and develop the essential factors to consider when installing heat shrink type joints or terminations on medium/high voltage power cable systems remain essentially unchanged. Materials quality allied with installation by competent trained Jointers is the fundamental basis to ensure reliability, safety and operational service of MV HV cables, joints and terminations.

Here, from the archive we reproduce an important Technical Article by Norman Poulter – Norman was the Managing Director of Shrink Polymer Systems, the UK’s leading specialist manufacturer and assembler of MV HV cable joints and terminations for standard and non-standard cable applications up to 33kV.

Today, SPS’s Managing Director Richard Poulter continues to support the UK and overseas market with the competitive supply of MV HV heat shrink cable accessories for all cable voltages including 11kV/33kV and types such as XLPE, EPR, PILC and Triplex cables.

Medium & High Voltage Cable Accessories

author Norman Poulter

Power cable installation throughout Europe and the UK until the early 1960s exclusively used impregnated paper for the primary insulation of the conductors for both single- and three-core MV-HV cables.

The UK adopted both aluminium and lead-sheathed cables with and without steel wire armouring (SWA); these are still in use today. In the very early days of paper-insulated cable terminations, dry-type systems were employed along with compound-filled end box designs and cast-iron boxes with hot pour bitumen for cable joints.

PILC SWA Paper-insulated Lead Covered & Steel Wire Armoured Cable

- Circular stranded copper phase conductors

- Conductive paper screen

- MIND paper insulation

- Metallised paper insulation screen

- Circularising fillers

- Lead sheath

- Bitumenised hessian bedding

- Galvanised steel wire armour

- Bitumenised hessian serving with whitewash coating

11kV PILC Cable

Cold shrink products such as push-on, pre-stretched tube and grease applied slip-on types also became popular in the 1960s and are still specified by specific electric authorities and utilities for terminating and jointing MV-HV cables.

In the early 1970s polymeric (XLPE) cable types began to emerge in Europe and the UK, mainly on three-core cables, while the USA employed the single-core cable concept at 10kV, 20kV and 35kV medium voltages.

The heat shrink concept began to be employed at this period by the utility companies and has now spread internationally as the preferred method of cable terminating and jointing.

There are many advantages of using heat shrink cable accessories and techniques, such as:

- Wide shrink ratio – one joint/termination kit assembly to cover numerous cable ranges

- Heat concept dries out moisture from the MV HV cables

- Mastic seals are activated by heat so sealants are usually visible at sleeve ends

- They are not size sensitive and can be used on sector-shaped conductors

Figure 1 – Cable Box Air Insulated Termination

Cable Joint & Termination Kit Instructions

Shrink Polymer Systems also realised the importance of good cable jointing and terminating instructions. By using pictorial drawings with a minimum of text, non-English speaking countries can identify the important highlighted areas in an easily identified format.

Cable Terminations 11kV 33kV – Instruction Excerpt

Failures are nearly always attributed to poor cable preparation by the jointer and failure to observe the correct jointing procedures in the areas where the electric cable stresses are prudent, such as the semicon screen cut back.

Although the USA shares a language with the UK, there are many differences in the selection of words to describe various things. Below is a list of some UK terminology and the common equivalent used in the United States.

- Core – Conductor

- Screen – Shield

- Joints Jointing – Splice Splicing

- Cable Jointers – Cable Splicers

- Earth Earthing – Ground Grounding

- Armour Support – Reinforcing

- Metal Sheaths – Armour

- Self-Amalgamating – Self-Fusing

Heat Shrink Cable Joints

& Cable Terminations

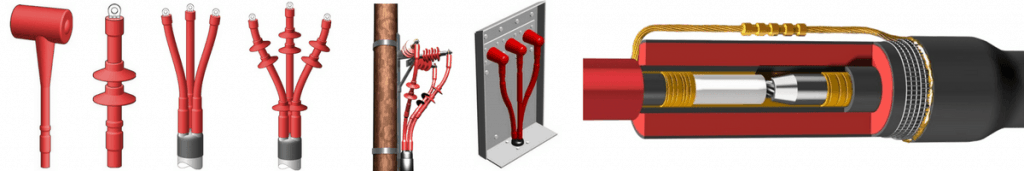

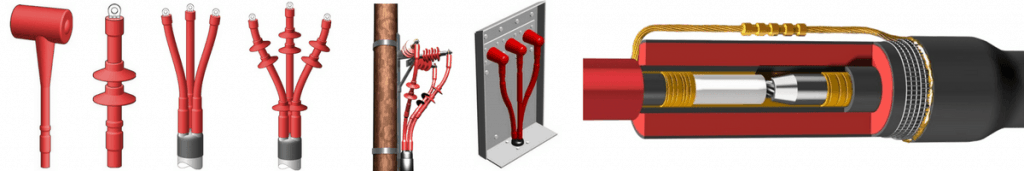

Terminations

Terminations | Indoor or Outdoor

The major MV HV switchgear and transformer manufacturers have, for many years, designed dry-air filled cable boxes, resulting in a much greater demand for heat shrink-on terminations.

All heat shrink cable terminations and joints have to be tested to various international standards, and while cables prepared by experts in perfect laboratory conditions will undoubtedly meet these requirements under test, field experience shows that failures still occur at working voltage due to a variety of reasons.

Typical List Of Weakness Resulting In Failures

Of Heat Shrink Terminations

- Compression lugs, or crimp lugs, fitted to outdoor terminations of the compression tube type with inspection holes allowing moisture to penetrate the conductor cores.

- Failure to eliminate air pockets on paper-insulated, lead covered (PILC) three-core “belted” cables in the crotch area.

- Core crossing resulting in discharge if cores are too close to each other in an unscreened area at the core cross point. This results in the air “breaking down” electrically at approximately 4kV on an 11kV cable, 6kV on a 24kV cable and 9kV on 36kV cable. The anti-track heat shrink material then begins to erode due to the ionisation of the air, which over time will inevitably cause failure of the cable termination.

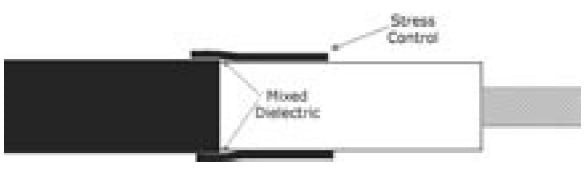

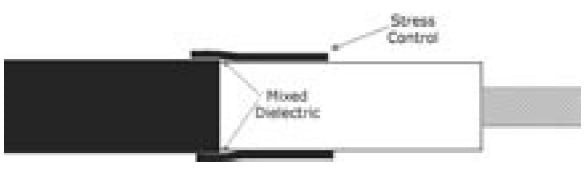

- Poor cable preparation, in particular on extruded dielectric types where insufficient care is taken on semiconductive screen removal at the crucial area of the screen cut-off. Cable jointers are generally reluctant to purchase engineered screen removal tools and rely on knives, blades and homemade tools for removal. This can result in cutting through the screen and into the primary insulation, leaving voids which result in the discharge phenomena described in the third item above. Even well-prepared screen removal at the cut-off point can result in a possible void, as the stress control tube may not follow the semi-conductive edge profile. (See figure 2.)

- Moisture penetration due to poor heat shrink and mastic sealing techniques.

- Inadequate phase-to-phase and phase-to-earth clearance.

- Tracking.

- Poor cable jointing instructions.

Figure 2

There are solutions and remedies to these weaknesses relating to MV HV cable accessories which will be described later in the article.

Joints

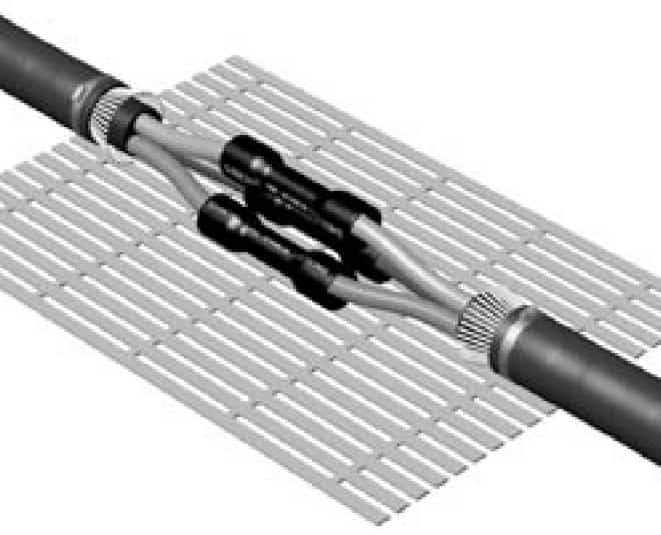

Many of the points discussed regarding cable terminations are also relevant to joints.

The object of the cable jointing exercise is to replace all the materials that were removed to joint the conductors and replace them in such a way as to replicate the cable as closely as possible to its original state.

There are many techniques used in conductor jointing from “sweating” the weak-back ferrule (normally associated with the original cast iron paper joints) to compression and the present popular “shear bolt” designs.

Connector jointing is a complex subject due to the variety of designs for copper and aluminium conductors in circular-solid, circular-stranded, and sector-shaped styles.

There is also the consideration of copper being jointed to aluminium, cables of unequal cross sectional area being jointed to themselves, and transition jointing where paper is being jointed to polymeric at medium or high voltages.

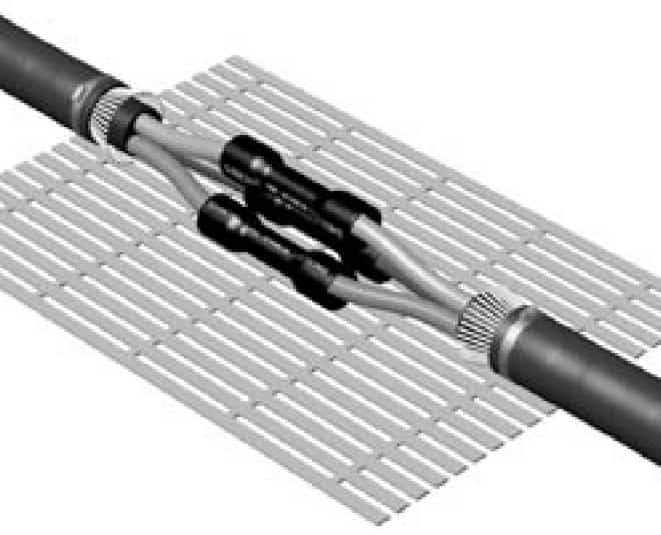

Figure 3 An 11kV 3 Core Heat Shrink Cable Joint

Let’s look at some of these designs.

Compression Connections – Crimps

There are a substantial number of manufacturers, such as Cembre, who specify suitability of their electrical connector design for voltages up to 33kV/36kV. Caution is needed if the body of the barrel is not smooth and does not have tapered ends.

Also, responsible MV HV connector manufacturers will be able to manufacture appropriate crimping tooling for their designs or confirm the compatibility of other cable tooling and die combination for their connectors. There are three types of crimping configurations currently in use: hexagonal, oval, and indent.

For instance, the Cembre HT131-C is the industry standard hydraulic crimping tool used by LV HV cable jointers to install copper type lugs and splices onto stranded cable conductors.

Oval and hexagonal crimping can leave sharp “ears” if incompatible tooling is used.

These “ears” must be filed smooth to avoid a highly stressed area which will be subjected to electrical discharge. Indent crimping will leave void holes which must be filled with high permittivity, stress relief tape.

Mechanical Connections – Shearbolts

Mechanical split type connectors are now very popular in the UK, as this design comes in two halves which are easy to apply to three-core cables at 11kV or 33kV where the cable conductors do not have to be bent. The heads shear-off at a given torque; therefore, no compression tooling or die combinations are necessary.

As this connector is “blocked,” it is also suitable for transition cable jointing for paper to plastic to stop the migration of the paper oils. There are several disadvantages of this type of connector, however. The ends of connector are non-tapered, resulting in high “step downs”, and the conductor insertion is non-centralised. (See figure 4.)

Figure 4 Mechanical Shearbolt Connector

These two conditions result in areas of high electrical stresses leading to probable discharge.

Shrink Polymer systems have now standardised on a shearbolt connector design where these critical areas of high stresses are removed by tapering the ends and centralising the conductor. (See figure 5.)

Figure 5 Mechanical Shearbolt Connector (Tapered)

Stress-Relieving Tapes

This type of stress relief tape generally has permittivity values between 7 and 13 (test method IEC 250). (See figure 6.) This does not necessarily mean that a value of 13 will perform better than a value of 7, as void filling characteristics are equally as important.

Figure 6 MV HV Connectors & Stree Relief Tape

Shrink Polymer Systems have a yellow stress control tape, reference number TS 31785Y, which possesses high tack, high stretch, and low viscosity void-filling qualities with a permittivity value of minimum 9. Whichever type of cable connector is selected, stress-relieving tape must be used in conjunction with heat shrinkable installations.

This is applied in a half width overlap with stretch by the cable jointer and must also be applied to any indents left by the tooling.

Gaps between end of primary insulation and connector must also be filled in.

Push-on molded components are also widely used, eliminating the need to fill voids and use stress tapes.

They rely on the Faraday Cage principle, in which conductive rubber-ribbed moldings are in contact with the connector. As the potential difference across the air is very low, discharge should not occur. Push- on molded components, joints and terminations have several disadvantages however.

On three-core cables the molded components prove to be very bulky and have no design features to eliminate moisture penetration unless used in conjunction with large diameter shells and resins. On large aluminium conductor sizes the ferrule could possibly be longer than the moulded component. The positioning over the ferrule is critical.

Stress Control Heat Shrink Tubing

Shrink Polymer Systems employ the heat shrinkable, high permittivity, and low resistivity stress control tubing which is shrunk onto the stress relief tape using heat applied by a jointers gas torch previously applied.

This has the effect of achieving a more uniform distribution of the field lines. This heat shrink tube extends over the ferrule or connector and onto the prepared screen cut-off points of the medium/high voltage power cable (See figure 2.)

Insulation Thickness

When designing cable jointing systems, the thickness of the insulation over the bare conductor (i.e. ferrule) should have a safety factor in excess of 15% of the original cable.

Shrink Polymer Systems employ a one-piece, combined dual wall (insulation / semiconductive) heat shrink tube of appropriate diameter to match this insulation at voltages to 11/12kV.

At 17.5kV, 24kV and 36kV additional heat shrink insulation tubes are added to meet these cable specifications.

The cable jointer must remember to shrink this material all around the heat shrink tube to avoid inconsistent wall thicknesses on full recovery.

Typical List of Weaknesses Resulting in Failures

- Incorrect crimping of connector.

- Air trapped in connector (if indent crimps not filled).

- Air trapped between end of insulation and end of connector.

- Discharge at screen ends caused by poor stress taping / cuts to primary insulation.

- Moisture ingress entering cable sheathing through poor sealing.

- Inadequate insulation levels over connector.

- Poor cable termination or cable joint kit instructions.

The solutions and remedies to these weaknesses are described below.

Earthing Cable Terminations

Earthing must be provided to carry any circulating currents to core screens, metal sheaths and armour wires. It must also have the ability to carry fault current. On indoor MV HV cable terminations the use of tin plated copper, solder-blocked braids, metal canisters, armour support, clamps and a complete corrosion protection system should be employed.

Figure 7 Low Voltage Heat Shrink Cable Joint For Multicore Cables

Earthing Cable Joints

Connecting the earthing components across a heat shrink cable joint requires correctly choosing and fitting the components to take care of both circulating currents and the short circuit requirements.

The outer semiconducting layer of the core/connector insulation should be wrapped in a tin copper mesh bandage and connected to the cable earth at each end.

There are a great many variations and earthing complexities and such a wide variety of cable types to consider.

Once a cable type, size, and voltage are specified it should be left to the manufacturer to supply the correct type of earthing system to meet both the national and local standards.

Remedies & Solutions To Overcome Cable Termination Failures

- Always use one-piece solid lugs for outdoor termination, not squashed tube type.

- Wrap butyl self-amalgamating tape around crotch and under lead cut on three-core belted cables to eliminate air. Check clearance dimensions on three-core cables.

- Care must be taken in semicon screen removal not to nick the primary insulation at the screen cut-off point.

- Ensure all mastic seals are in place on bushing boots, rain sheds and core tubes.

Remedies & Solutions To Overcome Cable Joint Failures

- Ensure cable connector is free from “burrs,” sharp points, not squashed tube type.

- Fill in all gaps with stress tapes before applying stress control tubing.

- Ensure correct application of stress tape at screen cut-off points. (See figure 2.)

- Fit all seals as supplied, in particular at crotch area, under armour beddings and end of connector insulations.

Cable Jointing & Terminating Instructions

It is the responsibility of cable accessory manufacturers to supply easy-to-read, simplified, pictorial jointing instructions and to avoid heavy reading of text manuals.

This point cannot be overstated, as, in the writer’s opinion, far too many jointing instructions are not read or understood, resulting in the installer compromising on the areas of importance previously mentioned. This all too often results in that first failure.

How Can We Help?

Since 1985 Thorne & Derrick have been servicing the UK and Export market with Joints, Terminations & Connectors for LV MV HV cables and power systems – call us to discuss your requirements including specialist LV cable joints for high performance applications including hazardous areas, marine and offshore cables, fire resistance cables and low smoke zero halogen cables.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

HV Cable Joints & Cable Terminations | Heat Shrink | 6.6kV 11kV 33kV Cables

The following LinkedIn Comments provide some expert guidance, insight and advice on how to avoid the dangers of substandard installation of heat shrink cable terminations on high voltage systems. Generally, when categorising voltages we include 11kV and 33kV power systems into the high voltage (HV) definition.

However contractors, manufacturers and the industry would also argue that 11/33kV should be classified as medium voltage (MV) and HV commences at 66kV.

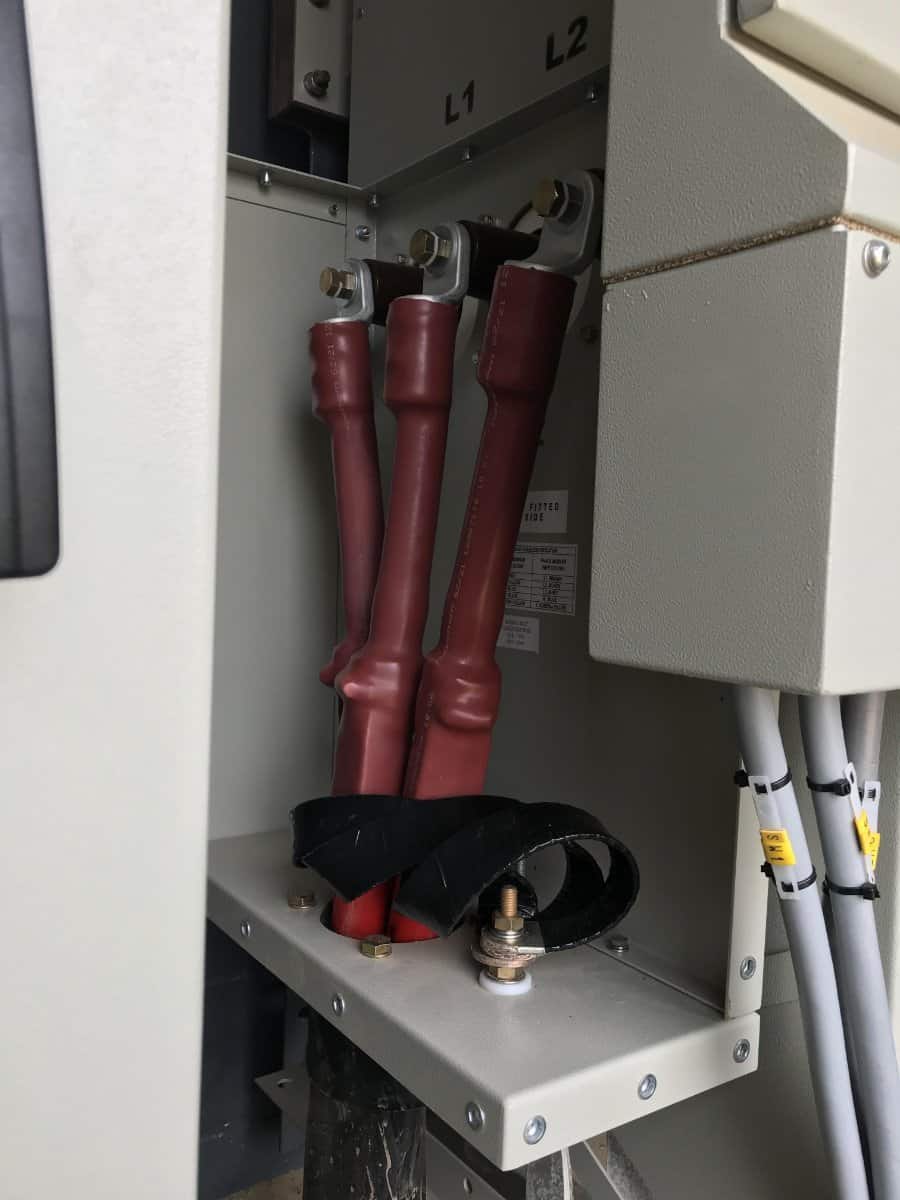

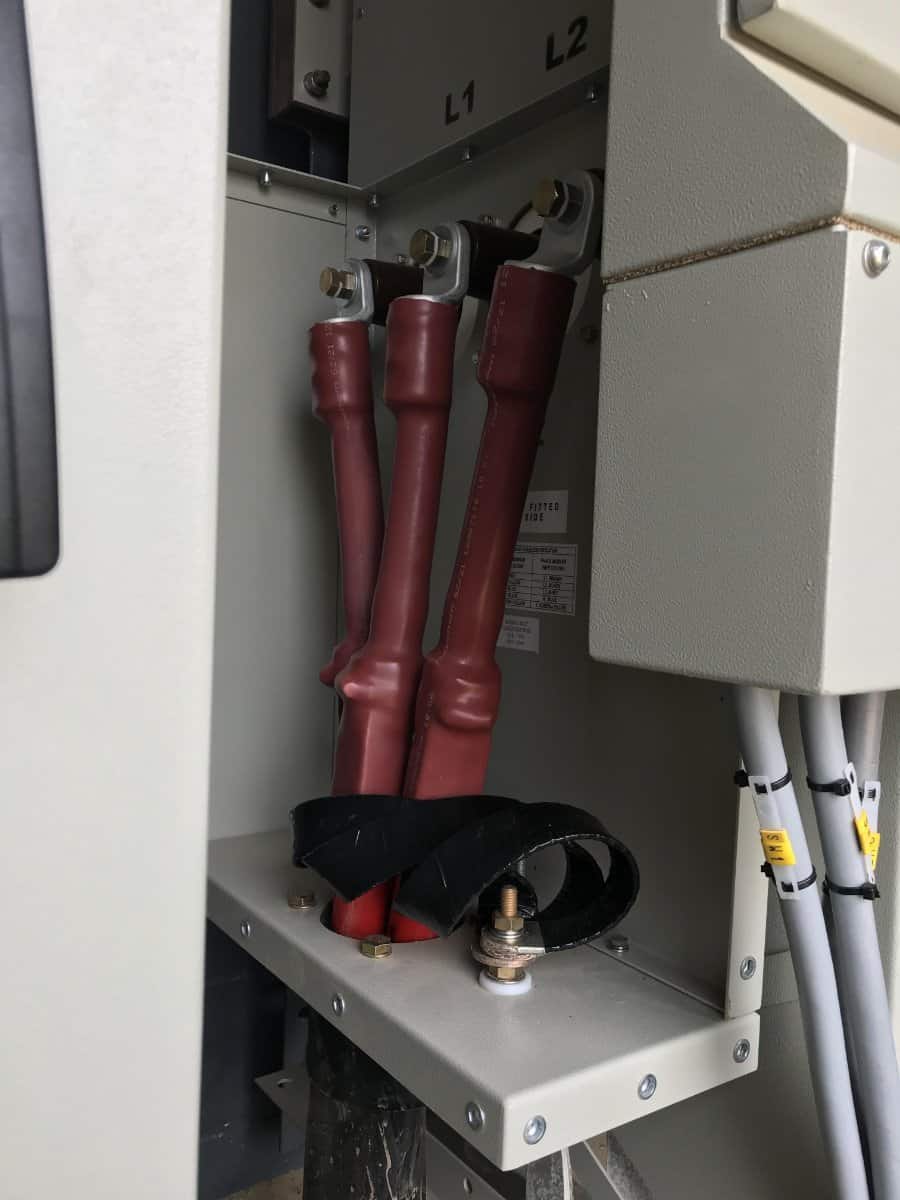

The Comments below were in response to the following site installation photograph of an 11kV cable termination. Let us know your thoughts and we will include to the thread in order to improve readers knowledge and reduce industry risk.

Scott Wilkie HV Power Distribution Engineer at Scottish Power – cable entry points through the cable gland plate would be better if centralised. Crossing cores with increased stress over insulation, clearly used to phase out the cable sections in the box. Would prefer to see 11kV single cores with a trifurcating joint outside of the cable box if that was possible.

♦ See: Cable Glands MV HV

Brendan Preece, P.E. HV Electrical Engineer – in addition to previous comment, use a high voltage two-hole compression lug that matches the two-hole terminal pad for good low-resistance metal-to-metal surface area contact.

♦ See: Cable Lugs & Connectors 11kV 33kV

Tony Haggis Director at Tony Haggis Consulting Ltd – the HV cable box is designed for single core cable terminations only. It’s impossible to use 3 core cable and maintain clearances between the cores – hence the black discharge marks. Not sure why anyone would use 3 core XLPE cable these days – single core triplex is cheaper and much easier to joint and terminate. Most UK DNOs and European utilities use it. There is no way to recover the heat shrink cable terminations other than cut all the cables out and replace with single cores with trifurcating joints outside. Also I’m amused by the use of the outdoor rainsheds – not only unnecessary but they also make the clearances worse.

♦ See: Cable Boxes HV High Voltage & Terminating 11kV Triplex Cables

Colin Woodman Team Leader & HV Cable Jointer DELPRO – I could be wrong but looking at it I am struggling to see where, other than down near the bottom of the heat shrink cable terminations, that the semi con screen had been cut and the mastic installed…cables must only cross where the semi con is still in tact. This is why HV cable terminations like this should be designed from the top down not from the cable strip up.

♦ See: Cable Jointing Tools

Tony Haggis Director at Tony Haggis Consulting Ltd – in view of Colin Woodman’s comment I’ve looked a bit closer at the picture and it could be salvaged by remaking the heat shrink termination using what we used to call a “crossed core” kit that we used to use with 11kV belted paper cable. This kit included heat shrink semicon heat shrink tubes that we used to screen the cores up to the stress control tube which was placed up near the cable lug.

Perhaps stripping off the existing cable termination and extending the core screen with semicon tubes could then place the stress control tubes up between the perspex phase barriers. I personally wouldn’t guarantee it as we don’t know what discharge damage has already been caused. If one was determined to use 3 core 11kV cable in this box then a top down screen off measurement would work but I would want the termination manufacturer’s view first. Looks like the semicon has been terminated taking a measurement from the crutch leaving unscreened core in the areas to be crossed.

I’ve always advocated taking the screen-off measurement from the HV cable lug thus leaving maximum screened core in the box. However, most termination manufacturers give a bottom up dimension but will give a top down dimension when asked.

♦ See: MV HV Cables 11kV 33kV

Michael White CEO at Campbell White – Colin you are spot on where a cross or a roll on end termination you must know creepage distance on these lineal stress terminations: on all Raychem terminations 90mm from top of black semiconductor heat shrink to open conductor then you can roll and cross on the semicon screen and have no trouble. There is no science taught these days on stresses and zero potential for cable jointers. I can understand third world jointers making mistakes but not educated ones.

♦ See: Cable Jointer Training Courses

Dan James MIET Technical Services Engineer – Senior Authorised Person at NG Bailey – complete mess. As suggested above this can’t be saved. Cut it all back, do a cable joint to single cores, get rid of them heat shrink sheds and perspex.

Richard Poulter SPS Managing Director – looks like a 33kV termination because of the phase barriers but more so the sheds per phase and the length of the stress control tubes which you can see the outline of below the anti-track tubes (they look about 260mm long). You can make out the semi-conductive screen ends because of the small bulge where the yellow stress tape is applied but most of the stress control tubes are fitted below this point rather than above it. So the majority of the stress tube is not doing anything.

I suspect the heat shrink cable terminations are fitted this low because the cable jointer was probably trying to achieve a distance of 250mm from the top of the stress tubes to the bottom of the lug barrels. The cable end termination box just does not look big enough for this voltage class termination, probably better to have used single core cable and they might have had a chance of achieving the cable spacings. Lots of discharge going on. That phase on the right looks like totally different anti-track but the intense heat has discoloured the other phases by the looks of things. Has it blown yet?

Maybe do a Trif joint below the cable box and take single cores in. If little space, use Raychem IXSU heat shrink kits or a cold shrink termination. Life expectancy is hard to pinpoint but there is a lot of discharge going on so they should schedule this within a week otherwise the damage will be a lot more. The temperature at the discharge can be as high as 1000 degC and once the carbon deposit increases on the cores, the quicker it will fail.

Andy O’Malley Allteck IBEW 258 EHV Cable Jointer/Splicer – they could have broke this 3 core cable into single cores outside of the 11kV box utilising jacket reintroduction kits and glanded the single cores individually and this would of been a perfect installation.

John Thompson High Voltage Cable Splicer – Okay, honestly it looks like hell. But let’s pick this apart. There are 12 cables in this picture (4 per phase). The 11kV terminations appear to be in some kind of a protected cabinet so they could operate for a length of time if this was some form of a temporary hookup. In my opinion this is more of an engineering catastrophe than a cable splicers mishap.

Joe Kinnane HV Electrician/ Transmission Cable Jointer With Western Power – they clearly needed to be “broke out” way lower than they have been with longer spaces between the stress point on the different phases! Heat shrink tubes weren’t pushed down fully on the breakout either.

- Application: 11kV Triplex Cables Terminated Onto Switchgear Bushings

- Cable Type: 11kV Triplex Cables BS7870-4.10 – 3 Core Cable High Voltage (HV) Power

- Cable Jointer: Watkins and Jacomb Construction Power & Consultancy

- Featured Product: Heat Shrink Cable Terminations 11kV

Heat Shrink Terminations

In order to safely and professionally prepare medium/high voltage cables a complete set of cable jointing tools are required to enable the stripping and removal of the 11kV triplex cable sheath, insulation and screen – this includes Alroc tools used by jointers for MV/HV cable preparation and Cembre tools to cleanly cut and crimp cables.

The jointers have used cable cleaning wipes to carefully remove debris, dust or contaminants from the Triplex cables to ensure the overall reliability of the 11kV heat shrink cable terminations.

Lucy Switchgear

11kV cables are shown terminated using heat shrink terminations into Lucy VRN2a SF6 Ring Main Unit with a 200A Circuit Breaker to UKPN specification – the Sabre range of RMU’s manufactured by Lucy Switchgear are non extensible ring main units for outdoor high voltage substations. Along with low voltage distribution cabinets, these RMU’s can be easily coupled to the distribution transformer forming a compact outdoor package substation.

The 11kV heat shrink terminations are crimped using mechanical shearbolt cable lugs and bolted to the interface bushings of the air insulated cable box.

Terminating Triplex Using Cold Shrink

Here, the 11kV Triplex cables are shown terminated into a high voltage cable termination box using 3M Cold Shrink terminations – the concertina style bushing boot is cold-applied and suitable for both straight or right-angled 11kV switchgear connections, part code 3M 92EE717-1.

The bushing boots insulate the cable lug connection onto the bushing interface located on the electrical equipment. The Triplex copper wire screens are shown bonded to earth using brass mechanical shearbolt cable lugs.

The unarmoured Triplex cables are provided with mechanical cable retention and moisture ingress protection using heat shrink cable glands – the glands provide a watertight and fume-tight cable seal where the Triplex cables enter high voltage connection boxes, switchgear, bulkheads, or other enclosures.

The HV cables are cable ducted within the hot zone and a stand-off insulator is mounted in each HV cable box. The cable sheath is shown terminated to an earth bar mounted onto the stand-off insulator.

Image: NPG Northern Powergrid

Triplex Cable Sheath Earthing Arrangement 11kV

Should you require any assistance with the selection or specification of 11kV triplex cables or 11kV cable lugs please do not hesitate to contact us.

♦ Also 11kV : Nexans Connectors | Pfisterer Plugs | 3M Joints & Terminations | Ellis Cable Cleats | Duct Seals

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog.

IMCORP – Providers of Factory Grade® technology, bringing MV HV power cable and accessory manufacturers’ QC reliability to field installations worldwide.

by Chris Dodds T&D - estimated reading time 5 minutes

OVERVIEW

0.1 Hz VLF test and IMCORP’s Factory Grade® technology are compared side-by-side at utility solar site

CHALLENGE

VLF test passes cables, but cable terminations were still failing

RESULTS

Based on distribution system experience, utility uses IMCORP’s Factory Grade® technology to identify workmanship defects and VLF test induced damage

A utility client of IMCORP asked them to commission medium voltage cable systems at a new generation facility after experiencing several MV  cable termination failures.

cable termination failures.

The cable installation contractor had already tested the MV cable systems with a very low frequency (VLF) test.

Uninformed contractors often make a claim based on a common myth that ‘proper’ VLF testing would detect serious MV-HV cable defects while not harming healthy cable insulation or aggravating minor defects.

In addition, the misguided claim often states that passing a VLF test means the medium or high voltage cable system will deliver years of trouble free service.

Wrong.

Unfortunately the owner initially believed these commonly held myths, energised the MV power system and subsequently experienced several catastrophic failures that damaged switchgear, costing them significant down time and losses in generation revenue.

Substandard MV HV cable jointing and installation necessitated the replacement of multiple HV heat shrink cable terminations after a succession of in-service cable termination failures.

Pictured opposite the heat shrink anti-track tubing has been removed shown the tracking between the medium voltage heat shrink and XLPE cable insulation.

The IMCORP Factory Grade® technology pinpointed dozens of MV cable terminations that did not meet the accessory manufacturer’s minimum performance standards.

When the cable terminations were dissected the technician not only found cable jointer workmanship issues, including insufficient shrinkage of heat shrink layers, but clear evidence of damage caused by the VLF test that passed the medium voltage cable terminations a short time before.

Ben Lanz (Director, Applications Engineering at IMCORP) comments, “a VLF test passed this heat shrink termination. An offline 1.5Uo 50/60Hz PD partial discharge assessment with 5pC sensitivity identified this MV cable termination which is why we have the picture. The original installation defect and VLF test damage are plainly visible. This case along with many others is the reason IMCORP recommend a factory comparable PD test for critical medium/high voltage power installations and QC spot checks for newly trained cable jointers and installers of MV-HV joints, terminations and connectors. I acknowledge that a VLF test was the best the utility and power industry had 10 years ago but with the evidence we have now, I generally don’t recommend going over the operating voltage with a VLF test since it can not find most MV-HV cable detects found by a factory comparable PD test.”

The 2 most serious cable termination anomalies were small voids on the medium voltage XLPE cable insulation shield interface and “fall-in” cable insulation problem at the conductor shield interface.

Could a failure to remove the semicon screen from the XLPE insulation of MV-HV cables contribute to this type of cable failure?

Here, the semicon screen was removed sufficiently from the MV-HV cable using correct cable jointing tools. Most likely the VLF test burned a track in voids caused by insufficient void filling mastic at the semicon cutback and/or insufficient shrinking of the heat shrink tube with the green zinc oxide (ZnO) stress controlling layer on the inside of the cable termination.

MV Cable Termination Failures

Here, failure of the heat shrink stress control component of the cable termination was poorly placed in relation to the semi-conductor screen cut causing termination failure of the substation cables linked to a generation plant on an onshore windfarm.

Manufacturers Standards

| Component Standard |

Testing Frequency |

Sensitivity |

Voltage |

| Cable Terminations IEEE 48 |

50/60 Hz |

5pC |

< 1.5 Uo |

| Cable Joints IEEE 404 |

50/60 Hz |

5pC |

< 1.5 Uo |

| Separable Connectors IEEE 386 |

50/60 Hz |

5pC |

< 1.3 Uo |

| MV Extruded Cable ICEA S-97/94-682/649 |

50/60 Hz |

5pC |

< 4.0 Uo |

| HV EHV Extruded Cable ICEA S-108-720 |

50/60 Hz |

5pC |

< 2.0 Uo |

Reducing Cable Termination Failures

Of course site standards and international working procedures vary but the following professional advice has universal methodology:

“There are three main components to reducing the risk of failure during the infant mortality phase of an installation’s life (bathtub curve): 1) Have policies that ensure you only procure high quality equipment 2) Ensure that equipment is installed by qualified, trained and experienced personnel who work to high standards 3) Commission it thoroughly with a view to exposing flaws and weaknesses and then correcting them. As has been proven many times before, thousands saved today may cost you millions tomorrow.”

Jason St Martin (Senior Electrical Inspector at DMIRS Building and Energy State of Western Australia)

Thorne & Derrick International

Cable Installation, Jointing, Substation & Electrical Equipment Distributors

Since 1985 T&D have serviced UK and international businesses involved in cable installations, earthing, duct sealing, jointing, substation, overhead line and electrical construction at LV, MV & HV.

Our customers are contractors, specifiers and end-users involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, MV & HV.

Medium voltage power cables can fail for several reasons – pictured below is a common installation error near the outer semicon screen cutback by the cable jointer on the heat shrink cable termination – the highest electrical stress point in an open air cable termination.

To prevent this IMCORP recommend MV HV Jointer Training coupled with a factory comparable partial discharge test after installation to provide feedback to the cable installer – 50/60Hz offline PD test with better than 5pC sensitivity.

Partial Discharge (PD) at the crossed cores of the HV cable causing failure of the heat shrink cable termination

cable termination failures.

cable termination failures.

Evan Paul Galleozzie Approved Electrician – bad design of the entry of the 11kV cables which has resulted in a mess of the cable terminations. And a few of the the cables look in a poor condition. And the CPC’s could have been installed properly using crimping tools, too much copper showing. Bad, bad, bad.

Christopher Williams Head of Services and Support at IPEC Ltd – looks like a severe case of surface tracking on the heat shrink cable terminations (a form of partial discharge). This is likely caused by the inadequate installation of the feeder cables increasing the electrical stress across the surface of the high voltage cable insulation. Any dirt/dust/contamination would then have helped create small electrical discharges across the insulation causing the carbonisation you see in the image. Over time this will compromise the insulation further, finally resulting in a catastrophic failure. Interestingly, this could have been detected via PD monitoring, in this case, ultrasonic emission would have been emitted and sensors could have detected the inception and location of this defect long before it got to this stage!!!

Thorne & Derrick

Suppliers of HV Joints, Terminations & Connectors

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

Thorne & Derrick stock 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.

Stockists & Distributors of High Voltage Joints Terminations Connectors