Arc Flash Protection

Understanding Arc Flash | Core Body of Knowledge for the Generalist OHS Professional

July 30th, 2021Republished by Kind Permission of The OHS Body of Knowledge – The OHS Body of Knowledge (OHS BoK) is the collective knowledge that should be shared by generalist OHS professionals to provide a sound basis for understanding the causation and control of work related fatality, injury, disease and ill health (FIDI). This knowledge can be described in terms of its key concepts and language, its core theories and related empirical evidence, and the application of these to facilitate a safe and healthy workplace. The OHS BoK has been developed for the Australian OHS context but has international application.

Source is Australian Institute of Health and Safety

Uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick UK

Authored by | Brett Cleaves, Director, Engineering Safety Pty Ltd

Peer Review by | Vanessa Garbett, Team Leader, Electrical Installation Safety, Energy Safety Victoria, Australia

Acknowledgements to | The Australian Institute of Health and Safety (AIHS) financially and materially supports the OHS Body of Knowledge as a key requirement of the profession. The Australian OHS Education Accreditation Board influences, supports and monitors the OHS Body of Knowledge.

Second Edition, 2019

The Understanding Arc Flash Document includes a content page as follows:

Table of Contents

A1 Introduction

A1.1 Some electrical terms

A2 The extent of the problem

A3 Understanding arc flash

A3.1 Electrical arcs

A3.2 Arc faults, arc flash and arc blast

A3.3 Impact of arc flash

A3.4 Arc flash and nature of work

A4 Risk assessment

A5 Legislation and standards

A5.1 Legislation

A5.2 Standards

A6 Control of arc flash hazards

A6.1 Elimination

A6.2 Substitution

A6.3 Engineering controls

A6.4 Administrative controls

A6.5 Personal protective equipment (PPE)

A6.6 Resilience of controls

A7 Implications for OHS practice

A8 Summary

List of Figures

Figure A1 Arc flash and arc blast

Figure A2 Electrical work and arc flash

Figure A3 Prevention and mitigation of arc flash hazards

List of Tables

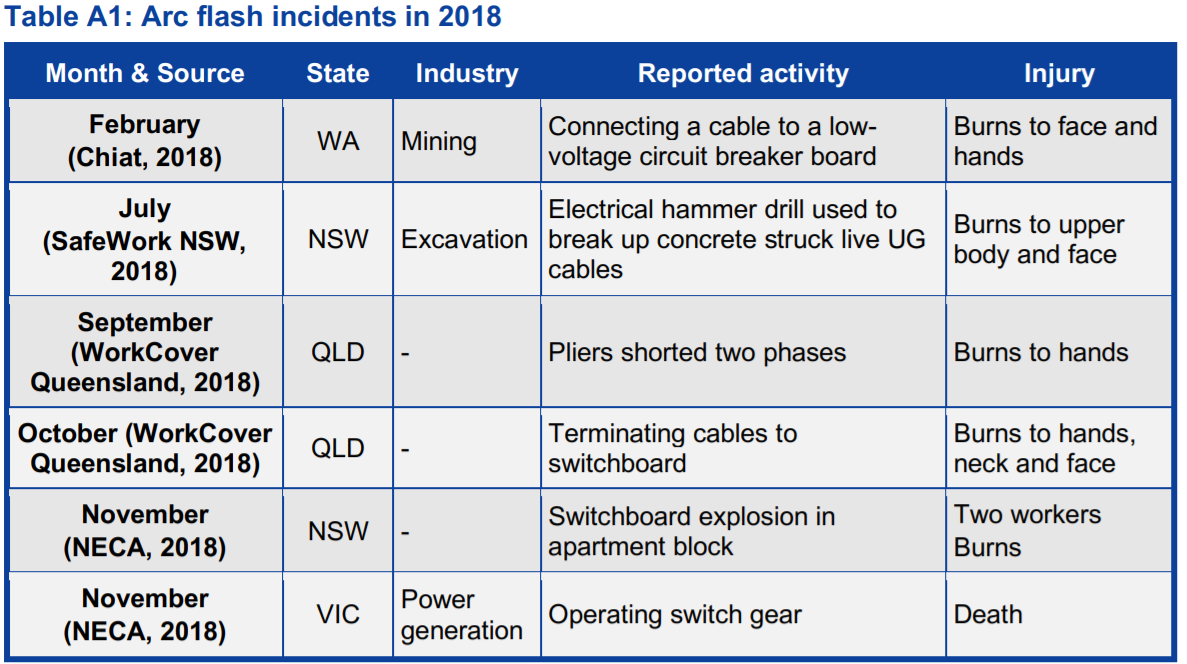

Table A1 Arc flash incidents in 2018

Table A2 Risk factors for arc flash

Table A3 Control options for arc flash

Table A4 Examples of impact of organisational context on implementation of arc flash controls

Abstract

This appendix to the OHS Body of Knowledge Chapter ‘Physical Hazards: Electricity’

focuses on the electrical hazard of arc flash from the perspective of the generalist OHS

professional. After defining relevant terms, examining the incidence of arc flash injuries and

reviewing relevant legislation and standards, it considers options for control of arc flash and

implications for OHS practice.

A1 Introduction

The OHS Body of Knowledge chapter Physical Hazards: Electricity presents information required by generalist OHS professionals to enable them to better understand the nature of electricity as a hazard, how it can harm the human body and the standard control measures.

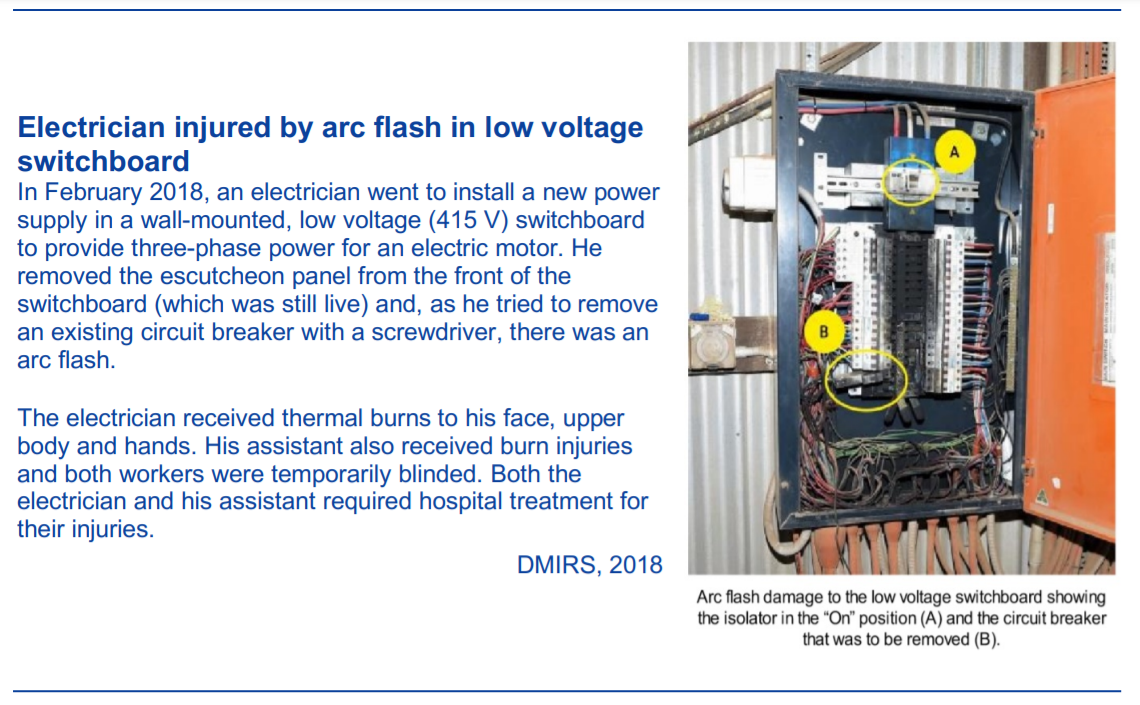

The chapter emphasises the severity of potential consequences of an electrical incident, noting that several deaths by electrocution occur in workplaces across Australia every year. This appendix focuses on one particularly dangerous type of electrical hazard – arc flash – the consequences of which can range from inconsequential to severe burns and death as well as power outages, fire and significant property damage.

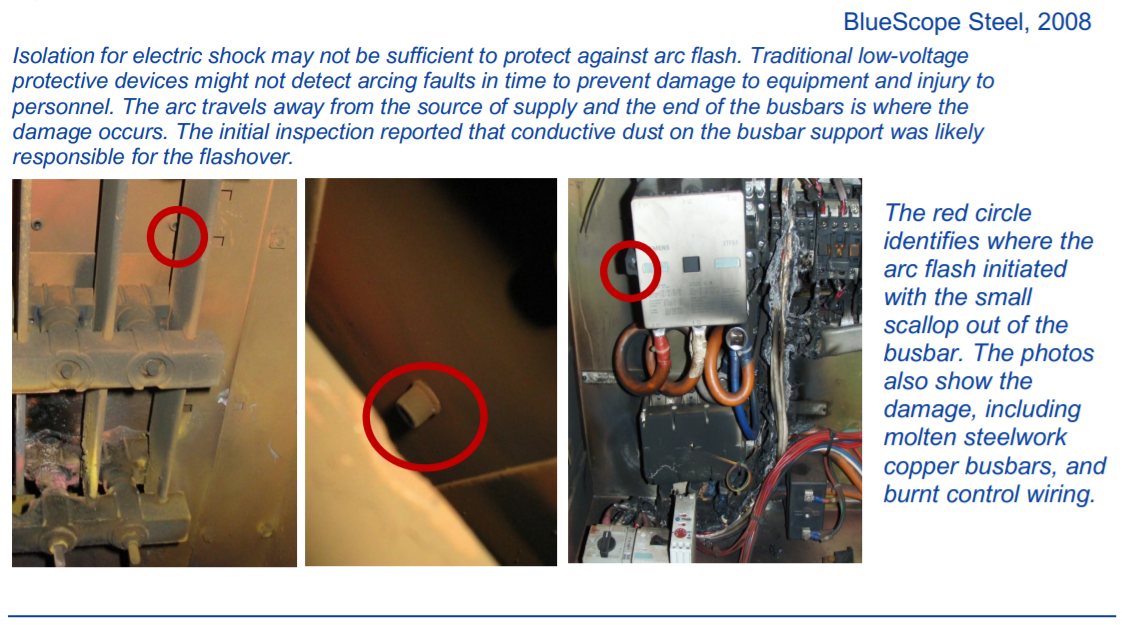

While arc flash is associated with electrical work, and may be considered a specialist topic, all workplaces have electricity and so arc flash hazards are of pervasive relevance. With the introduction of metal clad switchboards from the mid-20th century came the practice of switchboard arc flash containment and testing, and it was not until the 1980s that arc flash hazards were first quantified.

Consequently, knowledge of arc flash hazards, the risk factors and the mechanism of injury causation is still evolving. The dynamic nature of this knowledge is reflected in the existence and use of different standards and terminology across countries and organisations; this inconsistency can present problems for generalist OHS professionals working with electrical personnel to implement a risk management approach to minimising arc flash.

To Receive Your Free Copy

of the Full Report

Please Email

[email protected]

Meet the Author, Brett Cleaves BE(Elec)

Director, Engineering Safety Pty Ltd

Email: [email protected]

Since starting as a cadet with BHP in 1993, Brett has worked in steel mills, mines and electrical utilities, executing a range of duties in maintenance, engineering, governance, production and project management.

He developed a strong commitment to electrical safety, and received BlueScope awards for leadership and engagement. In 2013, Brett established Engineering Safety through which he provides project management services for a range of electrical companies together with general advice on electrical safety to industry.

At the leading edge of hazard identification, assessment and control for arc flash in Australia, Brett is a strong advocate for the need for knowledge of arc flash to evolve to provide clarity on the most appropriate practices and controls.

A Transcript | Arc Flash Survivor Story by Jason Brozen

July 29th, 2021➡ Read the original story here: Arc Flash Survivor Story – Jason Brozen

Let’s Hear Jason’s Survival Story

‘You know I ended up working on a big piece of gear, 2500 amp, it was a hotel and we got dispatched to install a new circuit for some pool equipment, a 200 amp breaker and we had to fit it in a spot that was sized for 200 amp breaker. But inside that space there’s a GE piece of equipment. They coat the bus bar in tape you know from the factory so spent a lot of time meticulously cutting that tape off while it was hot with no gear on because I’d done it before successfully and uh and I got through that process but I did call my boss to say “man this is pretty precarious here you know we might want to shut it off” and he didn’t encourage me to shut it off. So, you know as a boss now also working as a project manager now I encourage my guys to shut it off.

So, fourth section, uh it’s 208 uh which really kind of squashes the industry-wide misconception that you can’t have an arc flash of any substantial value in 208. So this was not even in the main section it was in a branch section. 2500 amp sections you know, 2500 amp gear, transformer was really close, uh 500 kva transformer. Anyways a four-section piece of GE gear, pretty standard in the industry lots of people use that um so 2500 amp main plus a bunch of branch sections three branch sections. I needed to install a 208 breaker in one spot so on that specific spot I just took the above on it and below pieces of dead front off instead of removing the whole dead front because i thought that would be safer. I mean it turns out it was a good decision it probably saved my life. As you can see in the pictures, you know a lot of the heat rolled up and that acted as a shield. There’s no doubt it would have you know burned my face off at that point but yeah I mean it’s just a standard thing that most guys do. They’ll take a box out of a you know, a breaker out of a box you know they’ll inspect it and turn it on and off a couple of times and then they’ll go you know fitting it in the gear and they’ll stick in that driver and bolt the thing in and they’ll do it hot and they do it every single day and 99% of the time they’re successful at it.

So, the second the arc flash happened I knew what was going on just because I mean it’s you know like most electricians that have been in the field for a long time have YouTubed arc flash, have seen all the nasty videos of all the arc flash events they can possibly see. Usually, some guys can’t do it but uh and so I’d been deep in fp70. I understood it, you know I knew better than doing what I was doing.

But anyway, to get back to it, so I knew what was going on, the arc flash was happening and I could feel it and as soon as the noise stopped because i can just you know describe it as just noise because it’s just you know an explosion, it’s going on. It’s just a millisecond but as I said before you slow down as soon as the noise stopped all the lights were out and the room is filled with smoke and I couldn’t see.

The very first thought was “am I on fire?” because I’d seen so many different videos from different vendors uh from you know arc fault or arc flash clothing you know arc rated workwear, where they show this kind of workwear and the mannequins on fire head to toe. So that’s the very first thought was “oh my god am I on fire” so you know just started you know kind of the vertical drop and roll type thing and then I saw a door a light crack open because somebody from the hotel management opened the door because they heard what was going on. The fire alarms are all going off and once I saw that, I was able to exit the room and then kind of gather my thoughts and see and then you know look at my hands and there was a bathroom I wanted to see what my face looked like and I just kind of assessed the damage. I’m not a real panicky guy, I don’t flip out with accidents and stuff uh I’m sure there was a level of shock of course.

Honestly, I thought after the accident I go yeah that’s pretty bad i was looking at my hands but I thought ‘a couple months’ you know I never thought I’d need skin grafts and be in a coma and sick and ICU for two weeks and off work for seven months. I never in a million years would have thought that.

The thing with burns is the first- and second-degree burns hurt and third-degree burns don’t. They burn your nerves you know and so my hands, there’s parts of my hands that hurt, they’re real tight because the burn just shrinks everything up. Uh my face was real tight and it was a little painful but it was 40 out so it was pretty cool and so it felt you know okay.

And then you see on the video man I started making calls. I called my boss you know and said ‘you need to get out here now! I blew this up it’s really bad I’m injured you know you gotta mobilize, get somebody here it’s bad’ and uh and I’m sure there was a level of panic in my voice to him because he recounts later that you know it was pretty panicked.

Uh then tried to call my wife, you know, couldn’t get a hold of her. I call her mom, say look I’m on my way to the hospital I got burnt pretty bad I’m going to KU Med so then as you saw the fire department worked on me there and carted me off you know to the hospital. Really the last thing I remember at the hospital was triage it was them just cutting clothes off, you know getting IVs set, cutting that ring off and then it’s gone. That’s it they put me out they know gave me something I was out and then that’s when they de-breed you and you always hear the stories where they oh you’re wide awake and they’re scrubbing you. That wasn’t my experience they put me out. Uh my expectation is they would put anybody out, but I’ve heard stories where they don’t uh so they de-breed which means they wire brush and you know scratch all the dead skin that they can get off. You know face, they shave your head they put me in a room, they put me in a coma for two, three, four days, something like that. I do remember coming to, it was probably two or three days somewhere at the end of that period.

The stories that you won’t hear from most arc flash guys are like the PTSD stories or the ‘I’m at a hospital bed and it’s a nurse change and there’s nobody around and I’ve got a 105-degree temp and I’m about to crap on myself and there’s nobody around to help me and you’re just like ‘hey’ there’s no button. And you’re like ‘hey’ you know and you crap on yourself.

Those are the stories you don’t hear about when guys aren’t in the hospital beds. It’s the stories you can’t work in that field anymore it’s these kinds of things and we talk about that later. But anyway, so yeah, I remember kind of coming to, had a bad fever uh infection is almost 100 guaranteed with burns because it’s just an open organ essentially. It’s open sores uh so you catch stuff. Especially guys that jump into ponds or stop drop and roll in the dirt you know whatever. So that hospital stay was largely just me being high on you know painkillers and getting a feeding tube as they don’t want you eating so they’re just feeding tube you and uh IV your liquids and you’ve got a tube stuck in your you know what and you’re peeing in a bag and it’s pretty uncomfortable.

And after a couple weeks you know, you’re ready. They got me into, I’m gonna say I had surgery I think on the fourth or fifth day because they go and the skin starts dying so they have to go pretty quickly and make that skin fresh cut it off your legs and stick that new one on there and staple it on.

Then they put you in and they were trying some new things, put my hands in bandages like this so that it would stretch and so you’re in there for days like that. But probably day six they unbandage me and I’ve got pictures of that you know that was the day they unbandaged me. And uh almost immediately they start getting you into therapy and also trimming excess skin that’s not sticking so every day you’re in there they’re snipping pieces of skin off that are tags that are hanging up that aren’t attaching or they didn’t attach. It’s still raw too so every day was that and then you know I could move my hands like this you know when I first got you know even after having this they just open and I couldn’t you know couldn’t bend. Real swollen you know that kind of stuff so uh recovery in the hospital was you know slight because the real work is for months after that you know. One thing I can tell you too is they use a yellow uh Vaseline covered kind of a canvas, uh Baxter band I think maybe is the name of it, but unfortunately my skin grew into it as they had that on there so part of my worst memories in there’s sitting under a sink and having to tear this off of a burnt hand.

It was stuck in my skin and it healed in there already and I just, oh my god it’s one of the worst. It’s probably my worst memory in there is dealing with that.

So, another thing uh that’s probably my most vivid memory of being in the hospital secondly is having to have nurses come in and wipe your butt. Your hands are, you can’t you can’t even take care of yourself you’re in there you can’t take a leak on your own you know. When they finally did pull a catheter out which again is another memorable moment uh that’s brutal. That is brutal.

So, you know there was just, starting from the hospital out you know there was trying to button shirts and put pants on and you can’t drive and you’re stuck at home and you know you’re pretty much a burden. And again, this is just 14% man. This is hands and face this isn’t arms this isn’t legs I mean my legs hurt uh you know from the graft site that was super painful but not permanent but super painful. Like I can’t even, it was worse on my hands just the graph sites so it’s 14% you know.

I got a fat head so I’m not sure how much of it was here opposed to here but you know it stops at the wrist right here on each side just past my watch and then face. Now face I didn’t get a, it largely was not third degree, I was largely just a deep second and with little spots you know of stuff where my hands were totally smoked. I mean second degree burns on my palms and then third on the back. You know the required skin grafts throughout my entire back of my hands, it’s pretty intense I wouldn’t recommend it you know. I went right back to doing what I was doing you know. It didn’t scare me out of the field.

Some guys aren’t that lucky you know. They you know they can they can lose a lot. Some of the things I tell people is you know you don’t expect the you know getting your butt wiped by nurses you know or helping people dress you. But like me, I had a wife, two kids – still do you know. When you lose the ability to support your family, as a man and speaking as a man, that’s a killer man it is not just a physical injury, it is a mental and emotional injury as much as anything.

So you can carry PTSD you know with you from explosion injuries uh but man if you can’t go back to work, and you just you’re sitting around you know I mean its depression is a major deal when you were injured and you can’t go back to work. You can’t get away from an arc flash. It’s too fast it’s instant. You get burned. You’re done. Yeah it’s an instant thing. It’s an instant mistake that you can’t, you can’t change.

So I’m Jason Brozen, got arc flashed over 10 years ago and the one point I’d tell you is don’t be me.

Plan your work – work your plan. Follow through with that plan and do not make exceptions on anything when it comes to safety.’

On LinkedIn, Jason said of his experience ‘Recently I have had a lot of exposure to my arc flash story. One thing that is misunderstood is how intense the instant heat is. Here is a picture of my watch that I was wearing. An arc flash only takes a split second to ruin your life and possibly your family’s. Do not take chances. You have the right and responsibility to turn it off. If not for you, do it for your family, your employer, and your customer.’

The watch Jason was wearing when the accident occurred.

PROGARM, THE ARC FLASH SPECIALISTS

Arc Flash Protection | Arc Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Helmets | Gloves

Thorne and Derrick distribute a range of LIFESAVING Arc Flash Protective Clothing from ProGARM – the leading UK manufacturer of high quality Flame Resistant & Arc Flash clothing, garments and workwear.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

“At ProGARM our mission is protect lives through the manufacture and supply of exceptional quality Arc Flash and Flame Resistant Clothing. Being the only specialist Arc Flash protection manufacturer in the UK we focus on providing the best protection possible to those who work at risk of Arc Flash on a daily basis with our inherent, specialist garments and industry-leading innovation. Supporting Utilities, Power Generation, Rail & Petrochemical industries we work with Thorne & Derrick to educate, inform and supply those who work at risk everyday allowing us to keep protecting lives throughout the UK & beyond.”

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Closing Thought – statistics show that between eight and ten arc flash accidents occur in the UK every week. Protect yourself, contact us to learn how.

RIS-3279-TOM Standard | Hi Vis Protective Clothing Against Arc Flash for the UK Rail Network

July 29th, 2021

Hi Vis Protective Clothing

Protecting Workers Against Arc Flash Risks Using Clothing & Garments

RIS-3279-TOM Standard

Arc flash risks are becoming more widely recognised as a specific cause for concern to those working in the rail industry, over and above general electrical incidents, although there is still work to do on raising awareness of the Arc Flash risks in the rail industry.

An Arc Flash incident can occur any time people are working with electrical components. For the rail industry there are particular risks around working with electrical services and also when breaking ground.

WHAT IS RIS-3279-TOM?

RIS-3279-TOM (formerly GO-RT 3279) is a high visibility standard that only applies to the rail industry in the UK, as opposed to the EU-Wide nature of other EN standards. The aim is to ensure that rail workers on or near the trackside are sufficiently visible to trains approaching at speed or any other traffic.

The background fabric, retro-reflective material and design of the garment must meet the requirements of the European standard for Hi-Visibility clothing EN ISO 20471, with fluorescent and reflective areas meeting a minimum of Class 2, based on a classification system from Class 1 to Class 3.

RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4693

SUMMARY OF THE RIS-3279-TOM STANDARD

High visibility clothing is the fundamental principle behind the UK Rail Industry Standard.

This is based on the European Norm EN 20471:2013, and garments must comply to Class 2 High Visibility, the middle of a three class range. The standard states the following: ‘high visibility clothing worn by people on the lineside or on or near the line should conform to a single standard for the colour and luminance of background material and that this standard will accord with the detail contained within BS EN 20471:2013 high visibility clothing – Test methods and requirements (ISO 20471:2013).’

Stated in the standard is that: ‘the colour specific requirements within this standard conform to the range specified within BS EN 20471 clause 5.1.2.’ In order to confine this to a specific orange colour, and to prevent the selection of a colour at the red end of the spectrum, the precise chromaticity co-ordinates for the colour are specified as: Fluorescent orange, X:0.588, Y:0.371. with a luminance factor of at least 0.4. The accepted tolerance in colour is as laid out in EN 20471. However, there is no tolerance for the luminance factor.

Also stipulated in RIS-3279-TOM is the need of retro-reflective materials, with photometric and physical performance aligned with EN 20471.

Mentioned in RIS-3279-TOM is the accepted use of a mini vest where the nature of the work being carried out will not obscure the high visibility clothing, and thus reduce the surface area’ that is visible. The same applies to company logos; these are permitted where they do not compromise the surface area of background colour, and compensation may have to be made for this.

Cable Trough – Network Rail Approved Elevated Trough LV HV S&T Power Cables

ARC FLASH RISKS SOLUTIONS: ESPECIALLY FOR RAIL

A wide range of our personal protective clothing is available in orange high viz, conforming to the new 2018 RIS railway specification.

All of our clothing is lightweight and breathable, ensuring worker comfort while also providing protection when workers are subject to Arc Flash risks. We use a variant of our VXS+ fabric which is tested to European standards, and all garments display an at-a-glance SafetyICON label so it’s easy to see what protection is offered.

Our orange high viz trousers and coveralls are available in male and female versions to ensure the best fit and maximum comfort. We have also designed waterproof salopettes, polo shirts and two jackets in the regulation orange high viz. Two types of helmet with visor are available, depending on the voltage.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- Arc Flash Risks In The Rail Industry

- NEW PRODUCT LAUNCH | RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4693

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Thorne & Derrick International supply arc flash clothing and protection equipment including coveralls, gloves, helmets, face shields and general head-to-toe PPE is used to protect against flashover – complete range of insulating matting is also available for worker protection when exposed to energised electrical switchgear and transformers.

Typical applications include LV, HV & EHV cable jointing and terminating, fuse pulling, switchgear commissioning, racking circuit breakers, electrical switching and live working on medium and high voltage electricity networks.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable cleating, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Electrical Safety Equipment & Cable Accessories for the Maintenance of Low, Medium & High Voltage Power Systems

Thorne & Derrick Appointed Official Distribution Partner for UK Leading Arc Flash Clothing Manufacturer

July 29th, 2021

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Press Release | 1st August 2021

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Official Distribution Agreement with ProGARM, the market-leading arc flash clothing manufacturer.

We have partnered with ProGARM to service and protect renewable, rail, oil/gas, data centre, battery storage, street lighting, smart-metering and utility workers.

“Together, we are leading an electrical safety awareness campaign to reduce preventable life-changing, life-threatening injuries by educating about risk – we will support clients to protect their workers through the everyday wearing of comfortable and practical arc flash workwear as a last line of defence against arc-related incidents. We can provide wearer-trial garments for you to field-test and experience the exceptional physical performance and market-leading protection that ProGARM clothing can provide to your workers,” says Chris Dodds (Sales & Marketing Manager with Thorne & Derrick).

“Everyday our customers face safety hazards, but arc flash is the most devastating and deadly electrical danger present in today’s workplaces – the explosive deafening and blinding fireball effects of an arc-flash blast can unleash metal-vaporizing temperatures.”

“Low voltage does not mean low-risk; a LV CNE 3 phase low voltage cable can pose greater risk than 33kV switchgear. We look forward to working closely with ProGARM to introduce their garments to our clients and launching our collaborative #protectinglives awareness campaign,” adds Chris.

➡ Contact us to arrange a personal visit, an online presentation or for a general conversation on how we can help with your electrical safety priorities. Arc-rated clothing. Wear it, it saves lives.

ProGARM Protective Clothing & Workwear With Next Day Delivery. High Quality, UK Manufactured Safety Wear & Arc Flash Protection Supplied by Thorne & Derrick

Pictured: Paul Hertherington (National Key Account Manager | ProGARM) during recent Technical Training & Product Training Day at Thorne & Derrick with Dave Tinning, Carl Cox, Chris Dodds & Jonny Hewitt.

PPE The Material Difference | Inherent v Treated Fabrics for Arc Flash Clothing & Protection

July 26th, 2021

Choosing the Right PPE for You

Arc Flash Clothing, PPE & Flash Protection Kits

In a world awash with baffling technical speak, we cut through the jargon to explain the difference between treated and inherent flame resistance and the considerations when weighing up which to buy when evaluating competing garments to protect against arc flash dangers.

The Big PPE Fabric Debate

If you’ve been browsing PPE catalogues searching for arc flash and flame-resistant (FR) workwear, you have probably noticed there are many ways to describe the nature of the fabrics the garments are made from.

The two main phrases used in descriptions of arc flash clothing are inherent fabrics and treated fabrics. So, what’s the difference? And why does it matter?

VXS Inherent Fabric | Arc Flash Clothing Fabric

PPE | Treated Flame-Resistant Fabrics

A fabric described as treated will be made from fibres which aren’t flame retardant by their nature, but have either had a chemical applied, or have been through a chemical process, to make them fire resistant by creating a chemical reaction when set alight which then extinguishes the flame.

PPE | Inherent Flame-Resistant Fabrics

Protecting Utility Workers Carrying Out Maintenance, Repair & Operations on Overhead Lines & Underground Cables

If a fabric is inherently flame-resistant (also known as inherently fire-retardant), its ability to protect you from heat and flames comes from the polymer fibres of the fabric which, at normal oxygen levels, don’t ignite.

Pros & Cons of Inherent & Flame-Resistant Fabrics

Most of our ProGARM range of PPE is made using inherent fabrics because this makes it impossible for the flame resistance to degrade over time or be washed out altogether. These garments also don’t shrink when exposed to heat, helping to maintain critical air layers between the fabrics.

The advantage of treated fabrics is that they’re cheaper. However, this passes considerable responsibility to the employer to devise a system for wearers to monitor their garment’s wear and record its laundry cycles so the company knows when to replace the item due to degradation of the protective treatment.

VXS+ 100% INHERENT

ARC FLASH PROTECTION FABRICS

By manufacturing all ProGARM garments with our unique VXS+ inherent fabrics, we ensure they deliver durability, consistent protection and outstanding comfort.

In the past, many Flame Resistant Garments have suffered from reduced protection over time. Through normal washing, treated fibres gradually lose their Flame Resistant properties. With that decreasing level of protection your team members will be at greater risk of injury.

Treating fabrics can also leave them stiff and uncomfortable. Worryingly we hear of operatives deciding to wash treated garments multiple times to make them more comfortable before wearing them. Alternatively, they choose to keep wearing their older garments which have become more comfortable over time. Both of these practices leave your team exposed to a greater risk of injury.

Arc Flash PROTECTION. DURABILITY. COMFORT.

Electrical Safety & Arc Flash PPE

ProGARM ensures this isn’t the case with our unique 100% inherent VXS+ fabrics that offer superb protection for your team, as well as being durable and comfortable to wear.

VXS+ fabrics are manufactured with a combination of yarns which makes the garment inherently Flame Resistant. Compare VXS+ Fabrics with alternative fabrics and the differences are clear. As well as being 100% inherent, VXS+ fabrics make some of the most comfortable Arc Flash protective garments on the market. Through combining yarns in the manufacturing process, we can deliver fabrics that are flexible and comfortable, and from that create garments that are “as comfortable as pyjamas”.

As well as the ultimate protection, you also need garments that are durable. ProGARM garments are have been shown to last up to 70% longer than comparable garments used by our customers. Some non-ProGARM garments can also suffer from shrinkage and their colour fastness isn’t as resilient as it should be, resulting in faded high visibility workwear. VXS+ fabrics have been tested through more than 50 industrial washes to ensure the longevity of the garments. (The European standard only requires demonstrating colour fastness through 5 wash cycles.)

When you equip your team with ProGARM Arc Flash and Flame Resistant garments made from VXS+ Fabrics, you can be assured of durable protection and comfort that delivers protection throughout the life of the garment. That’s why every ProGARM garment is manufactured using VXS+ 100% inherent fabrics to offer the ultimate protection.

ProGARM is Pro-Choice

In developing our products, we’ve researched what’s important to our customers and fully appreciate that the decision between buying inherent or treated arc flash PPE isn’t an easy one when working with budget constraints and trying to keep their workforce safe.

That’s why we’ve been researching and developing treated garments. This gives you a choice without quite such a dilemma about the degree of safety compromise when making price-based decisions.

Our new coverall (available in four colour options) has been designed in a way that offers the cost saving advantages of being made from treated fabric, while also being robust enough to withstand up to 100 washes – lasting much longer than many competitor products, which are only tested up to 50 washes.

Electrical Safety STANDARDS

When it comes down to it, it doesn’t matter whether the fire protection in the fabric is inherent or added afterwards with chemicals. What you should make your decision based on is proof of standards.

We’re proud that all of our PPE clothing (not just our fabrics) meet EU Conformité Européenne (CE) standards and the new United Kingdom Conformity Assessed (UKCA) mark.

Our arc flash garments also hold EN certifications relevant to their intended purpose and/or industry. For example, all our garments conform to a minimum EN ISO 6330: 2012 DOMESTIC for washing, and some go further to meet the industrial washing standard (EN ISO15797: 2004 Industrial).

We go a step further too. Having achieved ISO9001 (Quality Management) and added Article 11B[KC3], all our supply chain partners meet the same standards. For us, there are no compromises on quality.

As well as electrical safety considerations, when developing our garments and fabrics, we always research what’s important to our customers. This helps us maintain our reputation for the best safety, quality and comfort standards.

Our independent testing looks at fading and shrinkage, as well as comfort of electrical PPE. And all our buttons, zips and press studs are made from the same military-grade plastics as NASA uses, so that they won’t melt and will still work if exposed to heat, flames or a high-voltage electric charge.

These decisions result in pioneering safety standards and mean that, when a casualty needs urgent medical attention following an incident, you will be able to unfasten and remove the clothing far more easily.

You’ll find a label on each of our electrical safety workwear products, outlining which European and UKCA certifications it meets[KC5] [LT6], along with garment care guidelines.

If you would like a chat with one of our arc flash experts to discuss your PPE requirements, give us a call on +44 (0)191 410 4292.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

- Arc Flash Survivor Story – Jason Brozen

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.