Blog

Sealing Cable Ducts in the Process Industry

December 5th, 2024CSD Sealing Systems UK have recently completed work on the CATS Terminal in Seal Sands, for Wood Plc. Seal Sands is at the heart of the Teesside integrated energy network, connecting hydrocarbon-based transition fuels with new energy provision, powering the UK today and into a Net Zero sustainable future.

CATS – the Central Area Transmission System – is a natural gas transportation and processing system that transports gas through a 250 mile, 36inch diameter subsea pipeline from the Central North Sea to a reception and processing terminal in Teesside, Northern England. The initial construction of the pipeline reception and gas treatment facility, and the CATS gas and liquids processing plant, comprised two processing trains each with the capacity to handle around 17 million standard cubic metres (600 million standard cubic feet) of gas per day.

At the CATS Terminal, the pipeline gas is treated to remove contaminants. The gas is then delivered directly into the National Transmission System for commercial and domestic use.

CSD carried out the duct seals to multiple cable and pipe building entries and penetrations across the site – the critical areas to be sealed included offices, equipment rooms, the gatehouse and 2 refuge areas used during emergencies.

During the survey and following discussions with Wood plc, CSD established that these areas required the installation of a water and gastight duct seal system with some critical areas, including the refuge buildings, requiring fire-rated seals. The CSD Nofirno multi-cable and pipe penetration sealing system was provided as the preferred engineered and specification cable and duct sealing solution.

Nofirno provides the highest fire ratings, the shortest installation times, and a long-term, maintenance free service life for the sealing of cable ducts, penetrations and entries to building and substation infrastructure.

Sealing Cable Ducts

The fire, water and gastight system, consisting of Nofirno rubber filler sleeves and Nofirno sealant, provided the protection required on site. The system was used to seal a range of metallic and plastic pipe penetrations as well as all of the multi-cable transits of various diameters and configurations.

CSD’s highly skilled installation team installed the Nofrino system across the Terminal and the sealed penetrations will help ensure the safety and protection of personnel and assets should a disaster situation occur.

The work completed by CSD was delivered to a high-quality and will ensure long-lasting protection to the CATS Terminal.

Andy Pearson, Projects, Mods & TAR Manager at Wood Plc, said “the work carried out by CSD has been first class from start to finish. The survey and installation work carried out was all managed in a very professional manner. Likewise, the timely submission of the Installation Completion Report is much appreciated.”

Preventative & Planned Maintenance to Avoid Downtime & Damage

Failure to correctly and effectively seal cable ducts with compliant duct seals can inflict catastrophic damage to LV-HV electrical distribution networks, substations and power supply. View below our complete ranges of Duct Sealing Products including cable transits to provide a watertight seal and defence against flood damage to low, medium and high voltage cable ducts with additional protection against harmful flammable gas migration and fire spread.

The water flooding of building basements can inflict disastrous damage to sensitive electrical equipment and building fabric if adequate precautions are not implemented to mitigate risk. Poorly sealed or unsealed cable ducts in normal UK weather conditions are serious and widespread causes of flood damage – high groundwater can exert considerable pressure which can cause sub-standard and non-approved products, such as standard polyurethane expanding foam, to be flushed or degraded to destruction within the cable duct creating an open path for water ingress, flood entry and consequent damage.

Foam Fails | CSD Nofirno Duct Sealing System holds extensive UK Electricity (DNO) and Water (WIMES) industry approvals for utility infrastructure protection against fllood damage, this includes DSEAR Regulatory Compliance for the prevention of flammable gas migration in Potentially Explosive Atmospheres characterised by hazardous area locations (Zone 1 / Zone 2 Areas). Furthermore, Nofirno from CSD is approved for harshest fire ratings for pipe penetrations (EN, A, H and Jet Fire class).

T&D are Specialist Distributors to the Process Industries – this includes the fine and speciality chemicals, petrochemicals, pharmaceuticals and polymers manufacturing sectors.

manufacturing sectors.

We supply and support businesses working on the design, construction and maintenance of UK, European and international projects.

We can competently specify and competitively supply an extensive range of Hazardous Area Equipment (ATEX & IECEx) to provide Power, Heating & Lighting to the Explosive Atmospheres industries – this includes LV HV Cables, Accessories, Jointing, Substation & Electrical Eqpt from 600V to 66kV.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Cable Clamps: The BAND-IT BAND-FAST Range – IEC61914 Tested

December 2nd, 2024

Cable Clamps

-

uploaded by: Chris Dodds Thorne & Derrick Sales & Marketing Manager

Short Circuit Restraint for Power Cables

BAND-FAST is a versatile Cable Clamping System for harsh, hazardous and high-performance industrial cable support applications – the cost-saving cable banding solution comprises stainless steel pre-cut banding with pre-assembled buckle.

This IEC61914 compliant cable management system provides installers with significant labour productivity gains of up to 30% and up to 75% material cost savings compared to cable cleats for the short-circuit retention and support of power cables.

Two options are available: a PPA Coated version and an Uncoated version with captive clip both manufactured from type 316 stainless steel – high strength, compact flat profile, space and weight saving, non-corrosive and fire resistant.

The cable clamps have successfully been utilised on the following applications:

- Onshore & Offshore Windfarms (including Converter Stations

- Solar Farms

- Data Centres

- Offshore Platforms / FPSO’s

- Shipbuilding & Marine

- Refineries / Petrochem

- Public Buildings

Specialist Subsea Cable & Pipeline Applications

BAND-FAST cable clamps are also available in highly corrosion resistance materials including: Monel®, Alloy 625, Zeron100 and 316 Stainless Steel for the attachment of polyurethane mouldings, saddles, protectors and piggy-back clamps in subsea energy projects.

BAND-FAST cable clamps

Advantages

- Purchase price is significantly lower

–Up to 75% material cost savings

- Installation time is dramatically reduced

–Reduce labour cost up to 50%

- Low smooth profile

–Space savings on construction

- More versatile

–Conforms to most shapes / cable configurations

- Large diameter reduction (one size fits all)

–Fewer SKU’s to order / stock

- No accessories required

–No nuts / bolts / packing blocks

- Lighter weight cable clamps

–Reduced weight on construction

–Easier to carry around site

–Safer during installation at height

Cable Cleat Standard IEC61914

The cable clamps are independently tested to the latest Cable Cleat Standard IEC61914 for resistance to electromechanical force.

Short Circuit Testing of BAND-FAST Clamps

Subjected to 2x Short Circuits and dielectric test after wetting

PPA Coated BAND-FAST Cable Clamps By BAND-IT

Tests conducted to IEC61914

“Tests for Resistance to Electromechanical Force” Section 6.4.3 and 6.4.4.

➡ The following tables enables the selection of the correct BAND-FAST cable clamp manufactured by BAND-IT based on 300mm spacing between clamps according to IEC61914. Request Test Data for 600mm spacing of BAND-FAST clamps.

| BAND-IT Part Number | Width | Band Ref/Material | Length (mm) | Clip/Ref Material | Single Wrap or Double Wrap | *Max Cable OD (Single cable config) | *Max Cable OD (Trefoil cable config) | *Max Cable OD (Quadrafoil cable config) | Pack qty Piece | Weight Per Piece (kg) | **Pass IEC61914 Short circuit test in trefoil up to (KA PEAK) |

| LFAC-F1015M030–A900 | 15.88mm (5/8”) | AE435 316 SS |

300 | AE455 316 SS |

Single | 40mm | 13mm | 12mm | 100 | 0.025 | 50.8kA |

| LFAC-F1015M040–A900 | 400 | 75mm | 28mm | 25mm | 100 | 0.030 | |||||

| LFAC-F1015M050–A900 | 500 | 100mm | 43mm | 37mm | 100 | 0.038 | |||||

| LFAC-F1015M060–A900 | 600 | 130mm | 57mm | 50mm | 100 | 0.045 | |||||

| LFAC-F1015M070–A900 | 700 | 160mm | 70mm | 60mm | 100 | 0.052 | |||||

| LFFC-F1015M040–A900 | 400 | LE155 316 SS |

1Double | 40mm | 13mm | 12mm | 100 | 0.030 | 76.3kA | ||

| LFFC-F1015M050–A900 | 500 | 55mm | 21mm | 18mm | 100 | 0.038 | |||||

| LFFC-F1015M060–A900 | 600 | 70mm | 28mm | 25mm | 100 | 0.045 | |||||

| LFFC-F1015M070–A900 | 700 | 85mm | 35mm | 31mm | 100 | 0.052 | |||||

| LFFC-F1015M080–A900 | 800 | 100mm | 42mm | 37mm | 100 | 0.060 | |||||

| LFFC-F1015M100–A900 | 1000 | 130mm | 57mm | 50mm | 100 | 0.075 | |||||

| LFFC-F1015M120–A900 | 1200 | 160mm | 70mm | 60mm | 100 | 0.090 | |||||

| Ref C075 Bantam Tool for application of all PPA Coated BAND-FAST® Clamps | 1.040 | ||||||||||

Uncoated BAND-FAST Cable Clamps installed with additional cushion sleeve

| BAND-IT Part Number | Width | Band Ref/Material | Length (mm) | Clip/Ref Material | Single Wrap or Double Wrap | *Max Cable OD (Single cable config) | *Max Cable OD (Trefoil cable config) | *Max Cable OD (Quadrafoil cable config) | Pack qty Piece | Weight Per Piece (kg) | **Pass IEC61914 Short circuit test in trefoil up to (KA PEAK) |

| LFEC-F1030M050 | 15.88mm (5/8”) | C405 316 SS |

500 | C455 316 SS |

Double | 55mm | 21mm | 18mm | 100 | 0.062 | 112kA |

| LFEC-F1030M060 | 600 | 70mm | 28mm | 25mm | 100 | 0.070 | |||||

| LFEC-F1030M070 | 700 | 85mm | 35mm | 31mm | 100 | 0.078 | |||||

| LFEC-F1030M080 | 800 | 100mm | 42mm | 37mm | 100 | 0.086 | |||||

| LFEC-F1030M100 | 1000 | 130mm | 57mm | 50mm | 100 | 0.103 | |||||

| LFEC-F1030M120 | 1200 | 160mm | 70mm | 60mm | 100 | 0.120 | |||||

| LFEC-F1230M050 | 19.1mm (3/4″) | C406 316 SS |

500 | C456 316 SS |

Double | 55mm | 21mm | 18mm | 100 | 0.078 | 120kA |

| LFEC-F1230M060 | 600 | 70mm | 28mm | 25mm | 100 | 0.088 | |||||

| LFEC-F1230M070 | 700 | 85mm | 35mm | 31mm | 100 | 0.098 | |||||

| LFEC-F1230M080 | 800 | 100mm | 42mm | 37mm | 100 | 0.108 | |||||

| LFEC-F1230M100 | 1000 | 130mm | 57mm | 50mm | 100 | 0.128 | |||||

| LFEC-F1230M120 | 1200 | 160mm | 70mm | 60mm | 100 | 0.150 | |||||

| Ref C001 Band-It® Tool for application of all Uncoated BAND-FAST® Clamps | 2.000 | ||||||||||

*Note: Maximum cable OD are for a guide only.

Short Circuit Test Videos

PPA Coated BAND-FAST® Cable Clamps with Clip. Test Video #33 70.1kA (2nd Shock – 600mm Spacings).

Thorne & Derrick are Specialist Distributors to international Utilities, UK DNO’s, ICP’s and HV Jointing Contractors of an extensive range of LV HV Cable Jointing, Substation, Tooling & Installation Equipment from 600V to 66kV – we service wind energy, solar power, battery storage, rail, utility, datacentre and the explosive atmosphere industries.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Working Together | Thorne & Derrick with The Faraday Training Centre

November 27th, 2024

Uploaded by Chris Dodds | Sales and Marketing Manager at Thorne & Derrick

High Voltage Training for Cables & Power Systems

For 40 years Thorne & Derrick have proudly supplied the electrical industry with Power Cable Accessories to provide network reliability, security and energisation from 600V to 66kV – we distribute the most extensive range of Joints, Terminations & Connectors from 3M Electrical, Nexans Euromold and Pfisterer Connex to suit all types of electrical equipment connections in ColdShrink, heat-shrink and EPDM technology.

For 30 years The Faraday Centre, a world class facility, has been delivering hands-on, practical training coupled with theoretical assessment to empower the next generation of engineering talent.

Their 12 Training Rooms and 2 Practical Areas are equipped with a combination of the latest smart technology and legacy electrical equipment to support 50+ Courses delivered by highly qualified and experienced tutors with over 50 years experience.

The Faraday Centre also delivers on-site bespoke courses – this can be for private networks, DNO or tailored to suit the specific High Voltage operational requirements of a project or industry sector.

Expertise & Experience Combined

Both our businesses are now delighted to be Working Together – both our businesses with locations in the North East of England deliver our products and services to UK and international locations. Our industry partnership, based on market-leading Training Course delivery, now intends to close skills gaps, improve workplace safety and both to open and develop career opportunities for attendees.

Standard & Customised Training Courses

Working Together to improve electrical safety knowledge and implementation we will promote the most extensive of range of High Voltage Courses which enable the up-skilling of competency levels and career progression annually of over 2500 Electricians, Cable Jointers, Authorised & Senior Authorised Persons (AP’s & SAP’s) and Authorised Engineers (AE’s).

Standard module Courses are supplemented by tailored training packages to specific customer requirements.

Additionally, brand specific Offshore Wind Termination Courses can be delivered for leading cable accessory manufacturers including Nexans (Euromold), Pfisterer (Connex), 3M Electrical and NkT via The Wind Academy.

With dedicated lecture rooms for Cable Termination, Jointing & Authorisation Training, Thorne & Derrick are delighted to be Working Together in close partnership with The Faraday Centre – we support the delivery of best-practice Courses in the disciplines of High Voltage Jointing, Operational Safety, Protection, Testing & Switching up to 33kV.

“Following our recent visit and tour I am delighted to now be able to extend The Faraday Centre services to our existing and prospective clients. The UK confronts a significant shortage of skilled Electricians & Engineers which could hinder Net Zero goals – facilities like The Faraday Centre can accelerate policy, projects and people’s job opportunities to form the workforce to secure our Green Energy future. Should you have a general or industry specific Training gap, contact us to discuss it,” comments Chris Dodds – Sales & Marketing Thorne & Derrick.

Thorne & Derrick are Specialist Distributors to international Utilities, UK DNO’s, ICP’s and HV Jointing Contractors of an extensive range of LV HV Cable Jointing, Substation, Tooling & Installation Equipment from 600V to 66kV – we service wind energy, solar power, battery storage, rail, utility, datacentre and the explosive atmosphere industries.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

PICOUP Cable Spiking & Cutting Tool | Redefining Safety Standards in Underground Power Maintenance

November 20th, 2024

PICOUP Cable Spiking & Cutting Tool

Redefining Safety Standards in Underground Power Maintenance

The PICOUP Ultra-safe, electrohydraulic power cable spiking and cutting tool range from PENTA UKI is setting a new standard for safety and simplicity in underground power cable maintenance. Designed without traditional hydraulic hoses, the PICOUP tools safely check the absence of voltage on underground cables without the hazards and complexities associated with explosive cartridges.

The PICOUP tool boasts significant advantages over conventional cartridge-based spikers.

Unlike cartridge-driven spikers that rely on explosive charges to deadproof cables, the PICOUP tool employs a hydraulic system that eliminates the risks of unexpected discharge, misfire, and storage hazards, ensuring a safer working environment. The cable is immediately ready for the works after the use of PICOUP.

As the hydraulic system applies consistent, controlled force, it reduces the risks of cable over-damage and unintended electrical discharge. Cartridge-based spikers can apply uneven force, posing serious safety concerns for crews in the field.

Simplified by design, PICOUP’s user-friendly design is easy to learn, promoting safe and efficient usage among team members and its elimination of cartridges, makes preparation faster and reduces the risk of user error. Maintenance becomes effortless to as PICOUP tools bypass the rigorous inspections required for explosive-based spikers and make routine checks and servicing far simpler.

PICOUP Cable Spiking & Cutting Tool In The Field

Kevin Rushton, Managing Director of PENTA UKI said, “The PICOUP Safety Spiking and Cutting Tool is transforming safety in the industry, providing a highly reliable, non-explosive alternative to traditional cartridge-based systems. With safer force application, quieter operation, and streamlined usability, the PICOUP range is making underground cable maintenance not only safer but also more efficient.”

The PICOUP range is available to purchase in the UK from Thorne & Derrick or rent from Sunbelt Rentals. Read More Here – Spike & Cut Power Cables ! Improving Cable Safety with Sunbelt Rentals

The unique PICOUP 400 from PENTA provides a combined “Spike & Cut” capability up to 140mm in a single-tool operation – exclusively stocked by Thorne & Derrick.

About PENTA UKI

PENTA UKI is an expert manufacturer of electrical safety solutions, driven by a commitment to ensuring your safety in every intervention.

PENTA UKI is trusted by Linesmen, Maintenance Technicians, and Electrical Engineers working across global electricity generation, transmission, and distribution networks, as well as 9 other critical industries. We safeguard your operations with cutting-edge safety technology designed to meet the highest standards in the most demanding environments.

Count on PENTA—where safety meets innovation.

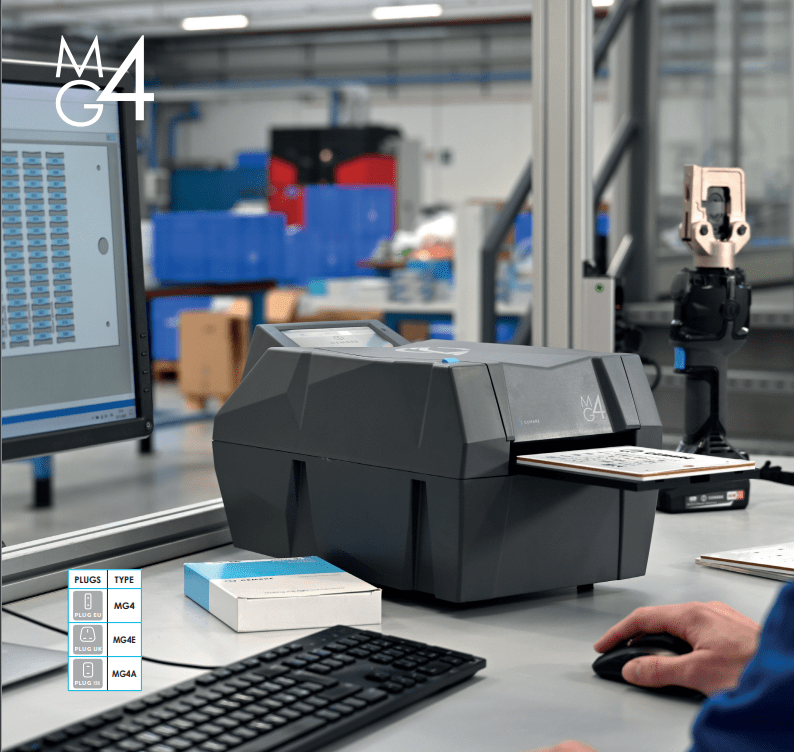

Cembre MG4 | The Newest Thermal Printer for Identification & Labelling

November 20th, 2024

CEMBRE MG4

THERMAL transfer PRINTER

The New Generation of Thermal Transfer Printing with the Cembre MG4

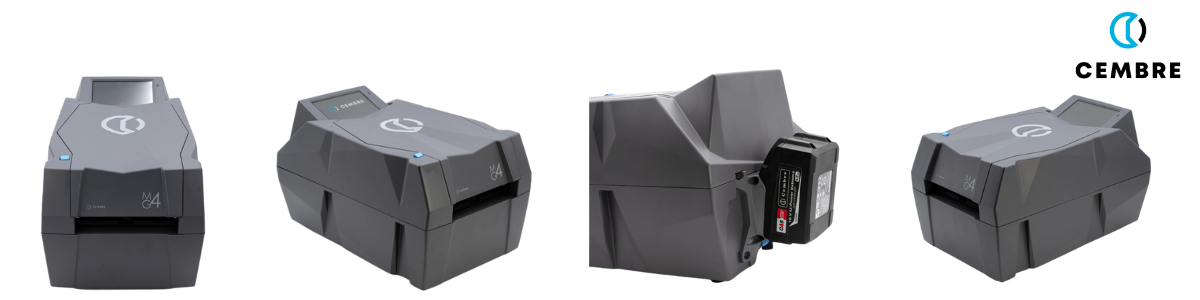

The Cembre MG4 Thermal Printer represents the next generation in thermal transfer printing technology, designed to enhance the efficiency and quality of cable cutting, crimping and labelling tools. Leveraging decades of industrial marking expertise, the MG4 is a versatile and portable solution that excels in a wide range of applications.

Equipped with a ribbon save system, the Cembre MG4 is a useful tool that improves the quality of work of its users by exploiting the technology and experience in industrial marking gained from working in the business sector. The large on-board touch screen enables quick and easy management of print projects, which can be used with both a mains power supply and with the Cembre CAS Alliance rechargeable batteries.

Cembre MG4 Thermal Kit

- MG4 Printer

- MiniRolly Printer

- M2-32-25-WH1 (Thermo Roll)

- M2-48-25-WH1 (Thermo Roll)

- M2-64-25-WH1 (Thermo Roll)

- TRR-055 842121 (Premium Ribbon)

CEMBRE MG4 PRINTER | Cable Labelling

Technical Specification

High-Speed Printing

- Capable of printing 112 cable tags in under 20 seconds, the Cembre MG4 delivers time-efficient production for high-demand environments.

Exceptional Print Quality

- The Cembre MG4 provides crisp and durable prints, suitable for text, logos, electrical symbols, QR codes, and vector images. It also supports various file formats, including clipart, drawings, barcodes, and bitmap images.

Durable Design

- Engineered for robustness, the Cembre MG4’s rugged construction ensures reliability in challenging work conditions. It is built to withstand frequent use while maintaining superior performance.

CEMBRE MG4

PRINTER BENEFITS

- Advanced Ribbon-Saving Technology: The MG4 is equipped with an innovative ribbon-saving system that optimizes ribbon usage for cost efficiency while delivering high-quality prints. This feature is ideal for businesses looking to reduce waste and enhance sustainability.

- Intuitive User Interface: The printer includes a large 5-inch touchscreen display, enabling effortless management of printing projects. This user-friendly interface ensures quick setup and seamless operation, whether in an office, production environment, or directly on-site.

- Versatile Power Options: The MG4 can operate using either a mains power supply or CAS Alliance rechargeable batteries—a system compatible with all Cembre 18V tools. This makes the printer fully portable and highly adaptable to various job sites.

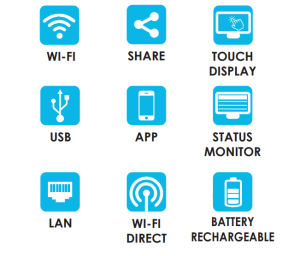

- Comprehensive Connectivity: The MG4 supports multiple connectivity options, including USB, LAN, Wi-Fi, and Wi-Fi Direct. Users can print directly from their PCs, smartphones, or tablets, ensuring flexibility in managing and executing projects.

TECHNICAL SPECIFICATION – CEMBRE MG4

The Cembre MG4 can be connected to the network via USB, LAN, and Wi-Fi networks and can connect devices through Wi-Fi Direct. Using this solution, a project can be printed in the office and sent directly to your smartphone or other communicative messaging methods.

The smart, large touch screen further allows quick and easy management of projects even if multiple users are connected to the system.

The Cembre MG4 is perfect for diverse cable marking tasks, including:

- Text Printing: For clear and precise identification.

- Logos and Clipart: Adding branding or visual elements.

- Electrical Symbols: Essential for compliance and clarity.

- QR Codes and Barcodes: Simplifying asset tracking and inventory management.

| Cembre MG4 Product Details | MG4 | MG4A | MG4E |

| Printer: | Thermal Transfer | ||

| Supply Voltage | 24V | ||

| Current | 3.75A | ||

| Gross Weight | 10540,000 g | ||

| Printing Speed (One Sheet) | 9 Sek | ||

| Maximum Resolution | 300 x 600 DPI | ||

| Maximum Printable Surface | 140 x 110 mm | ||

| Operating Temperature | +59 to +95 | ||

| Relative Humidity (without condensation) | from 30 to 80 | ||

| Dimensions: | 409 x 236 x 240 | ||

| Weight | 6,1 (13.4) kg (lbs) | ||

| Acoustic Noise (UNI EN ISO 11202) | L(pa) < 70 dB L(pCPeak) < 130 dB | ||

| Minimum system requirements to use the “GENIUSPRO” software | PC with Intel CoreTM i3 processor, equivalent or higher

4 Gb of RAM memory 2 Gb of available hard disk space, monitor resolution 1280 x 1024 operating system : Windows 7, Windows 8, Windows 10 32/64 bit |

||

| Interfaces (connectivity) | Ethernet 10 / 100 Base – T

WI-FI WLAN 802.11b/g/n 2.4 GHz USB 2.0 Hi-Speed |

||

| Interface Templates | MG2-PLT 991002

MG2-QTB 991011 MG2-PWC 991000 |

MG2-PLT 991002

MG2-QTB 991011 MG2-PTM 991010 |

MG2-PLT 991002

MG2-QTB 991011 MG2-PTD 991007 |

| Print Ribbon | 28 x 53 x 120 | ||

MG4 MARKING tAGS FOR INDUSTRIAL APPLICATIONS

The MG4 system offers metal-detectable tags and holders, produced with a unique additive that allows detection via metal detectors and X-rays. These tags ensure:

- High resistance to oxidation

- Easy identification in production processes

- Compatibility with third-party terminal blocks or direct application with cable ties

This feature is particularly valuable for industries requiring strict contamination control.

MG4 Marking Tags

Cembre MG4 Thermal Printer | GeniusPro

Cembre’s GeniusPro Mobile App enables seamless on-site management of print projects. Compatible with both iOS and Android devices, the app simplifies real-time updates and configuration changes, ensuring workflow efficiency.

Cembre is a leading European manufacturer of electrical connectors, crimping tools, cutting tools, and a variety of accessories for LV (low voltage), MV (medium voltage), and HV (high voltage) power systems. Designed for switchgear and control panels, Cembre tools are ideal for installing low and medium voltage connectors.