Blog

How To Install 3M Cold Shrink Cable Joints (LV)

May 18th, 2018

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

Cold Shrink Cable Joints

This video by 3M Electrical shows how to apply 3M Cold Shrink Cable Joints safely to splice, repair and connect low voltage power cables, 600V/1000V.

3M Cold Shrink cable joints utilise tool free cold shrink technology where no heat or gas torch is required for jointing cable in onshore and offshore locations with polymeric type cable insulation construction including both XLPE and EPR.

Cold shrink is an effective alternative to resin cable joints and can be used indoors, outdoors, overhead or used in cable trays.

Jointing Cables

Ensure all cables and conductors are free from dirt, residue and contaminants using cable cleaning wipes prior to preparing the cable to install the joint.

Cold shrink tubes and copper wire sleeves are first positioned over the cable.

The cable cores are then cut in such a way to stagger the position of the connectors – either mechanical shearbolt or crimp splice connectors are compatible. Check the proposed conductor connector is of suitable physical dimensions to be used with the cold shrink joint – on larger conductors due to volume displacement of multiple mechanical type connectors it maybe preferable for the jointer to use crimp/compression splices due to smooth profile design overcoming any potential bulging or distortion of the cold shrink tubes.

Accepted brands include Cembre, Arcus and Pfisterer Sicon type connectors.

The cable insulation is then removed and connectors are installed.

Most connector technology can be used providing they suit the requirements of the cable voltage, conductor construction and fit dimensionally within the 3M cable joint.

Scotch Electrical Tapes

Scotch 23 self-amalgamating tape is used to over tape the connectors. Layers of Scotch 23 are applied tightly around each connector overlapping into the primary insulation on each side of the connector position.

A piece of cable jacketing that has been saved from the cable preparation is then wrapped around the connectors for added mechanical protection.

Scotch 2228 mastic tape is then used to seal the crotch of the cable.

Scotch 33+ premium insulation tape is applied across the lengths of the cold shrink joint to improve electrical insulation and water sealing protection.

The copper wire sleeve is then repositioned over the joint and secured onto the cable armours (either wire or braid armour) with constant force springs providing a 360º earth screen around the cold shrink cable joint for added protection.

Scotch 23 self-amalgamating tape is used to tape over the constant force springs ensuring the application is in the same direction as the constant force springs.

Scotch 2228 mastic tape is wrapped over the constant force springs to ensure a smooth profile and to achieve the required cable seal.

The 3M cold shrink protection tube is then positioned over the cable joint. The coil is then removed by hand to install. The live memory action of the specially formulated material shrinks the cold tube into position and ensures a constant radial pressure and seal.

Cold Shrink Joints Selection Table For Power Cables

Selecting the correct 3M LC type cable joint for use with single and multi-core type power cables, typically BS5467 (SWA) or BS6883 (GSWB).

| Cold Shrink Joint Part Number | Cross Sectional Area (mm²) | Cable Diameter Range (mm) | Cable Armour Range (mm) | ||||

| Single Core 1kV | Two Core 1kV | Three Core 1kV | Four Core 1kV | Three Core 3.3kV | |||

| 3M LC1 | N/A | 1.5 – 4 | 1.5 – 4 | 1.5 – 2.5 | N/A | 16.1 – 33.1 | 9 – 15 |

| 3M LC2 | 50 – 95 | 6 – 10 | 6 – 10 | 4 – 6 | N/A | 16.1 – 33.1 | 14 – 22 |

| 3M LC3 | 120 – 150 | 16 – 50 | 16 – 25 | 10 – 16 | N/A | 16.1 – 33.1 | 18.5 – 29 |

| 3M LC4 | 185 – 400 | 70 – 120 | 35 – 70 | 25 – 50 | 16 – 50 | 24.9 – 56.4 | 23.5 – 37 |

| 3M LC5 | 500 – 630 | 150 -185 | 95 – 150 | 70 – 120 | 70 – 150 | 37.8 – 84.3 | 31 – 50 |

| 3M LC6 | 800 – 1000 | 240 – 300 | 185 – 240 | 150 -185 | 185 – 240 | 37.8 – 84.3 | 44 – 70 |

| 3M LC7 | N/A | N/A | 300 | 240 – 300 | 300 | 62.5 – 128.5 | 44 – 70 |

Cold Shrink FAQs

Can 3M Cold Shrink Joints Be Resin Encapsulated?

Standard 3M Cold Shrink cable joints in the LC range can be over-protected by using cable joint moulds and then filled by pouring resin into the mould to encapsulate the joint – for example the cold shrink joint can be modified to provide resistance to hydrocarbon damage in hazardous area locations by using 3M Scotchcast 1402FR resin.

Can 3M Cold Shrink Joints Be Used To Joint Halogen Free & Flame Retardant Cables?

3M cold shrink joints can be used in conjunction with 3M STFF outer-protection sleeve – the joint sleeve is designed to protect the joint from fire. STFF sleeve is halogen free/zero halogen, flame retardant and does not emit toxic fumes in fire situations. Specified for onshore, offshore and rail tunnel applications where fire resistant protection of the cable joint is critical to overall performance, safety integrity and operational fire performance of the electrical cable and power system.

Can 3M Cold Shrink Be Used For Cable Repair?

Where cables have been subject to sheath degradation overtime due to electrical and mechanical stresses whilst in service a cold shrink tube can be used to re-instate the levels of cable insulation – note this requires access to an open-end of the cable or disconnection of the cable due to the tubular design of the cold shrink. If disconnection or isolation of the power cable system is not possible a heat shrink wrap-around type cable repair can be carried out. Read more about this subject in our detailed Blog covering solutions for repairing damaged cables.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Low Voltage Cold Shrink Cable Joints.

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Learn more about the benefits and applications of Cold Shrink:

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

UKPN Cable Jointers Required | Immediate Start | Long Term Contract | Apply Now

May 17th, 2018

Contract: UKPN Network | Immediate Start

Work Type: Installing Service Termination Heads (Cut-outs ) 80- 100A

Posted By

Jordan Hamer (Recruitment Consultant at Cordant Group PLC / Utilities G.W.E.T)

My client is a successful infrastructure business offering services to the power, water, gas, rail, telecommunications and infrastructure sectors.

They have depots in Leicestershire, North London, Kent and Magherafelt.

Due to the acquisition of large contracts with DNO’s they have a large recruitment drive in progress and are recruiting teams of cable jointers for the duration of the UKPN project.

Role Outline

The Cable Jointers will be required to work in teams of 2 (Cable Jointer + Jointers Mate).

They will perform cut-outs across the M25 corridor and will be targeted to do 25 per week.

Any cut-outs completed after the 25, will be paid at £65 per cut off per jointing team.

Applicant Requirements

Jointers must have UKPN Authorisation (any area) – the successful applicants will be prepared to travel, hold EUSR Card and carry own tools.

Benefits

£500 per day per Jointing team

£65 bonus per Jointing team per cut off

Ongoing long term work up to 4 years

Immediate starts

What Next?

To apply for this role or if you would like to discuss in more detail please contact me directly or apply with an up to date CV:

Jordan Hamer | Contracts Consultant

Cordant Recruitment

No 1 St James Square, Manchester M2 6DN

t 0161 8311608

m 07757 674 066

Who Are Cordant Engineering?

At Cordant Engineering we research all aspects of low, medium and high voltage power generation, transmission and distribution, as the demands of power networks continue to grow across the UK.

A wide variety of problems can affect power anywhere and at anytime but it is by providing specialist engineering skills that consequently minimise problems encountered.

Therefore, we aim to support our clients to guarantee safe and reliable operation of LV MV HV electrical power systems today and in the future.

We have the expertise and capability to work with a range of businesses concerned with T&D, power generation, substation service and maintenance.

Staff and contractors are provided for everything from 11kV-33kV private network services to 132kV-400kV turnkey projects for all medium/high voltage cabling projects.

Our expertise covers a range of specialised sub-sectors including:

- 11kV 400kV Substation Services

- LV 400kV OHL Maintenance, Construction & Surveys

- LV 33kV Asset Replacement

- Underground Network Services

- Vegetation Management

Typical Roles

- Linesmen

- Cable Jointers LV MV HV

- Project Managers

- Site Engineers / Managers

- Planners

- Design Engineer

- Operations Manager

- Senior Authorised Person

- Quantity Surveyor

- Patroller

Thorne & Derrick

Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

We distribute and supply from stock LV, MV & HV Cable Joints, Terminations, Substation & Electrical Equipment from our Key Suppliers including:

| 3M | CMP | Ellis Patents |

| Nexans Euromold | Elastimold | Pfisterer |

| Prysmian | Alroc | CSD |

| Roxtec | CATU Electrical | Cembre |

| Lucy Zodion | ABB | Emtelle |

Thorne & Derrick – Stockists & Suppliers of MV HV Joints, Terminations & Connectors

Underground Cable Photo Album 1890-1940 – Western Power Distribution (WPD)

May 15th, 2018

-

uploaded by: Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Electricity history courtesy of the Western Power Electricity Historical Society UK – photographs of pulling, laying and jointing LV up to 33kV cables from yesteryear.

Peer into the past to a time when dapper, bowler-hatted and waistcoated Cable Gang Managers attired in three piece suits oversaw the hand pulling of cables into trenches worked by Jointers in cloth caps, trouser braces and brogues.

The first picture is poignant, The Cable Gang.

Workmates Tom, Arthur and Albert carted up and ready for a day in the cable trench.

It’s 1915 and the First World War is raging across Europe. No doubt the Gang would have friends and family in an altogether different type of trench somewhere along the muddy and bloody Western Front.

The Cable Gang – a cable jointing gang in Shirehampton Road. Bristol. Tom Webb was in charge of driving cart, tall man is Arthur Attwood and on the extreme right is cable jointer Albert Keepin (1915).

Cable Laying – power cables being manually pulled from cable drums and laid underground at High Street/Back of Bridge Street, Bristol (1898).

Cable Protection – Baldwin Street cable works with cable protection covers and markers made from brick, Bristol (1893).

Cable Pulling – electric power cables being laid into cable trench from The Strand to Beacon Quay electricity works Devon, Torquay (1897).

Power Rectifiers – three Willans steam engine/Easton Anderson alternators with three Ferranti rectifiers in background. Devon, Torquay (1898).

Cable Jointing – Baldwin Street, near Bristol Bridge. Mr J Duggan behind cloth capped gentleman on left. Note bricks with circuit description (1900).

Trimming Team – arc lamp maintenance and trimmer team. Bristol (1904).

High Voltage Jointing – 10kV 0.4 PILC high voltage cable in Mannesman tubes and low voltage cables in a bunch. Cornwall, Causewayhead, Penzance (1912).

Cable Diversions – Temple Back from Half Penny Bridge direction. On the photograph, the cables have been identified in ink. Bristol, Temple Back (1914).

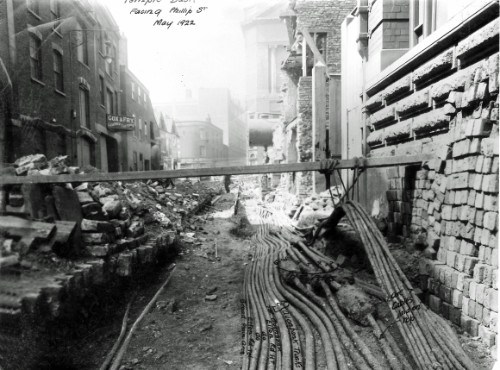

Cable Works – extensive cable works in Temple Back facing Phillip Street. On the photograph, the cables have been identified in ink. Bristol, Temple Back (1914).

Cable Diversion – cable diversions from Temple Back adjacent to Half Penny Bridge. On the photograph, the cables have been identified in ink. Bristol Tramways and Carriage Power Station opposite and Castle Flour Mills across bridge in background (1914).

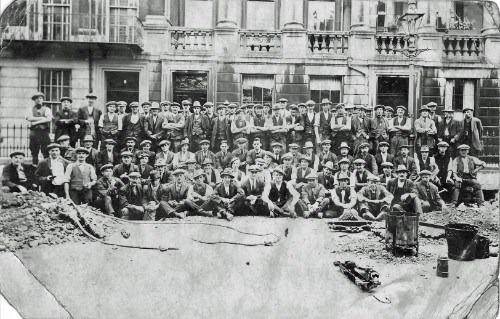

Cable Jointers – some cable jointers and workmen involved in the single to 3 phase changeover photographed in Vyvian Terrace. Bristol, Clifton (1921).

Power Cables – delivery of Henley cables. Small van of Cornwall Electric Power Company (1927).

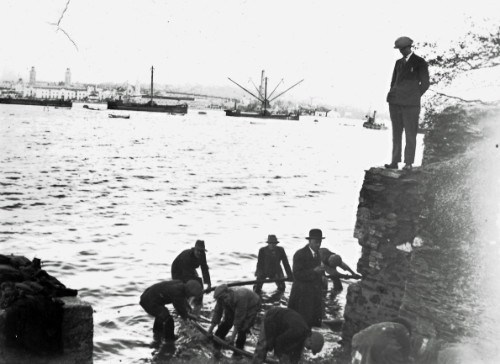

33kV Cables – submarine cable from Saltash to Devonport being installed. Devon, Torpoint (1931).

33kV Cables – Devonport to Saltash 33kV power cable crossing. Barge with high voltage cable on Devonport shore (1931).

33kV Cables – cable laying and jointing 33kV cables from Portishead Generating Station across River Avon (to Avonmouth). North Somerset, Portbury (1934).

33kV Cables – laying 33kV cables from Portishead Generating Station between Avonmouth Dock and Avonmouth. Bristol, Avonmouth Dock (1934).

Laying 33kV Cables – from Portishead Generating Station between Avonmouth Dock and Avonmouth at River Avon crossing. Avonmouth Dock high voltage cables being greased before being pulled through pipes across River Avon (1934).

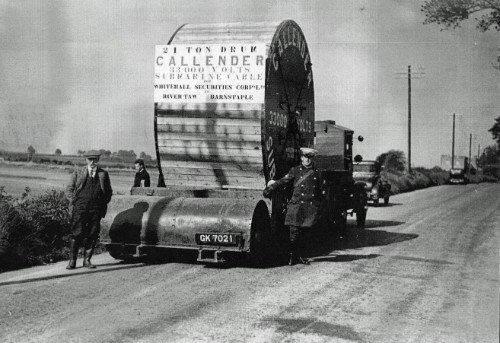

33kV Cables – 33kV Callenders submarine cable passing through Barnstaple. Devon, Barnstaple (1934).

33kV Cables – River Taw crossing. 21 ton drum of Callender 33,000kV submarine cable for Whitehall Securities Corp. Ltd. View of cable drum on special low loading wagon. Devon, Barnstaple (1935).

Thorne & Derrick Working With Western Power Distribution

Today Western Power Distribution (WPD), is the electricity distribution network operator for the Midlands, South Wales and the South West.

Electricity is conveyed countrywide via the National Grid at 275kV or 400kV – the EHV (Extra High Voltage) power is reduced to 132kV for regional distribution at high voltage substations known as Grid Supply Points. From there the power is distributed to further electricity substations via overhead lines or underground cables at 132kV. The voltage is reduced again to 33kV and then to 11kV by medium voltage transformers.

This power distribution network then carries electricity to individual towns and villages throughout the Midlands, South West and Wales where distribution substations transform the voltage to low voltages (230 volts).

WPD network is comprised of over 220,000 kilometres of overhead lines and power cables and 185,000 transformers which are used to step down voltages. These medium/high voltage transformers vary in size from large units capable of supplying an entire town, to tiny ones serving isolated remote cottages.

Since 1985, Thorne & Derrick have been proud to supply and support WPD with an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt.

Headquartered in Bristol, Thorne & Derrick’s home DNO is WPD.

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Specialist Distributors Of LV MV HV Jointing, Cabling & Electrical Equipment

Lamprell

May 15th, 2018- Client: Lamprell

- Company Type: EPC

- Location: International

- Sector: Oil, Gas & Chemicals

Thorne & Derrick are Approved Vendors to Lamprell of LV, MV & HV Cables, Accessories, Jointing, Substation & Electrical Eqpt.

T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

We supply UK and international businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

We provide global express delivery from stock at competitive prices.

![]()

Export Services ♦ International Delivery ♦ Certification ♦ Packing ♦ Inspections ♦

Thorne & Derrick International

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu Electrical, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

SNC Lavalin

May 15th, 2018- Client: SNC Lavalin

- Company Type: EPC

- Location: International

- Sector: Oil, Gas & Chemicals

Thorne & Derrick are Approved Vendors to SNC Lavalin of LV, MV & HV Cables, Accessories, Jointing, Substation & Electrical Eqpt.

T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

We supply UK and international businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

We provide global express delivery from stock at competitive prices.

![]()

Export Services ♦ International Delivery ♦ Certification ♦ Packing ♦ Inspections ♦

Thorne & Derrick International

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu Electrical, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment