Blog

Thorne & Derrick Appointed UK Stockists & Distributor for the Hand Safety Tool Company

February 14th, 2023

Press Release | Uploaded by Chris Dodds 14.2.2023

Thorne & Derrick are delighted to announce we have been appointed the UK Distributor for the Hand Safety Tool Company range of No Touch Hands Free Tools.

This range of market-leading tools reduce serious hand injuries in the workplace when manoeuvring suspended loads during push-pull operations. To support the introduction of the product range we can provide on-site or online Demonstrations to end-users. There are a diverse range of all-purpose designs that keep hands off and away from potential injury areas and keep workers out of the risk zone. Over recent months our Sales and Marketing Teams have benefited from Product Training with Jim Walts (Director – The Hand Safety Tool Company) and we now have in place stock of their ShoveIt range of tools.

Reducing Risk & Worker Injury

Thorne & Derrick are available and interested to discuss potential applications to improve safe operations in the utility, rail, renewable, oil/gas, port authority, manufacturing and construction industry sectors. The tools mitigate high-risk pushing and pulling operations and associated hand or finger injury – users can guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

The range of Safety Tools keep your hands off loads enabling “hands-free” lifting – this mitigates the risk of load handling and improves Health & Safety in the workplace.

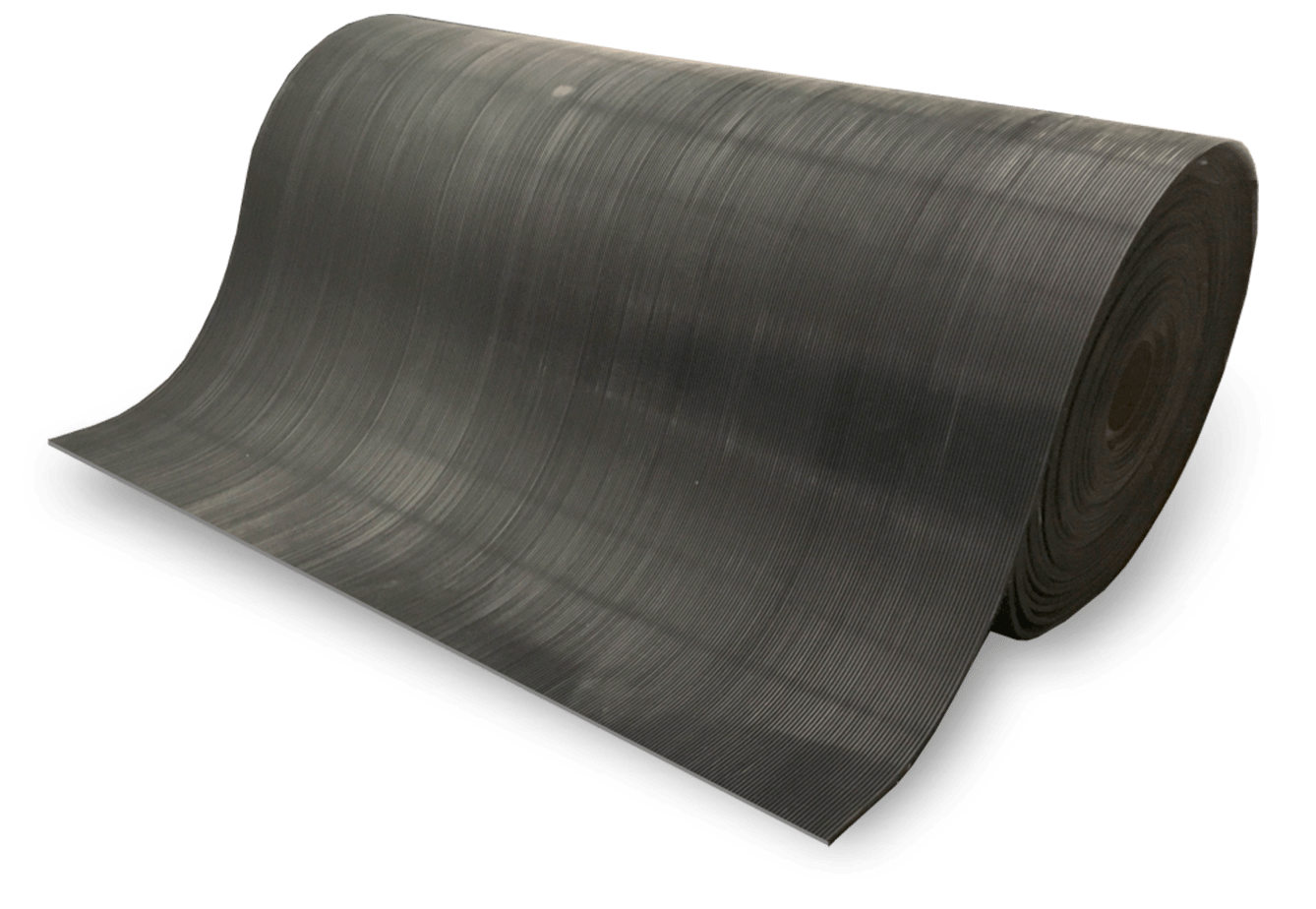

Insulating Matting | Bespoke Cut to Size Switchboard Mats

February 14th, 2023Matting

Thorne & Derrick are able to arrange manufacture of insulating and switchboard matting from our wide range of premium, low odour, rubber matting to your exact sizes and design and in accordance to IEC61111. Our REACH/PAH/CE approved compliant rubber compounds provide no off gassing which can cause nasty smells within internal environments. Rubber which has a pungent odour usually has been heavily recycled and been manufactured with the use of prohibited chemicals which are banned by REACH/EU. REACH regulations are tightening, and many online reviews of current non regulated matting products found on the market have regular end user complaints of a ‘toxic odour’ and ‘smell’ that does not disappear’. The advice given by the supplier is to ‘clean with soap and water’ or ‘leave outside for a prolonged period’.

The truth is really these products are most probably non-compliant and should not be placed into the European market. Contact us for odour free matting options.

Stockists & Suppliers of the CATU Electrical Safety range of Insulating Matting | LV MV HV

| Class Of Insulating Matting According To IEC61111 | Proof Test | AC Maximum Working Voltage | Withstand Test Of Insulating Matting |

| Class 0 Matting | 5kV | 1000V – LV Low Voltage | 10kV |

| Class 1 Matting | 10kV | 7500V – MV Medium Voltage | 20kV |

| Class 2 Matting | 20kV | 17000V – MV Medium Voltage | 30kV |

| Class 3 Matting | 30kV | 26500V – MV Medium Voltage | 40kV |

| Class 4 Matting | 40kV | 36000V – HV High Voltage | 50kV |

LV MV HV Electrical Safety

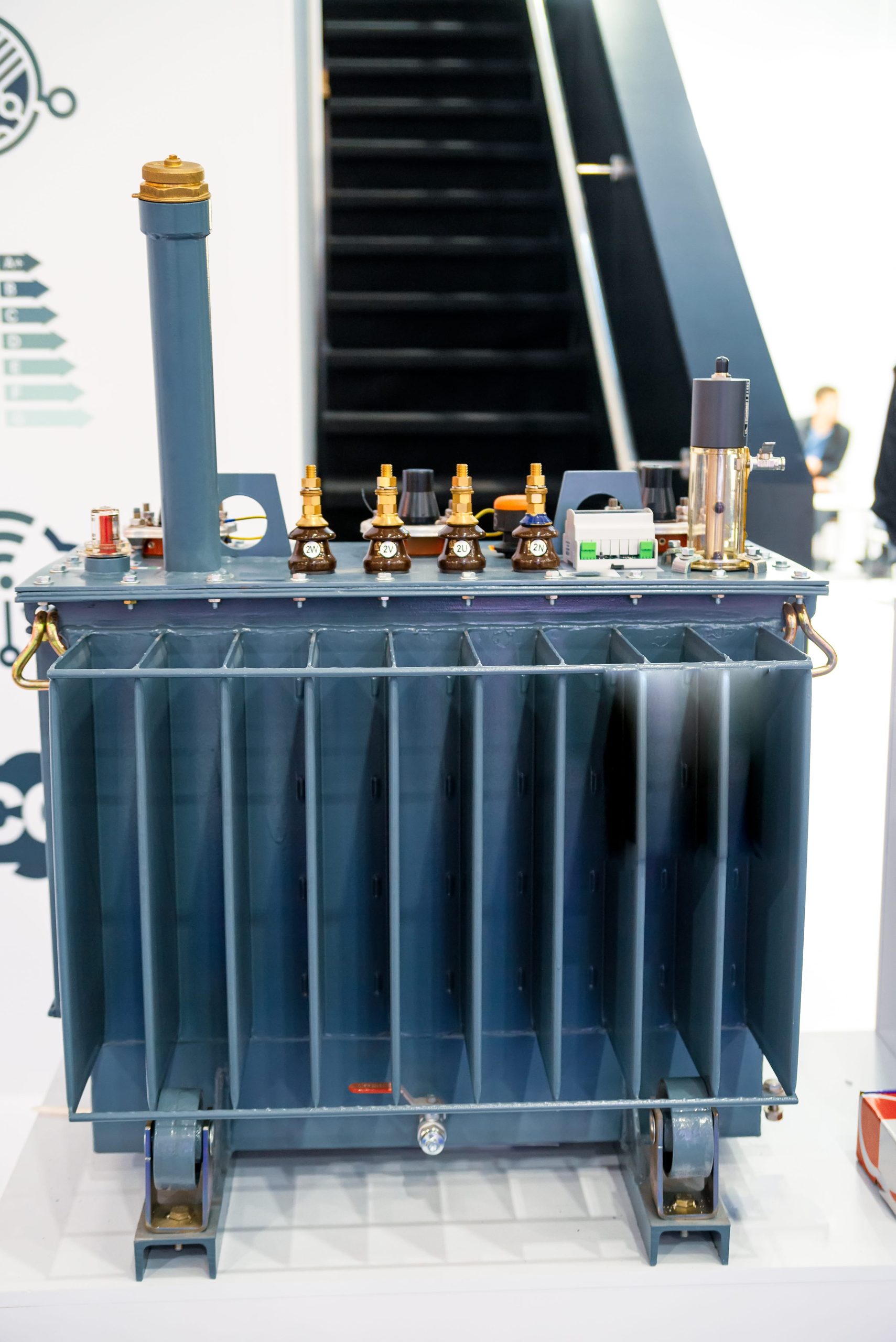

Oil Filled Transformers | Driving Uptime Through Asset Winterisation

February 1st, 2023

Oil Filled Transformers

in the Wind Power Industry

Are Low Oil Level Trips Causing Asset Downtime?

This Case Study covers the problems caused by low oil level trips on aging transformers, the impact it has on downtime, availability and power generation. It goes on to discuss how Thorne & Derrick assisted Ventient Energy in custom designing and supplying a fit for purpose electrical heating solution to overcome the problem and effectively Winterise assets preventing downtime.

Who should read this? – Asset Managers in the onshore wind industry with responsibility for managing and maintaining oil filled transformers.

Causeymire – Ventient Energy

Thorne & Derrick have recently worked in partnership with Ventient Energy to provide a bespoke electrical heating solution for an onshore wind application. After a number of site meetings and application surveys with the client to understand the problem, T&D proposed a bespoke heating jacket solution to prevent downtime due to low temperatures.

Jon Priddy of Ventient Energy describes the problem

“For those of you managing assets with ageing oil filled transformers you may find this useful. If you do you’ll know that the tank expands and contracts with heat and cold. As they age the tank loses that capacity to contract and so now you have a bigger volume but the same amount of oil and usually a very finely tuned oil level sensor which as we know is a primary safety and protection feature.

Come the winter and those high pressure low wind speed days and bang, we have a trip. I have spent many a late night with the site team topping up, getting the contacts to close and getting everything back on. The result is downtime, a hit on availability and a hit on generation.

What’s the answer? A hugely costly campaign to change out all the transformers, a nearly as expensive retrofit of conservators (if you have the room and a good design), heating the transformer compartment in a large drafty steel tower fighting the physics of heat loss.

Obviously it doesn’t affect every site but typically anything over 15 years where the tank has lost that capacity to contract back to normal shape after the summer or high generation is a candidate.”

The nature of the problem included a number a variables and it was agreed that T&D would provide 5 trail heating jackets which would be put into use throughout the winter of 2022/23. The jackets were installed to the “top 5 offenders” during previous winters. The trials have proven successful and the client experienced no outages as a result of low oil trips during one of the harshest UK winters on recent record.

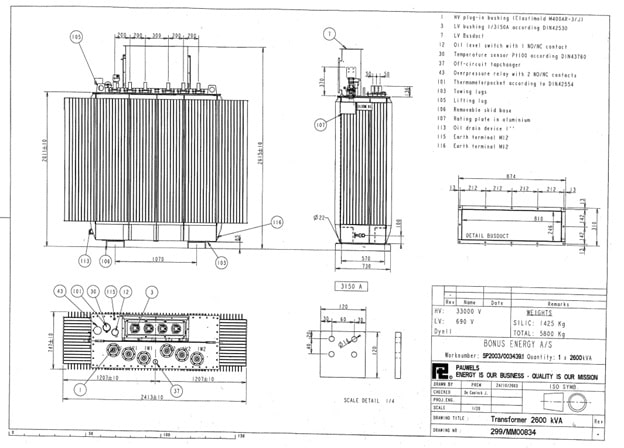

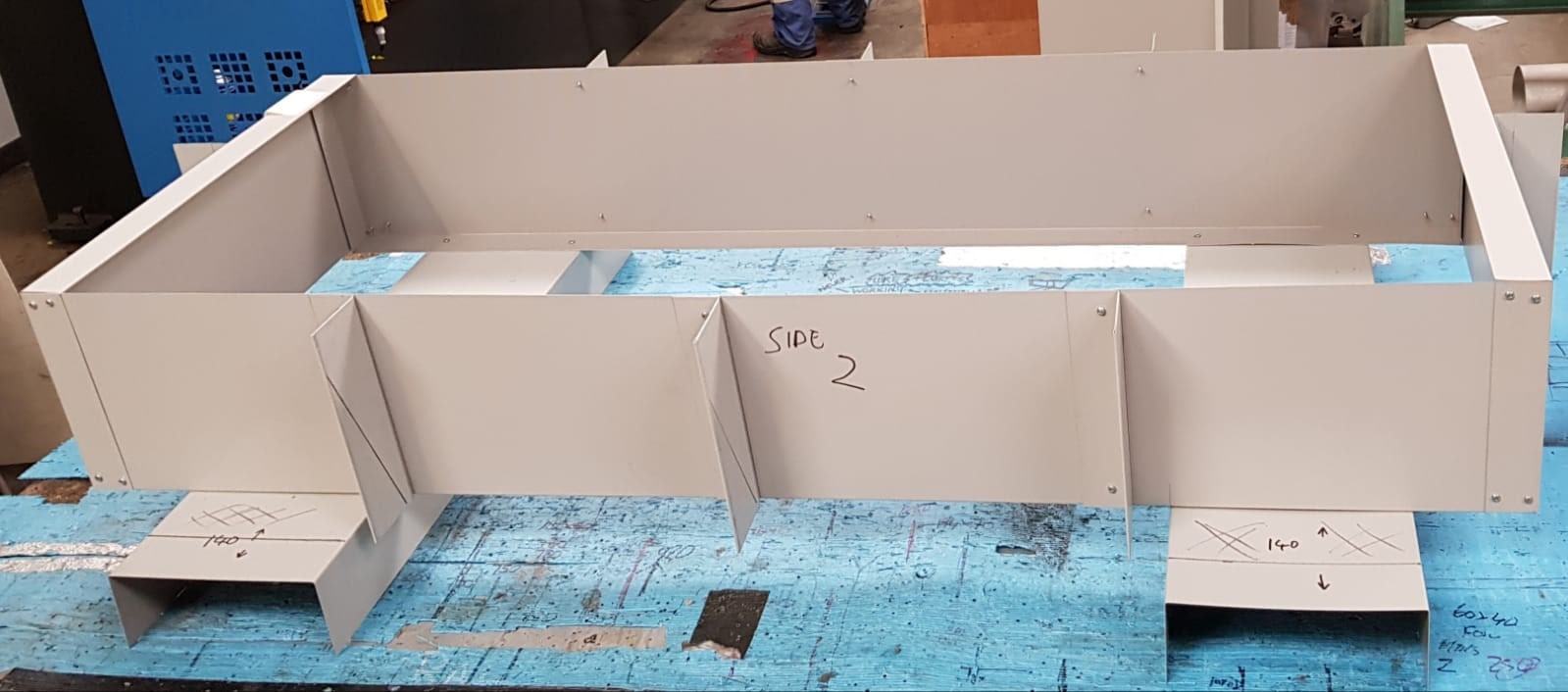

Pictured – fabricated model of the bottom of the transformer was made using the measurements taken from site survey. This meant the electrical heating jackets could be manufactured and test fitted prior to delivery.

The Solution for Oil Filled Transformers

Ventient approached Thorne and Derrick with a request for feasibility on applying a thermostatically controlled electric heating blanket to the base of the transformer with a view to stopping the oil from contracting to the point of a trip. This typically applies on high pressure (clear skies) low wind speed days and nights when there’s little in the way of current going through the transformer and temperatures drop to or minus zero.

Consideration had to be given to:-

Jacket Design – the client needed a solution which was simple and could be easily fitted, ideally as a single piece. The jacket also had to provide a very good fit as any additional heat losses may have negatively affected the overall performance. Representatives from T&D made the journey to Causeymire wind farm to carry out a site survey.

Power Supply – the power available was restricted due to only a single socket outlet being available.

Energy Efficiency – the design needed to be fit for purpose but using excessive power to solve the problem wasn’t an option.

Heat Loss – T&D have many years trace heating design experience and have carried out thousands of heat loss calculations for pipes, tanks and vessels. This was particularly challenging as we didn’t know the optimum oil temperature that would prevent it contracting enough to cause a trip. A safety factor had to be built into the design without using unnecessary power/energy.

Maintenance – any solution needed to be low/zero maintenance due to the remote location. The solution offered a fit and forget heating jacket. Once commissioned the jackets will operate using built in digital control thermostat. Any maintenance/inspections can be carried out alongside other routine maintenance.

Before & After Jacket Was Fitted to the Oil Filled Transformers

Heating Blanket For Oil Filled Transformer

Custom Heating Solution

Bespoke Heating Jacket

Client feedback

“The blankets were installed last year and wired up in November. A winter with some spectacularly low temperatures and some nights with low wind speeds has followed. And until 2 weeks ago, no low oil trips. This is the first winter in the last 6 where we haven’t had the problem.

Almost by way of verification the low oil trip 2 weeks ago occurred on one of the transformers without the blankets. The blankets are currently set to come on at 5°C ambient air temperature.

As usual with these things team work makes for the dream work. A huge shout out to Terry McDonald of Thorne & Derrick for crunching the numbers, doing the physics and coming up with a design, that was easy to fit and forget.

The great support and encouragement from the Ventient team, Alexa Belsham, Rui Meneses, who were willing to spend the cash and give it a try. For the support as ever from Tony Crombie who helped make the case and for Colin McIver of DWT for coming up with a power supply solution. A true “can do” team and collaboration.

So in short, it looks like we have a fix for this expensive (in every sense) issue with ageing oil filled transformers in colder climes.”

T&D have over 30 years process heating experience and are your pro-active problem solvers. If you are reading this and experiencing similar issues, please reach out to T&D and we will be happy to arrange an initial meeting to discuss your requirements.

Who are Ventient Energy?

Ventient Energy is a dynamic, pan-European renewable energy business and is one of the leading generators of renewable energy in Europe. They are Europe’s leading independent onshore wind group, with over 140 generating sites.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Pfisterer CONNEX & SEANEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages. Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.

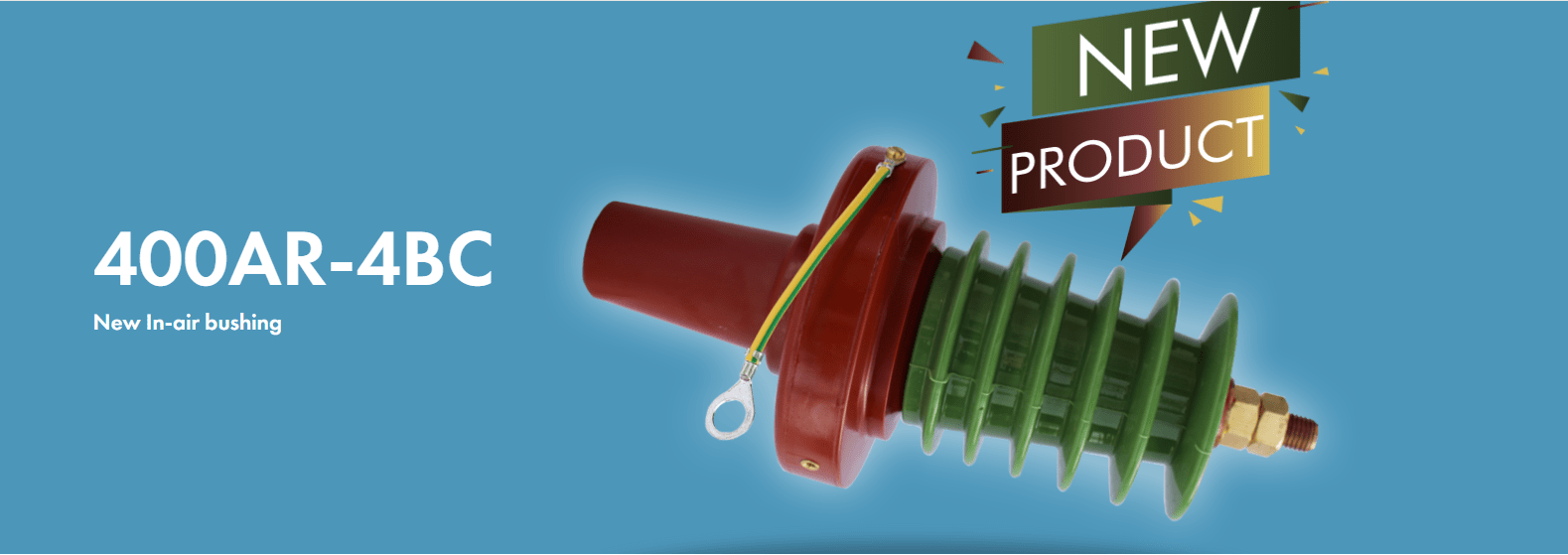

400AR-4BC from Nexans | NEW Euromold Interface C High Voltage Bushings

January 24th, 2023Nexans 400AR-4BC HV Bushings

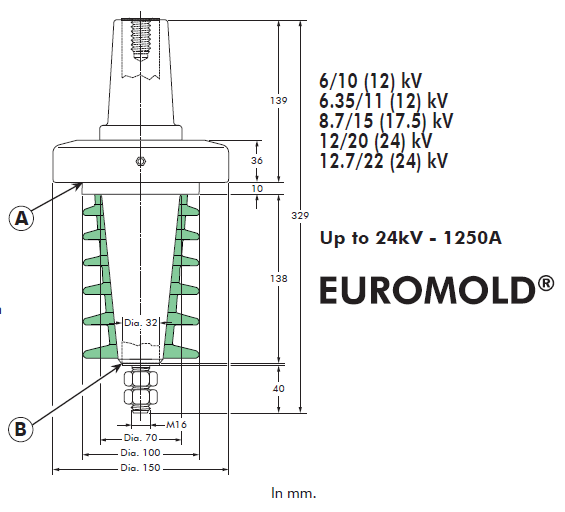

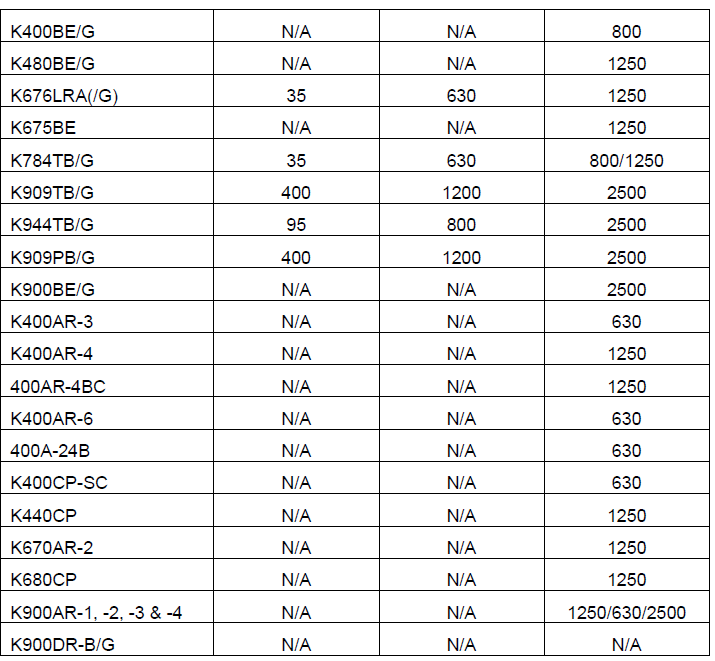

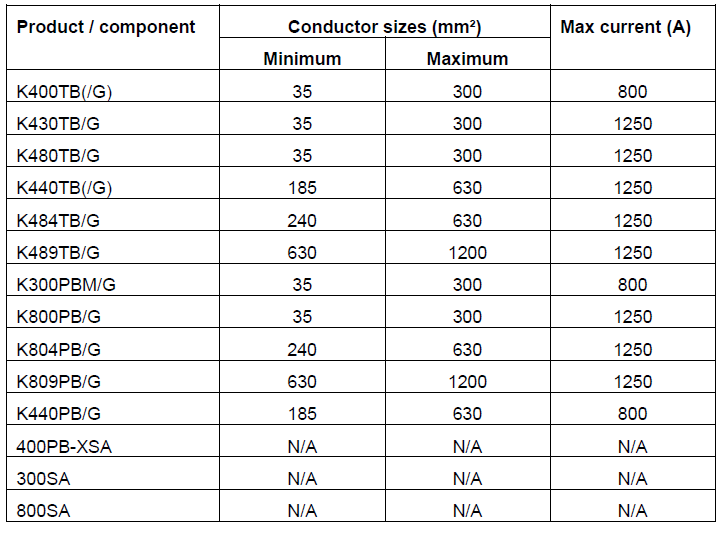

Thorne & Derrick, UK Distributor for Nexans Power Cable Accessories, are pleased to announce the release of the new EUROMOLD® Interface C in-air bushing 400AR-4BC, up to 24kV – 1250 A. The new Interface C in-air bushing 400AR-BC will replace the Interface D in-air bushing 672TBC, for use in medium voltage electrical equipment insulated with air in hazardous area locations according to the ATEX Directive.

The in-air MV equipment bushing is used in industrial applications such as the manufacture of motors, pumps and locomotives – the bushing is ATEX Certified for use in Potentially Explosive Atmospheres according to the following classification:

- II 2 G

- Ex eb IIC Gb

- Ts= -20°C to 95°C

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from Nexans Euromold to connect, splice, repair and maintain medium/high voltage cable and power distribution systems

The correct selection and specification of Nexans Euromold connectors is dependent on the cable specification and the electrical equipment MV HV bushing type. There are 6 bushing interfaces common to MV electrical equipment (A, B, C, D, E or F).

Nexans 400AR-4BC In-Air Bushing

400AR-4BC Advantages

- On the new Interface C in-air bushing you can install all separable connectors of the Interface C product family. It also offers the possibility to install a Surge Arrester.

- The new Interface C in-air bushing is also available with ATEX/IECEx/UKEx certification.

Part Number

703937 – K400AR-4BC/J + KBC-RING CLAMP 3 *SS

703939 – K400AR-4BC/J-ATEX-IECEx + KBC-RING CLAMP 3 *SS

The bolted type equipment bushings 400AR-4BC are moulded epoxy insulated parts and meet the requirements of CENELEC EN 50180. A non-tracking insulating rubber boot is installed over the bushing shank.

Specification | Construction & Electrical Characteristics

- Connector Shape | Bushing

- Connector Type | Male

- Conductor Material | Copper & Aluminium

- Technology | Cast Resin

- Rated Voltage Uo/U (Um) | 12/20 (24)kV

- Maximal Partial Discharge at 2Uo | 10 pC

- Dielectric Withstand Voltage, 50Hz 1mn | 55kV

- Impulse Voltage | 125kV

➡ Contact Thorne & Derrick for further order information

T&D Win Excellence in Customer Service Award At HazardEx 2021 | Read Press Release

Thorne & Derrick International, based in the UK, were voted Winners of the Award for ‘Best Customer Service’ at the HazardEx Gala Dinner in 2021. The competitive Award category at the prestigious event was for providing excellent customer service over previous 2 years.

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries. Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas. Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Low & Medium Voltage Cables & Hazardous Area Electrical Equipment to UK and international projects.

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick supply LV HV Cable Accessories, Installation & Electrical Equipment – we can assist with the Competitive Supply & Technical Specification of joints, terminations, connectors and preparation tools for the energisation of all types of air or gas insulated electrical equipment from stock up to 66kV.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Filoform, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

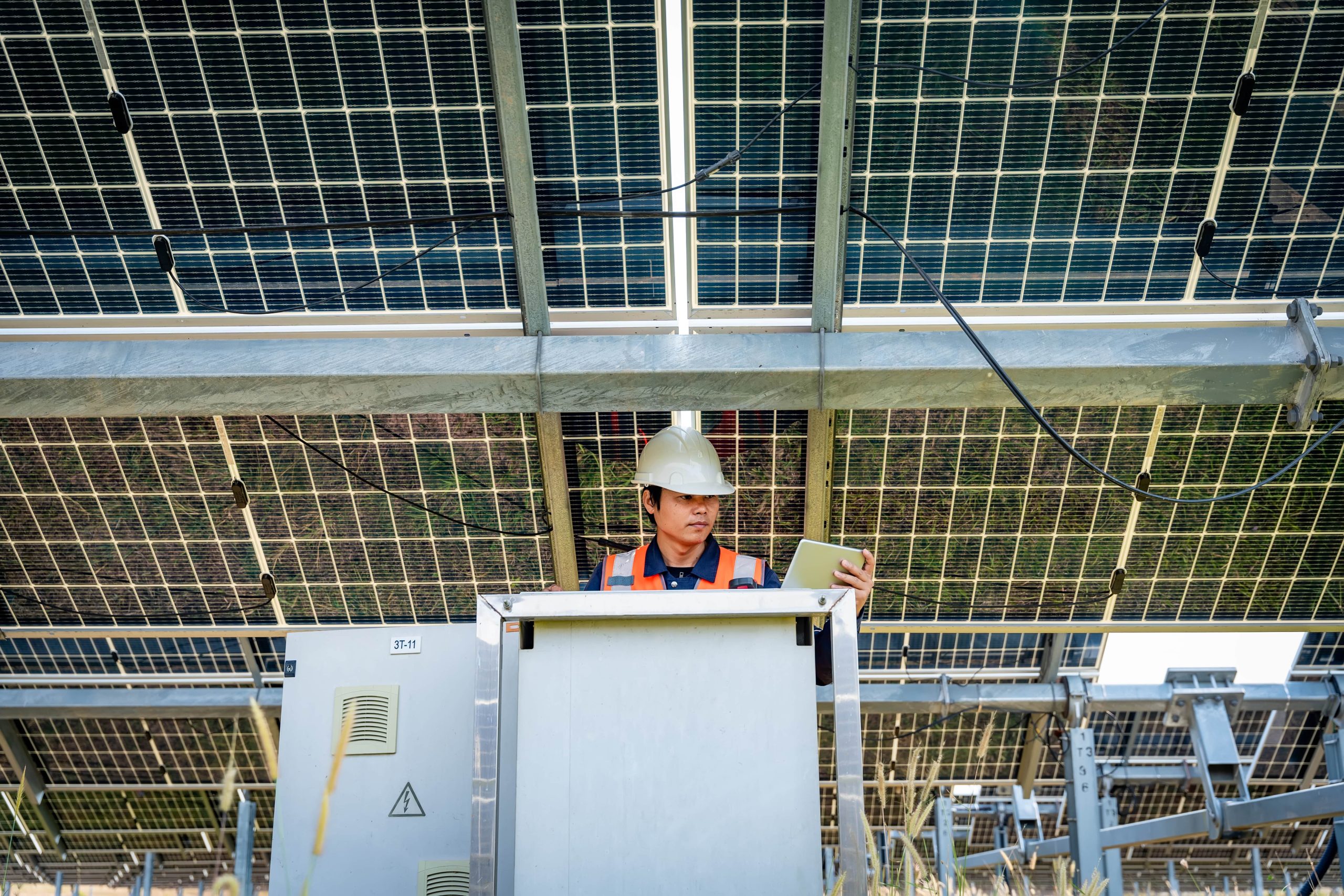

Electrical Safety Management | Solar Farms & Electrical Safety

January 23rd, 2023

Electrical Safety

Solar Farms

-

Guest Article By Paul Hopton Deputy Managing Director at Electrical Safety UK Limited

Thorne & Derrick distribute electrical safety equipment to substation engineers, cable jointers, overhead linesmen and utility workers – this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment in the solar industry.

Electrical Safety Products for LV MV HV Cables, Conductors, Substations & Overhead Lines

Electrical Safety UK

Electrical Safety UK have helped many companies in different industries in a number of locations around the World to improve their electrical safety management systems.

In this Article we are going to focus on Solar Farms and discuss whether there any hazards that may be specific to that industry.

We recently carried out an electrical safety audit in the Middle East at one of the largest solar farms in the world. The brief was to carry out an audit of their current operations and safety management system to identify if any improvements could be made.

We started by interviewing Electrical Managers, Supervisors and Tradesmen to ascertain where they had good practice and where improvements could be made. The scope of these interviews covered but was not limited to:

- Electrical Safety Policy

- Electrical Safety Rules

- Tools, Test Equipment and Test Leads

- Competency and Authorisation

- Asset Integrity and Maintenance

- Portable Electrical Apparatus

- Arc Flash Risk Management

- Electric Shock Risk Management

- Lightning Protection

- Toxic Gases

- Isolation Practices

- Electrical Accident Investigation and Root Cause Analysis

- Software and Device Parameter Backups

- Reliability and Bad Actors

- Safe Systems of Work including Switching Programs and Earthing Diagrams

We also carried out site surveys and asked personnel who were working on site about electrical safety and the management of electrical risks.

Results

We identified several areas where there were opportunities to improve. These were presented to the site management team in a feedback presentation and more formally in a report. The findings showed significant opportunities in Arc Flash Risk Management, Isolations and Electrical Shock Risk Management.

Hazards specific to Solar Farms

The main issue specific to Solar Farms that we identified was with the Solar Panels themselves as they generate electricity. The good news is that Solar Farms are modular and so it is easier to produce isolation and safe working procedures, than for more typical industrial or commercial electrical distribution systems.

“Test before touch” or “Test for dead” processes are very important. You should ensure that the correct type of test equipment is used. Voltage indicators should be tested immediately before and after use with a proprietary proving unit.

There are also a lot of power inverters and other enclosures out in the field that should be shrouded to IP2X to minimise electric shock risk during fault finding activities. As the Solar Farm gets older, it is important to make sure that the IP2X protection is maintained by auditing and inspection especially during and after maintenance activities.

Electrical Safety Management Systems

I think it is fair to say that Solar Farms have not been around as long as many industrial and commercial electrical networks and can be operated by organisations that do not have a long history of electrical safety management experience. This lack of experience can lead to gaps in their Electrical Safety Management Systems.

Unfortunately, failures of an Electrical Safety Management System can result in serious injury or fatality. Fortunately, these events are rare but because of the complacency that can result from their scarcity, when the holes in the Swiss cheese line up, the worst can happen.

Far better to have someone independent to the Organisation to audit your Electrical Safety Management System to prevent the accident before it happens.

Solar Farms can sometimes be operated and maintained by the Company that designed and installed them rather than the owner. Dependent upon the Company supplying the Solar Farm, they may or may not have a great deal of operational and electrical safety management experience. If they do lack experience, they might be more likely to have an electrical accident.

The Company owning the asset (Electrical Duty Holder) might not take kindly to the exposure to public/regulatory scrutiny that this would bring.

READ Blog | Ten Most Common Errors in Arc Flash Studies

Arc Flash Studies

Calculating the arc flash hazard for each of piece of equipment on a Solar Farm should cost significantly less that carrying out an arc flash study on a typical industrial or commercial electrical distribution system.

The reason for this is that Solar Farms tend to be very modular in their construction. Therefore detailed modelling of one of the modules can be quickly and cheaply replicated many times for the rest of the network.

This obviously reduces the overall cost of the arc flash study for a Solar Farm versus other types of electrical networks.

About Electrical Safety UK

Electrical Safety Management is our core business. We provide expert consultancy and advice services for blue chip organisations across Europe concerned with the safe management of risk associated with all electrical work activities.

Electrical Safety UK provide a multi-faceted holistic approach including a full electrical safety management programme, project management and policy documentation all bespoke to the client’s requirements including fully accredited and bespoke training courses and personnel assessment programmes.

2 Genesis Business Park

Sheffield Road

Rotherham

S60 1DX

Tel: 0800 652 1124

Tel: 01709 961 666

Email: [email protected]

To find out more information click here

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Further Reading

- Solar Farms | Insulate, Connect & Protect LV HV Electrical Cables & Equipment

- Electrical Safety Management | Solar Farms & Electrical Safety

- Jointing, Grounding & Terminating DC Solar Cables

- PR: Solar Industry Relaxes Planning Laws For Large Scale Battery Storage

- UKPN 33kV Primary Substation Construction – Swanland Solar Farm