Cable Glands

Correct Installation of Hawke Cable Glands

May 16th, 2025

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Hawke Cable Glands Installation

Installing Hawke cable glands correctly is essential to ensure the integrity, safety, and performance and cable termination of your LV MV HV electrical systems—especially in hazardous environments like oil & gas, petrochemical and industrial sectors.

In this guide, we’ll walk you through the correct method for installing Hawke cable glands, share common mistakes to avoid, and explain why proper installation matters.

Step-by-Step: How to Install Hawke Cable Glands Correctly

1. Select the Right Cable Gland

Identify the cable type and choose the correct Hawke gland suited to both your cable and application. For example:

-

501/453/Universal – for unarmoured cable

-

501/453/RAC – for armoured cable

Confirm compatibility with:

-

Cable diameter

-

Armour type (SWA, braid, tape, etc.)

-

Zone rating (Zone 1, Zone 2)

2. Prepare the Cable

-

Strip the cable sheath as specified

-

Ensure no damage to internal conductors or armour

-

Trim and shape armour to fit cleanly inside the gland

3. Assemble the Hawke Cable Gland

Follow Hawke’s installation sequence precisely. Key components include:

-

Entry item

-

Inner and outer seals

-

Armour cone and clamping ring (for armoured cables)

-

Compression nut

Install in the correct order and apply any IP sealing washers where required.

4. Tighten & Secure

Use two spanners:

-

One to hold the gland body

-

One to tighten the compression nut to the recommended torque

This ensures:

-

Proper grip on the cable

-

Correct compression of sealing elements

-

Safe electrical continuity and strain relief

The cable gland is permanently marked with various lines/numbers indicating the correct tightening level related to the cable diameter. Following the relevant cable gland Installation Instructions, the back seal should be tightened until a seal is formed on the cable outer sheath and then tightened one further turn

5. Final Cable Gland Checks

-

Confirm ingress protection (IP rating)

-

Check earth continuity for armoured installations

-

Inspect for visible damage or loose components

Common Installation Mistakes to Avoid

-

❌ Using the wrong gland type for the cable

-

❌ Over-tightening or under-tightening

-

❌ Incorrect sequence of gland components

-

❌ Poor cable preparation or incorrect stripping of cable

-

❌ Forgetting to earth the armour

What Makes Hawke Glands Different?

Hawke’s range of cable glands are globally recognised for their robust construction, Ex-rated safety, and easy-to-install designs.

Whether it’s Ex d (flameproof), Ex e (increased safety), or Ex nR (restricted breathing), Hawke has a solution that safeguards your installation integrity—whatever the environment.

Need Support Choosing the Correct Cable Gland?

At Thorne & Derrick, we help you get it right the first time. As trusted Stockists & Distributors of Hawke cable glands, we provide:

-

Technical support

-

Product selection advice

-

Same-day dispatch for stocked cable gland items

Contact our team today or explore our full range of Hawke cable glands.

Cembre Cable Glands | MAXIBLOCK & MAXIBRASS New Ranges

May 28th, 2024

Cembre designs and manufactures solutions for the connection, glanding and termination of electrical conductors: including connectors, cable lugs and installation tools for cutting and crimping cables.

Cembre MAXIBLOCK & MAXIBRASS Cable Glands

Thorne & Derrick are a UK Specialist Distributor for Cembre, the leading European Manufacturer of electrical connectors, crimping tools, cutting tools and a variety of accessories for LV, MV & HV (Low, Medium and High Voltage) power systems. Designed for working in and around switchgear and control panels, Cembre tools are ideal for installing low and medium voltage connectors and cable lugs.

MAXIblock & MAXIbrass rANGES

Cembre have expanded the new range of MAXIblock & MAXIbrass cable glands, which are becoming more flexible and practical for equipment and electrical panel applications.

|

|

- Cembre MAXIblock 1940.M Metric Thread 1.5 Pitch

- Cembre MAXIbrass 2940.M Metric Thread 1.5 Pitch

This new range of MAXIblock and MAXIbrass cable glands manufactured by Cembre allow the passage of cables with a larger diameter, saving space and time on installations by becoming increasingly flexible and practical compared to the standard range of cable glands which makes it possible to install large diameter cables.

The 1940.M and 2940.M series are characterised by the extended cable entry compared to the standard range, a longer thread makes installation on thick plates easier.

Extended Cable Entry | EV CHarging Points

The installation of cables with larger diameters is now possible due to the extended cable entry. An extension on the entry thread makes it possible to install on thicker sheet metal.

The 1940.M and 2940.M series are in fact characterised by an extended clamping range compared to the standard range. In this way, the needs of installers and customers are met by maximising the relationship between the diameter of the cable and the entry hole in the electric panel or equipment.

ev cHARGING POINTS

The new designs of the MAXIblock 1940.M and MAXIbrass 2940.M are ideal for applications such as EV chargers and wind turbines.

With the same thread as the standard range, the 1940.M and 2940.M allow the passage of cables with a larger diameter, saving space and time on installations. Additionally, a longer thread also makes installation on thick plates easier.

- Ideal for EV chargers and wind turbines

- Single hole on electrical panel for multiple uses

- Stop using adaptors

IP Protection

Cembre Cable Glands

Cable glands are mechanical cable entry devices that attach, secure and terminate cable ends to an electrical enclosure or directly into equipment providing for mechanical support, earth continuity for armoured/braided cables and protect against the ingress of dust and moisture according to the ingress protection (IP) rating.

Benefits

- Ingress protection IP68 guarantees protection against water and dust

- Temperature range: -40°C a +100°C (Static) of operating temperature

- MAXIblock and MAXIbrass are NEMA Certified

- VDE Certification provides a guaranteed safe use of the product for the user

Cembre is a leading European manufacturer of electrical connectors, crimping tools, cutting tools and a variety of accessories for LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) power systems. Designed for switchgear and control panels, Cembre tools are ideal for installing low and medium voltage connectors.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

T&D are Specialist Distributors of LV MV HV Cable Installation, Jointing, Substation & Electrical Equipment – we supply companies in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors with products to enable the energisation, operation and maintenance of underground cables and overhead lines.

Cable Glands & Sealing Solutions For Hazardous Areas

October 5th, 2020Triton CDS & RapidEx from CMP

Cable Gland & Sealing Solutions For Hazardous Areas

-

Special thanks to Jade Appleby (Digital Marketing & PR Co-ordinator) and Laurie Wilson (UK & Ireland Sales Manager) at CMP Products Limited | Uploaded by Chris Dodds (Thorne * Derrick International)

Thorne & Derrick, a leading UK based Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt for use in Explosive Atmospheres, are proud to present product innovation from CMP – the world-leading manufacturer of cable glands for the safe termination and sealing of cables in potentially explosive atmospheres.

This Guest Article contributed by CMP describes their cable sealing solutions for hazardous areas featuring their Triton T3CDS cable glands and RapidEx barrier cable glands.

Triton CDS

Right-First-Time Installation

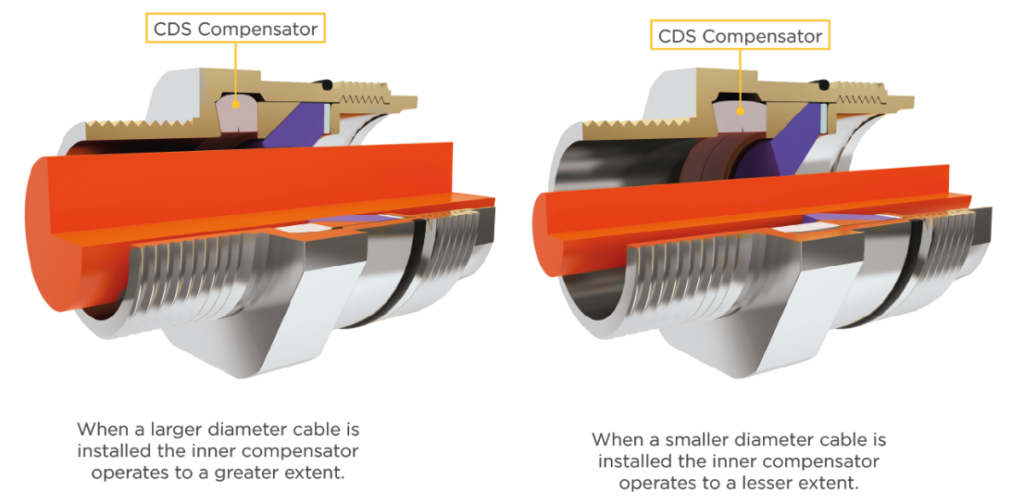

Triton T3CDS cable glands deliver a unique concept in cable sealing techniques incorporating the Compensating Displacement Seal system (CDS).

This concept provides effective sealing on the cable inner sheath utilizing a proven reliable and robust flameproof seal.

The CDS system is activated at the critical cable sealing point, protecting the inner sheath from any excess force. The force is instead transferred and absorbed by the internal compensator in the CDS system, allowing metal-to-metal tightening every time regardless of cable diameter.

Triton CDS Compensator | Triton CDS (T3CDS) | Ex eb, Ex db, Ex nR & Ex ta | The Explosive Atmosphere Cable Gland for all types of Armoured Cables

CMP Displacement Seal

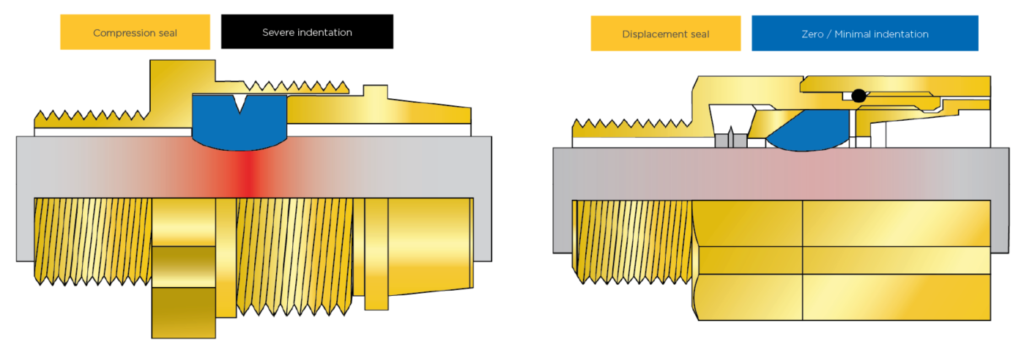

The below illustrations demonstrate how CMP’s displacement seal reduces indentation on the cable – the installation is independently controlled by the user during installation of the cable gland to achieve secure flameproof sealing and wire armour termination.

CMP Displacement Seal

Additional Cable Sealing Benefits

- Deluge protection seal, third-party tested to DTS:01

- Full sequential, three step make-off procedure

- Complies with low voltage directive 73/23/EEC

- Uniform hexagon profile

- Options available for VSD and lead sheath cables

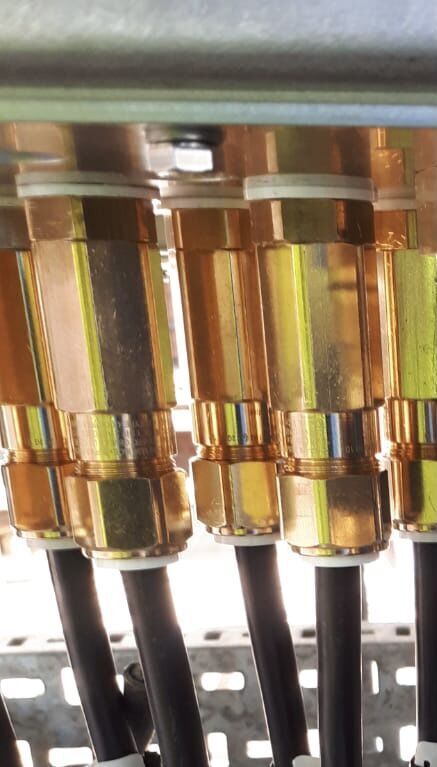

Cable Glands | The T3CDS hazardous area cable gland, manufactured by CMP, supplied in brass as specified by the end customer allows for quick installation and ease of inspection throughout its life on site.

RapidEx – The Original Sealing Solution for Barrier Cable Glands

A barrier gland is a cable gland that provides an effective seal around the individual cores of a cable to maintain the flameproof integrity of Exd Explosion Protected equipment.

Traditional barrier cable glands employing an epoxy-cured clay-based sealing compound, have been used in the industry for many years, to provide effective explosion protection.

However, a certain degree of skill is required with this traditional installation process and the risk of voids increases with the number of cable cores.

Multi-core cable requires the highest degree of competence and a long installation time to ensure a void-free, safe installation.

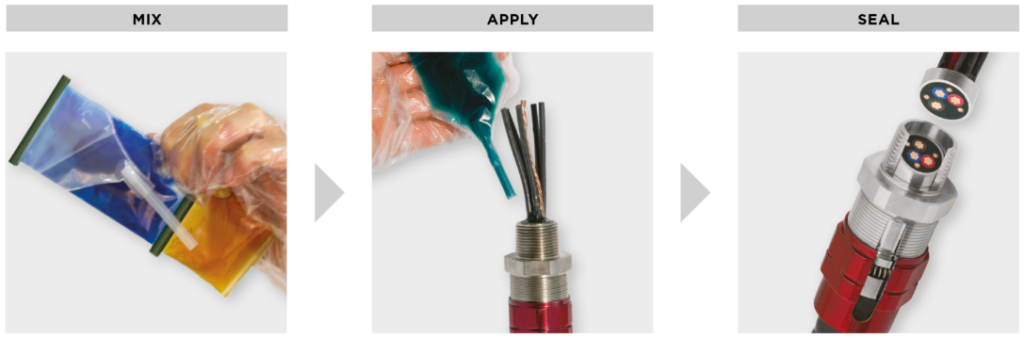

Revolutionary Rapidex | RapidEx is a revolutionary liquid resin sealing solution for barrier cable glands and unions, for use in conjunction with flameproof or explosion-proof enclosures.

In 2012, CMP introduced RapidEx to the market.

RapidEx is a liquid-pour, fast-curing, liquid resin barrier seal that installs in seconds and cures in minutes. The barrier gland has since been installed on a number of major global projects for safe and secure sealing of cables in explosive atmosphere industries including oil, gas and petrochemicals.

Its unique formula begins with a low viscosity liquid that flows into the cable interstices, completely surrounding the cable conductors, and in the process displacing the air from the cable gland’s sealing chamber ensuring the perfect seal.

The viscosity increases and completely cures in less than 40 minutes (at 20°C / 68°F).

- Enhances reliability, reduces risk

- Delivers unprecedented reliability

- Minimises installation time

- Clean and easy to use

CMP RapidEx is certified for use in explosive atmospheres with global certification including approval under ATEX, NEC, CEC and IEC installation codes, and is available with a series of CMP barrier cable glands and unions.

➡ See the full range of CMP RapidEx Barrier Cable Glands for hazardous areas and explosive atmospheres.

NEW Product Launch

717 Stopper Plug

CMP 717 nylon stopper plug range is available for use in industrial applications (717) or explosive atmospheres (717e).

The 717 range of stopper plugs allow customers to ‘blank’ unused cable entries and are manufactured from a unique polymer; providing a combination of strength and durability over the longer term – or simply providing a temporary solution.

Designed to reduce cost and installation time, both the 717 and the 717e feature a universal installation design, comprising a hex-head for spanners, a flat screwdriver and allen key recess. Both products are tested to IP66, IP67, IP68 & IP69(K) without the need of an additional entry thread seal, reducing time as well as cost of installation.

The interface between the stopper plug and its associated enclosure / cable entry does not require additional sealing to achieve ingress protection (IP) ratings higher than IP54.

The minimum protection level is IP54 for explosive gas atmospheres and IP6X for explosive dust atmospheres.

CMP GLANDS

DISTRIBUTORS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stocks for the complete range of CMP cable glands for connecting, terminating and sealing all types of LV MV HV cables located in industrial non-hazardous, hazardous area zones and medium/high voltage electrical systems.

As well as cable glands, CMP offer a range of cable cleats that are designed for a variety of industries including the data centre, renewable energy, utility and rail market where high performance and a compact design of cable cleat is critical for the retention of cables in the event of a short circuit fault situation.

UK Leading Dsitributors of Hazardous Area Electrical Equipment | LV MV HV

Experts in Equipment for Explosive Atmospheres

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, Heating & Lighting Products to your UK and international projects.

NEW BLOG

IECEx Cable Gland Selection Guide For Hazardous Area Zones

October 9th, 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

In this Blog titled IECEx Cable Gland Selection Guide For Hazardous Area Zones we will cover the following sections of the classification and guidance document for the selection of cable glands for hazardous areas:

- Cable Type / Cable Gland Type

- Hazardous Area Protection Method

– When to use a Barrier Gland - Environmental Conditions

- Installation / Inspection Considerations

Credit to ➡ International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx System).

Cable type & Cable gland type

Unarmoured

W – Single wire armour SWA

or Aluminium wire armour AWA

X – Braid

T – Pliable wire armour

Y – Aluminium strip armour

Z – Double steel tape armour

A – Single seal only

B – Armour clamp only

C – Armour clamp and seal on outer sheath

D – Armour clamp and seal on inner sheath

E – Armour clamp and seal on inner and outer sheath

Each cable gland type has sub-sets:

e.g.

E1W = E1W cable glands with IP66 seals on inner and outer cable sheath

E2W = As E1W type cable gland but E2W cable glands are with an electrical bond for a metallic inner sheath (e.g. lead sheathed cable)

Cable glands are often named to describe their function, e.g. E1FX, E1FW.

Cable Gland Size

The cable gland size must be selected to match the cable size.

IEC 60079-14:10.2 Selection of Cable Glands

The cable gland shall be selected to match the cable diameter. The use of sealing tape, heat shrink tube or other materials is not permitted to make the cable fit to the cable gland.

Hazardous Area Protection Method

Ex d / Ex e / Ex nR

The protection method MUST meet or exceed the protection level of the equipment that the cable gland is connected to. This is a requirement of IEC 60079-14: Clause 10.2.

Extract from Table 10 of IEC 60079-14

| Explosion Protection Technique For The Equipment | Cable Gland Protection Technique | ||

| Ex d | Ex e | Ex nR | |

| Ex d | X | ||

| Ex e | X | X | |

| Ex nR | X | X | X |

| Ex i Group II | X | X | X |

| Ex p | X | X | X |

When to use a barrier gland

Barrier glands are always certified Ex d, but can be used in an Ex e environment.

How do you know when to use them?

When to Use a Barrier Gland – Ex d

A barrier gland MUST be used in an Ex d environment unless the cables:-

- Circular and compact

- Have an extruded bedding or sheath

- Use non-hygroscopic fillers

Old Rules in IEC 60079-14

New Rules – Barrier Gland Ex d

The cable entry system shall comply with one of the following:

a) Cable glands sealed with setting compound (barrier cable glands)

b) Cables and glands meeting all of the following:

– cable glands comply with IEC 60079-1 and are certified as equipment

– cables used comply with 9.3.2(a)

– the connected cable is at least 3 m in length;

c) indirect cable entry using combination of flameproof enclosure with a bushing and increased safety terminal box;

d) mineral-insulated metal-sheathed cable with or without plastic outer covering with appropriate flameproof cable gland complying with IEC 60079-1;

e) flameproof sealing device (for example a sealing chamber) specified in the equipment

documentation or complying with IEC 60079-1 and employing a cable gland appropriate to the cables used. The sealing device shall incorporate compound or other appropriate seals which permit stopping around individual cores.

The sealing device shall be fitted at the point of entry of cables to the equipment.

The cable entry system shall comply with one of the following:

a) Cable glands sealed with setting compound (barrier cable glands)

b) Cables and glands meeting all of the following:

– cable glands comply with IEC 60079-1

– cables used comply with 9.3.2(a)

(They shall be circular and compact. Any bedding or sheath shall be extruded. Fillers, if any, shall be non- Hygroscopic)

– the connected cable is at least 3 m in length

The HSE in the UK has issued a bulletin stating that installations to the ‘new rules’ may not be safe and has suggested that the old flowchart used.

If in doubt USE A BARRIER GLAND.

➡ CMP PX2K-REX RapidEx – Revolutionary Sealing Solution for Barrier Cable Glands

Barrier Glands

When to use a Barrier Gland – Ex d

Barrier glands should also be used:-

- In Ex e applications when there is a risk of gas migrating down a cable. (IEC Ex 60079-14 clause 9.3.2)

- In Ex nR applications where the cable is not sealed. (IEC Ex 60079-14 clause 10.8)

Modern ‘liquid resin’ barrier glands are easy to install.

Environmental Conditions

Four main areas to cover in this section:

• Temperature

• Ingress protection (IP)

• Dissimilar metals

• Corrosive environments

Temperature

- Cable glands do not have a ‘T’ rating

- Under existing IEC Ex rules, the temperature rating of a cable gland does not have to include the thread sealing gasket

- Responsible cable gland manufacturers test and certify their cable glands and sealing gaskets together

Ingress Protection (IP)

A sealing gasket may be needed to maintain the IP rating of the assembly.

(IEC Ex 60079-14 clause 10.2)

Check that the thread sealing washer has been tested with the cable gland as part of the certification process. (The IP rating will be shown on the IEC Ex certificate.)

Dissimilar Metals

- Ideally the cable gland should be made of the same material as the equipment and the cable armour it is connected to

- For most equipment electroless nickel plated brass is the best option

Brass gland fitted to an aluminium enclosure

Superior Marine grade nickel plated brass gland fitted to an aluminium enclosure

Corrosive Environments

Corrosive environments may typically include:-

- Salt / salty water

- SO2

- NH3

For many corrosive environments a good quality nickel plated brass cable gland is the best choice

- Not all plating is equal

- Specify at least 10 microns of plating thickness

(The rules on plating thickness changed with the 2014 edition of IEC 60079-1. Clause 5.1 now allows a thickness greater than 8 microns.)

Not all electroless Nickel Plating is equal – Before & After Salt Spray Test

For highly corrosive environments the choices are either:-

- Stainless steel

- Specialist corrosion protected cable glands

Installation / Inspection Considerations

Choose cable glands that are:-

• Easy to install

• Don’t have parts that can get mixed up

• Don’t have loose parts

• Can be inspected easily

Further Reading

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick International, based in the UK, are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Prysmian Glands – Industrial Cable Gland Selection

March 29th, 2018➡ The following selection table enables the specification of Cable Glands manufactured by Prysmian to suit industrial cable installations – view the complete range of Prysmian Cable Glands for industrial, hazardous area and medium/high voltage cables.

| Location | Armour | Cable Gland Description | Prysmian Part Reference | Cable Gland Type | |

| Industrial | Indoors | SWA | BW Cable Gland | KA410 | |

| BW Cable Gland LSF LSOH | 420LSF | ||||

| BWL Cable Gland | KJ417 | ||||

| Outdoors | Unarmoured | A Type Nylon Gland | 403K |  |

|

| A Type Nylon Fire Resistant Cable Gland | FP2520 |  |

|||

| A1 A2 Cable Gland | KM409 (V) | ||||

| A1 A2 Cable Gland LSF LSOH | 423LSF (V) | ||||

| CY SY Braid | AXT Cable Gland | 423AX | |||

| SWA | CW Cable Gland | KA419 (V) | |||

| CW Cable Gland – Elongated Equipment Thread | KA419B |  |

|||

| CW Cable Gland LSF LSOH | 422LSF (V) | ||||

| AWA | CW Cable Gland – Aluminium | KA422 | |||

| CW Cable Gland Aluminium LSF LSOH | 432LSF | ||||

| Braid | CX Cable Gland | KA414 | |||

| CX Cable Gland – Extended | KA414B |  |

|||

| Wet Areas | SWA | E1W Cable Gland | KAA413 (V) | ||

| E1W Cable Gland – PCP Shroud | KA413 (V) |  |

|||

| E1W Cable Gland LSF LSOH | 421LSF | ||||

| High Fault Current | SWA | CW Integral Earth Gland Kit Brass | 419CE |  |

|

| AWA | CW Integral Earth Gland Kit Aluminium | 454CE |  |

||

| Dual Copper | Dual Screen Cable Gland Kit | 422DA |  |

||

Cable Glands | BW CW A2 AXT E1W | Brass & Aluminium | Prysmian