Cable Pulling & Laying

Cable Pulling Machine | Southwire Maxis XD10 EXTREME Duty Cable Puller

October 6th, 2020

Cable Pulling Machines

Southwire Maxis XD10

EXTREME Duty Cable Puller

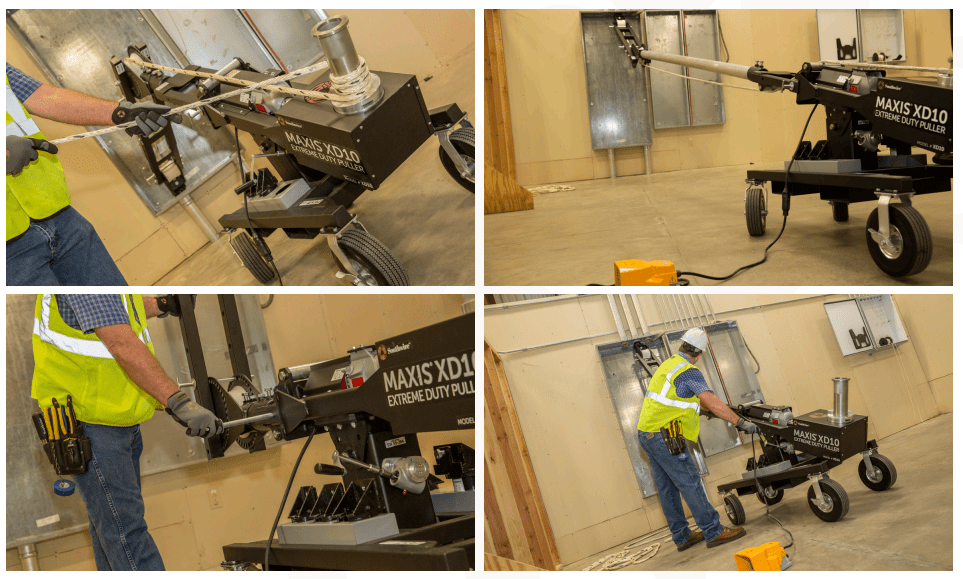

The Southwire Maxis XD10 EXTREME Duty Cable Puller is a cable pulling machine designed to get the job done, thriving in the most extreme cable pulling conditions – XD10 from Southwire allows you to pull cable faster and safer up to 10,000 lbs.

Designed and manufactured in the USA by Southwire and distributed in the UK by Thorne & Derrick – contact us for further information or to discuss a potential cable pulling or installation application.

Cable Pulling Machine – Southwire Maxis XD10 EXTREME Duty Cable Puller

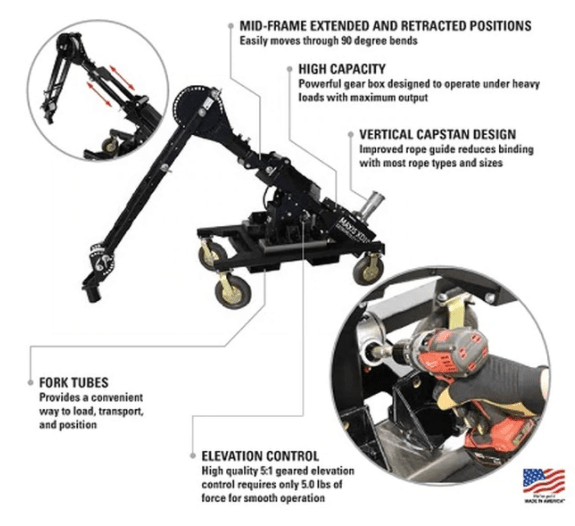

Southwire Maxis XD10 Cable Puller Features

- 10,000 lbs peak cable pulling force with a continuous pulling rating of 7,000 lbs

- High capacity: powerful gear box operates under heavy loads with maximum output

- Self contained: ready to pull cable with no need for additional parts to use for set up

- Single person set up: quickly adapts from underground cable to overhead pulls

- Smooth elevation: operates with handle or 18V cordless drill to eliminate cable lifting

- Collapsible down to 40″H x 26″W x 70″L for ease of transport and site location

➡ Best in Class rope guide and capstan prevents rope binding, the XD10 is ready to pull with no additional parts.

Southwire Maxis XD10 EXTREME Duty Cable Puller – Technical Specification

| Southwire Model | Cable Puller Description | Height | Width | Length | Weight |

| XD10 | Maxis XD10 EXTREME Duty Cable Puller | 40″ | 26″ | 70″ | 598 lbs |

| XD-10-BD | XD10-BD Maxis XD10 Bolt Down Kit | 18″ | 14″ | 16″ | 35 lbs |

Capacity – Cable Pulling Speed Low

- At 2,000 lbs 11fpm

- At 4,000 lbs 10fpm

- At 6,000 lbs 9fpm

- At 7,000 lb 8fpm

- At 10,000 lbs 7fpm

Cable Pulling Speed High

- At 2,000 lbs 20fpm

- At 4,000 lbs 18fpm

Southwire

Southwire is one of the world’s leading developers, manufacturers and suppliers of building wire and utility cable, as well as the cable tools used in their installation. As such, Southwire is continually improving its cable products, studying how they’re used in the field and assessing the needs of its customers to find new and better ways to solve the problems facing the industry – this includes underground cables and overhead line conductors.

THORNE & DERRICK

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.

SEB CD980S Extendable Cable Drum Trailer

September 22nd, 2020

CD980s Extendable Cable Drum Trailer

Cable Drum Trailer

CD980S

SEB CD980S is a cable drum trailer suitable for use “off road” with the ability to handle up to 5000mm diameter cable drums – cable drum trailers ensure safe loading, transportation and laying of LV, MV, HV & EHV cable from drums into a cable trench with a payload up to 48,000Kgs.

CD980s extendable cable drum trailer capable of off loading and carrying 50T Drums of cable. The SEB CD980S trailer concept and design which was a joint initiative between the Energy Ops Teams and Magnor Plant, Morgan Sindall’s in-house Plant Business.

The cable drum trailer successfully off loaded a 45T drum, one of 109 drums required to complete the project.

The cable trailer design has removed the need for cranes on site, no lift plans, no spindles for the trailers, all in all a much safer and cost-effective way of off loading and transporting large drums of medium and high voltage power cable.

It was three years in the design and making but a great result and real game changer for the industry, another first for Morgan Sindall.

T&D distribute the complete range of LV-HV Cable Pulling and Laying Equipment including cable rollers, cable socks, drum jacks, drum trailers, cable lubricant, underground cable protection and conduit duct rod.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Access Chambers for LV HV Power & Trackside Rail Cables | HS2 Case Study

September 7th, 2020

Access Chambers for LV HV Power & Trackside Rail Cables

Access Chambers

LV HV Power & Trackside Rail Cables

HS2 Case Study

The vast scope of redevelopment by Cubis to transform London Euston Station into the first modern, intercity transport hub for high-speed rail services is well underway. Euston Station is one of 4 stations that will be transformed ahead of the new High Speed 2 (HS2) rail line connecting London to the Midlands, the north of England and Scotland.

Network Rail and Skanska, on behalf of HS2 are delivering enabling works at the station and surrounding area, with the groundworks being subcontracted to Kilnbridge. This will see the eventual construction of a 25,260m² terminus, new high-speed platforms and improvements to the surrounding open public areas.

To enable the new Euston station development to take place, works have begun on constructing a new electrical substation that will assist in powering the station and its facilities.

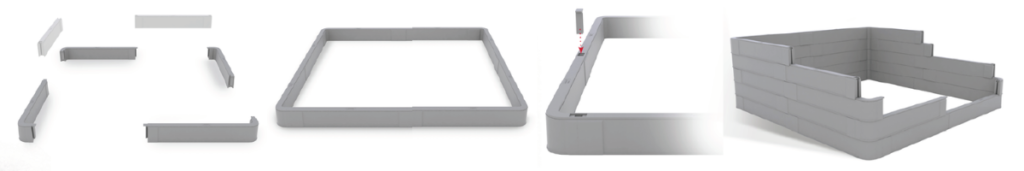

Cubis Modular Access Chamber Range STAKKAbox

The new substation, located just off the main London Euston line at Barnby, has been erected to distribute both HV and LV power cables into the substation and onward to the track and station. The substation, like many new buildings in London, is located within a restricted area with limited access, storage and mobility.

The project had a requirement for cable draw pits with easy accessibility for new power cables and in the future-proofing of the development for any new HS2 station and track cabling requirements. However, site conditions would not allow for a traditional concrete access chamber construction due weight and access restrictions. Cubis were approached to provide advice on our innovative, lightweight and modular access chamber range, STAKKAbox™.

ULTIMA Access Chamber

The team at Skanska worked with the Cubis Technical team to design and specify STAKKAbox™ ULTIMA Connect due to its lightweight and flexible onsite capabilities with the capacity to be installed manually without the need for skilled wet trades.

The individual 150mm deep sections of twin-wall GRP that make up the ULTIMA Connect chamber system provided a lightweight, modular solution with components falling under 25kg making them suitable for a single person lift under manual handling regulations.

With the added flexibility of being delivered to site with pre-drilled duct entries and the need only to reassemble the chamber components, the overall installation was significantly faster in comparison to conventional alternatives.

STAKKAbox™ ULTIMA Connect was designed and supplied to seamlessly integrate with Cubis’ B125 composite AX-S™ recessed access covers, providing a complete site chamber access and cover solution, while offering an improved aesthetic finish to the open public space, situated alongside the new substation. This integrated system offered a complete solution for the customer, reducing both time, health and safety risks and resulting in a significant overall cost saving.

Access Chamber Step By Step Installation Guide

CUBIS ACCESS CHAMBERS

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis | Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Preventing Cable Theft with Ander-Fin Rail Cable Anchoring Systems

August 18th, 2020Ander-Fin Cable Anchoring Systems

ANDERTON REDUCING CABLE THEFT

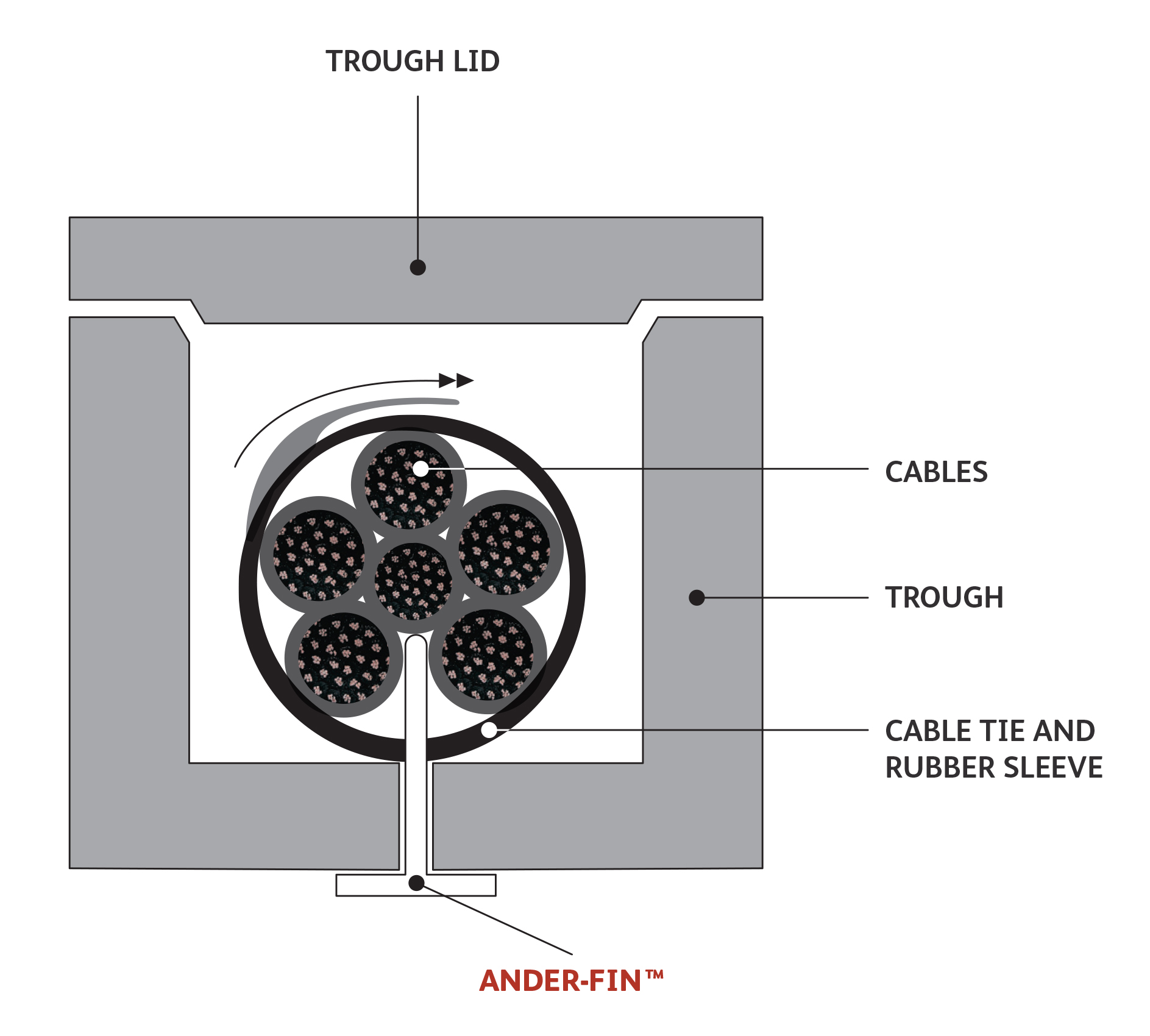

With cable theft costing the UK rail network millions of pounds each year, Anderton are tackling the issue with the launch of a new innovative-patented product, Ander-fin – this complements their market-leading range of cable trough systems specified extensively throughout the UK and international rail networks.

Ander-Fin Cable Theft Deterrent

Metal & Cable Theft

Theft of metal on the rails has been a prominent problem for many years, not only at the cost of taxpayers, but it also has the potential to bring the network to a standstill. As the leading manufacturer of precast concrete products, we have designed a system to make cable theft virtually impossible.

Ander-fin is a newly approved cable anchoring system, which is patent approved and can be used in conjunction with our cable troughs to protect from metal theft.

Every reduced weight trough, which we now manufacture, incorporates a slot in its base to allow Ander-fin to be fitted at the point of installation, which when used in unison creates a system that makes cable theft virtually impossible.

Shaun Forrester, Sales Director for Anderton Concrete commented: “We believe Ander-fin offers an extremely effective solution to a continuing problem within the rail network and its shocking to learn an estimated 50,000 minutes per year are lost on the rail system due to cable theft. The beauty of our patented system is that we have protected every aspect of the system; this includes the void in the trough and the fin itself to anchor down the cable, which prevents any other system replicating the anchoring of cable via a void in the trough.

“For any railway scheme designers who are working in high risk areas, we encourage to specify the patented system as early as possible within the process. This will mean that the trough route is protected against potential theft and therefore reduces the chance of costly delays once the network is operational.”

Ander-Fin Rail Cable Anchoring System

Anderfin Cable Anchoring Systems

Protect against cable theft with Ander-Fin – the newly approved cable anchoring system from Anderton.

Benefits Of The Ander-Fin

- Cable theft costs the rail industry thousands of delayed minutes each year and is costly to replace

- Cable theft causes safety hazards

- Ander-Fin helps to prevent cable theft by securing and tying the cables to the trough

- Ander-Fin secures long lengths of cable

- Can be used in conjunction with Anderton cable troughs

- Ander-Fin cable anchoring system is patent approved

How Does The Ander Fin Work?

How The Ander-Fin Works

The Ander-Fin is inserted into the Anderton trough from below. Then, a Network Rail approved cable tie with rubber sleeve is threaded through the Ander-Fin. Cables are then bundled and secured with a cable tie.

Specification

- The fin is compatible with a range of Network Rail approved clips and sleeves

- The fin is manufactured from glass filled nylon

- Strength depending on orientation of the fin has a failure load in excess of 2kN

- FIRE – The fin material has been tested to UL 94 and achieved V5A rating

- Limiting Oxygen Limit is 32.5 and the material contains no halogen

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

NEW MANUFACTURER – We have signed a new distributorship agreement and are now approved distributors of Cubis. Contact us for Access Chamber Systems, Cable Troughs and Cable Protection.

How To Measure & Install Access Chambers

August 17th, 2020

How To Measure & Install Access Chambers

Access Chambers

Installation Guide

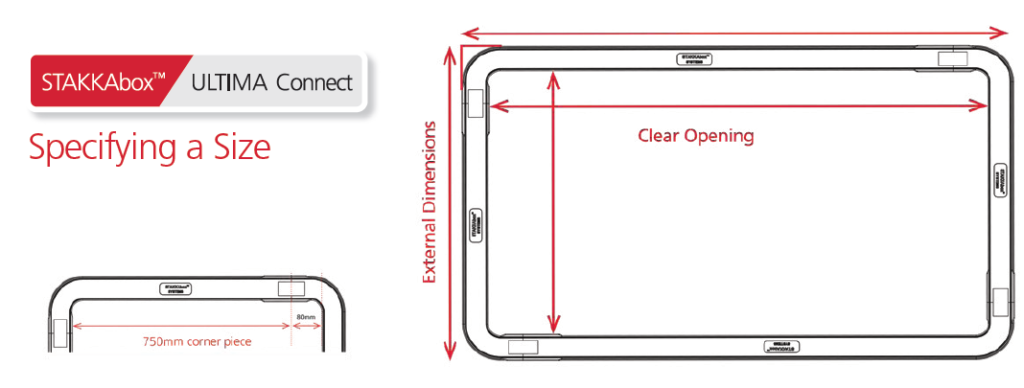

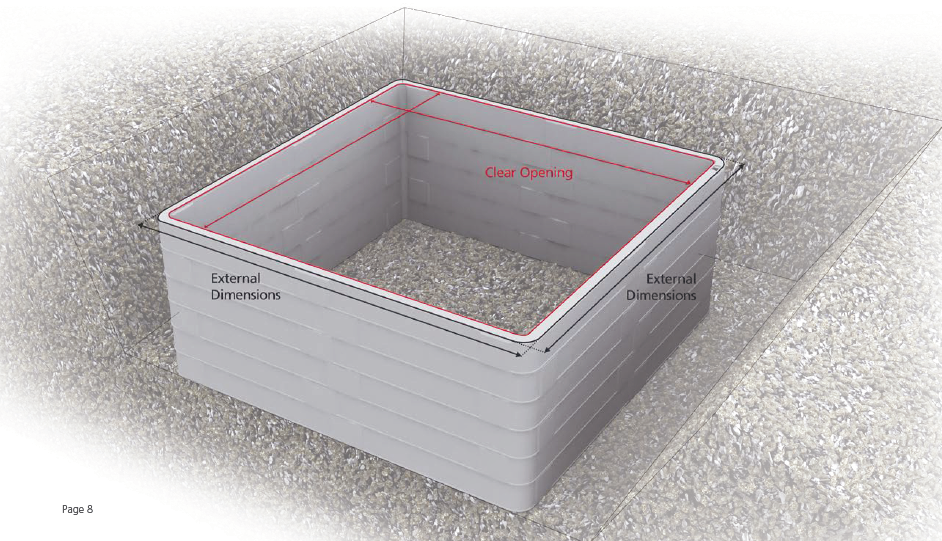

Network access chamber sections are measured by the measurements inside of the chamber. Attention should also be paid to the external dimensions when deciding whether the network access chamber will fit into the area required.

Access Chamber Dimensions

Rapid & Easy Installation

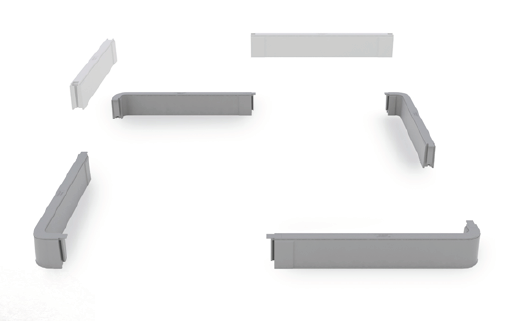

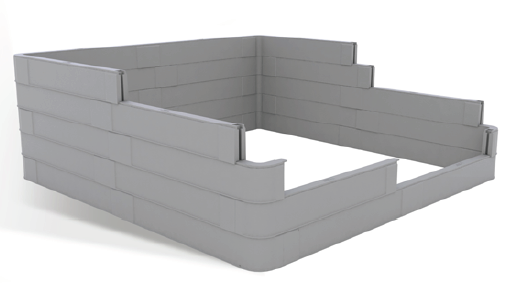

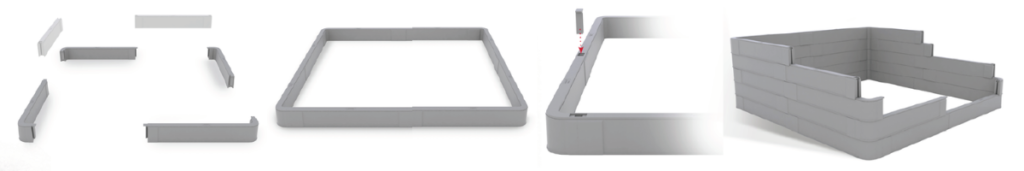

Step 1: Arrange corner pieces and sidewalls to match the chamber clear opening dimensions. Ensure that the lip is on the outside of the chamber. The corner pieces should be all ‘left’ or all ‘right’ on each section and will alternate between the two as the chamber increases in depth.

Step 1

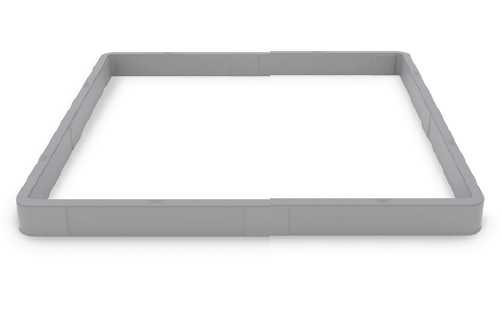

Step 2: Layout the first ring section of connect pieces to ensure you have the correct components.

Step 2

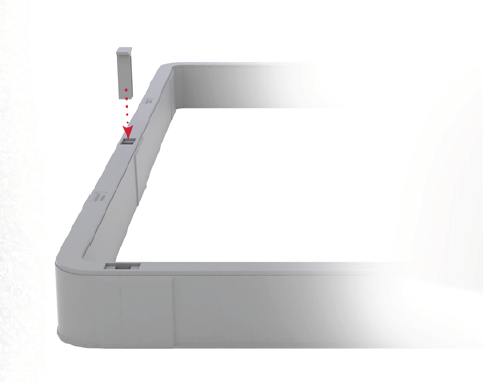

Step 3: Now connect the sections using the jointing peg, ensuring that the top of the peg is level with the top of the section.

Step 3

Step 4: Build the next section on top, using the alternative corner pieces. This will provide a ‘brick worked’ chamber ensuring any joints are not in a vertical line.

Step 4

Access Chamber Step By Step Installation Guide

CUBIS ACCESS CHAMBERS

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis | Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV