Earthing

Earthing | An Introduction To Earthing & Earthing Designs | Part One

August 19th, 2019

An Introduction To Earthing & Earthing Designs

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Earthing

Earthing & Earthing Designs

AN Wallis

In this 2 part series of articles AN Wallis introduces earthing system designs including earth electrode systems designed to safely dissipate fault current or other unwanted electrical current to the general mass of earth and also an introduction to lightning protection focusing on systems, strategies and earth terminations and networks.

An earth electrode system, professionally designed by competent Engineers, is essential to ensure the safety of personnel and the protection of equipment from dangerous voltages in and around LV MV HV substations.

AN Wallis are able to offer earth electrode system designs and associated testing services using the most up-to-date equipment and design software ‘CDEGS’. All this is carried out by competent and highly experienced Electrical Engineers and Technicians.

All design works are carried out in accordance with BS 7430:2011 — The code of practice for protective earthing of electrical installations and BS EN 50522:2010 — Earthing of power installations exceeding 1 kV a. c. amongst other specifications.

All materials supplied by A. N. Wallis have been tested and certified by an independent body ensuring the highest quality materials are made available to you.

➡ Lightning | An Introduction To Lightning Protection | Networks, Strategy & Systems | Part Two

Earthing System Design

Earthing System Design

Considerations

An earth electrode system should be designed to safely dissipate fault current or other unwanted electrical current to the general mass of earth. This could include power transmission and distribution, static dissipation, lightning protection as well as other associated systems.

An earth electrode system should be designed to safely dissipate fault current or other unwanted electrical current to the general mass of earth. This could include power transmission and distribution, static dissipation, lightning protection as well as other associated systems.

The main considerations of an earth electrode system design should be:

- Is the system safe and suitable for the purpose for which it is intended?

- Is the system rated to carry the design fault currents?

To achieve this a number of steps are required and are detailed below.

Soil Resistivity Surveys

BS 7430:2011 states that ‘on-site resistivity testing should always be carried out prior to carrying out an earth system design and installation’.

The soil resistivity survey is the first step in ensuring the correct design of an earth electrode system. It is essential that accurate measurements are taken at this stage as this data is used to determine what conductors are required in the finished earthing system to give a safe and suitable design. Corrupt data taken with inadequate test equipment could lead to a vastly over- or under-engineered solution.

AN Wallis use high specification test equipment to carry out soil resistivity testing, gaining data from tried and tested methods. This raw data is then analysed using CDEGS software to produce a representative electrical equivalent soil model which can then be used in the earthing design process.

Earth Electrode System Design

There are many factors that go into producing a compliant earth electrode system design: fault current levels, fault duration, ground make up and interconnected sites are but a few.

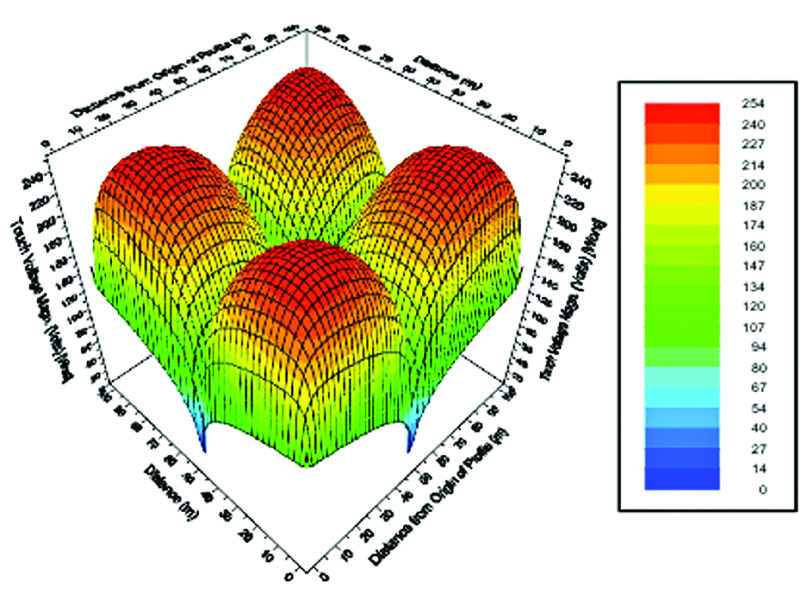

All of the parameters are analysed using the CDEGS software to ensure Touch, Step and Rise of Earth Potentials are within safe levels.

Our team of competent Engineers consider all of the above and more to ensure the final design is not only safe and suitable for its purpose, but also to ensure the system can be installed using the most economic processes giving you the most cost effective solution.

Overall System Testing

BS 7430:2011 states that ‘all work should be carried out under the control and direction of a competent person.’

AN Wallis are able to offer test and inspection services for both new and existing installations. All works are carried out in accordance with BS 7430:2011 by our trained and competent Engineers and Technicians.

The period between periodic inspection and tests can only be determined by the environment that the system is installed in, for example the harsher the environment the more regular the inspection.

Please feel free to contact us to discuss your particular requirements.

Earthing – Copper Earth Tapes | Bars | Clamps | Rods

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Marconite Electrically Conductive Earthing Aggregate

January 24th, 2019

Marconite – Electrically Conductive Aggregate Material

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

About Marconite

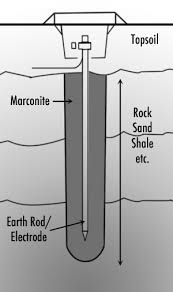

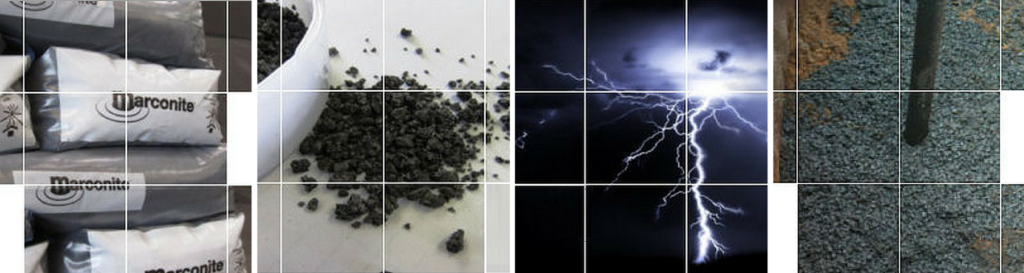

Marconite, the low resistant earthing solution, combined with copper earth rods and copper lattice mats has been delivered from stock to provide essential earthing protection to vital S&T infrastructure on the Network Rail infrastructure in the UK.

Marconite, the electrically conductive aggregate material, conducts electricity much in the same way as metals, through the movement of electrons.

Traditional earthing materials, such as Bentonite, conduct electricity through the movement of charged ions. These ions require the presence of an effective electrolyte, such as water and the presence of salts. Unlike Marconite, ionic based systems are subject to drying out and without water they do not conduct electricity.

Bentonite

Marconite does not need water to conduct electricity and so does not suffer any effects from drying out.

Marconite is the world’s premium electrically conductive aggregate material. Used as a backfill to enhance the effects of earth electrodes, such as copper bond earth rods, Marconite enables electrical and civil engineers to achieve permanent, stable and low resistance earthing solutions, even in difficult ground conditions.

Specifically developed for the needs of the earthing industry, for over 40 years Marconite has allowed electrical engineers to tackle the toughest conditions and achieve the satisfactory earthing of installations throughout the world.

Marconite is a synthetic material manufactured specifically for use in earthing applications and, unlike Bentonite, it is not a naturally occurring mineral or ore.

Marconite has distinctive properties result from a unique manufacturing process, utilising specific raw material feedstocks, carefully selected and mixed in tightly controlled ratio’s before undergoing a range manufacturing process and thermal treatments.

Earthing Compounds

The resulting product is a precisely measured, granular material, dark grey in colour, that is virtually dust free and with exceptional electrical properties. This is then packaged in high strength, UV resistant valve topped sacks and palletised.

Marconite is the low resistant building and substation earthing solution for rail projects.

Marconite Conductive Concrete is a registered product of the James Durrans Group and is solely produced by their subsidiary company Carbon International Limited. T&D provide fast delivery and competitive prices for genuine Marconite brand Earthing Products.

MORE MARCONITE READING

- Marconite – Electrically Conductive Earthing Compound

- Marconite Earthing – Conductive Concrete, Mixing & Use Of Marconite

- FurseCEM Earthing Conductive Aggregate Concrete

Contact T&D for Copper Earthing Tapes – Bare Tape & Covered

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

Thorne & Derrick – Stockists & Suppliers of MV HV Joints, Terminations & Connectors

Marconite – Worlds Premium Electrically Conductive Aggregate Material

January 24th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Marconite

Thorne & Derrick are a leading distributor of Earthing & Lightning Protection Systems, including Marconite, the world’s premium electrically conductive aggregate material.

Marconite compound is used as a backfill to enhance the earthing effects of copper earthing rods – Marconite enables permanent, stable and low resistance earthing solutions even in difficult ground and soil conditions.

Pictured below T&D off-loading recent Marconite delivery of over 1000no 25kg bags – T&D can provide most competitive prices and delivery schedules for Marconite in the UK.

Marconite Benefits

- Low resistivity – 0.001 ohm.m is extremely low when compared to Bentonite type earthing compounds with resistivity at 3 ohm.m

- Versatile – Marconite is suitable for most ground conditions and becomes a permanent, solid structure that is not prone to shrinking, drying out or being washed away

- Cost effective- permanent earthing solution, there is no need to remove and replace or “maintain” with additional water/salts every few years in order to achieve the desired earth values

- Chemically inert – non-corrosive to steel or copper earthing products, Marconite does not attack cement structures and has a pH within the neutral range

- High strength – Marconite can be used as part of the building structure itself and can achieve strengths higher than Grade 25 concrete

Thorne & Derrick are distributors of LV-HV Cable Installation, Cable Jointing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, earthing, substation and electrical construction at LV, 11kV, 33kV and EHV.

T&D service utilities, power, construction, rail, mining, offshore, oil, gas and petrochemical industries. T&D distribute Electrical Safety Equipment protecting workers on underground cables, overhead powerlines, switchgear and substations at LV, MV and HV.

More Marconite Reading

- Marconite – Electrically Conductive Earthing Compound

- Marconite Earthing – Conductive Concrete, Mixing & Use Of Marconite

- FurseCEM Earthing Conductive Aggregate Concrete

Contact T&D for Copper Earthing Tapes – Bare Tape & Covered

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

Exothermic Welding – 5 Benefits of the Exothermic Weld Connection

November 29th, 2018

Exothermic Welding

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

The following table highlights 5 Benefits of using Exothermic Welding systems for Earthing & Lightning Protection when permanently joining copper conductors.

| Mechanical Connection | Exothermic Welding |

| Connection is made by pressing and tightening. Contact connection. | Connection is made by fusion – welding is more reliable and durable. Irreversible molecular bond. |

| Lower conductivity than the copper conductors involved. | Conductivity equal to or greater than the copper conductors involved. |

| Transient connection. Electrical degradation over time. | Permanent connection. Lifetime equal to that of the earthing system. |

| Suffers with the flow of current, faults or repetitive discharges. | Able to withstand repeated current flow without degrading. Minimum maintenance. |

| Connection depends on the tightening torque applied by the installer. | Once the exothermic welding mould is closed the process is autonomous, reproducible and uniform. |

Exothermic Welding

AT3W & Thorne & Derrick

Thorne & Derrick are working with AT3W to introduce and develop specifications and business for the Apliweld Secure+ exothermic welding system.

Jason Leatherland (UK Manager AT3W) comments, “having worked successfully together with Thorne & Derrick in the past, I was keen to demonstrate and discuss this product system with them as I knew they would be best suited to showcase the system, and in particular, its increased health and safety benefits, to the most relevant sectors in order to increase the users efficiency and reduce the potential of site accidents from exothermic welding.”

Jonny Hewitt (T&D UK Power Team) added, “working with the UK DNO’s and their preferred ICP’s we look forward to further developing relationships and presenting the exothermic welding system to existing and new clients. We will be working closely with AT3W to introduce the product to market and improve worker and site safety in the utility industry.”

Pictured: Jonny Hewitt (T&D) with Jason Leatherland and Chris Dodds (T&D).

💡 HV Earthing & Lightning Protection Training Courses go to ➡ Online Training Resource provided by Ian Griffiths, Principal Engineer at GreyMatters. Ian is an Earthing & Lightning Consultant of 27 years, one of the top 1% UKAS accredited CDEGS consultants and professional advisor to international utility companies, data centre and infrastructure developers. See our Blog to learn more about GreyMatters and High Voltage Earthing.

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Substation Earthing, Jointing & Installation Equipment.

LV MV HV cable accessories from stock used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Marconite – Electrically Conductive Earthing Compound

November 14th, 2018

Marconite

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Low Resistance Earthing Compounds

for Substations

Marconite is developed and manufactured specifically for use in electrical earthing installations enabling electrical engineers and earthing system designers to achieve permanent, stable and low resistance earthing solutions even in difficult ground or soil conditions – typically used for substation earthing applications.

Adding Bentonite and similar earthing compounds, such as Marconite, in a trench or larger drilled hole around the electrode, typically an earth rod, has the effect of increasing the surface area of the earth conductor, assuming the resistivity of the added material is lower than that of the surrounding soil.

Earthing Compunds

Marconite compound is a precisely measured, granular material, dark grey in colour, that is virtually dust free and with exceptional electrical properties.

| Marconite Earthing Compound Benefits | |

| Low Resistivity | 0.001 ohm.m is extremely low when compared to Bentonite’s 3 ohm.m |

| Versatile | Suitable for most ground conditions and becomes a permanent, solid structure that it is not prone to shrinking, drying out or being washed away |

| Cost Effective | It is a permanent solution; there is no need to remove and replace or ‘maintain’ it with additional water / salts every few years in order to achieve the desired earth values |

| Chemically Inert | Is non-corrosive to steel or copper, does not attack cement structures and has a pH within the neutral range |

| High Strength | Can be used as part of the building structure itself and can achieve strengths higher than Grade 25 concrete |

| Easy To Use | Forms a concrete like material that from first pour, achieves a low resistance earth, no need to wait or return to test |

More About Marconite

Marconite is essentially a conductive concrete in which a carbonaceous aggregate replaces the normal aggregate used in the conventional concrete mix – Marconite earthing compound has some similar properties to Bentonite, i.e. causes minimal corrosion with certain metals and has a low resistivity. It was developed as a process which started in 1962 when Marconi engineers sought a material which conducted by movement of electrons rather than ions. It contains a crystalline form of carbon and the overall material has a low sulphur and chloride content.

There is stated to be some corrosion of ferrous metal and copper whilst the Marconite is in slurry form, but it is suggested that a thin protective layer forms. When the concrete has set, corrosion is said to cease. Metal should ideally be painted with bitumen or a bitumastic paint as it enters the Marconite structure to prevent corrosion at this point. Aluminium, tin coated or galvanised steel should not be installed in Marconite.

When Marconite is mixed with concrete, its resistivity can fall to as low as 0.1 Ohm-metre. It will retain its moisture even under quite dry conditions so has been used in the hotter climates as an alternative to Bentonite compound. Its principle application in the UK is at locations where theft or third party interference is likely to be a problem, or to enclose copper electrodes in bore-holes or voids within rock when driven into the ground.

When surrounding an earth rod with Marconite which has been installed in rock, the resistance of the copper earth rod will be reduced as the volume of Marconite used is increased. For example, if a 1 metre earth rod is installed at the centre of a hemisphere of Marconite of radius 1.5m, it would have a resistance of approximately 2,000 Ohm if the surrounding rock is of 2,000 Ohm-metres.

Call T&D for Copper Earthing Tapes | Best Prices | Large Stocks

If the radius of the hemishere is increased to 3 metre and then 5 metre, the resistance would fall to 1,080 Ohm and 650 Ohm respectively. Because of the prohibitive cost of removing such a volume of rock, it makes sense to make use of existing cavities for this purpose, where possible. Also, the void is likely to be part filled with other materials (such as concrete) to reduce the amount of proprietary material required. Marconite is normally considered as having a resistivity of 2 Ohm-metres.

T&D provide fast delivery and competitive prices for genuine Marconite brand earthing compounds.

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection & Exothermic Welding products we stock and distribute the most extensive range of copper earthing equipment.