Earthing

Marconite Earthing – Conductive Concrete, Mixing & Use Of Marconite

November 12th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

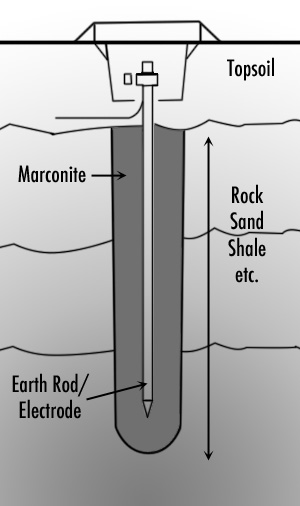

Marconite is the world’s leading premium electrically conductive backfill material which significantly enhances the effects of copper earth electrodes to reduce the resistance of a lightning protection or copper earthing system.

Marconite is a dark grey, granular material that replaces traditional sand and aggregate materials used within concrete mixes – it should be mixed in the ratio of 3 parts of Marconite to 1 part cement by weight with addition of 1 litre of water per 4kg of total mix:

Mixing Marconite

3 x 25 Kg bags of Marconite

1 x 25 Kg bag of Cement

25 litres (25 Kg) of Water

Ground enhancement materials such as Bentonite and Marconite earthing compounds are used to lower the resistance to earth of Earthing & Lightning Protection Systems – simple to install and used as backfill for earth electrodes, including earth rods or earth mats.

When mixed as described above, the Marconite forms a relatively dry material with an ‘as poured’ density of around 1300 Kg / m³ for earthing purposes.

The water content may be adjusted as the application requires, but this will affect the concretes final compressive strength and the drying times accordingly.

Typically Marconite concretes are touch dry within hours but can be several days before being fully cured.

Marconite is chemically inert with very low soluble sulphate content. It can be used with all conventional types of cement, as well as most proprietary resin-based cements, adhesives and gypsum plasters – due to the inert structure Marconite is non-corrosive to steel or copper and with a pH level in the neutral range will not degrade or erode cement structures.

Marconite Conductive Concrete is a registered product of the James Durrans Group and is solely produced by their subsidiary company Carbon International Limited.

Resistivity of Marconite

Marconite earthing aggregate provides exceptional resistivity with a resistance level of .001 ohm.m – even when mixed with cement the resulting resistance level is only 0.19 ohms.m.

Reducing Earth Electrode Resistance

Marconite is a conductive carbonaceous aggregate which, when mixed with conventional cement, has the effect of increasing the surface area of the earth electrode, thus helping to slightly lower its resistance. These earthing back-fill materials can provide a significant improvement to earthing system performance but also provide several secondary functions: maintain the resistance value at a more constant level throughout the year, to provide protection against 3rd party damage, or to protect the earthing electrode from corrosion.

Marconite is also useful for surrounding electrodes installed in rock.

Where a decision is taken to use FurseCEM, Bentonite, Marconite or any other special back-fill material, the design engineer should ensure that this information is passed to the construction staff – construction methods can be used to limit the amount used and therefore associated cost.

Examples are mixing Bentonite with local clay, reducing the hole diameter drilled (for vertical copper electrodes) and minimising the width and volume of the horizontal trench section into which the earth electrode will be installed.

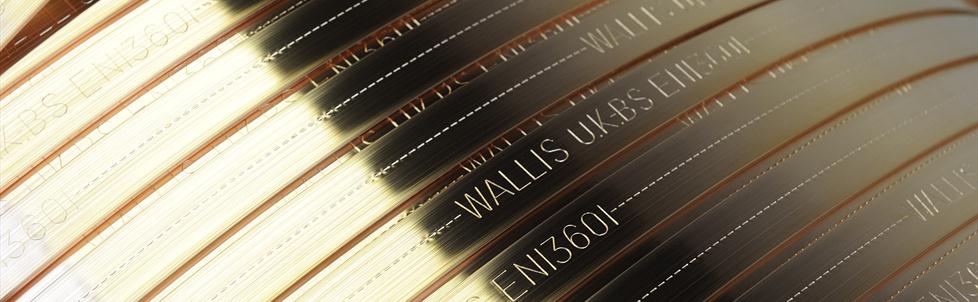

Contact T&D for Copper Earthing Tapes – Bare Tape & Covered

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

FurseCEM Earthing Conductive Aggregate Concrete

November 12th, 2018-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

FurseCEM

FurseCEM is an earthing conductive aggregate concrete, manufactured by Furse, offers a convenient and permanent solution to Furse earthing problems by obtaining a reliable earth resistance even in installations that require a very low resistance regardless of ground conditions – this includes low LV, medium MV and high HV substations.

A conductive concrete is formed when FurseCEM is added in place of sand and aggregate. This electrically conductive medium has many applications in the electrical/construction industry including RF and microwave screening, static control and of course earthing for which it was specifically developed.

FurseCEM concrete used as a backfill for conventional earth rod to achieve a lower earth electrode resistance

When used as a backfill for an earth electrode or earth rods, FurseCEM impregnated concrete greatly increases the electrodes’ surface area. For example, increasing the effective diameter of a copper earth rod from typically 15mm to 200mm, could lower its resistance to earth by as much as 50% (see graph below).

Resistance versus Diameter

FurseCEM Features & Benefits

- Permanent earth reading – resistivity that will remain constant over the life of the installation without the requirement for maintenance

- Constant volume – regardless of water content, FurseCEM will not shrink or expand, thus maintaining constant contact between the earth electrode and the soil

- Cost effective – reduces drilling, saves on earthing materials, and requires no expensive maintenance

- Non leaching – FurseCEM is a conductive concrete and therefore cannot be washed away

- Chemically inert – completely non-corrosive, and will not in any way damage earth electrodes, steelwork or concrete

- Fast drying properties – allows for quick and easy installation

- Mechanical strength – provides high compressive strength where required

- Long shelf life – can be stored for long periods without deterioration

- Versatile installation – suitable for use in boreholes and trenches

FurseCEM Earthing Conductive Aggregate Concrete

Earthing Conductive Aggregate Concrete

FurseCEM Part Numbers

FurseCEM should be mixed in a 3:1 ratio by weight (not volume).

| Description | Sack Weight | Part Number |

| FurseCEM | 25kg | CM025 |

| FurseCEM (supplied with cement) | 25kg | CM030 |

Contact T&D for Copper Earthing Tapes | Large Stocks | Best Prices

FurseCEM versus other methods of earth improvement

Chemical solutions — such as copper sulphate, sodium carbonate, calcium sulphate and sodium chloride (table salt) mixed with charcoal are sometimes poured into the ground to improve earth readings, but these have the disadvantages of:

- being required in large quantities to make a difference

- requiring constant moisture to remain effective

- drying out if moisture is not present

- eventually leaching out of the soil, returning the earth to its former high value, unless regularly and expensively maintained

- causing corrosion of the earth electrode system and deterioration of concrete (particularly relevant to transmission towers).

Chemical earth rods — perforated metal tubes packed with a with a chemical compound are also sometimes used but these:

- are costly

- are subject to leaching or washing away of the chemicals unless maintained

Bentonite — and certain other compounds intended to absorb and retain moisture in and around an earth electrode.

- rely on constant moisture to maintain volume and hence work effectively

- without moisture, drying and shrinkage occur, causing loss of contact with the surrounding soil and a deterioration in the earth reading

- regular checking and/or maintenance may be required

FurseCEM is a non-corrosive permanent solution to earthing problems, providing a fixed earth reading that will not very significantly regardless of seasonal factors, and without maintenance.

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

Further Reading

How to Size High Voltage Earthing Conductors Correctly

October 15th, 2018

A Guide To High Voltage Earthing Conductors

-

Guest Blog by Ian Griffiths - Principal Partner at GreyMatters

What size earthing conductors should I use?

And, is there a simple table I can use for this high voltage earthing design?

These are great questions that I’m often asked. This post answers these questions together with the choice of conductor materials and jointing method within a high voltage earthing design project.

Assessing conductor size is entirely dependent on the electrical configuration and the load that the conductor must take. For example, an above-ground bonding conductor serves to transfer current with minimal voltage drop, from A to B.

A directly buried conductor has an additional purpose, that of leaking the fault current/voltage into the local geology (as part of an electrode).

When considering Lightning, the same conductor above might also see a high-frequency component and which will impose yet another requirement.

High Voltage Earthing Conductors

Design Considerations

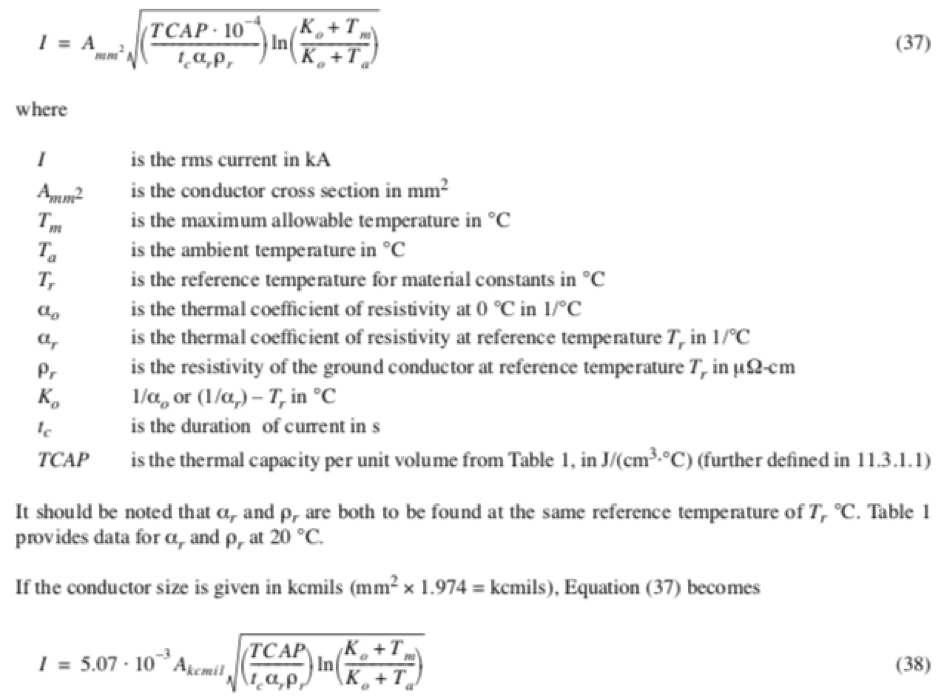

In IEEE-std80ƒ Guide for Safety in AC Substation Grounding, section 11 – states the basic requirements are:

Each element of the grounding system, including grid conductors, connections, connecting leads, and all primary electrodes, should be so designed that for the expected design life of the installation, the element will

a) Have sufficient conductivity, so that it will not contribute substantially to local voltage differences.

b) Resist fusing and mechanical deterioration under the most adverse combination of a fault magnitude and duration.

c) Be mechanically reliable and rugged to a high degree.

d) Be able to maintain its function even when exposed to corrosion or physical abuse.

Earthing Materials

Copper has traditionally been the go-to material for years in high voltage earthing because it is not only highly conductive but also resistant to most sources of in-ground corrosion.

Similarly, aluminium has sufficient conductivity but suffers from in-ground corrosion, and the oxidation that forms around its surface is not conductive, therefore, compromises the conductor’s ability to leak current when buried, which is why buried aluminium conductors is a no-no.

Stainless steel or mild steel (when appropriately coated – galvanised or copper bonded), on the other hand, may not have the conductivity of copper or aluminium but it is sufficiently conductive to be utilised as a buried conductor.

Dealing with the Heat

So now we’ve covered the materials that are widely used for high voltage earthing.

Point ‘b’ from IEEE-std 80 above calls for the conductor to retain its mechanical strength when being exposed to a fault.

Conductors get hot when current flows through them. And they will potentially be at their hottest when subjected to a fault from the electrical system. This fault means the conductor needs to maintain its physical integrity as temperature increases and not transform into a shower of hot molten metal!

Up to this point, we’ve discussed conductor conductivities, materials and thermal-mechanical characteristics.

Another consideration for high voltage earthing is the method of the joint between conductors.

Conductor Joints

Joints in conductors are as critical to current-flow as the conductors themselves. The jointing method must not allow the joint to introduce excessive resistance. Therefore, the selection of the jointing method will impact the earthing system’s thermal resilience massively. This thermal resilience is why welded joints are the go-to choice for the high voltage earthing system.

Welded joints achieve the nearest physical match to the native conductor itself and are the gold-standard in conductor jointing because they accomplish a molecular similarity to the native material’s conductivity, as well as similar mechanical robustness.

Here’s an example of a safe method of igniting an exothermic weld.

A Word of Caution

Bolted joints and clamps are made up of multiple parts which can creep and loosen over time. Loosening will add resistance across conductor joints, which as previously mentioned… is not a good thing (thermal runaway is a topic for another day).

Bolted joints fall into the category of mechanical joint methods and have a derating factor to keep the conductors operating at lower temperatures. When designing a high voltage earthing system, this means the seemingly unrelated selection of jointing method will also impact the conductor size calculation.

IEEE adiabatic equation

Calculating High Voltage Earthing Conductors

In Summary

So there you have it. Without going into great detail, the following factors influence conductor sizing:

- The magnitude and duration of fault current (i.e. the heat source)

- The method used for the joint

- The conductor material

- The conductor’s role in the high voltage earthing design

These factors may vary project by project, so, using a particular size of the conductor on a previous project does not mean that the same will apply to the next project, which means calculating conductor sizes (adiabatic equation) to fit the particular requirements of the project is usually very necessary.

ƒ IEEE P80 – Guide for Safety in AC Substation Grounding

This guide is primarily concerned with outdoor ac substations, either air-insulated or gas-insulated. With proper caution, the methods described herein are applicable to indoor portions of such substations, or to substations that are wholly indoors. No attempt is made to cover the grounding problems peculiar to dc substations. A quantitative analysis of the effects of lightning surges is also beyond the scope of this guide.

Further Reading

- High Voltage Earthing & Grounding System Design Protecting Lives

- Safer Exothermic Welding With Apliweld Remote Electronic Ignition

- Data Centre Earthing

Ian Griffiths CEng, MBA, BEng, MIET

Principal Engineer at GreyMatters, an Earthing & Lightning Protection Consultant of 27 years, one of the top 1% UKAS accredited CDEGS consultants and professional advisor to international utility companies, data centre and infrastructure developers. Risk Assessment Surveys and measurements for substation earthing or generation schemes on your electrical earthing system, voltages from 1kV to 765kV are undertaken by their highly qualified engineers.

Some LinkedIn Comments

Charles Shannon Senior Application Engineer at IMCORP

Hey Chris Dodds and Ian Griffiths – Substation Earthing. Great subject. I would add two minor clarifications to that blog. #1 when mentioning buried earthing conductors it’s worth clarifying that is for unjacketed cables. Additionally there in the maximum energy calculation note that with proper surge arresters this energy can be significantly reduced which can significantly reduce the size and thus the cost of the cable.

Ian Griffiths – Substation Earthing

Hi Charles, you might be right to add an additional clarification re buried conductors. Still, the piece is intentionally brief (so it’s not intended to be a definitive reference covering all the nuances), still, it does make the clear distinction between above-ground and below-ground conductors to try and get people to think about there being TWO differing purposes that an identical-sized conductor can have i.e. to either leak current (into the geology) or to transfer it (equipotn)… or a combination of both – Oh, that’s 3 but hey. So, for the sake of simplicity, it might be better to leave coatings for another blog 😉

Earth Mats | Earth Plates | Earth Rods | Earth Bars | Earth Tapes | Exothermic Welding from T&D, The Earthing Equipment & Lightning Protection Eqpt. Distributors

Safer Exothermic Welding With Apliweld Remote Electronic Ignition & Bluetooth Starter

October 8th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Exothermic Welding

Today, Thorne & Derrick welcomed Jason Leatherland (UK Manager at Aplicaciones Tecnológicas (AT3W) Lightning Protection & Earthing) to their UK office to learn more about their innovative Exothermic Welding System – Apliweld Secure+ is the safest + most efficient system for establishing Exothermically Welded Connections on substation earthing projects in the UK DNO, Power Transmission & Distribution and ICP sectors.

So What’s New?

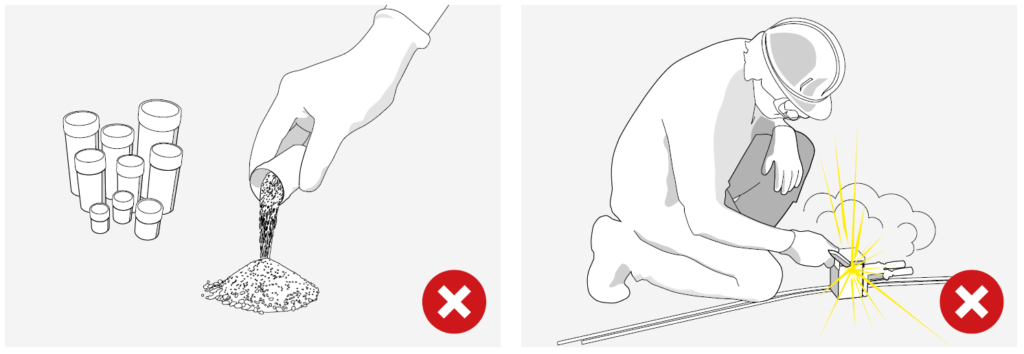

The market-leading modern technology with remote electronic activation using Bluetooth replaces the conventional exothermic welding system dependent upon a manually applied spark using a Flint Gun for the welding and bonding connection of copper conductors including copper earth rods, cables and earth tapes.

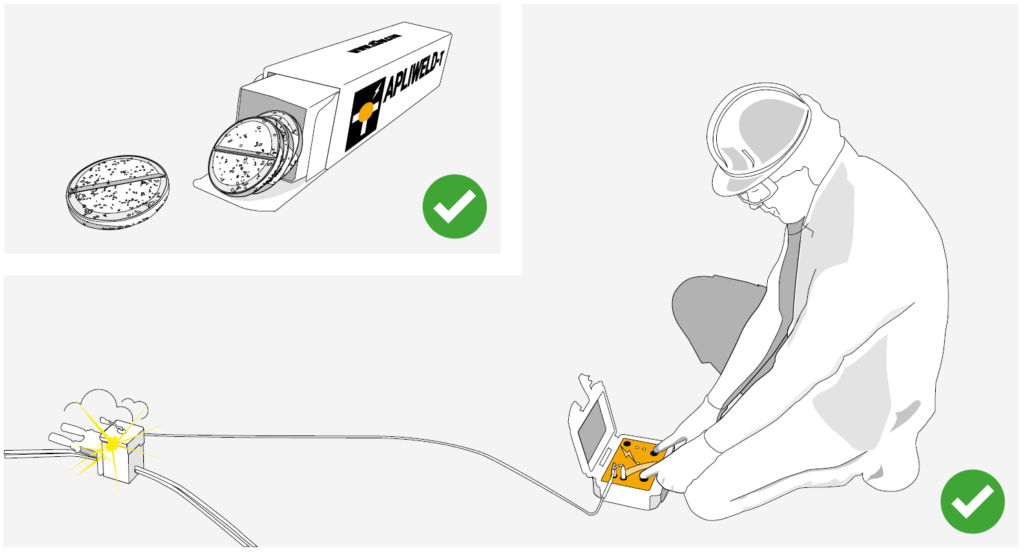

Apliweld Secure+ replaces traditional welding powders (and all of their size variations) with a welding tablet compound activated remotely, by up to a safe 5 metre distance, from the controlled explosion location – the electronic starter reduces risk of burns injuries and improves operational Health & Safety.

Apliweld Secure+ is accepted or in the approval process for use at National Grid, Northern Powergrid, Western Power Distribution, Scottish Power Energy Networks (SPEN) and Electricity North West (ENWL).

AT3W are a Spanish manufacturer and supplier of Earthing & Lightning Protection products and solutions – their unique selling point is their dedication to innovation and R&D within the industry along with their complete product/solution portfolio.

What is Exothermic Welding?

Apliweld exothermic welding is a process that achieves the molecular bonding among two or more metallic conductors by a chemical reaction. This molecular bonding improves mechanical, electrical and anti-corrosion properties compared with any mechanical or clamped connection. Apliweld exothermic welding is the most efficient method to achieve permanent, reliable and high conductivity connections for any LV MV HV substation or installation requiring an earthing system.

Secure Exothermic Welding At Safe Working Distance

APLIWELD Secure+ Exothermic Welding SYstem

Apliweld Secure+ is the most innovative, efficient and safest method for making electrical earthing connections with exothermic welding and comprises the of following components:

| APLIWELD Part Reference | Product Image | Product Description | Technical Characteristics | Benefits |

| APLIWELD-T Exothermic Welding Tablets |  |

Innovational tablet utilising only 2 sizes to produce all exothermic welded joints. Two references AT-020N, the most common one (valid for 90% of connections )and AT-021N larger size tablets, for use on larger joints. | • Reference: AT-020N • Tablet dimensions: ø 43 mm. • Units per pack: 20 tablets • Packaging dimen.: 52x52x220 mm. • Total weight: 900 gr.• Reference: AT-021N • Tablet dimensions: ø 55 mm. • Units per pack: 20 tablets • Packaging dimen.: 66x66x200 mm. • Total weight: 2.000 grams |

• Compact and easy to use • Reduces stock costs • Improves welding process times • Increases equipment life-time • Both electronic and powder starters can be employed |

| APLIWELD-E Electronic Starter |  |

Not flammable. Electronic starters only ignite through the power supplied by the ignition device. | • Reference: AT-010N • Dimensions: 26 mm. ø24 mm. • Units per pack: 10 • Packaging dimen.: 125x105x40 mm. • Total weight: 87 grams • Time of reaction: < 10 sec. • Material: not flammable |

• Its safety handle and storage features reduce labour risks • Safe & easy setup |

| APLIWELD®-E Electronic Ignition/Starter Device |

|

Ignition box enables controlled and remote electronic ignition of exothermic welding connections in a quick and safe way. Includes: ignition unit (AT-096N), cable (AT-098N), 5 crocodile clips (AT-099N), battery charger and bag carrier. | • Reference: AT-100N • Power supply: • Lead acid battery 6V 7Ah • DC Voltage: 6V DC • Battery charge: 12-36V DC 500 mA • Battery life: more than 100 joints • Battery charging time: 10 hours • Dimensions: 216x180x102 mm • Weight: 2300 grams |

• Remote control ignition reduces labor risks. |

Apliweld Secure +

Benefits

- Eliminates the need for numerous variety of exothermic welding size powders

- Single welding compound reference for every welded earthing joint or connection

- Reduction of stock volume : cost ratio

- No shelf life and is non flammable

- Much safer to use – electronic ignition unit / Bluetooth starter as opposed to flint gun

- Minimises user error – every mould engraved with components/materials to be used

- Can be used in windy conditions (zero powder spillage)

- Highest possible ignition rates – less material failure

- Reduced wastage from cartons, cups etc

- Easy to use, reduces costs in labour and training

How to use Apliweld Secure+ Components

| AT3W Part Number | Product Image | Product Description | Stage | Process |

| APLIWELD-T |  |

Welding compound in tablets | 1. Insert the tablets APLIWELD-T |  |

| APLIWELD-E |  |

Electronic starter | 2. Place and connect the electronic starter APLIWELD-E |  |

| APLIWELD-E |  |

Electronic starting device | 3. Press both push-buttons on ignition device or Bluetooth remote at the same time |  |

| Exothermic Weld |  |

Graphite mould | 4. Remove the completed joint from the graphite mould |  |

Specific Exothermic Weld Mould Video

The following video shows the operating procedure for specific mould Apliweld Secure ensuring the process of exothermic welding is efficient.

Step 1 – Clean and remove any impurities from the mould or conductors

Step 2 – Heat the mould to 120°C before welding or when the mould is not hot enough

Step 3 – Fit the copper earth conductors into the mould and close the handle clamps

Step 4 – Set the proper number of tablets (see engraved on mould surface) in the crucible

Step 5 – Close the mould cover and place the electronic starter. Fix in position using lever

Step 6 – Open the Ignition Unit and connect the plugs. Connect the other side of the cable to the lateral part of the mould. Fix the clamp to the spike of the Electronic Starter

Step 7 – Keep away from the mould and switch on the Ignition Unit. Press both ignition buttons simultaneously until the exothermic welding process starts

Step 8 – Result is below image of an exothermically welded connection

Apliweld Secure – reliable electrical grounding, bonding and connection products for medium/high voltage substation earthing.

Innovation, Reduction In Storage Costs & Increased Safety

Traditionally, exothermic welding required the user to be provided with multiple cartridges with different welding powder weights for establishing various connections.

Once the conductors were inserted in the graphite mould the welding compound and the reactive powder (usually a flammable compound) were poured into the crucible. Then a flint gun applied manually to the starting powder at arm’s length produced a spark triggering the exothermic reaction.

Apliweld Secure+ utilises exothermic welding tablets NOT powders which are activated at safe working distance to suit all conductor combinations and configurations. The exothermically welded earthing connections are engineered to provide a permanent, molecular bond that will resist corrosion and loosening.

AT3W & Thorne & Derrick

Thorne & Derrick will be working with AT3W to introduce and develop specifications and business for the Apliweld Secure+ exothermic welding system.

Jason Leatherland comments, “having worked successfully together with Thorne & Derrick in the past, I was keen to demonstrate and discuss this product system with them as I knew they would be best suited to showcase the system, and in particular, its increased health and safety benefits, to the most relevant sectors in order to increase the users efficiency and reduce the potential of site accidents from exothermic welding.”

Jonny Hewitt (T&D UK Power Team) added, “working with the UK DNO’s and their preferred ICP’s we look forward to further developing relationships and presenting the exothermic welding system to existing and new clients. We will be working closely with AT3W to introduce the product to market and improve worker and site safety in the utility industry.”

Pictured: Jonny Hewitt (T&D) with Jason Leatherland and Chris Dodds (T&D).

💡 HV Earthing & Lightning Protection Training Courses go to ➡ Online Training Resource provided by Ian Griffiths, Principal Engineer at GreyMatters. Ian is an Earthing & Lightning Consultant of 27 years, one of the top 1% UKAS accredited CDEGS consultants and professional advisor to international utility companies, data centre and infrastructure developers. See our Blog to learn more about GreyMatters and High Voltage Earthing.

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Substation Earthing, Jointing & Installation Equipment.

LV MV HV cable accessories from stock used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Lightning Protection Earthing Systems – Type A,B & Foundation Earth Electrodes

July 10th, 2018

-

uploaded by - Chris Dodds (Sales & Marketing Manager Thorne & Derrick)

The following information has been provided courtesy of AN Wallis, leading UK manufacturers of Earthing & Lightning Protection Systems.

In general the Lightning Protection System (LPS) system should:

- Be an integrated system for lightning protection, power systems and telecoms systems

- Have a low overall resistance of 10 ohm’s or less

- Have an even spread of readings across all the individual earth electrode terminations to ensure as far as possible the current is evenly distributed

- Have a high resistance to corrosion

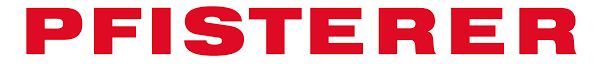

Lightning protection and earthing equipment is usually made up of earth rods either copperbonded, solid copper or stainless steel (figure 25) – also forming the earthing system are copper earth plates (figure 26), copper lattice earth mats (figure 27) or 25 x 3mm copper earth tapes.

Driven earth rods manufactured from solid copper and bonded with copper are available from stock – contact Thorne & Derrick

There are three types of LPS Earthing systems types A, B and Foundation Earth Electrodes

Type A – The conventional LPS Earthing system using

vertical or horizontal electrodes such as

copperbond Earth rods or copper tape

Type B – The ring electrode sited around the periphery of the structure

Foundation Earth Electrodes

The foundation electrode system installing the conductors in the concrete foundations of the structure.

Type A Earthing Arrangement

This is the conventional type of LPS Earthing System where earthing rods are used to form the earth electrode and usually each down conductor, such as copper earthing tapes, are connected to an earth rod.

The type A earth termination arrangement is suitable for low structures (below 20 metres in height) or an LPS with rods or stretched wires. For an isolated LPS the British Standard BS EN 62305 recommends a type B earthing arrangement where the structure is housing extensive electronic systems.

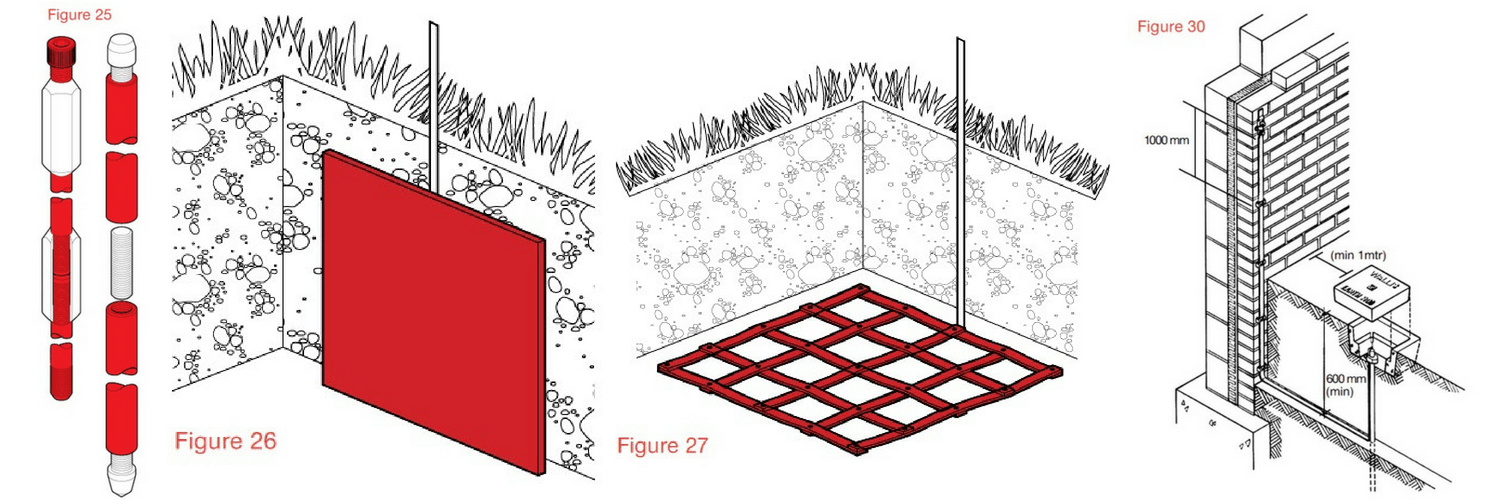

The type A arrangement uses vertical or horizontal earth electrodes. Practically it uses both connected to each down conductor, installed outside the structure (below the foundation) to be protected and housed in a plastic or concrete pit for ease of inspection (figure 30).

Lightning Protection – Copper Earthing Equipment

The minimum number of electrodes is 2.5 metres, regardless of the perimeter of the structure/class of LPS.

The minimum length of each earth electrode at the base of each down-conductor is specified in BS EN 62305 and the table below.

Minimum length l¹ of each earth electrode according to class of LPS

It is 11 for horizontal electrodes – usually copper tapes.

Or

0.511 for vertical copperbonded rods or solid copper rods. Or

>11 in the case of a lattice mat measuring the total length of the conductor in the earth mat.

Or

If copper plates are to be used the surface area of the plate should be at least equal to either.

The surface area of the length of earthing conductor that would need to be used to satisfy the requirement for a vertical electrode 0.511.

Or

The surface area of the length of earthing conductor that would need to be used to satisfy the requirement for a lattice mat electrode 11.

Or

If using vertical and horizontal electrodes, the individual earthing electrode lengths should follow the 0.511 and 11 principle respectively.

Type A earth electrodes should be installed so that the top of the earth rod is 0.5 m below the surface, this distance is to reduce the effects of step potential at ground level.

The earth rod should be housed in an inspection pit, commonly concrete or plastic for ease of inspection and registering the location during and after installation figure 30.

Full range of copper earth tapes available from stock in range of widths and thicknesses.

Type B Earthing Arrangement

The type B Earthing arrangement is most suitable for:

- Structures built on rocky ground

- Structures housing sensitive electronics/equipment

- Large structures

The type B earthing is recommended as either a ring conductor outside the perimeter of the structure which it’s recommended should be in contact with the soil for at least 80% of its total length.

The alternative is to use a foundation earth electrode which can be in a mesh form.

It is recommended that the type B earthing network whichever method is chosen should be integrated as a meshed network buried to a minimum depth of 5 rats.

The reinforced concrete floor slab can be used around the structure.

If the required resistance cannot be achieved by this method the vertical or radial earthing electrodes can be added to the network.

For ease of testing after installation an inspection pit with an earth bar should be installed where the legs of the ring and conductor routing onto the ring from the each test clamps join (figure 31).

Any internal down conductors should be connected to the internal foundation using a test clamp for ease of maintenance.

Foundation Earth Electrodes

Once all the services are connected its unlikely the installer will be able to measure the earthing resistance of the foundation earth in isolation.

The use of the foundation as an earth electrode is allowable only where the reinforcement network is below any insulating or waterproof membrane.

Where a foundation is used as an earth-termination the reinforcing bars must be clamped or welded together to ensure electrical continuity.

Alternatively an additional meshed network of conductors can be installed to ensure continuity. The additional network should be connected to the reinforcing bars by clamps or welded joints every 20 m throughout the system.

The earthing system whether using reinforcing bars or additional conductors or a combination of both must be connected to every down conductor and internal steelwork.

Internal Lightning Protection System

The internal LPS is important to fully complete the installation to fulfil the requirements of BS EN 62305.

The main reason for installing an internal LPS is to avoid any dangerous sparking within the building.

The sparking is caused by current flow and the difference in potential between internal conductive components such as steelwork and the external LPS on the outside of the building or from the use of the internal steelwork as part of the LPS.

The earthing system whether using reinforcing bars or additional conductors or a combination of both must be connected to every down conductor and internal steelwork.

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV