Arc Flash Protection

Arc Flash Clothing – PPE To Protect Utility Contractors

November 2nd, 2020by Chris Dodds | Thorne & Derrick UK

ARC FLASH | Protecting Lives of Lighting Engineers Against Arc Flash Dangers

In the following article, we assess the types of Arc Flash risks and the prevention of those same risks through the implementation of effective Arc Flash Clothing & PPE for workers in the UK Highways & Street Lighting industry.

With guidance from the UK Health & Safety Executive’s HSG85, Engineering Recommendation G39/1 and the Highways Electrical Association (HEA), we provide advice on management procedures to facilitate a continued achievement of safe working practices.

The role of Risk Assessment Method Statements (RAMS) and Safe Systems Of Work (SSOW) are mentioned as key underpins to arc flash mitigation and worker protection.

In recognition of those dangers and working with ProGARM, the leading UK manufacturer of the Flame Resistant & Arc Flash Clothing, we show how together we ensure workers return home safe.

We hope to clear the current ambiguity of attitudes to the subject with some interesting statistics that in conclusion may or may not achieve that objective.

Let me know your thoughts later here or vote in our Poll below – so lets get started.

According to the UK Health & Safety Executive (HSE) most electrical accidents occur because people are working on or near equipment:

- thought to be dead but which is live

- known to be live but those involved do not have adequate training or appropriate equipment to prevent injury, or they have not taken adequate precautions

Arc flash can only occur on live cables, circuits or electrical equipment.

Arc Flash Defined

“Electrical arcing (sometimes called a ‘flashover’ or ‘arc flash’), perhaps as a result of a short circuit caused by unsafe working practices, can generate intense heat leading to deep-seated and slow-healing burns, even if it persists for a short time. The intense ultraviolet radiation from an electric arc can also cause damage to the eyes.

Often those working with or near electricity do not appreciate the risk of serious injury and consequential damage to equipment that can arise from arcing. Arcing, overheating and, in some cases, electrical leakage currents can cause fire or explosion by igniting flammable materials.

This can cause death, injury and considerable financial loss.”

Extract from HSG85 UK HSE Electricity At Work – Safe Working Practices.

The UK HSE is an independent regulator providing advice, guidance, news, tools, legislation and publications for work-related health, safety and illness issues.

♦ ARC FACT Electric arc causes an ionization of the air with arc flash temperatures generating a fireball reaching up to 35,000 degrees Fahrenheit. This is hotter than the surface of the sun.

Arc Flash – The Risks

Street Lighting Electrical Cable Dangers

Injuries are usually caused by the explosive effects of arcing current, and by any associated fire or flames that may result when a live cable is penetrated by a sharp object such as the point of a digging tool. Excavating around public utilities always carries the potential for those utilities to be damaged and for those involved to be seriously injured.

In particular electrical cables carrying low voltage domestic electricity can cause serious burns. It is therefore important that all those involved in excavation work comply with safe digging practices to ensure the safety of themselves and anyone else who may be close by.

➡ Further reading: HSG47 UK HSE Avoiding Danger From Underground Services

Street lighting engineers and operatives are exposed to arc flash risks if correct digging procedures are not followed while excavating underground electricity cables – operatives have suffered arc flash burns when digging with a hammer drill directly above an identified live buried cable. Upon making contact with a 415v street lighting cable, ‘arc flash’ occurred resulting in burns to the wrist and elbow and a visit to the hospital A&E – this could have been much worse. Never dig directly over an identified live buried service. Powered hand tools used close to live cables are likely to represent the greatest risk of injury.

Ad: Lucy Zodion | Feeder Pillars | Cut Outs | Isolators – The Street Lighting Specialists

Arc Flash Clothing

In the street lighting industry arc clothing should be rated according to IEC61482 – under test method IEC6182-1-1 garments are tested and then categorized into 5 levels of protection as per the chart below. Typically Category 2 arc flash clothing covers workers for the majority of tasks however this should be dependent and based on risk assessment of the job in hand.

ProGARM recommend worker should be protected from arc flash by a helmet with full visor, insulating gloves and garments such as arc flash polo shirt, arc flash trousers and coveralls with Category 2 flash protection.

Hazard Risk Categories According To IEC 61482

| Incident Energy Level (caVcm2) |

Hazard Risk Category |

PPE Type | Arc Flash Clothing & PPE Details (Basic Examples) |

| 0 – 3.9 | 0 | 0 | 1 full FR/ARC layers (covering all body), polycarbonate safety spectacles, lightweight cotton gloves. |

| 4 – 7.9 | 1 | 1 | 1 layer flame retardant (FR) work wear, helmet, polycarbonate safety spectacles, lightweight FR gloves. |

| 8 – 24.9 | 2 | 2 | As above but with 2 layer FR outer work wear that has wrist closures, and a full face polycarbonate visor. A FR single-layer balaclava may also be worn to protect the face. |

| 25 – 39.9 | 3 | 3 | 3 layer FR outer work wear and FR shirt, a full-face hood or visor with safety spectacles underneath, chrome leather gauntlets. |

| 40+ | 4 | 4 | Typically 4 layer FR outer work wear (as illustration), FR and electrically insulated footwear and suitable FR material spats to close off the ankle area, FR gloves or chrome leather gauntlets, a hood constructed from a triple layer of FR material with a sewn-in polycarbonate face shield with a minimum of 2 panels of suitable thickness with one coated with a gold film for UV protection. |

♦ ARC FACT The arc blast can rupture ear drums and project molten metal into the face and lungs without adequate PPE protection.

G39 Working In the Vicinity Of DNO / IDnO Electrical Equipment

Engineering Recommendation G39 is a Model Code of Practice covering Electrical Safety in the Planning, Installation, Commissioning and Maintenance of Public Lighting and Street Furniture. G39 scope covers low voltage electrical installations (up to 1000V), the associated inherent risks, hazards and requirement for implementation of thorough and proper PPE to protect workers against electrical injuries.

Under obligation of law the employee must provide a Safe Systems of Work (SSOW) to enable safe working where hazardous work processes are present, for instance the risk of arc flash when working in the vicinity of live conductors in a cable trench during jointing of utility cables.

G39 does not mandate PPE requirements – this is the absolute responsibility of the employer (or if you’re the employer, the employee and vice versa).

However, leading industry bodies including the Highways Electrical Association would always recommend arc flash clothing and protective PPE where this is available.

Perilous Contradictions, Mixed Messages & A Mexican Stand-Off

Despite this a recent study by ProGARM in conjunction with the British Safety Industry Federation (BSIF) revealed a shocking level of widespread industry ignorance with 25% of employers attributing the sole responsibility to the employee, not the employer, to self-protect against arc flash.

Worryingly, 50% expect the employee to also self-educate through personal research.

Perverse as it may sound, try Googling “how to save my life against arc flash“. Over 43 million search results to wade through – some contradictory, some misleading.

This employer-employee confrontation across the knowledge gap is exacerbated by government passivity, resulting in an unresolved tension with workers endangered daily due to lack of understanding and ultimately absence of UK legislation – until legal action is taken, as in the USA, the stand-off prevails and the risk pervades.

More findings from the BSIF report:

- 84% Understood the risk of arc flash – Good, only 16% to educate.

- 57% Were aware of someone who has suffered an arc flash injury – The threat is real.

- 90% Believe revised Government guidelines or enacted legislation is required to protect workers exposed to arc flash hazard – Voice your opinion in our Poll below.

Established providers of training courses covering G39, such as the Highways Electrical Association, ensure engineers working in highways environments such as street lighting are equipped with the knowledge, awareness and practical key skills when working in the vicinity of DNO electrical equipment.

Arc flash clothing is commonly worn when working on overhead power lines, during the removal and replacement of DNO cut-out fuse carriers, jointing live cables and the commissioning, maintenance and repair of distribution feeder pillars.

G39 training courses ensure delegates work in a safe and responsible manner to comply with company obligations and legislative policy.

Noting the recent swing in the UK HSE view of risk management through significance it would be reasonable to conclude that Arc Flash Clothing & PPE including visors and suitable head / hand wear, on a balance of risk vs cost vs availability should be specified – otherwise offending management or neglectful decision makers could face fines or imprisonment.

In addition to this Electricity at Work Regulations 1989 place a duty on an employer to protect against the risk of death or personal injury from electricity in work activities.

EAWR places a legal responsibility on employers and employees, as duty holders, to ensure that electrical systems used at work under their control are safe.

Make Arrangements For Management Checks & Supervision Of Work

“Employers and workers must comply with the EAW Regulations in so far as they relate to matters within their control. You should check that workers are following the rules and correct procedures. Sometimes, some or all of these checks may be delegated to the supervisor of the work. Even in organisations with effective written safety rules and safe systems of work, regular and systematic management checks of the work are necessary. This is particularly important if the work is being done in the field, on another occupier’s premises, or by peripatetic workers.”

Extract from HSG85 UK HSE Electricity At Work – Safe Working Practices.

ProGARM | Functional Arc Flash Clothing, Protection & PPE For Everyday Wear

Check Your rams – Risk Assessment Method Statements

In the UK risk assessments are undertaken to identify, mitigate and eliminate workplace risks and then additionally a method statement is prepared to control residual risks – this is known as RAMS and demonstrates safety precautions have been sanctioned to protect employees against worksite hazards and comply with Law.

Pictured: 4 Core Waveform LV Cable Terminations Into Schneider Feeder Pillar. Image: Darren Street (D&R Cable Jointing).

5 Simple Steps To Assessing Risk Of Arc Flash Incident

- Identify the arc flash risk

- Who can be harmed and how

- Evaluate the arc flash risks

- Record your findings

- Monitor and review

With respect to arc flash protection a company risk assessment would cover PPE requirements at the planning stage before any works commencing – typically an electrical engineer would isolate and test energised equipment is dead and absent of voltage prior to removal of incoming mains power supply.

Live Working & Working Dead

Working dead with secure electrical isolation eliminates arc flash risk completely, but working on or near live exposed conductors or electrical equipment occurs because it is difficult, even impossible, to programme work to allow all job tasks to be carried out where cables and equipment are dead:

- Commissioning feeder pillars without full or partial energisation can be impossible

- Cable fault finding and tracing location of malfunction requires energised circuits

- Unacceptable multiple disconnections necessitate live working where LV supply must be connected to existing mains

- Isolation of power supply to essential services is precluded due to repair work causing disproportionate disruption and cost

- Inadvertent live working on public lighting cables, signs, traffic signals and equipment when presumed de-energised

In these conditions, arc flash clothing and protective helmet with insulating gloves should be worn – if in doubt contact us to discuss your requirements.

Live Cable Jointing

Utlities in the UK undertake live cable jointing using insulated tools to prevent interruption to multiple occupancy buildings and businesses. Shown pictured, a live 185sqmm Consac to 185sqmm Wavecon low voltage mains repair straight joint has been installed to restore power to 13 industrial units “off-supply” in Reading. The fault was a “phase to phase” fault with two cable faults on a 1 meter section of cable.

Credit: Cable Jointer – Grant Butler 33kV/11kV HV & LV Cable Faults Jointer at SSEN

T&D distribute Flame Resistant & Arc Flash Clothing to local authorities, private lighting contractors (Highways Agency & NERS), ICP’s and DNO’s.

ProGARM, The Arc Flash Specialists

ProGARM are a the leading UK manufacturer of high quality Flame Resistant & Arc Flash clothing, garments and workwear – they work successfully with their UK Distributor Thorne & Derrick to save lives and reduce accidents.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

“At ProGARM our mission is protect lives through the manufacture and supply of exceptional quality Arc Flash and Flame Resistant Clothing. Being the only specialist Arc Flash protection manufacturer in the UK we focus on providing the best protection possible to those who work at risk of Arc Flash on a daily basis with our inherent, specialist garments and industry-leading innovation. Supporting Utilities, Power Generation, Rail & Petrochemical industries we work with Thorne & Derrick to educate, inform and supply those who work at risk everyday allowing us to keep protecting lives throughout the UK & beyond.

When lives are at stake, trust a specialist.” Mark Lant, Sales Manager at ProGARM – Protecting Lives through ARC Flash & Flame Resistant Clothing solutions.

Arc Flash Protection | Polo Shirts | Jackets | Coveralls | Trousers | Helmets | Gloves

Closing Thought – EU statistics show that between eight and ten arc flash accidents occur in the UK every week. Protect yourself, contact us to learn how.

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Arc Flash Protection Hoodie with FR Protection | ProGARM 5530

October 13th, 2020

ProGARM Arc Flash Hoodie 5530

Arc Flash Clothing

ProGarm 5530 Arc Flash Protection Hoodie

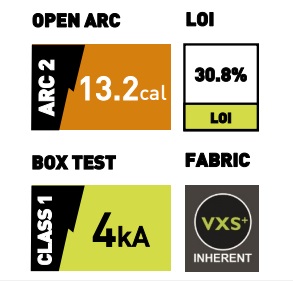

ProGarm have always been ahead of the game when it comes to arc flash protective clothing design and their new product the arc flash protection hoodie is no different. The 5530 hoodie doesn’t only provide arc flash protection to 13.2cal/cm² but also is stylish, comfortable and practical to wear.

This premium hooded sweatshirt features a warm neck design, ideal for working outside as well as a drawstring hood. Constructed from ProGarm’s very own 320gms VXS+ Jersey fabric with a brushed inner fleece lining for warmth, it also features ribbed waistband and cuffs for a great fit and the usual front pockets too – great for storing mobile phones.

This 13.2cal/cm2 arc flash protection hoodie has also been layered and tested with the ProGarm 7cal/cm² 5280 Arc Flash Polo Shirt and the combination delivered results of Class 2 and 31.0cal/cm² protection.

The 5530 arc flash hoodie – already a winner, scoring 9.2 out of 10 in a recent user trial.

In stock and available for immediate delivery, T&D have sizes S-4XL.

Arc Flash 5530 Protection Hoodies

Arc Flash Hoodie 5530

Features & Benefits

- 13.2 cal (ATPV) to provide Arc 2 protection (combine it with 7cal 5280 polo shirt for 31cal protection!)

- Supersoft fabric makes it comfortable to wear and easy to work in

- Snug neckline and draw string hood help with cold and arc flash protection

- 100% inherent fabric means that protection won’t wash out or diminish over time

- Lifetime Seam Guarantee shows our confidence in the quality of the product

- Brushed fleece inner for Winter warmth

- VXS+ blend for natural feel, comfortable and soft

- Breathable with good moisture management

- 5cm stretch rib hem – best fit around waist and cuffs

- Colour matched to other navy ProGARM arc flash garments

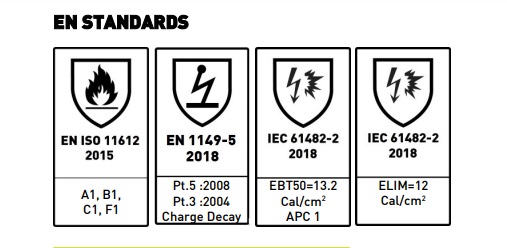

Arc Flash Protection – EN Standards

Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Further Reading

- IEC 61482-2 2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

- IEC 61482-2 | Arc Flash Protective Clothing Standards

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

IEC 61482-2 | Arc Flash Protective Clothing Standards

September 15th, 2020

IEC 61482-2 | Arc Flash Protective Clothing Standards

Arc Flash Protection

IEC 61482-2 Arc Flash Standard

ProGARM produces safety garments that protect workers against the Thermals Hazards of an Electric Arc. Each arc flash protective garment is carefully designed by ProGarm to offer the maximum protection to the new arc flash standard IEC 61482 whilst ensuring comfort and outstanding durability.

As Arc Flash clothing items come under the requirements of Category 3 Protective Clothing, these garments are manufactured under Module D Quality Control Procedures.

WHAT IS AN ELECTRIC ARC?

Electric Arc and the arc flash created is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

The intense heat can create temperatures as high as 19,000°C and it also produces electric shock, force and large quantities of thermal radiant energy.

What is the Risk?

In any situation where your employees are working with electricity, an Arc Flash can occur and as such the maximum energy of default circuits in any electrical installation must be able to be determined. The risks of an electric arc exposure are:

- Electrocution – potentially fatal

- Extremely high levels of Radiant Heat

- 1st, 2nd or 3rd Degree burns – 3rd Degree burns cause permanent damage

IEC 61482-2:2018 PERFORMANCE & DESIGN REQUIREMENTS

Performance requirements for materials and design requirements for garments, plus Marking and User Information.

This part of IEC 61482 is applicable to protective clothing used in work if there is an electric Arc hazard. This standard specifies requirements and test methods applicable to materials and garments for protective clothing worn by electrical workers to protect them against the thermal hazards of electric Arc based on relevant general properties of the textiles, tested with selected textile test methods, and one of the Test Methods as defined below.

IEC 61482-1-1:2019 ‘OPEN ARC’ TEST METHOD

‘Open Arc’ test method (ATPV test and garment test). This replaces IEC 61482-1:2002. The ‘Open Arc’ test method is the same as the original North American method for measuring the Arc Thermal Performance Value (ATPV), as used in ASTM F1959. Materials or assemblies are given an ATPV/EBT/ELIM value, expressed in kilojoules per square metre (kJ/m2), which can be converted into the familiar cal/cm2.

Or

IEC 61482-1-2:2007 ‘BOX ARC’ TEST METHOD

‘Box Arc’ test method (Fabric classification and garment test). The ‘Box Arc’ test method is based on the original European method described in ENV 50354, with a heat transfer measurement. Materials or assemblies are classified as Arc Protection Class (APC) 1 (4 kA) or APC 2 (7kA).

During this test, a fabric sample is exposed to an electric Arc produced by a 4kA or 7kA short circuit. In the test, the Arc does not last any longer than 500ms. The amount of heat transmitted through the sample is measured during and after the test. On the basis of the resulting data and a Stoll curve, the length of time it would take to cause the onset of second-degree burns is subsequently determined. Samples are also assessed for after-flaming, hole formation, melting, etc.

GARMENT TESTING & FABRIC TESTING

It is important to note that not only the fabric should be tested for conformance to the Arc Flash Standard, but also the complete garment or garment assembly itself.

The garment test is not testing for energetic value but is testing to ensure that the garment structure remains intact after the Arc exposure and that components such as zippers and buttons are still functional and do not contribute further injury to the wearer by melting or heat transfer.

ProGARM | Functional Arc Flash Clothing, Protection & PPE For Everyday Wear

As a result of this ProGARM have written a short guide to the new IEC 61482-2:2018 standard to highlight the key bits of information you need to be aware of when reviewing your PPE specification and the key terminology that you need to understand.

Choosing the right PPE for your team can be difficult and with all the standards to consider it can feel quite overwhelming. This guide aims to help people make a more informed decision about what PPE is best for you.

You can download the PDF guide via this link or see the attached pdf below.

IEC 61482-2 2018 Free Guide

Arc Flash Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts | Helmets

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Further Reading

- IEC 61482-2 2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Arc Flash Protection | A Whitepaper on Clothing & Garment Selection

August 18th, 2020 Helping educate companies and raise awareness amongst operatives about what garments to wear and how to wear them, when at risk of an ARC FLASH

Helping educate companies and raise awareness amongst operatives about what garments to wear and how to wear them, when at risk of an ARC FLASH

-

Author: Hamilton Smith Technical Sales Manager 2020

What is an arc flash / electric arc?

Definition: An arc flash is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

… and in laymans’ terms

- An arc flash occurs when electrical current jumps across an air gap between conductors, like when lightening jumps down to earth

- That large instantaneous discharge of electrical current causes an explosion

– Extremely high levels of energy, heat and light are released in fractions of seconds

– Temperatures can reach up to 35,000ºF (19,000ºC) = 4 times the temperature of the Sun’s surface!

– A blast and pressure wave that can damage eardrums and even strip away garments

➡ Ultra Slow Motion Arc Flash 480V

Where & when does an arc flash occur?

Where?

- Industrial electrical environments – Factories, manufacturing plants, electrical maintenance even including areas such as electric vehicle maintenance and manufacture

- Power generation -Traditional environments but also including renewables such as wind turbine maintenance

- Utilities – Anyone breaking ground in electrical, gas and water, even operatives installing street lights

- Rail sector – Electrification and maintenance

- Petrochemicals – Protecting plant workers and even tanker drivers in the same way as for arc flash against flash fire

When?

- Whilst undertaking installation, maintenance or repairs, but also when breaking ground, undertaking excavations and construction

Why does an arc flash occur?

- Tools or equipment inadvertently touch live conductors or are dropped

- Faults or mistakes in isolating equipment

- Equipment failure due to faulty parts, poor installation, or even normal wear + tear

- Dust, corrosion or other impurities on conductor surfaces

- Cable strikes when breaking ground 8 to 10 cable strikes are reported daily in the UK

Arc flash vs Operative … only one winner!

- Skin burns right to 3 rd degree from direct heat exposure

- Damage to eyesight caused by heat and the high intensity flash which includes UV light

- Hearing loss and physical damage as the blast can greatly exceed the sound of a jet engine

- Significant injury risks from flying debris such as equipment, shrapnel wounds and molten metal

- Loss of memory or permanent impairment of brain function from concussion

- Burns from hot liquids in oil cooled or insulated equipment

- Other physical injuries from being blown off ladders, into walls etc

It’s no exaggeration when we say the implications and injuries can be life threatening, they’re certainly life changing.

Employee protection what can be done?

Employers have a duty to protect their employees against injury and other hazards.

There is a hierarchy of steps to safeguard workers:

- Reduce the exposure of operatives to risk

- Define and enforce safe working practices to reduce risk – they can undertake an AF study

- Provide appropriate level sot PPE – AF assessments or studies can help to predict potential exposure and suggest the level of protection.

PPE is designed to reduce the risk of life changing or life threatening 2nd or 3rd degree burns. Arc flash clothing and PPE is the last line of defence when risks cannot be totally eliminated.

Arc Flash Protection standards

IEC 61482 2 : 2018 Protective Clothing Against the Thermal Hazards of Electric Arc

Arc flash testing information – there are two test methods:

BS EN IEC 61482-1 1:2019 | Method 1: Determination of the arc rating (ELIM, ATPV and/or EBT) of clothing materials and of protective clothing using an open arc (Open Arc Test).

- ATPV = Arc Thermal Performance Value

the value of incident energy at which the heat transfer through the test specimen is enough to reach the Stoll criteria with 50% probability of 2nd degree burn e.g. if a product that achieves 8cal/cm² ATPV, is hit with 8cal arc exposure then there is 50% probability of 2nd degree burns. - EBT = Breakopen Threshold Energy

the value of incident energy at which breakopen occurs with 50% probability of 2nd degree burn e.g. a product that achieves 8cal/cm² EBT, if hit with 8cal arc exposure then there is 50% probability of 2nd degree burn and with breakopen of material. - ELIM = Incident Energy Limit

a numerical value of incident energy attributed to a product, below which there is no data point with the amount of heat transmitted through the product reaching the Stoll criteria or with the product exhibiting breakopen e.g. a product that achieves 8cal/cm² ELIM, if hit with 8cal arc exposure then there is 0% probability of 2nd degree burn.

IEC 61482 2 : 2018 Protective Clothing Against the Thermal Hazards of Electric Arc

Arc flash testing information – there are two test methods:

BS EN 61482-1 2:2014 | Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (Box Test)

- APC 1 (Class 1):

• test current 4kA (+/-5%)

– voltage 400 volts a.c. (+/-5%)

– arc duration 500 ms (+/-5%)

– frequency either 50hz (+/- 0.1hz) or 60hz (+/- 0.12hz) - APC 2 (Class 2):

– test current 7kA (+/-5%)

– voltage 400 volts a.c. (+/-5%)

– arc duration 500 ms (+/-5%)

– frequency either 50hz (+/ 0.1hz) or 60hz (+/ 0.12hz)

Fibres, Fabrics & Creating Protective Garments

Arc Flash Lineman Coverall ProGARM 6458

Treated vs Inherent

- At ProGARM we believe fundamentally that inherent FR fabrics offer the best solution

- Traditionally treated fabrics have been stiff, uncomfortable, lacked breathability and even smelly!

- Protection from treatments reduces every time a garment is washed

- Inherent means that characteristically the fibre will not burn – Inherent fibres create inherent yarns which are knitted or woven into inherent fabrics instant extinguishing

Our fabrics are called VXS+.

Arc Flash Clothing systems

Examples of garments that are often combined into a PPE system

Protection in layers where 1 + 1 = 3

Make sure they are the right layers though

- We’ve developed a total range of garments from underwear and thermal base layers to 47cal waterproofs

- Many H&S Managers and operatives are not aware that wearing the wrong fabrics, even under AF protective garments, can compromise the AF garments and result in injury

What makes a great garment?

Let’s take a look at some of the features that protect and save lives.

Arc flash garment features to be aware of:

Take a look at the garment design features that show the attention to detail.

- Triple stitched seams

- Inherent fabric & instant extinguishing

- FR threads

- ThermSAFE components tested to continue to function after an incident

- Wrist tabs and neck fastening

- Reflective tape

- SafetyICON marking

- Internal labelling inc batch numbers for traceability

- Stretch panels

- Napoleon pockets for harnesses

- Garments available from S to 4XL

- Women’s garments

Let’s sum up

Education is one of our core missions – we’re here to help.

ProGARM’s Mission

- Educate and inform to save lives

- Constantly develop and innovate

- Deliver an exceptional customer experience

- Never compromise. Lives depend on it

We’re here to help you find the right solution for your operatives who are at risk of an electric arc to make sure they come home safely.

Polo Shirts | Jackets | Coveralls | Trousers | Gloves | Sweatshirts | Helmets

Overview of Arc Flash Clothing | Contact us to discuss your garment and PPE requirements, we can mitigate risk with guidance on safe working practices and by providing appropriate worker clothing that offers advanced Arc Flash Protection that saves lives every day. Whether working on underground cables or overhead lines, here is a selection of workwear clothing – contact us to discuss your requirements;

>> Download Your Guide To Here <<

Further Reading

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

- Latest Arc Flash Legislation & Regulation Explained By ProGarm

- Arc Flash PPE | 7 Top Considerations

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

HV Cable Joints, Terminations & Connectors | Approved Stockists & Distributors | 3M Electrical (Cold Shrink) | Nexans (Euromold JTS MONO) | Pfisterer (CONNEX SEANEX) | 11kV 33kV 66kV Medium & High Voltage Cable Accessories

NEW | Arc Flash Hoods From Protection Specialists ProGARM

April 21st, 2020

Arc Flash Hoods, Coveralls & Gloves

ProGARM delivers ultimate Arc Flash clothing and protection, including Arc Flash Coveralls, and Arc flash Hoods conforming with the relevant industry and EN standards ensuring protection from Arc Flash incidents.

Specialists in Arc Flash Protection

THE SPECIALIST CHOICE FOR ARC FLASH PROTECTION

ProGARM is the leading UK manufacturer of high-quality flame-resistant Arc Flash coveralls, garments and workwear – they work successfully with their UK Distributor Thorne & Derrick to save lives and reduce accidents.

ProGARM is the only UK manufacturer concentrating on and specialising 100% in Arc Flash protection and Flame Resistant garments for industry.

The dangers of Arc Flash incidents and the importance of protection from these hazards has never been as significant as it is today. This prominence will continue to increase over the next few years.

With multiple cable strikes every day in the UK and numerous major Arc Flash incidents, businesses are looking at how best to protect their team with the right Arc Flash and flame resistant garments. The correct clothing can significantly reduce injury and save lives.

ProGARM is committed to continual research and improvement to innovate and develop their range as quickly as possible to bring you the best Arc Flash protection for your team.

Product Launch: 9700 ARC FLASH HOOD

Arc Flash Hood: Product Launch From ProGARM

Thorne & Derrick are delighted to announce the launch of a brand new 47 cal/cm² Arc 4 Hood, manufactured by ProGARM, helping us to provide even more clothing solutions to reduce the risk of injury during an Arc Flash incident.

Due to the high risks involved when working in electrically high areas, the importance of adequate protection levels is vital in providing a suitable last line of defence.

The 9700 Arc Flash Hood is designed for use in close proximity to live electricity. This hood contains an anti-fog coated, transparent grey visor to keep vision as clear as possible when being worn. With a high quality and ultralight helmet, comfort is increased along with practicality; with seamless hood integration as well as a unique Velcro® brand fastener system for simple assembly and deconstruction.

The Arc Flash Rated Hood is designed to be used alongside your existing clothing systems to provide specialist protection when working with high incident energy levels.

Made from VXS+ inherent fabric, this Arc Flash Hood won’t lose it’s protective qualities, no matter how much you wash it.

ARC FLASH HOOD 9700 PRODUCT SPECIFICATION

ASSEMBLY

|

The assembly of hood, visor and helmet has been tested to and certified to EN 166:2002, GS-ET-29:2011 (APC 2), and ASTM F2178-ATPV 47cal/cm². |

|

|

|

FABRIC

|

VXS+ Inherent special weave 395gms outer shell fabric with VXS+ inherent 200gms lining woven fabric, meeting the following standards:

|

|

|

|

VISOR

|

Premium anti-fog coated Highly Transparent Arc flash protective shield, colour grey, meeting the following standards:

|

|

|

|

HELMET

|

Manufactured from high quality strong ABS material, up to 20% lighter than most other helmets, features Dry-Tech sweatband for maximum comfort and an adjustable ratchet. Meeting the following standards:

|

|

|

|

WHAT IS AN ARC FLASH?

An electric arc occurs whenever a circuit breaker, switch or isolator (Device) is opened and when there is current flowing in the circuit. However, most devices under normal operating conditions are designed to control the arc when opening or closing.

An arc flash may occur when the arc is uncontrolled and there is sufficient energy released to cause harm or damage.

Arc flashes occur both at high voltage and low voltage. There is little discrimination: low voltage arc flashes injuries are just as damaging at high voltage injuries.

Put simply: An Arc Flash is the light and heat produced from an electrical arc supplied with sufficient energy to cause significant damage, fire or injury.

An Arc Flash can cause minor injuries, third-degree burns and potential death as well as other injuries including blindness, hearing loss, nerve damage and cardiac arrest. Fatal burns can occur when the victim is several feet from the arc. Serious burns are common at a distance of 10 feet – arc flash can generate heat 4 times greater than the surface of the sun.

The dangers of an Arc Flash

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV