Blog

SICON By PFISTERER | Shearbolt Connectors with Stepless Shear-Off Bolts

May 11th, 2021SICON Shearbolt Connectors

The Right Connection for All LV MV HV Conductors – For years, bolted clamps, connectors, and cable lugs have been gaining ground – with good reason. Bolted connectors offer technical and practical advantages that compression technology cannot match.

Meet the Next generation SICON connectors from Pfisterer.

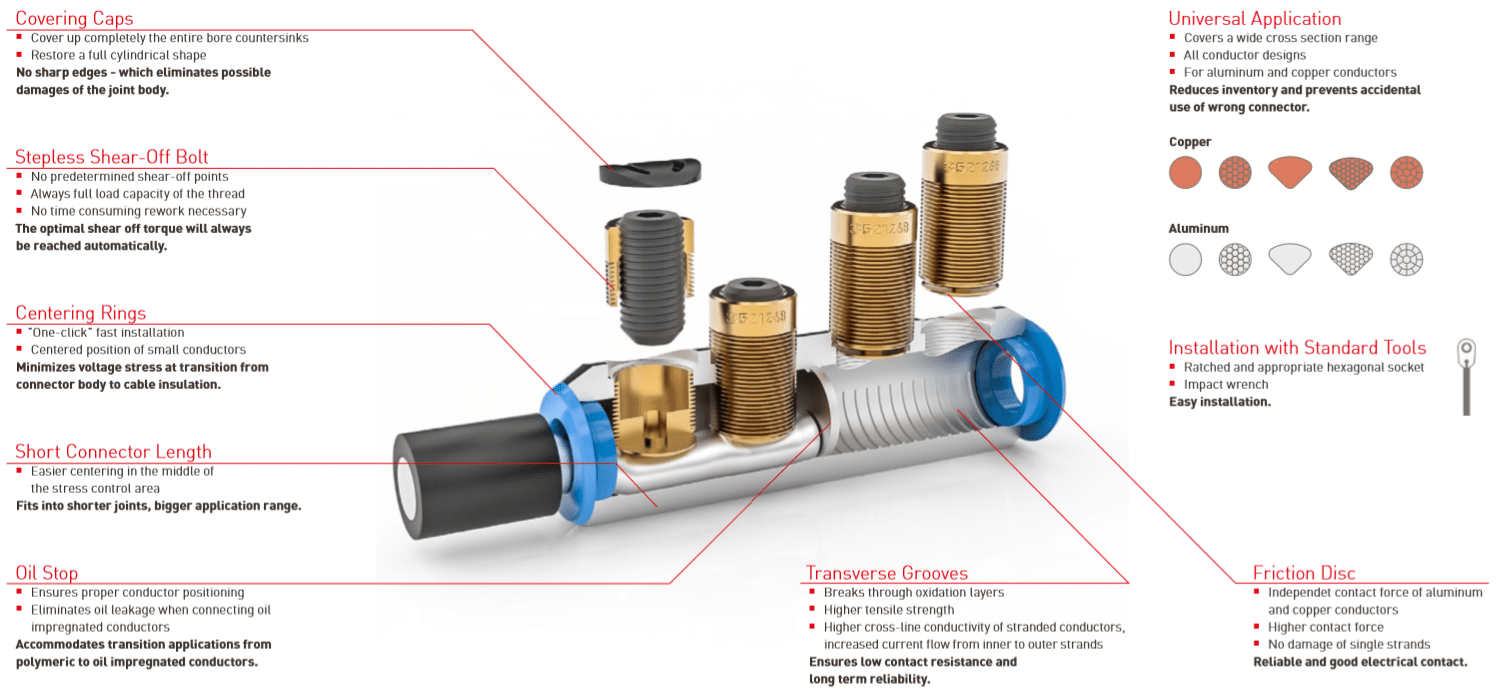

Bolt type connectors offer not only technical, but also practical advantages over compression technology. All SICON Shearbolt Cable Connectors cover a wide conductor cross-section range so that you always have the right connectors on site for any application.

Main benefits of Sicon Connectors include:

- Reliable connection for all conductors

- Optimal contact force for all conductors

- No damage to individual strands

- Installation with standard tools

- Ideal for all type of joints or terminations

- Wide application range

- See also SEANEX Connectors

PFISTERER

DISTRIBUTORS, STOCKISTS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of LV MV HV Power Products manufactured by Pfisterer – this includes Pfisterer CONNEX MV HV cable plugs and terminations.

Pfisterer Sicon

Benefits of the Pfisterer Shearbolt Connectors

Simple Installation of sicon with Standard Tools

SICON bolted connectors are installed directly onto the ends of the conductor with a standard allen key. The innovative design of the stepless shear bolt allows simple installation regardless of the conductor type. Optimal contact force is always achieved with the special design of the bolt.

Easy To Install shearbolt connectors

All SICON connectors can be easily installed, even under tight spots. The bolt shears off smoothly when it is tightened, while the remains stay in the tool and can be safely disposed of. The bolt always shears off at the top edge of the connector body. This way, there are no sharp protrusions. All edges of the connector body are rounded.

Cost-Effective Sicon Connectors

Every SICON connector covers a wide x-section range. This way, you always have the right connectors with you on site. And even if during repair work it is unclear what type of conductors must be connected and in which condition are they in, SICON is the right choice.

SICON connectors are electrically/mechanically type-tested in accordance with IEC 61238-1 class A and ANSI C119.4.

All Conductors Are Optimally Connected

SICON connectors can be used independently of the conductor material , type, voltage level and current. No matter whether aluminum or copper, solid or stranded – the conductor is always connected with perfect contact pressure. For aluminium conductors, this means with a contact force up to 30% higher than of conventional connectors. The transverse grooves in the clamping channel break through the oxidation layers and reliably establish the contact.

Pfisterer SICON Shearoff Cable Connectors

Sicon Application Range

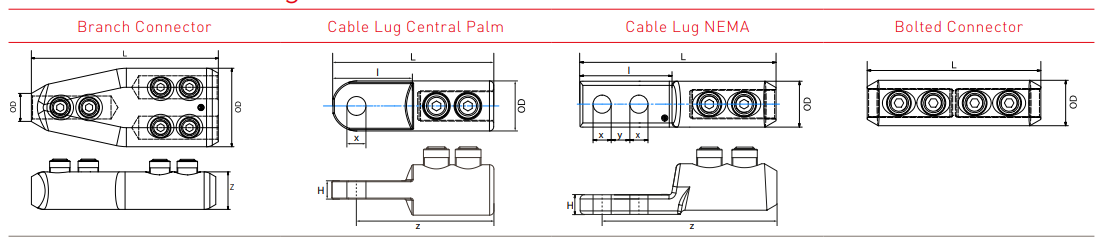

The Pfisterer SICON range of Shearbolt Cable Connectors is made up of Split Connectors, Branch Connectors and Cable Lugs.

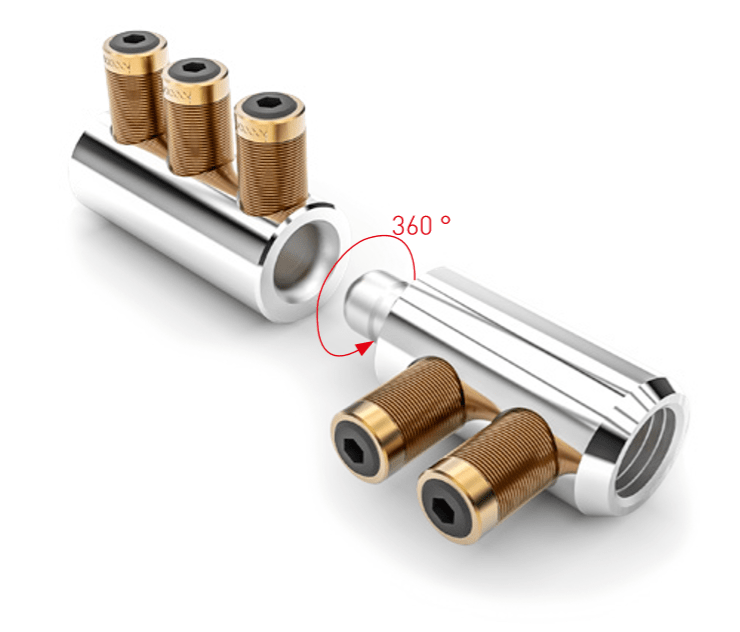

- Split Connectors are for use in installations where it is difficult to install the connector on the conductor

- Branch Connectors can be used to join 3 different conductors regardless of size or material

- Cable Lugs enable the cable ends of electrical devices to be connected with a bolt or a stud

Branch Connector |

Cable Lug Central Palm |

|

|

Cable Lug NEMA |

Split Connector |

|

|

Thorne & Derrick JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

11kV Flexible Rubber Reeling Vulcanised Cable Joint

May 11th, 2021Picture Courtesy of: Corey Caulfield – Director/Cable Jointer at HV Connect Pty Ltd

Pictured: 11kV Flexible Rubber Reeling Vulcanised Cable Joint

11kV Flexible Rubber Reeling Vulcanised Cable Joint

This vulcanised type cable joint is smooth profile preventing “snagging” of the 11kV joint during the reeling process – there is absolute minimal increase to the overall outside of the cable diameter despite the joint.

“The cable joint was completely taped using a variety of 3M Scotch vulcanising tapes and the outer sheath was re-instated using Prysmian rubber tape. A complete cable joint carried out on a stacker,” said Corey.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

High Voltage Lead Sleeve Y Joint

May 11th, 2021This striking splicing image demonstrates traditional cable jointing techniques requiring exceptional manual dexterity, acute concentration and advanced skill levels.

Modern polymeric cable jointing is now dominated by cold-shrink, click-fit and push-on type splices which are frequently alleged to have de-skilled the Jointer by introducing simplified installation processes.

Whether you agree or disagree, no jointer can dispute that “old-school” jointing skills demand the highest levels of professionalism, knowledge and ability:

- Sweated ferrules

- Hand applied oil tapes

- Plumbed lead sleeve

- Compound filled

Single end wipe completed by Jimmy Nicklin, double end wipe completed by Andrew O’Malley.

Image Courtesy of: Andrew O’Malley (IBEW 258 EHV Cable Jointer/Splicer).

High Voltage Lead Sleeve Y Joint

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Ellis Patents Engineer Change In Cable Management Market

May 11th, 2021

The following article has been republished from Ellis Patents, whereby Managing Director Danny Macfarlane discusses the rapid technological development in the cable management market.

According to Macfarlane, one key change this has led to is that standard product ranges now form the backbone of a far more flexible product offering. He talks to ECN.

When I first joined Ellis Patents in 2003, we very much had standard product ranges, which specifiers selected from according to their project requirements,” says Danny. “We still have these ranges today, and the likes of our Emperor and Vulcan+ cable cleats remain our bestsellers, but alongside them we have a slew of new, innovative products that have been developed as a result of a major shift in the way the market operates; which in itself has been enabled by technological development.”

Ellis Patents Vulcan, Atlas & Emperor Cable Cleats

In the last few years alone Ellis Patents has designed, developed and manufactured a completely new product for a major Siemens offshore wind project; solved installation headaches with bespoke solutions for Balfour Beatty; and consigned a major health and safety issue for National Rail to history with a product that went on to win a number of innovation awards.

The Siemens job was the first of these projects, with the company going to Ellis Patents with a need for a new product during a live project situation. The challenge was to develop a way of feeding, and then restraining, seven 117mm diameter cables along a specified route within a fabricated structure that featured a significant number of twists and turns.

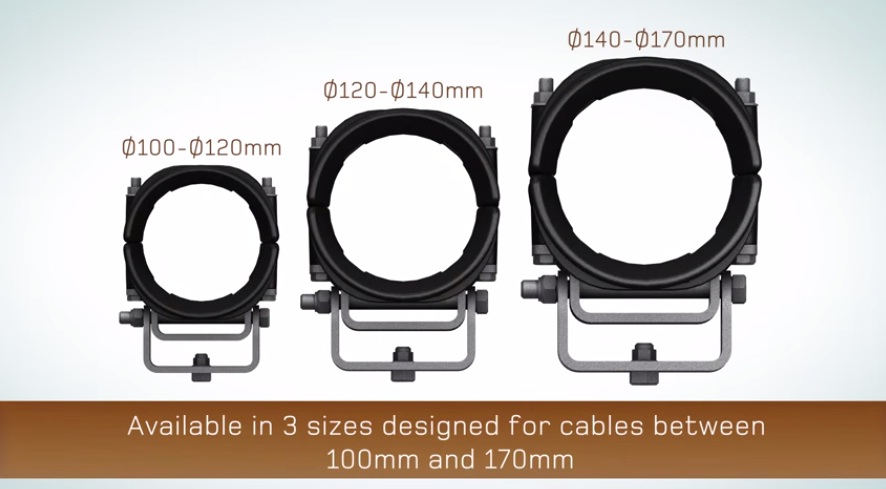

Ellis Patents Cable Guide Clamp

The Cable Guide Clamp that was designed, developed and manufactured in response not only solved Siemen’s problem, it also secured an order that wouldn’t have been won had the company been relying solely on its standard product offering. And Ellis Patents didn’t stop with that one project, the Cable Guide Clamp has since been developed into a full range that regularly secures orders from around the world.

Ellis Patents Cable Guide Clamp

The Ellis Cable Guide Clamp is designed to be installed in place of rollers along the HV cable route where the cable length is pushed and pulled through to its final destination.

“Our ability to deliver these innovative bespoke solutions, some of which were done in live project situations, is something we’re immensely proud of,” says Danny.

“But without the technology we simply wouldn’t have been able to turn our ideas into fully functioning products in such pressurised, time-sensitive situations.

“Traditionally, creating a production ready prototype would have required the development of injection moulding tools, which involved significant investment in time and resource, and typically took six to eight weeks to manufacture. And once received only small changes to the tools were feasible, meaning any major alterations could add another six to eight weeks to the already lengthy process.

“Now, thanks to 3D CAD and rapid prototyping 3D printing, we can take products from an idea in a brainstorm to a fully functional, production ready prototype in less than a fortnight – something we have done on a number of occasions. And it’s a combination of the growing availability of rapid product development technology and ever-growing levels of in-house engineering expertise amongst manufacturers that has led to such significant change in the market.”

Siemens, for example, didn’t go to Ellis Patents with its complex installation issue because it saw the company as solely a manufacturer of standard products. It was because Ellis had the in-house expertise and technological capacity to solve its problem within the confines of an extremely tight time frame. And it’s this kind of expertise that is playing an ever more important role in the cable management market – in particular amongst those manufacturing cable cleats.

“Projects are often far from straightforward and installation and maintenance issues regularly arise, so having the people and the in house technology to be able to solve problems; firstly on paper and then with an adapted or wholly bespoke product; is now as important as that strong standard product range”, concludes Danny.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Cable Strikes | Gas and Electric Service Strikes

May 11th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is usually caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding a series of cable strikes to a 20mm gas pipe and a low-voltage electric cable.

Series of Service Strikes

Background to the Incident

In May of 2020, a 20mm gas pipe and a low-voltage electric cable were struck in Wardington and on the M40 J11 improvement works respectively.

In August 2020, another low-voltage electric cable was struck on the M40 J11 improvement works. Investigations into these incidents revealed that all Fusion processes were followed:

- Prior to works being undertaken, utility drawings were made available.

- PAS 128 survey of the area was undertaken including the Ground Penetrating Radar (GPR) and Electro-Magnetic Locating (EML) surveys.

- A permit to dig was issued and the gang was briefed on the work to be carried out.

- The gangs were experienced and deemed competent.

- Works were supervised and service locators were on-site.

- All hand tools were insulated.

- All services were shallow (< 300mm).

Considerations

Utility drawings can be inaccurate and out of date, and so alone are not to be relied on.

Utilities should be installed as per industry standards, which include depths of over 450mm with proximity warning aids including coloured tape to identify utility types and surrounding the service in a bed of peashingle – none of these services struck complied.

Key Findings and Action Taken to Prevent Reoccurrence

- The Junction 11 package of works obtained their PAS 128 data for their permit to break ground system from an external source rather than from the established Fusion PAS 128 team. It was not mandated by Fusion to have to use this team. It has now been mandated that all PAS 128 surveys required for Fusion sites, will now be managed by the Fusion PAS 128 team and follow the same stringent analysis and assurance process.

- Further investigation of the PAS 128 data – i.e. interpretation of utility drawings and other information available when on site conducting the Electro-Magnetic Location (EML – CAT&Genny) surveys, showed the external supplier interpreted the information differently to the Fusion PAS 128 team. Although people with the appropriate training are deemed competent, it should be recognised that those with more experience are more likely to interpret information with a higher degree of accuracy.

- The absence of street furniture and other equipment is not a reliable indication of a lack of underground cables and caution must be exercised at all times whilst breaking ground and digging.

➡ Thorne & Derrick distributes Insulated Tools for the Rail & Utilities industries manufactured to British Standard BS 8020-2011.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.