Blog

January 5th, 2021

Denso Webinar l How to Prevent Corrosion of Wind Turbine Anchor Bolts l Register Here

Preventing Corrosion of Wind Turbine Anchor Bolts

Denso Tape System | Leaders in Corrosion Prevention

FREE Webinar

In this webinar, we will discuss how to easily prevent corrosion of wind turbine anchor bolts and other areas of these structures that may be subject to corrosion.

Addressed in this webinar will be:

• Brief history of Denso Tape which has been on the market for over 90 years.

• Discussion of how the Denso Tape System works and it’s many benefits.

• Ease of application overview and where additional Denso corrosion prevention products may apply.

Speaker Info:

Thomas Keadle

Technical Manager – NACE CIP Level 2

• Thomas Keadle has been a part of the Denso team for over 9 years. He is qualified to NACE CIP Level 2 and has been involved in numerous corrosion prevention projects in many different industries. Mr. Keadle has conducted hundreds of training classes and presentations on the proper application of Denso’s various corrosion prevention systems.

About Denso

Denso North America Inc. is a subsidiary of Winn & Coales International, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics, primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems. Winn & Coales was originally established as a business in London, England, in 1883, and the first petrolatum tape manufactured in the UK was Denso tape, manufactured under license by Winn & Coales (Denso) Limited.

Denso tape was developed over 80 years ago for the “Long Life Protection” of buried steel pipelines against corrosion. The Denso SeaShield Marine Systems include fiberglass forms, epoxy grouts, underwater epoxies, injectable epoxies, petrolatum tape and wrap systems.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

MV HV Cables 11kV 33kV 66kV | Cable Joints, Terminations & Connections

Texcan provides electrical and electronic wire and cable products for power distribution, control, industrial automation, automotive, premise wiring, and networking applications.

Guest Article By Blair Sackney, Dec 2020

Texcan | Major Projects & Engineering Support

This article contains my technical opinion and is for general information purposes only.

Cable Pulling Large Cables

Calculations

It’s good design practice to perform a cable pull calculation for cable pulling and cable laying runs that might be difficult. Doing this early in the project allows for cable sizing and routing options that are often not available late in the game. Pull calcs are relatively easy to do but surprisingly few engineers or contractors use them.

The type of damage commonly created by excessive pulling forces will typically pass DC HiPot or VLF acceptance testing. Medium Voltage cables are especially susceptible to this kind of damage. It can result in partial discharge, leading to premature failures, commonly after 5 or 6 years of use.

While hand calculations can quickly spiral in complexity, there is software available to help simplify the process. Personally, I like Southwire’s Cable Pull Calculator, but a quick search will result in several other on-line options. Calculators are also available in most electrical modelling software.

The process involves inputting a few cable and pull set up parameters to verify that pulling forces will not result in cable damage. These parameters include gauge size, the number of conductors, cable OD and weight, raceway type and size, and each pull segment.

Performing more pull calcs and comparing them to real site experiences will result in an improved ability to make accurate assumptions. Pull calcs are more an art than a science as the calculations involve a lot of big assumptions making many other parameter assumptions rounding figures.

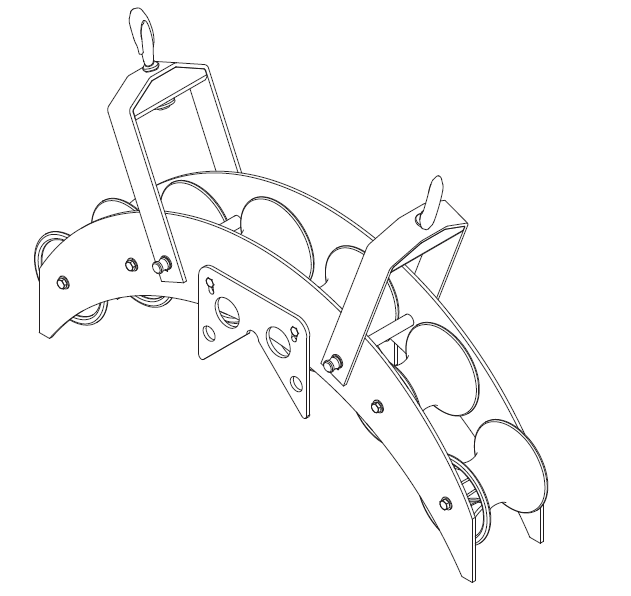

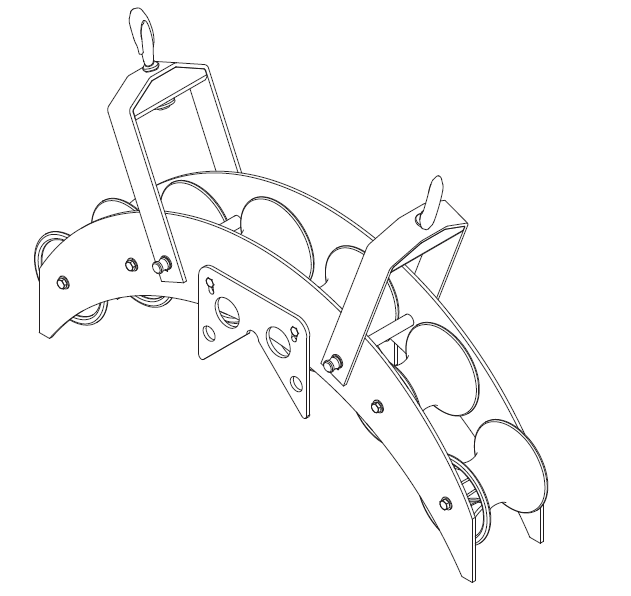

Figure 1: Conveyor sheaves can significantly reduce sidewall bearing pressure if installed

Side wall bearing pressure (SWBP), the radial force imposed at the bends, is by far the most common limiting factor. Excessive SWBP, usually visible in flattened armour or stretched jackets, can result in insulation damage which decreases cable life.

Common misconceptions that have only minor effects on the resulting pull calculations:

Maximum Pulling Tension – For power cables, this is usually not a limitation as the basket grip or pulling equipment usually limit pulling tensions before the conductors.

Upsizing the Conduit – Although you must maintain code required maximum fill requirements, upsizing conduits doesn’t lower tensions or SWBP by much.

Incoming Tension Assumption – Don’t sweat +/- 25 lbs on incoming tension assumptions as that will be a rounding figure in the final pull. However, using a cable feeder to push the cable in access points can help.

What does help:

Advance Planning & Field Communication – Can the field handle the reel you are specifying? Can it be placed where your pull calculation starts? Is there room to lay down cable for hand pulls or refeeds?

Straighten Out the Run – The fewer bends, the better. After two 90ᵒ bends, SWBP rises quickly.

Reduce run lengths – This reduces pulling tensions.

Bigger Conduit Sweeps and Sheaves – This makes a big difference to the SWBP. You should ensure that the cable minimum bend radius limitations are respected. That big 24” OD sheave is probably too small!

Tighter Coefficient of Friction (COF) Assumption – This parameter makes a huge difference in the final numbers. 0.35 is a common COF number for most common PVC jacketed industrial cables or regular building wire pulled through existing conduits. For a new installation with a good lubrication plan and experienced installation crew, 0.25 could be a more aggressive number. Southwire uses 0.15 for their no lube building wire products in PVC conduit.

Pull Boxes / Assist Tuggers – Add pull boxes to break the pull up into sections (pull out through the manhole and refeed back in). If the cables can be accessed in the middle of the run somewhere, properly set-up assist tuggers can also break up the run.

Reverse the Pulling Direction – Pull calculations are directional.

Use Equipment or Cable Products that Reduce COF – No lube cable, hydrophobic pulling ropes, Southwire SIM reels, cable tray rollers, etc., …

The final few bends might be hand pulled, reducing the need to include those sections in the cable pulling calculation. Be careful not to overbend the cable during these manual pulling steps.

Cable pull calculations can save a lot of field issues and help ensure a long, trouble-free service life of your big cable runs. A little extra effort upfront can save a lot of trouble down the road.

THORNE & DERRICK

THORNE & DERRICK

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.

December 22nd, 2020

Reposition or support connected cable with lace up cable socks

Lace Up Cable socks

How do you pull cable or pipe when the exposed end is not available? How can you add support to a wire or conductor that is already connected? How do you take slack out of cable without disconnecting it?

A great way is to use a Slingco lace-up or rod-closing sock.

You can pull or support cable, wire or pipe at any point quickly and easily with a lace-up or rod-closing cable sock from Slingco.

Lace-up cable socks are an excellent support and pulling solution when the end of the cable or wire is not available, or for when a connection is already made but added support is needed. A lace-up cable sock can add support or pull conductor anywhere along the wire.

If you need to remove some slack from a LV MV HV cable that is in place, just use a lace-up sock to grab the cable and provide pulling leverage.

Lacing up a sock is safe, easy and quick. Slingco offers open weave cable socks in lace-up or rod-closing styles for a wide variety of cable ranges and strengths.

➡ Thorne & Derrick distribute the complete range of Cable Pulling Products to support safe installation of LV, MV & HV cables into underground ducts, conduits and trenches by cable pulling, laying and jointing contractors.

Simple instructions for installing a lace-up Cable sock

| STEP 1

Start the lacing from the ‘eye’ end or anchoring end of the cable sock. |

|

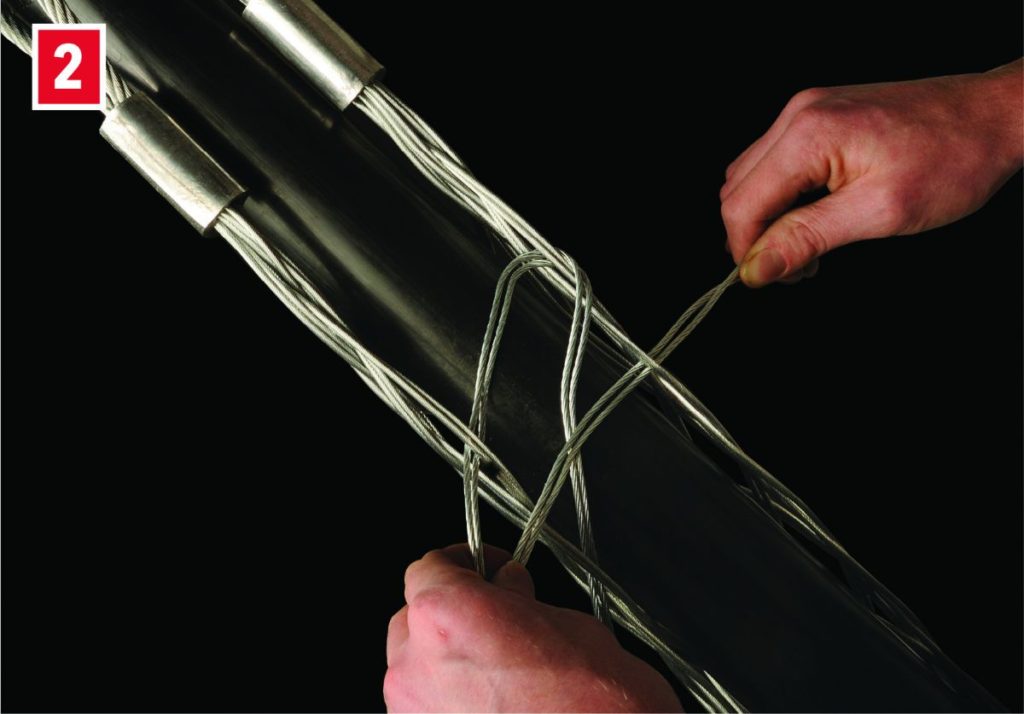

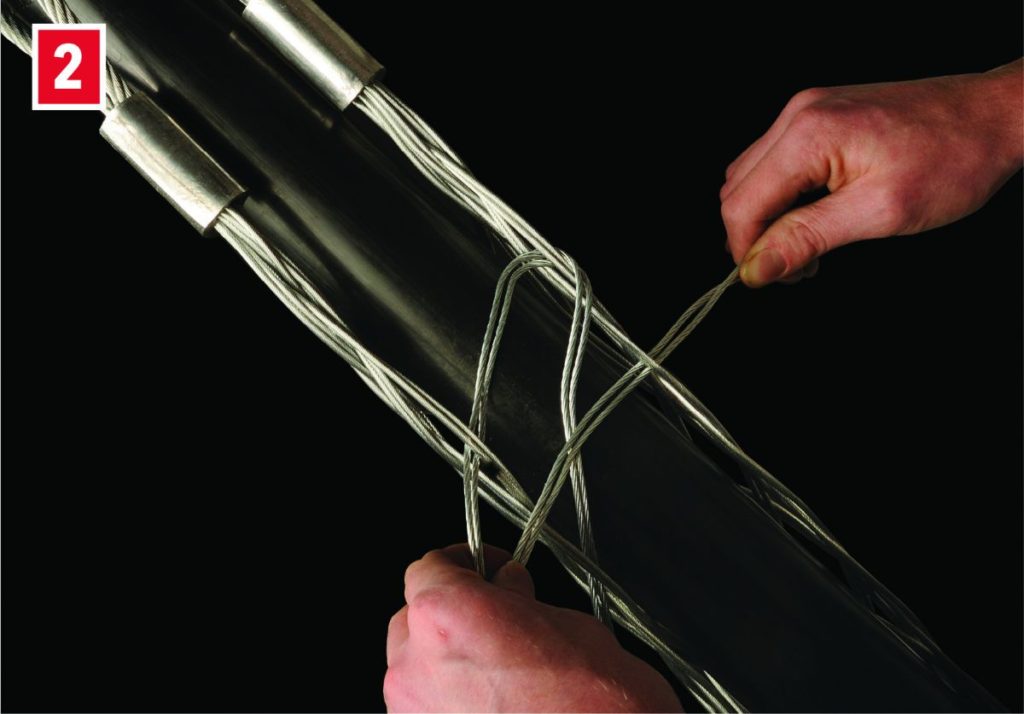

| STEP 2

Thread the lace through the first two loops of the split and pull through until the laces are centred at this point. |

|

| STEP 3

Don’t pull the lace too tight at this stage. Leave a space between adjoining loops roughly equal to the width of one diamond of the mesh. |

|

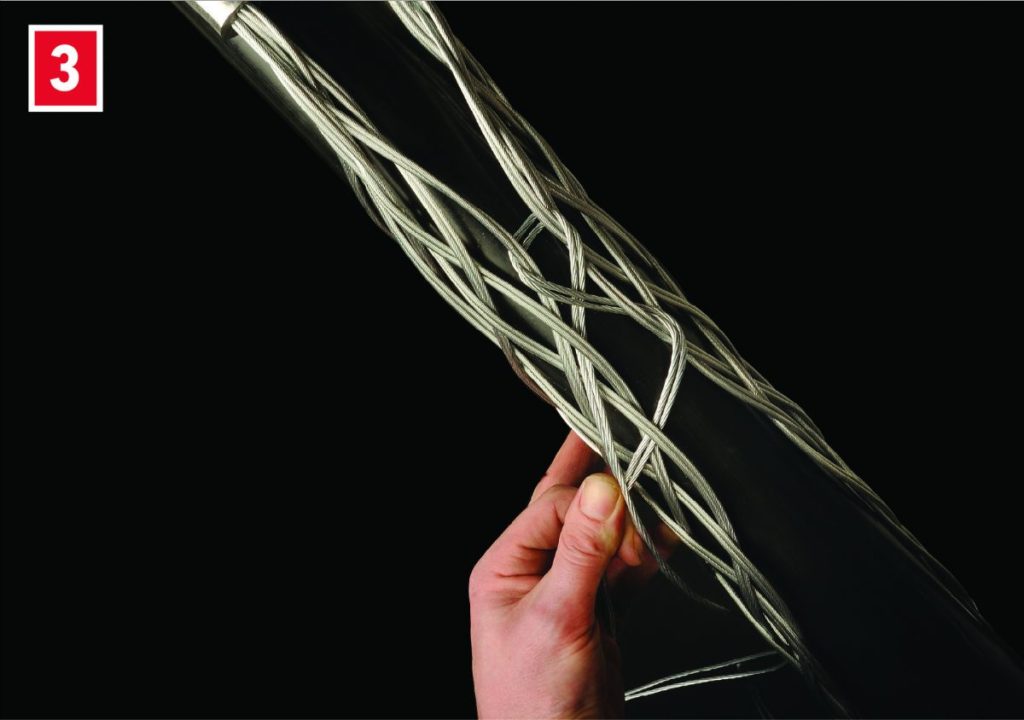

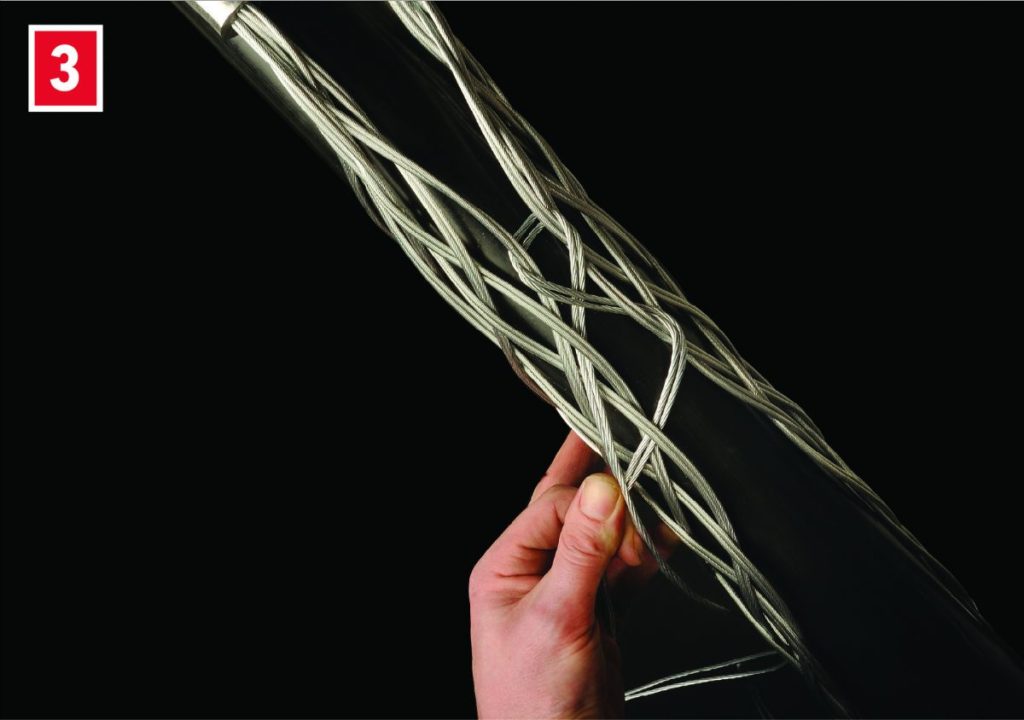

| STEP 4

Continue down the length of the cable sock. Try to maintain equal tension and equal spacing throughout as this leads to a more stable and equal sock. |

|

| STEP 5

As you continue down the length, pull the open sides of the cable sock as wide apart as required. |

|

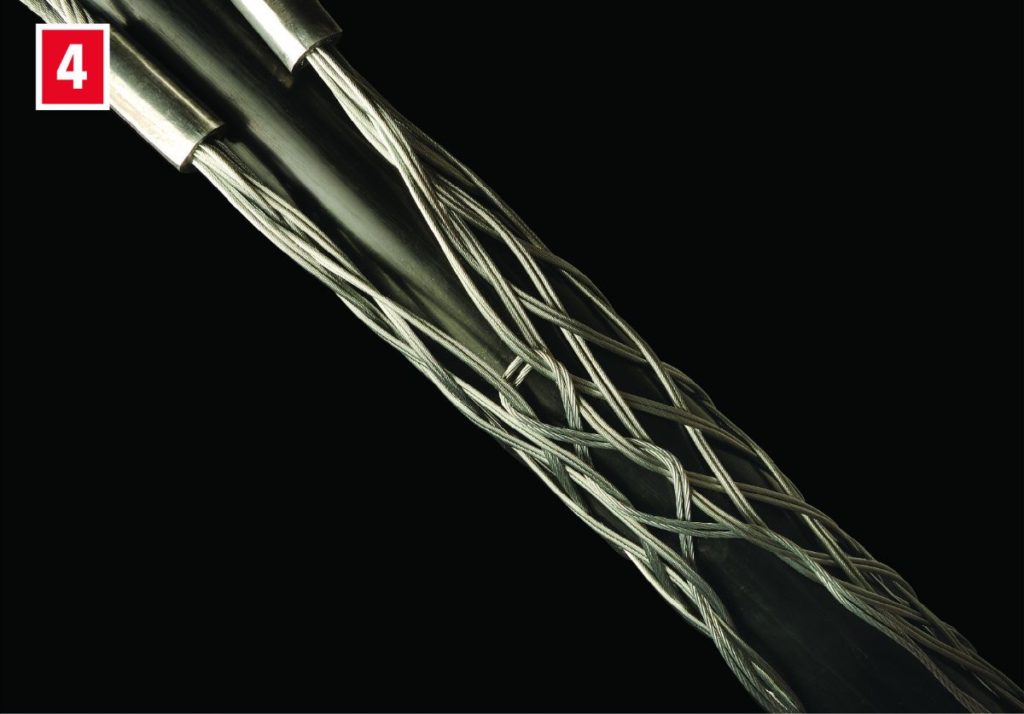

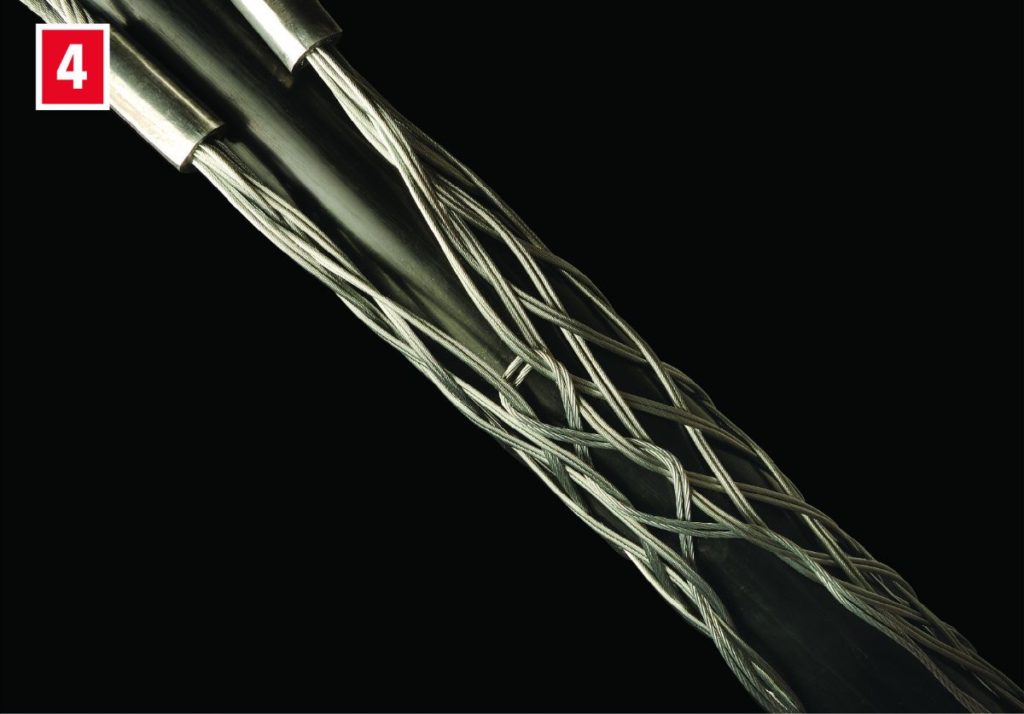

| STEP 6

Try to achieve an even and neat lace-up as this assists with the strength of the sock when pulling. |

|

| STEP 7

Finally, tie the ends of the lace once or twice round the end of the cable sock twisting the ends together securely. Excess lace can be cut off. |

|

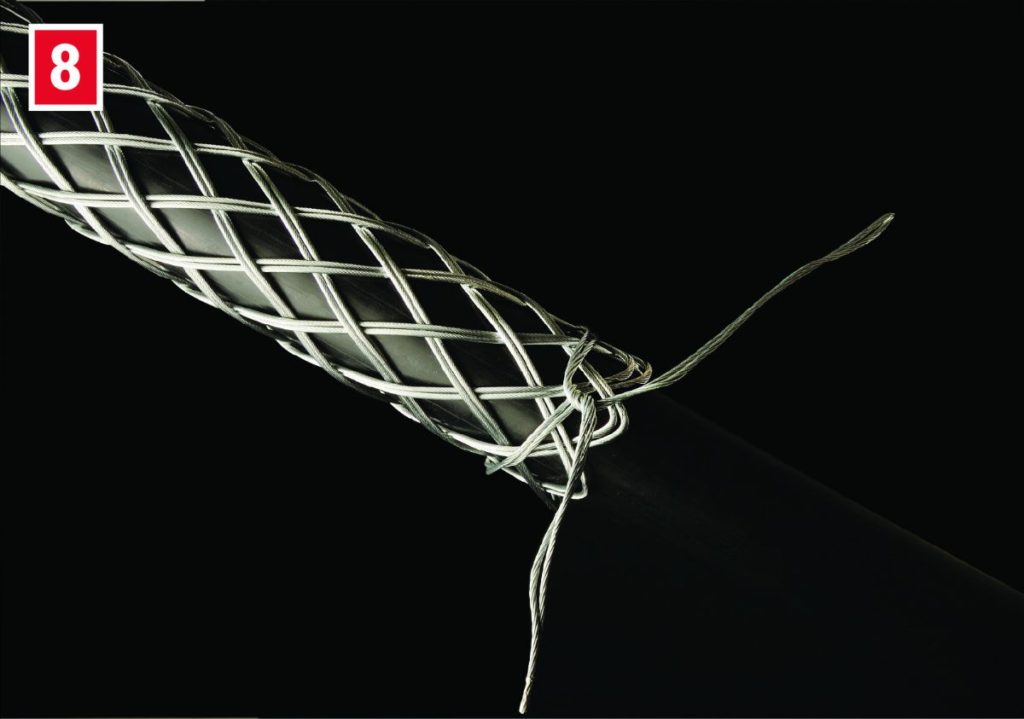

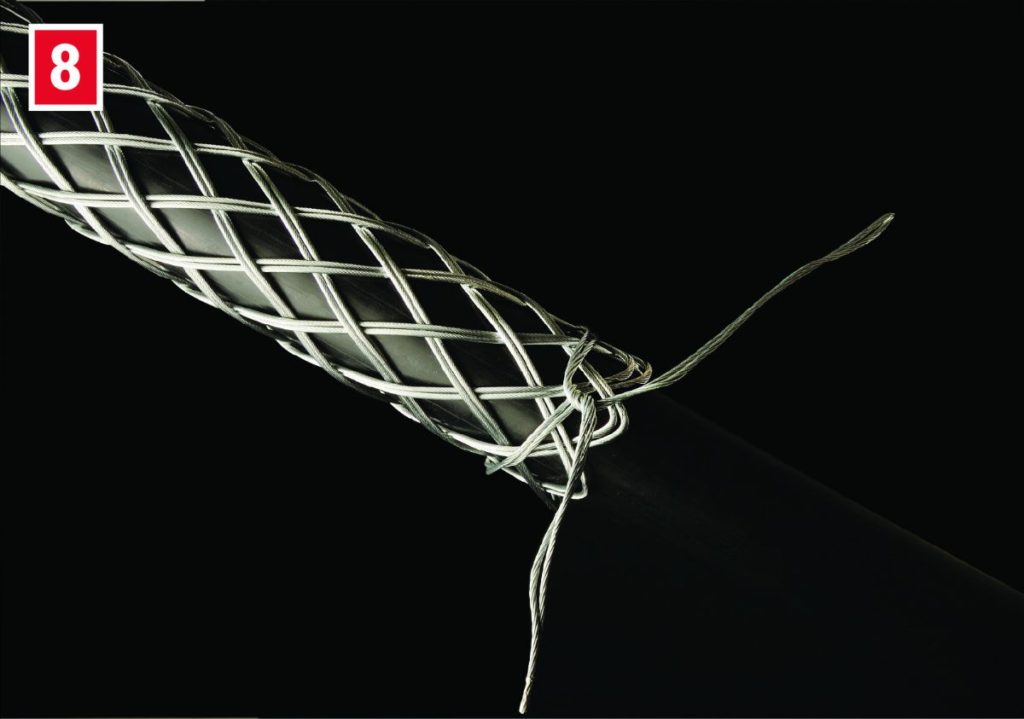

| STEP 8

Add any additional support as required – banding is recommended. The Slingco cable sock is now ready to use. |

|

PLEASE NOTE: The images shown here use double weave cable socks. When lacing single weave cable socks please use single wire lace; use double-laced for double weave cable socks; and use triple-laced for triple weave cable socks.

Cable Socks | Pulling Underground Cables & Stringing Overhead Conductors LV MV HV

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

➡ See Also Cable Laying, Installation & Support Products | MV HV Windfarm

December 22nd, 2020

Hellenic Cables

HV Land Cables

Hellenic Cables solidifies its position in the UK market with new turnkey contract for High Voltage (HV) Land Cables.

Hellenic Cables has been awarded a contract by SP Transmission PLC (“SPT”), one of UK’s largest grid operators, for the supply and installation of 132kV land cables required for the connection of Douglas West Windfarm to the new SPT 132kV Douglas North collector substation and Kennoxhead Extension Windfarm to Middlemuir Windfarm substation, via a modification of the existing Coalburn – Middlemuir 132kV underground circuit.

The existing Coalburn to Middlemuir 132kV underground cable circuit is required to be modified in order to facilitate the connection of two new wind farms: Douglas West (51 MW) and Kennoxhead Extension (60 MW).

The works include modifications of the existing circuit as well as uprating of the existing cables and redesigning of the earthing system of both the new Coalburn to Douglas North and Douglas North to Middlemuir circuits to ensure that the bonding is balanced following the diversion required to connect Douglas North 132/33kV substation.

Under the contract, Hellenic Cables will supply approx. 10 km of 132kV XLPE-insulated cables and associated accessories, including installation and final testing services through selected partners in the UK.

This contract testifies to Hellenic Cables’ continuous presence and investment in the UK market, where it already operates three stock locations.

The cables will be manufactured at Hellenic Cables’ plant in Thiva, Greece, in the fourth quarter of 2020. With its highly skilled and experienced personnel, state-of-the-art facilities and adherence to best working practices, the plant can produce and deliver high quality power cables serving the biggest utilities in Europe and beyond.

About Hellenic Cables

Hellenic Cables is one of the largest cable producers in Europe, manufacturing power and telecom cables as well as submarine cables for various industries, including offshore wind and utilities, as well as undertaking turnkey power transmission and distribution projects. Through its fully owned subsidiary Fulgor, Hellenic Cables operates its submarine cables plant in Corinth, Greece, where the production and testing of some of the longest submarine cable lengths without factory joints on a worldwide basis is empowered by the Company’s state-of-the-art facilities and equipment. Hellenic Cables recently implemented a EUR 200 million-investment plan for the production of high and extra high-voltage submarine cables at Corinth plant. Looking ahead, additional investments in technology and innovative cable solutions are decided, as a way of contributing to the creation of a sustainable future for its stakeholders. Hellenic Cables represents the cable production segment of Cenergy Holdings SA. For further information, please visit Hellenic Cables website at www.hellenic-cables.com.

About Cenergy Holdings

Cenergy Holdings is a Belgian holding company listed on both Euronext Brussels and Athens Stock Exchange, investing in leading industrial companies, focusing on the growing global demand of energy transfer, renewables and data transmission.

The Cenergy Holdings portfolio consists of Corinth Pipeworks and Hellenic Cables, companies positioned at the forefront of their respective high growth sectors.

Corinth Pipeworks is a world leader in steel pipe manufacturing for the oil and gas sector and major producer of steel hollow sections for the construction sector.

Hellenic Cables is one of the largest cable producers in Europe, manufacturing power and telecom cables as well as submarine cables for the aforementioned sectors. For more information about our company, please visit our website at www.cenergyholdings.com.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

December 22nd, 2020

NEWS | 2020 RECORD SALES RESULTS with 3M Electrical

NEWS | 2020 RECORD SALES RESULTS with 3M Electrical

A 42% Year-on-Year Increased Sales By Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment with 3M – so many thank you’s are due to our Microsoft Teams Organiser today Kate Rushbrooke.

Together we have smashed to smithereens all account KPI’s under your responsibility.

This year our Sales Team have achieved emphatic performance results in the rail, renewable and datacenter sectors. We look forward to further growth in 2021.

THORNE & DERRICK | COLDSHRINK | SCOTCHCAST | JOINTS & TERMINATIONS | EX STOCK UP TO 66KV | CONTACT US WITH YOUR ENQUIRY

3M | Record Sales Results 2020

THORNE & DERRICK

THORNE & DERRICK