Blog

EV Insulated Matting | Enhancing Safety in the Workplace | LV MV HV

January 2nd, 2024

Mitigating Risks | High Voltage Systems | CATU

EV Insulated Mats

Protecting against accidents in LV MV HV Systems

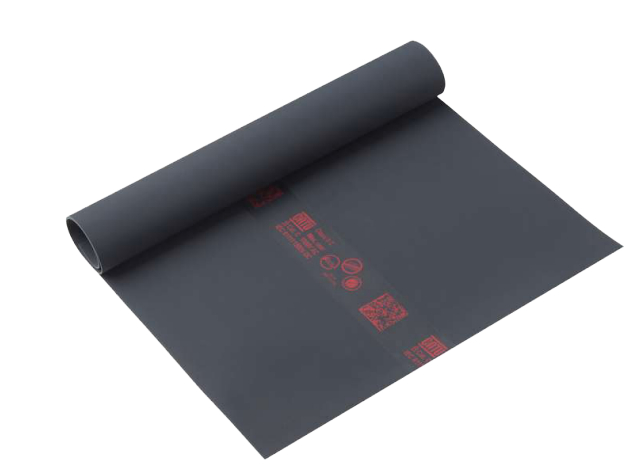

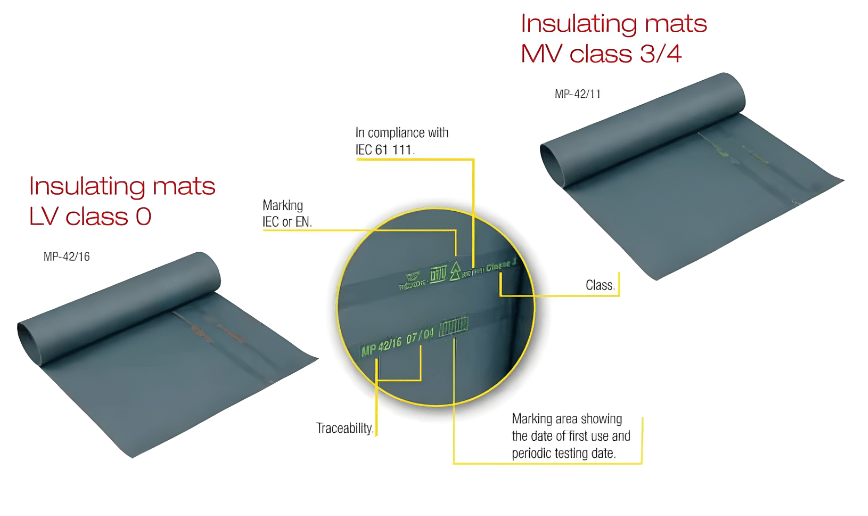

CATU’s electrical insulating matting provide electrical safety protection for individual and collective protection for workers involved on LV MV HV installations for voltages of 3.3kV, 6.6kV, 11kV, 15kV, 20kV and 33kV – generally used in conjunction with additional PPE such as insulating gloves for worker safety.

Insulated Mats, manufactured by CATU Electrical Safety and distributed by Thorne & Derrick, made from elastomer are used to cover ground for electrical protection of operators during work or interventions on electrical installations.

By incorporating insulated matting into safety protocols, the EV sector can enhance workplace safety, comply with industry standards and mitigating any risks associated with high voltage systems in electrical vehicles.

The mats are tested to IEC61111 and certification is provided upon request.

Insulating Matting | Thorne & Derrick hold the largest stocks in the UK of all types and Class of electrical matting for LV MV HV substations and switchgear applications to protect workers from protect people from hazardous electric shocks.

Purposes of using EV Insulated Matting

EV insulated matting is commonly used for a variety of reasons:

- Electrical Safety – Electric Vehicles (EV) operate with high voltage systems, preventing a risk of electrical shock during maintenance or repair.

- Preventing Grounding

- Compliance with Safety Standards

- Workplace Safety Practices

- Protecting against accidents

Meeting these specific standards is essential for creating a safe working environment and ensuring the well-being of technicians.

EV Insulated Mats | Compliance with IEC Standards

IEC61111 Standards

Insulated Mats, manufactured by CATU Electrical Safety and distributed by Thorne & Derrick from elastomer is used to cover ground for electrical protection of operators during work or interventions on electrical installations. By incorporating insulated matting into safety protocols, the EV sector can enhance workplace safety, comply with industry standards and mitigating any risks associated with high voltage systems in electrical vehicles.

The withstand test of insulating matting for electrical insulation is applied to each manufacturing batch of switchboard matting to ensure it does not have an electrical breakdown if exposed to high voltages – the working and withstand voltages must not be confused.

The proof test of insulating matting are dielectrical resistance tests provided by the mat manufacturer on the total running metre of the product and are used to safeguard a standard conformity of resistance throughout the entire section, roll or surface area of the electrical mat – the proof test must be applied to the insulating mats for a set time at a specified voltage level.

The information table below highlights and explains the IEC standard classification according to the maximum working voltages for rubber insulating matting.

| Class Of Insulating Matting According To IEC61111 | Proof Test | AC Maximum Working Voltage | Withstand Test Of Insulating Matting |

| Class 0 Matting | 5kV | 1000V – LV Low Voltage | 10kV |

| Class 1 Matting | 10kV | 7500V – MV Medium Voltage | 20kV |

| Class 2 Matting | 20kV | 17000V – MV Medium Voltage | 30kV |

| Class 3 Matting | 30kV | 26500V – MV Medium Voltage | 40kV |

| Class 4 Matting | 40kV | 36000V – HV High Voltage | 50kV |

High Voltage Electrical Safety

Further Reading

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

- IEC 61482-2:2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash PPE | 7 Top Considerations

- Arc Flash The Basics

Insulating Matting | Voltage Detectors | Substation Kits | Phase Comparators

Arc Flash Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts | Helmets

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Thorne & Derrick stock and distribute a complete range of IEC61111 insulating matting for electrical safety, protection and working on low, medium and high voltage substations and switchgear up to 33kV – the IEC61111 standard provides a selection category for Low Voltage (1000V) to High Voltage (36kV).

Medium Voltage Jointing & Termination Programme | 3M Cold Shrink

December 13th, 2023

Medium Voltage Jointing

During our monthly Distributor Review Meeting this morning with Kate Palmer-Randle we discussed further developing the Qualified Electrical Construction Contractor Accreditation (QECC) from 3M Electrical in the UK.

The Qualified Electrical Construction Contractor Programme (QECC) has been set up as a partnership designed to provide valuable benefits to appointed 3M Electrical Contractor Partners.

As part of the QECC programme, contractors receive in-depth 3M product and technology training, including theoretical training on 11kV, 22kV, 33kV, 52kV & 66kV Cable Accessories, including Joints & Terminations.

Once Certified the QECC contractor can apply for a 3M 20-year MV Product Warranty) on completed projects which can be passed on to their client to offer them peace of mind on their investments and evidence Competency.

To date four companies have been geographically appointed, with a select number of new members set to qualify over the coming months.

Choosing a 3M QECC certificated company allows you to have peace of mind that the contractors you’re working with are trained to the highest level and backed by an extended 3M 20-year product warranty.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages.

Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.

Marechal – The Decontactor

November 22nd, 2023

Thorne & Derrick UK | Main Stockist & Preferred Distributor

-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick International

Improve Electrical Safety & Power Reliability

Inertia and a resistance to change prevents progress even where the allure or reason for the initial attraction has long since past.

Working with Marechal, a world-leading manufacturer of industrial plug-socket assemblies, Thorne & Derrick can provide increased safety and improved reliability compared to the traditional “hard-wiring” approach to low voltage power distribution using their innovative Decontactor technology.

The decontactor

DECONTACTOR = PLUG + SOCKET + integral switch disconnector

Marechal Decontactors can be disconnected under full electrical load for planned maintenance or rapid change out of equipment during plant shutdowns and turnarounds.

- Load Break Release Button & Safety Shutter

Marechal plugs feature a safety button placed on the upper section of the safety socket enabling the user with a single press of the button to disconnect the equipment up to 250A – no specialist skills or training is required to install the plugs.

Marechal plug-socket assemblies can be removed in complete safety – the power outlet installation is safe and does not represent an electrical hazard guaranteeing operating speed and time savings during installation operations or machine shutdown.

As an additional feature a safety shutter protects the user according to IP4X/IPXXD – the live contacts are inaccessible behind the closed shutter.

Electrical power can be controlled and distributed up to 1100V, 660Amps using the Marechal P66 high voltage connector for industrial applications.

Anatomy Of The Decontactor

The Marechal decontactor is a plug and socket with an integral load-break switch – this unique design offers various benefits :

- contact quality

- safe disconnection

- automatically watertight

- cost reduction due to dual-voltage

- robust and reliable

Marechal | The Decontactor

Make The Switch!

Out With The Old, In With The New. Contact T&D to arrange a UK site demonstration or survey of your power distribution requirement. No obligation. No cost.

Whatever The Weather, Wherever The Zone

We think we can meet any Power Distribution challenge.

Automatic IP66/IP67 dust and liquid tightness – check.

Hazardous area Zone 1 and Zone 2 – yes, compliant with ATEX and IECEx.

Signal and control options – yes, up to 37 contacts.

High current capability – got it covered, connect up to 250amps. Single pole options up to 700amps.

Handle heat – we can cope, withstand 400°C.

Ex Decontactors | Plugs and socket-outlets with integrated switch, designed and certified for hazardous areas (ATEX 2014/34/EU Directive) – this includes Zones 1 & 2 (Flammable Gas) and Zones 21 & 22 (Combustible Dust) potentially explosive atmospheres.

Datacentre | BESS | Windfarm | Construction | Solar | Process Industries

Avoiding Hand & Finger Injuries in the Wind Energy Industry

November 15th, 2023

Manual Handling

& Hand Safety Improvements

Protecting Workers by Reducing Pinch & Crush Injury

uploaded by Chris Dodds | Sales Marketing Manager at Thorne & Derrick

Thorne & Derrick are Specialist Suppliers to the UK and international Renewable Energy Industry of products and equipment to provide safe and reliable LV HV Electrical Cable Termination, Jointing, Tooling & Installation of Power Systems up to 66kV.

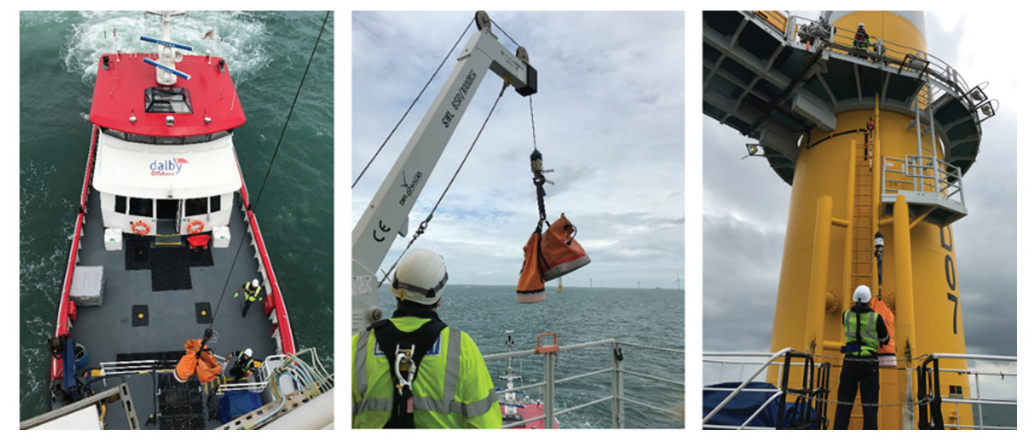

This article covers the introduction of a Hand Safety Measure to reduce risk and improve safety for workers in the offshore wind industry involved in both construction, operations and maintenance (O&M).

Thorne & Derrick working closely alongside a multinational power company leading the energy transition from fossil-based to renewable generation of electric power have introduced a significant improvement to industry Health & Safety.

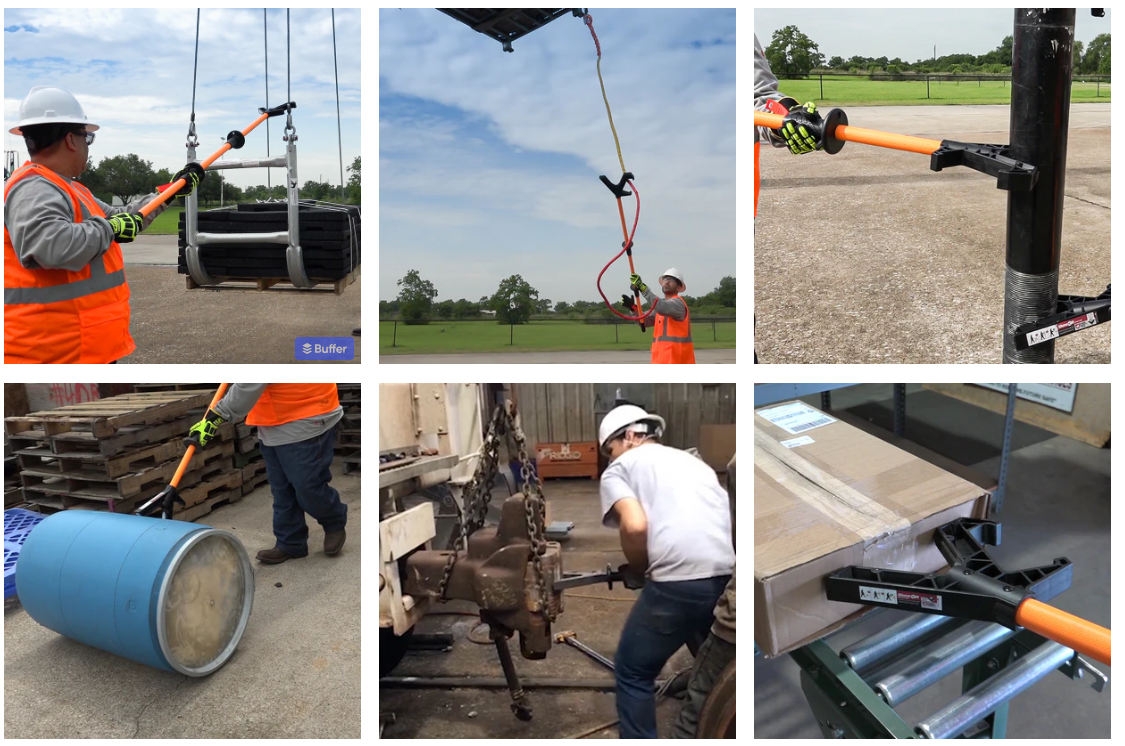

The adoption of the innovative ShoveIt product from Hand Safety Tools will reduce hand injuries while working with suspended loads or manoeuvring objects in offshore wind turbine nacelles. This could include manual handling activities, such as moving suspended heavy items including tooling, equipment, kit personnel bags to the work area.

Thorne & Derrick, a leading Distributor of Personal Protection & Site Safety Products, were invited to propose product recommendations to ensure a “hands-free” working procedure for turbine technicians and workers guiding suspended or hoisted loads into and out of nacelle loading hatches.

A Risk Assessment identified potential hand injury hazards relating to Pinch-Points when manoeuvring, grabbing, guiding and positioning suspended loads – the mitigation measure required adequate working length (up to 1.75m), lightweight for ease of use and allowance for a tool lanyard attachment.

Following risk review, Thorne & Derrick submitted the ShoveIt product for field trail and evaluation over a 2 week rotation period to gather collective performance feedback from the clients team – the 72” Length Rubber Insert Shove-It Hand Safety Tool was concluded to be optimal for the safe movement of the loads.

During the product trial the No Touch Hands Free safety tool was field tested during all weather conditions to ensure its suitability, particularly in high wind and low temperature periods (affecting grip ability) when conditions for manoeuvring loads into and out of the hatch can be most difficult and dangerous.

This Hand Safety Tool is made from non-conductive materials and features a rubber insert that provides a secure grip on the load without damaging it – the lightweight design makes it easy to handle, even in windy conditions. The tool lanyard attachment allows the operator to secure the tool to their wrist or harness, reducing the risk of dropping the tool and causing an accident.

The ShoveIt tool was found to be very effective in guiding loads in and out of the Nacelle loading hatch and the client was delighted with the results – ShoveIt has now been introduced by the H&S Team into their working Method Statement to reduce hand and finger injuries to the turbine and deck crew working across Irish & North Sea assets.

The ShoveIt Hand Safety Tool pictured in field use within a wind turbine tower to safely guide hoisted loads into and out of the nacelle loading hatch avoiding manual dragging and associated injury.

The load movement, handling and transfer of items from the Crew Transfer Vessel (CTV) to an asset via a crane mounted on the TP external platform can involve risk and exposure to potential hand injury accidents and incidents during the physical handling of loads.

ShoveIt | The No Touch Hands Free Safety Tool

The ShoveIt No Touch Push / Pull Pole Hand Safety Tool helps avoid hand injuries while working with suspended loads or manoeuvring objects across all industries. Users maintain proper ergonomic body positioning for safe handling out of the line of fire – this enables users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

Stocked by Thorne & Derrick | Specialist Distributors of Industrial Safety Products, Tools, Equipment & PPE

Push Pull Tool Design

SHOVEIT Head Design

- Lightweight yet extremely durable head

- Versatile V-shape and opposing grab hooks allow workers to safely push and pull a multitude of objects

- Three insert options for various applications:

- Nitrile rubber insert for grip

- UHMW-PE plastic insert for glide

- Aluminium insert for high heat

SHOVEIT Shaft Material

- Lightweight and durable plastic coated FRP material

- Hi-Viz safety orange tools

- Textured shaft for slip-resistant handling

Hand Guard With Tethering, Point D-Handle, Rubber End Grip

Further Reading

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Ellis Emperor Cable Cleats | Sunrise Wind Offshore Wind Farm Case Study

November 9th, 2023

Cable Cleats Offshore Windfarm

Windfarm cable cleats

Ellis Patents, a global leader in the manufacture and innovation of cable cleats, including the Emperor and Flexi Straps range are being installed in the first offshore windfarm in the USA to use a high voltage direct current system (HVDC) to deliver power onshore; the advantages of HVDC are as follows:

- the ability to interconnect networks that are asynchronous

- the ability to transmit power over long distances without technical limitations

- the ability to control power flows on the HVDC connection for all system backgrounds

- the ability to transmit power in either direction as desired by the network operator

- in certain cases the ability to improve AC system stability

The Sunrise Wind Offshore Wind Farm is a significant step towards New York’s clean energy goals. When it is completed the 800MW windfarm will power nearly 600,000 households with renewable electricity by 2025 and help New York accomplish a carbon-free energy grid by 2040.

Sunrise Wind Offshore Wind Farm

Ellis Patents Offshore Wind Project

Experts at Ellis Patents worked closely with the UK Design Team on this. This ensured the highest safety standards and optimal cable management on the offshore platform.

Furthermore, the platform is characterised by a steel jacket substructure and a topside deck housing essential electrical equipment and is the heart of the windfarms operations.

Kelly Brown Ellis Patent’s Sales Director made a statement on this. She said: “Sunrise Wind is a major project for the advancement of the wind sector in the US and having Ellis Cable Cleats installed gives us a huge feeling of pride to be involved in something on such a global scale. This clearly demonstrates the trust in Ellis’ expertise in cable management to enhance safety and efficiency in the offshore platform”.

The Offshore Converter Station is designed to collect the 66kV alternating current (AC) power generated by the wind turbines, relies on a robust subsea export cable that spans an impressive 100 miles to connect to the onshore converter station located at Holbrook on Long Island. The onshore converter station plays a vital role in converting the power back to AC before feeding it into the distribution grid, ensuring clean energy reaches homes, industries, and other end-users across New York.

Cable Management Solution for Sunrise Offshore Windfarm

Ellis provided a cable cleat and management solution tailored to the unique performance requirements of the Sunrise Wind Project.

The Ellis Patents Cable Cleats and Flexi-Straps were installed in the first offshore wind farm. This also played a pivotal role in securing and supporting the cables in the challenging offshore environment.

Emperor Cable Cleats

Ellis Patents Flexi Straps

Emperor Cleats

Manufactured by Ellis Patents, the Emperor Cable Cleats are designed for use where the highest levels of short circuit withstand are required, Ellis’ Emperor cable cleats are available for both trefoil and single cable applications. All products in the range are manufactured in type 316L stainless steel. This helps them provide ultimate corrosion protection, even in the harshest of environments.

Key Benefits of using Cable Cleats

- Low Smoke Zero Halogen Material & Grade 316 Stainless Steel – Corrosion Resistant

- Soft LSF Cable Liner – Cable Sheath Protection

- Captive Closure Fixings – Fast Installation

Thorne & Derrick | Cable Cleats | Ellis Patents UK Distributors

Specialist Distributors of High Voltage Jointing & Electrical Safety Equipment

Further Reading

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Emperor Cable Cleats | Golden Eagle Offshore Platform

- Emperor Cable Cleats | Gwynt y Mor Offshore Wind Farm

Thorne & Derrick International are Specialist Suppliers of products to provide safe and reliable LV HV Cable Termination, Jointing, Installation & Power Systems up to 66kV.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.