Blog

Calculating Oglaend Smart Cable Cleat Spacings On Cable Ladder Installations

April 2nd, 2019

Cleats & Clamps | LV MV HV Cables

-

uploaded by - Chris Dodds Thorne & Derrick Sales & Marketing Manager

Oglaend

Cable Cleats & Clamps

Theoretical Background

Source: EFI report TR A3901 Jan 1993

The following article and formula enables the calculation of cable cleat/clamp spacings to enable adequate short-circuit restraint of LV MV HV cables onto cable containment in onshore or offshore medium/high voltage substations.

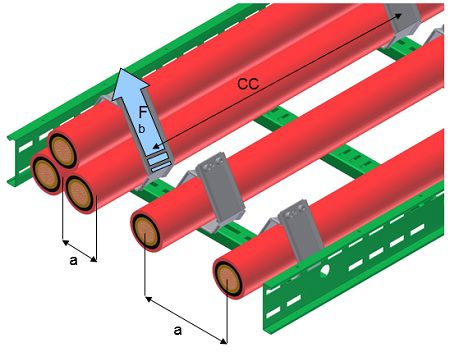

Fb=(0.5 x 0.2 x kApeak2)/a where:

- Fb: Force (N/m)

- kA.peak: Short circuit current peak value (kA)

- a: Distance between the centre points of the cables/cable diameter

- Cable run. Length of cable run

Recommended distance between Oglaend Smart Cleat clamps mounted on cable ladders is shown in the image below:

The calculated number of Oglaend cable clamps is included using Smart Securing Plate in both ends of the cable run.

The distance between the cable clamps should be reduced in vertical and horizontal bends.

The recommended maximum distance between Smart Cleats is 0.9m.

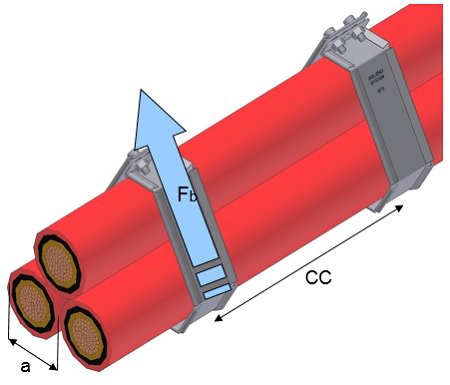

Recommended distance between Oglaend Smart Cleat clamps when not installed on cable ladder is shown in the image below:

At the start and at the end of the cable run it is recommended to install 3 cable cleats with 150mm distance between them. The calculation above is including these cable cleats.

The distance between the cleats must be reduced during vertical and horizontal bends. The maximum recommended distance between Smart Cleats is 0.9m.

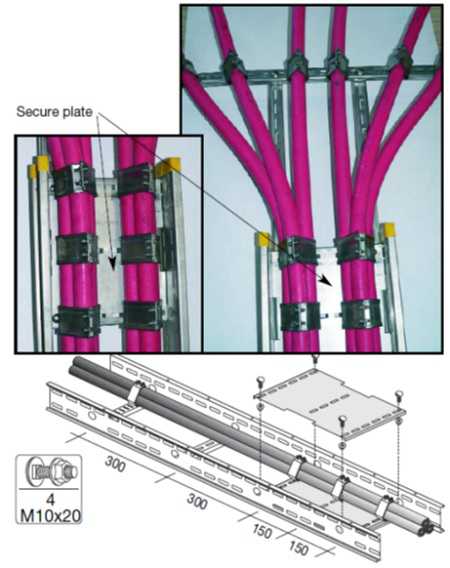

Smart Securing Plates

Secure plates are strongly recommended to be used at both ends of a trefoil cable run. Realistic tests done on several cable lengths and clamp distances confirms the theory that the cable must be additionally secured at both ends to reduce arching and eliminate deformation and stretch marks on the cable.

Smart Securing Plates Part References

| Type (State Ladder Width) | Art. No. SS |

| Oglaend A-OE EX-Smarcl-150 | 87544 |

| Oglaend A-OE EX-Smarcl-300 | 87545 |

| Oglaend A-OE EX-Smarcl-450 | 87546 |

| Oglaend A-OE EX-Smarcl-600 | 87547 |

| Oglaend A-OE EX-Smarcl-750 | 87548 |

| Oglaend A-OE EX-Smarcl-900 | 87549 |

| The Smart Securing Plate is designed to fit all standard ladder types with 300 cc rungs. Includes our RZE and FRP systems. | |

Distance between Smart Cleats manufactured by Oglaend given that the distance between the centre points of the cables or the cable diameter is 42mm

Smart Cleat

- Smart Cleat saves space – both in cable clamp height and width

- Plastic liners are not required for trefoil installations due to the design of the cable clamp providing a smooth surface

- Manufactured by Oglaend the Smart Cleat is suitable for fixing to preslotted rung design

- Fixing bolts are easily accessible from underneath the rung

- Low weight – compact and light design cable clamps

- The design fixes the cables so close to the rungs, that the rungs in between cleats give full support for distribution of load

- Low product price and low installation cost

- Smart Cleat trefoil cover cables from Ø 25 mm – Ø 99 mm and Smart Cleat single cables from Ø 39 mm – Ø 99 mm

- Smart Cleat is tested up to 160 kA-Peak

- Smart Cleat single and trefoil are certified by DNV according to IEC 61914

Further Reading

- Cable Clamps: The BAND-IT BAND-FAST Range – IEC61914 Tested

- Stainless Steel Cable Cable Cleats v Cable Ties – By Ellis Patents

- Understanding the Importance of Cable Cleats in Offshore Industries

- Stainless Steel Cable Cleats

- A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

Cable Cleat Distributors | Ellis Patents | Torgy | id-Technik

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Sealing Cables In Offshore Substations – A Roxtec CPD

April 2nd, 2019

Sealing Cables In Offshore Substations – A Roxtec CPD

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick International

The Importance of Cable Sealing in Substations

An overview of sealing cables in LV MV HV offshore substations based upon industry standards and practical experience – understand and learn about the importance of sealing cable entry points and cable ducts.

The focus of the CPD relates to the causal of Partial Discharge in substation switchroom environments and looks at the primary mitigation measure of deploying proper cable sealing solutions in order to achieve optimum switchroom conditions for electrical switchgear and assets to operate in.

The CPD seminar lasts approximately 1¼ hr and is aimed at Engineers involved in the design, build and installation of electrical substations, in addition to Managers responsible for Asset Management and Maintenance, Quality, Safety and Environment.

By attending this seminar you will gain a greater understanding of:

- The impact of insufficient substation cable sealing

- The benefits of adequate sealing, including cables passing through bulkheads and decks

- The impact of main risks / hazards relating to fire – A and H class

- Ensuring the design and installation of substation seals meet the requirement of the client through clear design and specification

- Different LV and HV cables and how they are best sealed

- How to seal transformer, GIS and busduct cables

- The importance of civil structural considerations when designing and building a substation

- The design requirements for switchgear operation, manufacturers’ recommendations and control measures

Who should attend?

- Engineers involved in the design, build or installation of substations

- Managers responsible for Asset Management and Maintenance, Quality, Safety and Environmental

- Electrical, control, instrument, mechanical and civil engineers and designers

- Owners, operators, design engineering companies and site contractors

Additional Course Information

CPD Points: 1

Location: This seminar can take place at your office or Roxtec’s office in Bury, Greater Manchester.

How to book:

To arrange this free seminar contact us:

Email: [email protected]

Office tel: 0191 410 4292

➡ Also: Sealing Cables In Onshore Substations – A Roxtec CPD

ROxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects water, gas and fire.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Sealing Cables In Onshore Substations – A Roxtec CPD

April 2nd, 2019

Sealing Cables In Onshore Substations – A Roxtec CPD

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick International

The Importance of Cable Sealing in Substations

An overview of sealing cable entry points and cable ducts in substations, looking at the impact of water ingress and continuous water pressure on LV MV HV substation performance and the implications of failure and costs.

The focus of the CPD relates to the causal of Partial Discharge in substation switchroom environments and looks at the primary mitigation measure of deploying proper cable sealing solutions in order to achieve optimum switchroom conditions for electrical switchgear and assets to operate in.

The CPD seminar lasts approximately 1¼ hr and is aimed at Engineers involved in the design, build and installation of electrical substations, in addition to Managers responsible for Asset Management and Maintenance, Quality, Safety and Environment.

By attending this seminar you will gain a greater understanding of:

- The benefits of adequate sealing in cable trenches

- The design requirements for switchgear operation, manufacturers’ recommendations and control measures

- The importance of civil structural considerations when designing and building a substation

- Ensuring the design and installation of substation seals meet the requirement of the client through clear design and specification

- Sealing earth tapes and trefoil single core cables

Who should attend?

- Engineers involved in the design, build or installation of substations

- Managers responsible for Asset Management and Maintenance, Quality, Safety and Environmental

- Electrical, control, instrument, mechanical and civil engineers and designers

- Owners, operators, design engineering companies and site contractors

Additional Course Information

CPD Points 1

Location: This seminar can take place at your office or Roxtec’s office in Bury, Greater Manchester.

How to book:

To arrange this free seminar contact us:

Email: [email protected]

Office tel: 0191 410 4292

➡ Also: Sealing Cables In Offshore Substations – A Roxtec CPD

Roxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects of water, gas and fire.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

33kV v 66kV | A Wind Farm Collection Grid Technical Comparison

March 29th, 2019

With Kind Permission of: Edvard Csanyi (Editor-In-Chief & Electrical Engineer at EEP)

Author: Anne Thyssen (DTU Electrical Engineering, Center for Electric Power and Energy (CEE), Technical University of Denmark)

33kV & 66kV Models

A generic wind farm with a 33kV collection grid is compared to a wind farm with a 66kV collection grid in Powerfactory. As the collection grid voltage is different in the 33kV and the 66kV wind farm the same wind turbine transformer cannot be used as the high voltage level of the transformer will be different.

To be able to make a good comparison between the two wind farms, it has been decided to use the 33kV wind farm’s wind turbine transformer as base component and only change the high voltage level of the transformer in the 66kV wind farm.

Model design

The 33kV wind farm is built in Powerfactory using standardised components based on an existing project library provided by Siemens Wind Power.

The 66kV wind farm is a modified version of the 33kV wind farm where the size of high voltage cables, the wind turbine transformers and substation transformers are changed to fit the 66kV level in the collection grid.

Hence, both wind farms have the same layout which is shown in Figure 1.

Figure 1 – Layout of wind farm as designed in Powerfactory

All the wind turbines consist of a generator, filters and a transformer. An example of a wind turbine is shown in Figure 2 representing wind turbine AA01.

The layout of the wind farms, in terms of number of wind turbines in an array, number of turbines connected to each substation and the length of the cables, has been predetermined using a standardised model provided by Siemens Wind Power.

It is assumed that this layout is a well representative model of a real offshore wind farm.

Figure 2 – Layout of wind turbine AA01 in Powerfactory. All wind turbines in the model are designed in a similar way.

The point of common coupling (PCC), the location where the public network is entered, is chosen to be after the sea cable and land cable at the PCC busbar.

At PCC the results of all load flow simulations carried out are recorded as generally up until PCC the wind farm operators are accountable for the losses and only the power delivered after PCC is paid for.

The overall specifications of the two wind farms are summaries in Table 1.

Table 1 – General Information About 33kV & 66kV Wind Farm

| Total wind power plant capacity | 183.6 MW |

| Total number of wind turbines | 51 |

| Size of wind turbines | 3.6 MW |

| Number of substation transformers | 2 |

| Size of substation transformers | 180 MVA |

| Size of wind turbine transformers | 4 MVA |

| Length of cables between wind turbines in the internal grid | 0.562km – 2.321km (majority are 0.858km) |

| Distance from offshore substations PCC | 47.8km |

| Voltage level at PCC | 132kV |

| Nominal operating frequency | 50 Hz |

Follow EEP – Electrical Engineering Portal

Powerfactory Model of the 33kV & 66kV Wind Farm

The wind turbines modelled in Powerfactory consist of a static generator connected to a turbine transformer and a harmonic filter.

The wind turbines modelled are the Siemens 3.6 MW.

It is equipped with a full-size converter, which control the behaviour of the wind turbine as seen from the grid side, and can therefore be modelled as a static generator in Powerfactory.

The wind turbine has an apparent power of 4 MVA with a power factor of 0.9.

The turbines are modelled with PV control and the capability curve of the Siemens 3.6 MW turbine have been specified in the Powerfactory model.

➡ Please Note: For the simulations conducted in Powerfactory, the harmonic filters are only of interest in term of their active and reactive power consumption.

When running a load flow, the turbine filters produce 0.08 MVAr reactive power, hence, affecting the reactive power capability of the high voltage wind farm and consume 0.4 kW of active power.

A harmonic filter is also connected at the point of common coupling. This harmonic filter consumes 1.4 MW, hence, increasing the active power loss while it produce 27 MVAr reactive power also affecting the reactive power capability of the wind farm.

As the harmonic filters will affect the results of the simulations, they are kept as components in the wind farm and the exact same harmonic filters used in the 33kV wind farm are duplicated into the 66kV wind farm.

➡ To read the full article please click here 33kV v 66kV | A Wind Farm Collection Grid Technical Comparison

➡ Further Reading

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

- PFISTERER CONNEX Size 4 | HV High Voltage Cable Jointer Training

- 66kV Connectors, Cables & Junctions Boxes – An Interview With Nexans

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Stockists of MV Cable Accessories up to 66kV for Power & Inter-Array Cables (IAC)

Slips, Trips & Falls | Cable Hooks For Reduced Accidents & Improved Safety During Shutdowns

March 25th, 2019

Reducing Slips, Trips & Falls With Tidi-Cable Steel Cable Hooks

Accidents are expensive: but is it safety, or housekeeping that will make the change?

Slips, trips and falls on the same level (excluding falls from height) accounted for 31% of all UK workplace accidents in 2018 according to RIDDOR 2017/2018 (Reporting of Incidents, Diseases and Dangerous Occurrences Regulations).

These accidents are extremely expensive to both companies and the individuals who get injured, causing days off work and expensive insurance claims. A list of all UK workplace accidents can be found here.

Using the 80/20 rule, the main focus should be to reduce these common accidents.

Let’s look at common causes of workplace accidents, and find some quick, free or low costly cable hook solutions to prevent this unnecessary evil.

Preventing Slips

Slips often happen due to wet or slippery floors. Wet and slippery floors can sometimes be easily tackled by small adjustments in the work environment. For example, a change in the cleaning regime proved one company to reduce its slips by 80%.

Think small adjustments; choose a convenient time to clean the floors when most employees are behind their desks, workstations or worksites in the field, rather than cleaning floors at 7:45 am, just before all employees arrive to work, or just before the shift change. Have a door mat for all entry points, it’s cheap and effective.

Simple slip prevention includes using the correct type of slip-resistant footwear. Remember, if footwear is supplied as personal protective equipment (PPE), it must be supplied free of charge to employees.

The decision to involve the affected employees in choosing the right shoes, will help the employees understand the issues and will promote positive change.

Also, consider age and construction of buildings, whether there is evidence of leaking roofs, if walkways are exposed to the elements, or whether there is a potential for water, mud, ice or other substance build-up.

The most important factor in slip accident prevention is to have decent grip at all times. In a food industry plant this method reduced slipping accidents up to 60%.

Having arrangements for routine cleaning and dealing with accidental spills is normal practice in every company. Where floors cannot be kept clean and dry, again, slip-resistant footwear can prevent accidents.

How To ‘Tackle’ Trips

Trips are often caused by uneven floor surfaces and obstacles, or trip hazards. These can be prevented by design and good housekeeping regimes.

Keeping the workplace clean and organised is the clear prevention message. Are there any trip hazards in corridors and walkways or in the entire industrial work environment?

Think of tripping hazards such as cables, tools, hoses, boxes, pallets, or other objects that could cause a potential tripping accident.

Removing these hazards can be done by tying them up next to the walkways, or re-routing these items away from the walk spaces.

Quick solutions to remove hazardous obstructions from the work floor vary, from cable tie-wraps, steel wires, welding anodes and ‘S’ shaped cable safety hooks.

Steel S Shaped Hooks

Cable Hooks For Safe Cable Support, Suspension & Management

Tidi-Cable Products are a simple cable support range of products designed to suspend hoses, wires, cables and ropes. Tidi-Cable steel cable hooks are used by most of the major oil and gas and construction companies and enable employees to adhere to their housekeeping and safety policies.

Tidi-Cable Steel Hooks are designed to be fire resistant and help to manage LV-HV power cables, as well as welding cables, extension cords and hoses. The simple Steel S Hooks and Figure of 8 Hooks are simple, effective products that enable the users to fix cables to hand rails, fences and scaffolding.

Tidi-Cable’s Steel S Hooks come in various different sizes including:

- TCS003 – 235mm length, small hook internal diameter 55mm, large hook internal diameter 72mm, max. load 10kg

- TCS004 – 235mm length, small hook internal diameter 55mm, large hook internal diameter 72mm, max. load 20kg

- TCS005 – 310mm length, small hook internal diameter 55mm, large hook internal diameter 90mm, max. load 30kg

- TCS006 – 415mm length, small hook internal diameter 64mm, large hook internal diameter 115mm, max. load 55kg

The cable hooks are made from galvanised steel and coated in a highly visible powder coated orange. For special projects, Tidi-Cable are able to ‘own brand’ and colour any products to the customers specification.

Checking Your Walkways

Check for suitable walkways. Are they in the right place? Are they being used? Are they available for use? What tasks are taking place on the walkway? Are some tasks preventing the employee from seeing where he or she is going?

Lessons: Walkways must be safe to walk over at all times. Confronted with tasks carrying loads of tools or boxes in hand, employees should have the confidence that you and your co-workers have housekeeping elements embedded in their work operation.

This can be done by well described company policies and procedures, which should be implemented through company campaigns and brought into the company culture by training for all employees.

By keeping walkways safe and clean, employees’ experience free walkways with no clutter. Well-marked and obstructed repair sites will have better visibility during construction, maintenance or turnaround activities.

Do you already have enough policies and procedures, but still want to improve the bottom line by safe work attitude adjustment? Try to apply a teach-by-example approach.

For example, a refinery with many contractors, different job requirements and safety policies may pressure the workers to cut corners by not following these company guidelines and procedures.

Tidi-Cable Heavy Duty Cable Management Products

Keeping Walkways Safe & Clean

Slips, trips and falls put pressure on families, cost money, and hurt the bottom line. Could all of this be avoided? Lost time injuries by slips, trips and falls are often simple to prevent and can improve the companies’ incident ratings in the short term.

Housekeeping simply improves the workplace for others, who can in their turn dedicate time to focus on their core jobs and appreciate not having to sort their cables and hoses out in the end. A benefit is that hoses and cables do not wear as fast by-passing traffic, resulting in fewer spills.

Adequate Site Signage

All workplaces have dangers and risks, from taps that run with scolding hot water to big open floor spaces on construction sites. One of the easiest ways to inform stakeholders of the risks is to always put up adequate signage warning of any dangers. More information can be found on the signage requirements Health and Safety (Safety Signs and Signals) Regulations 1996 here.

Improving Essential Housekeeping Elements

It is not just good enough to have a walkway; it must be kept clear, no obstructions and no trailing wires. Employees and cleaners need to have “see it, sort it” attitude to ensure these and other work areas are kept clear. Safety is everyone’s responsibility in any workplace and has been for decades, however there is still much to be done to change the ‘not my responsibility’ culture all over the world.

Is the cleaning regime effective? Are there enough storage bins on the facility? Have you described this standard type of working in your company?

Lessons: Keep it clear, remove cables and hoses and work in a clean environment by suspending obstructions with tie-wraps or hooks from the work floor. This will not only improve the lifecycle of these tools and cables, but it will significantly reduce the number of tripping points.

Applying good housekeeping to keep walkways clean and clear helps employees and contractors understand that your company applies high safety standards by tackling direct causes of the highest incident rate; slips, trips and falls.

Steel Tidi-Cable Hooks

Design & Maintenance Of The Workplace Environment

When assessing the quality of your safety regime, ask the following questions:

- Is the floor suitable and safe for the workers?

- Is it fitted correctly and properly maintained?

- Are walkways wide enough and do they have no unexpected level differences?

- Are stairs suitable?

- Is there adequate signage warning people of hazards?

- Are solid handrails available at every stair case?

- Do environmental factors such as good lighting conditions also fall in the category of good housekeeping? Is there enough light for employees to identify hazards?

Tidi-Cable 8 Hooks

Lessons: Floor openings used for maintenance or repair should be well‐marked. Make sure lighting is sufficient and that slopes, unbalanced variations in floor levels, and steps are clearly visible.

Keep walkways and work areas clear of obstructions. Blunt objects in walkways should be well marked and have soft padding.

Slips and trips are not only unpleasant, but are costly to the bottom line. Use common sense to review risks. Discuss “What if’s…”, and find low cost solutions.

It leaves us with the question; should housekeeping be an essential part of your safety department when it comes to preventing the most likely type of accidents on your work floor?

Shutdowns & Turnarounds

With an ever increasing need for cost control and management of project complexities, the significance of every decision made by a TAR manager during the planning and execution stages of these events is continuously imperative.

As the current oil price downturn has widened refining margins and set owners smiling from ear to ear, the realities are still the same for the shutdown manager.

In this interview, IQPC speak with a Shutdowns and Turnarounds veteran, André Bokma, Turnaround Coordinator at Neste.

The interview confronts the growing difficulties of finding the right people for the job, and how the simple, graphical visualisation of the turnaround process can really swing the balance between success and failure.

Steel Cable Hooks | Power Cable & Trailing Cable Support | BS7671 Regulations

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV