Blog

How To Use Cold Shrink Cable Caps For Permanent Cable Abandonment

June 25th, 2018

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cold Shrink Cable Caps

This video by 3M Electrical shows how to apply 3M Cold Shrink End Caps safely.

3M Cold Shrink end cable caps environmentally seal and mechanically protect exposed low and high voltage cable ends using no specialist tools, mastics or tapes – manually applied the cable caps are safe and fast to install in the field for immediate protection of unsealed cable ends against water ingress.

The 3M video explains how a Cable Abandonment Kit can be used to safely abandon a cable either permanently or temporarily. The Cold Shrink kit ensures that if the cable is accidentally re-energised it remains safe.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Cold Shrink Cable End Caps and Cable Abandonment Kits.

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

Earthing Spiders

June 22nd, 2018

Portable Earthing & Short Circuiting Kits

-

uploaded by - Chris Dodds Thorne & Derrick Sales & Marketing Manager

➡ Thorne & Derrick stock a complete range of Earthing Spiders to provide portable earthing and short circuiting solutions for LV MV HV substation and overhead line applications – contact us for UK and Exports Sales of substation and transmission line portable earth leads. Largest European stocks of CATU Electrical.

Removal of MDPE Cable Oversheath From 33kV Cables Using Alroc PG Pliers

June 22nd, 2018

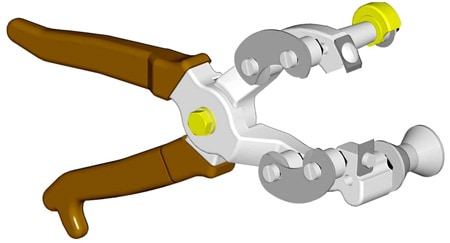

Alroc PG Pliers

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager - Information Courtesy: CA3C/2 Relating to General Requirements for 33kV Cable Jointing (Western Power Distribution)

MDPE stands for medium density polyethylene – this material is used principally as a cable sheathing material on larger size conductor cables with higher voltage ratings, such as BS6622 11kV and 33kV power cables.

MDPE cable oversheaths must be removed from medium/high voltage cables with care using depth guarded jointers tools – incorrect use of tooling may cause damage to the underlying copper screen wires thus reducing the cross sectional area of the screen and its ability to carry fault current to which its designed.

Thickness of the oversheath should be of equal thickness at any point within the cable sheath of the MV HV power cable.

This may not always be the case and the use of specialised cable tooling may cause damage to the underlying copper screen wires, it is therefore, advisable to test on a scrap length of cable before jointing commences.

This applies to the installation of cable joints, terminations or connectors when using PG type cable stripping pliers manufactured by Alroc.

Removing Cable Sheath

Removal using the correct size of Alroc PG pliers according to the outside and overall diameter around the MDPE sheath.

- Adjust the depth of cutting blade in accordance with the thickness of the MV HV cable oversheath, there is a depth variation of 1, 2 or 3; try the depth of cut on the end of the cable or on some spare core

- Hold the Alroc PG pliers at 90° to the cable and place on the cable oversheath termination mark is, apply a slight pressure to the plier handle and rotate the Alroc pliers through 90°. This will create a full 360° circumferential cut in the oversheath of the 11kV/33kV cable

- Note – excessive hand pressure on the handles of the Alroc pliers will result in copper wire screen damage. This will place a 360° circumferential cut in the oversheath

- Remove and turn the stripping pliers so as they are parallel to the cable fit the cable between the support roller and cutting wheel

- Ensure the cutting wheel is placed to the waste side of the circumferential cut, apply a good pressure to the plier handle and pull the pliers longitudinally towards the cable end

- Using the claw blades at 90° to the cable, place the top blade into the cut line, apply pressure and pull down and away from the cut line, this will open the oversheath

| Alroc Tool Part Number | Cable Sheath Diameters | Tool Weight | Cable Tool Dimensions |

| PG1 | 8-22mm | 430g | 265 x 92 x 80mm |

| PG2 | 21-35mm | 500g | 265 x 92 x 80mm |

| PG3 | 26-52mm | 600g | 265 x 92 x 80mm |

| PG4 | 47-75mm | 840g | 300 x 109 x 104mm |

| PG5 | 55-95mm | 2000g | 360 x 140 x 160mm |

| PG6 | 80-130mm | 3000g | 515 x 195 x 200mm |

Should you require any technical support or field demonstration of Jointing Tools to remove the sheath, screen or insulation from LV MV HV cables please do not hesitate to contact Thorne & Derrick.

132kV Link Boxes & Bonding Leads For High Voltage HV Cable Systems

June 20th, 2018

Link Boxes For High Voltage Cable Systems | HV EHV 132kV | Transmission & Distribution

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

HV Link Boxes & Bonding Leads

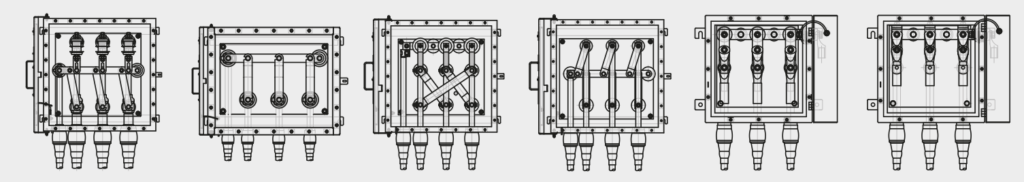

What Are Link Boxes?

Link boxes are installed on medium/high voltage power systems in conjunction with MV HV Cable Joints & Terminations incorporating a sheath break to prevent sheath circulating currents and limit induced voltage in the cable screen using bonded systems up to 132kV.

Underground cable bonding systems utilising 132kV XLPE insulated HV power cables are designed to provide cable sheath bonding to eliminate or reduce the circulating sheath currents and limit standing induced cable sheath voltages for safety reasons.

In an internal fault condition or short circuit of the high voltage power system the electricity current flows directly and safely to earth via the link box.

High voltage link boxes manufactured from corrosion resistant stainless steel (AISI 304L) are installed in association with cable joints to provide bonding of the HV cable circuit and at both circuit ends of the cable connected to the cable terminations – this product range complements our line of 132kV surge arresters with UK DNO and National Grid Approval.

Thorne & Derrick are Approved Suppliers for EMELEC, who offer an extensive range of electrical MV HV Link Boxes, expertly designed for bonding/grounding connections, made through removable links. We can provide excellent customer support, product selection and competitive prices with next-day delivery from extensive stocks of electrical Link Boxes.

Link Box Types

The standard ranges of single or 3 phase high voltage link boxes:

- Wall / Gantry / Structure Type IP66 – 3 Phase & Single Phase, Single Bonding Link Box (Cable Termination & Joint Location)

- Partial Discharge (PD) Type IP68 – 3 Phase Cross Bonding Link Box With SVL (Cable Joint Location)

- Pedestal Type IP66 – 3 Phase Earthing or Cross Bonding Link Box With SVL (Cable Termination & Joint Location)

- Underground Type IP68 – 3 Phase Cross Bonding & Single Bonding Link Box With SVL (Cable Termination & Joint Location)

- Underground Wall Type IP68 – 3 Phase & Single Phase Earthing Link Box With SVL (Cable Termination Location)

The link box is installed with cable joints and terminations to provide shield break accessibility for HV test purposes and to limit voltage build-up on the cable sheath – overvoltages on the sheath can be caused by fault currents, switching operations and lightning effects.

Multiple configurations are available – call to discuss your link box requirements up to 132kV

132kV

Single Phase & Three Phase Earthing Link Boxes

Thorne & Derrick can supply a complete range of 132kV Link Boxes in accordance with the Energy Networks Association (ENA) Engineering Recommendation C55/4 – ENA is responsible for maintaining the industry developed and published Technical Specifications (TS), Engineering Recommendations (ER) and Engineering Technical Reports (ETR).

ENA is the voice of the networks, representing the ‘wires and pipes’ transmission and distribution network operators for gas and electricity in the UK and Ireland.

The range of single phase and 3 phase High Voltage Link Boxes manufactured by EMELEC are ingress protected to IP66 or IP68 and suitable for indoor/outdoor wall mounting or underground direct burial – the internal connections/links are easily accessed and removed permitting disconnection of the individual sheaths for cable sheath fault testing.

Sheath testing is mandatory to ensure cable sheath integrity has not been compromised by cracks, cuts or snags during the cable pulling and laying installation.

A full set of Type Tests have been completed by the IPH Laboratory in Berlin including:

- Internal Power Arc 40kA/0.1 second

- Short Circuit 50kA/1.0 second

- Lightning Impulse 40(60)kVp

- DC Withstand 25kV/5 minute

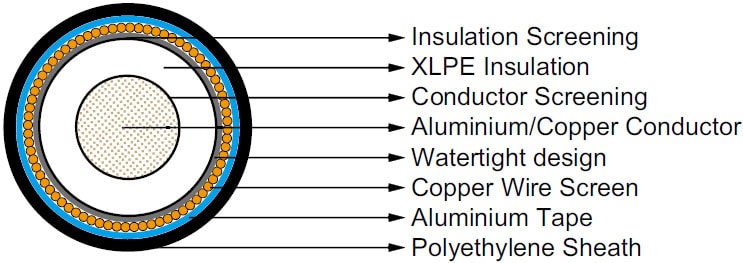

Typical 132kV Cable Construction – IEC 60840

Link Box Routine Testing

All high voltage link boxes are factory tested before shipment to customer – applied tests include visual and dimensional inspection followed by electrical tests such as AC/DC Withstand Test, Insulation Resistance Measurement Test and Contact Resistance Measurement Test.

Link boxes are available with screen bonding options including:

- Cross Bonding With SVL (Sheath Voltage Limiters)

- Direct Earthing Without SVL

- Earthing With SVL

- Single Point Bonding With SVL

Surge Arresters & Sheath Voltage Limiters

Thorne & Derrick can also supply Sheath Voltage Limiters to suit the HV cable system bonding arrangement as well as Normal Bonding Leads, Concentric Bonding Leads and High Voltage Earthing Kits for connection between the link box and the cable accessory.

SVL’s are protective devices to limit induced voltages on the bonded cable system installation due to short circuits – SVL’s are installed between the metallic screen and ground inside the link box.

The screen separation of the power cable joints would be protected against potential damage inflicted by short circuit/break down. SVL rated voltages can be produced in accordance with client specification and the bonding system design requirements.

Bonding Cable Leads – Single v Concentric Leads

Bonding Leads

Single Core Bonding Leads | Concentric Bonding Leads

An integral component of a Specially Bonded System is the use of bonding leads with the correct physical and electrical properties for high voltage power cable system earthing – 120sqmm, 240sqmm, 300sqmm and 500sqmm single core and concentric type leads are available for use with 132kV link box installations in buried or gantry mounted applications.

The bonding system is critical for improving and stabilising current carrying capacity of the power system – Engineering Recommendation C55/4 describes in detail the cable specification, system design and installation for HV bonding leads.

Thorne & Derrick supply both normal and concentric bonding leads with conductor sizes from 120sqmm-500sqmm compliant with the physical and electrical specification established in Engineering Recommendation C55/4.

Fire retardant sheaths can be manufactured for tunnel or substation basement applications.

Common size bonding leads are generally available from stock.

Single Bonding of High Voltage Cables – the simplest form of special earth bonding consists in arranging for the cable sheaths of the three HV cables to be connected and bonded at one single point along the circuit length without cable joints and typically comprising shorter cable circuits. At all other points, a voltage will appear from sheath to ground that will be a maximum at the most distant point from earth bond. The high voltage cable sheaths must be adequately insulated from the ground – since there is opened sheath circuit (except through the SVL) current does not normally flow longitudinally along the cable sheaths and no sheath circulating current loss in incurred.

Single Bonding – Bonding Leads

Cross Bonding of High Voltage Cables – consists essentially in sectionalising the cable sheaths into minor sections and cross connecting them so as to approximately neutralise the total induced voltage in 3 consecutive sections as show below. Typically, the HV cables are sectionalised into 3 equal length sections and cross bonding is achieved within the link box.

Pictured: Typical layout of 132kV Joint Day design with location of link box pit and bonding cables positioned.

Cross Bonding – Bonding Leads

National Grid Type Registration

The full range of EMELEC Link Boxes have completed the National Grid Type Registration process. The Registration covers wall-mounted and buried link box types, across the voltage range 132kV – 400kV and is supported by authoritative test data from the IPH GmbH high voltage laboratories.

Globally, cable manufacturers and utilities specify and install EMELEC link boxes – recognising the proven consistent quality, durability and suitability of the HV EHV link boxes.

Link boxes are a critical component in any high voltage underground cable system, either for direct earthing or through Sheath Voltage Limiters and their reliability is essential for fully efficient operation including human safety. In the event of a system fault the short circuit current goes directly to earth through the link box in a controlled manner.

Contact Thorne & Derrick with link box and bonding lead sales enquiries for National Grid, UK DNO and IDNO project requirements.

Cable Joints, Terminations & Connections | 3M | Pfisterer | Nexans Euromold

PB Weir Working With Thorne & Derrick – Portable Earthing & Electrical Safety Specialists

June 15th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick (Sales & Marketing Manager)

Earlier today, Thorne & Derrick the UK specialist distributor of LV, MV & HV Cable Jointing, Earthing, Substation & Electrical Eqpt welcomed Mick Fowler (Business Development Engineer – PB Weir) to their new offices in Chester-le-Street, County Durham UK.

Since 1985, T&D have developed a strong reputation for supplying UK DNO’s and NERS accredited Independent Connection Providers (ICPs) with an extensive range of LV MV HV Electrical Equipment including arc flash clothing and protection to utility workers.

T&D service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

PB Weir are the globally recognised designer, manufacturer and supplier of temporary portable earthing, voltage detectors and Buchholz Relays.

T&D met PB Weir following several recent project successes including supplying portable earthing systems to Hornsea Project 1, Scottish Power and a number of National Grid approved contractors working on projects at HV High Voltage and EHV Extra High Voltage.

Chris Dodds comments, “the commercial and technical support provided to Thorne & Derrick by PB Weir is excellent – in 2017 Thorne & Derrick experienced a record intake of new business, new customers and new account openings. That set the stage perfectly for 2018. Now our half-year sales targets and goals for 2018 have been met we look forward to introducing PB Weir to our existing and potential customers over the remainder of the year”.

Pictured left to right: Mick Fowler (PB Weir), Chris Dodds, Martin Wigham and David Tinning (T&D Sales Engineers).

😀 Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

PB Weir Portable Earthing & Electrical Safety Equipment

- Substation Earthing – Line End & Earth End Clamps

- Substation Operating Poles & Sticks

- Link Box Earthing Kits

- Network Rail PADS Approved Operating Poles

- Network Rail PADS Approced 25kV OLE Electrified Lines AC & DC Portable Earths

- Transmission & Overhead Line Portable Earthing EHV 132kV 275kV 400kV

- Westminster Voltage Detectors

- Distribution Line Earthing Equipment

- Buchholz Relays

➡ See how Thorne & Derrick working with PB Weir can supply standard and develop customer bespoke Portable Earthing Equipment for all substation earthing applications – this includes Line End Clamps, Earth End Clamps, Aluflex Leads, Operating Poles and Connectors.

Thorne & Derrick

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Cable Jointing & Pulling Equipment

Cable Blowers | Cable Lubricant | Duct Rods | Cable Socks | Cable Jacks | Cable Rollers | Cable Protection Covers MV HV | Cable Joints MV HV | Duct Sealing

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, PB Weir, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, earthing, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.