Blog

On-line Partial Discharge Monitoring & Location on a 33kV Offshore Wind Farm Export Cable

April 19th, 2022

-

Special thanks to Jordan Edmenson at HVPD for the kind permission to republish Link to the original article can be found here

Partial Discharge

Monitoring & Location on a 33kV Offshore Wind Farm Export Cable

Project

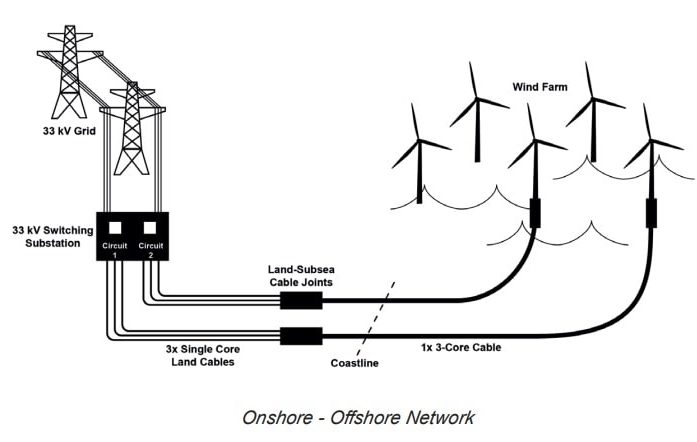

An offshore wind farm operator in the UK requested On-Line Partial Discharge monitoring and cable fault location on two 33kV XLPE land sea export cables to an offshore wind farm. The 33kV circuit began from a grid-connected onshore substation feeding a 2 km long land subsea transition joint, which in turn fed a 12 km 3-core cable directly to the offshore wind farm.

Solution

Short-term continuous monitoring was conducted using an HVPD diagnostic device connected to High Frequency Current Transformer (HFCT) and a Transient Earth Voltage (TEV) sensor.

- The HFCT and TEV sensors were installed at the cable terminations during a temporary outage

- The HFCT sensors are split core enabling them to be easily installed around the cable core and earth for detection of PD activity within the cable

- The TEV is a capacitive probe designed to detect local, high frequency PD pulses originating within the switchgear and terminations

Conducting short-term continuous monitoring over a number of days enables intermittent PD activity to be captured and correlated with other parameters such as load, temperature and humidity.

HFCT and TEV Sensors

Background Theory

If significant levels of PD activity were detected, fault location could be carried out using the cable mapping function of the HVPD diagnostic device. Cable mapping is conducted by detecting the an original PD pulse from the fault location as well as a reflected PD pulse (caused when the original PD pulse reaches the far end of the cable). Using the time delta between these pulses, and the signal propagation speed (which is provided in the cable data sheet) the approximate location of the PD source can be identified.

Results

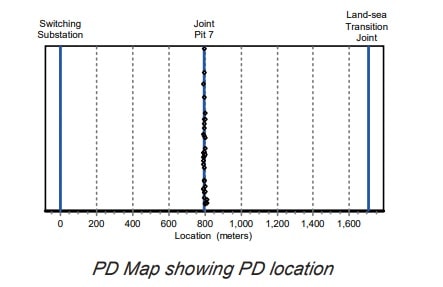

During the short-term monitoring period, high levels of PD activity were detected with the HFCT on Phase L3 of Circuit 1. Cable mapping on this circuit was then carried out to confirm the location of the fault, with the results indicating that the source was located 800m from the onshore substation.

This result was then corroborated with the cable schedule which confirmed the presence of cable joint no.7 at this location. Based on these findings, it was recommended that the affected joint no.7 be replaced. Following this replacement a forensic analysis on the joints was conducted in which significant insulation damage and tracking within the inner insulation section was found.

Partial Discharge Map Showing PD Location

Forensic Examination of Cable Joint

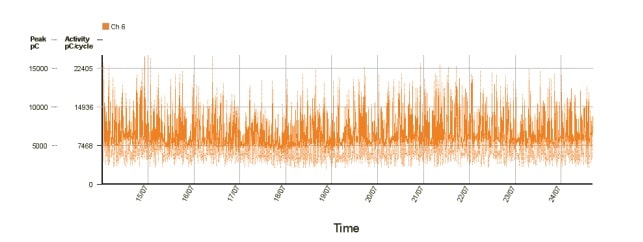

PD Trend Line Before Replacement

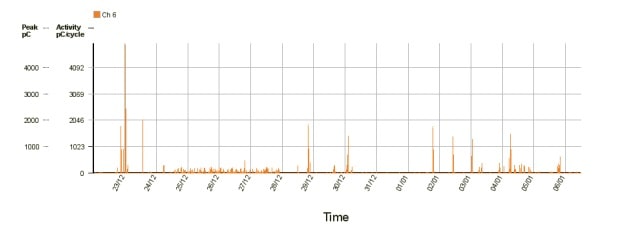

PD Trend Line After Replacement

Conclusions and Recommendations

During the short-term monitoring period, high levels of PD activity were detected and cable mapping on this circuit then confirmed the location of the fault. The affected joint was able to be taken out of service and replaced during a scheduled outage, avoiding the risk of an in-service cable failure.

About HVPD

HVPD supplies a comprehensive range of equipment to detect and monitor On-line PD for the condition assessment of in-service power cables, switchgear, motors and generators, and transformers rated at 3.3kV and above. Our PD testing and monitoring technology provide you with an early warning of developing insulation faults, helping you to avoid costly failures and resulting unplanned network outages.

To find out how we can test and monitor your cable network for PD and locate any faults, terminations or joints, get in touch today at [email protected] or call us on 0161 877 6142.

Thorne & Derrick

Specialist Electrical Distributor

Established since 1985, T&D International based in the UK distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Access Chambers, Cable Cleats, Duct Seals, Cable Transits, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

Distributors for : 3M, Pfisterer CONNEX, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Cembre, Prysmian, Ellis Patents, ABB & Furse.

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Caring & Maintaining Arc Flash Clothing by CATU Electrical

April 14th, 2022

Heavy-Duty Arc Flash Clothing

Industrial Washing & Drying

Maintaining Arc Flash Clothing For Long Term Multi-Risk Protection

The CATU range of Arc Flash Clothing Kits are comfortable, lightweight and range from 12 cal/cm² – 40 cal/cm². The Pro Kit gathers a selection of essential garments to guarantee protection against electrical arc risks – should you require guidance on selection and use of an Arc Flash Calculator please call Thorne & Derrick.

Thorne & Derrick stock and distribute an extensive range of arc flash clothing and protection available in a range of sizes and cal ratings to ensure protection against the dangers and risks of arc flash hazards manufactured by market-leading specialists CATU.

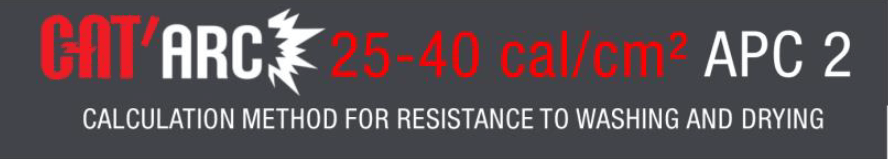

The CAT’ARC range now offers multi-risk and Arc-Flash protection from 12 to 40 cal/cm². These comfortable garments are worn on a daily basis and therefore need to be cleaned regularly. CATU helps you to maintain their protection levels, even after many washes.

Technical and innovative, the 12 cal/cm² CAT’ARC garments have been tested according to the ISO 15 797 standard, which certifies that they retain their properties throughout their period of use. This standard verifies that our garments support global industrial maintenance solutions offered by service providers, such as professional laundries.

The arc flash protective garments were subjected to 50 wash cycles at 75 ° C and drum drying at 70 ° C – this makes it possible to check the maintenance of the different protections, the dimensional stability, the behaviour of the colours, the wrinkling, the formation of creases, the pilling and the visual.

12 Cal Arc Flash Protection Kit

-

-

-

- Flame spread (ISO 11612 – A1 A2)

- Source of heat emmited by convection, radiation, or contact

- (ISO 11612 B1, C1, F1)

- Molten metal spatter (ISO 11612 E2)

- Protection against welding hazards (ISO 11611 class 2)

- Electrostatic dissipation (EN 1149-5)

- Arc-Flash resistance

- box test (IEC61482-1-2 / Box Test APC 1)

- Mechanical strength (tensile, tear)

-

-

The innovative CAT’ARC 25-40 cal/cm² fabric has been subjected to 50 complete wash cycles at 40°C and tumble drying at 60°C, in accordance with ISO 6330, Household Washing and Drying Methods for Textile Testing. This standard verifies that our garments can withstand the care solutions. Thus, the fabric has been tested and validated after 50 industrial wash-dry cycles for the following performances:

25-40 Cal Arc Flash Protection Kit

-

-

-

- Flame spread (ISO 11612 – A1 A2)

Source of heat emmited by convection, radiation, or contact - (cf ISO 11612 B1, C2, F2)

- Protection against welding hazards (cf ISO 11611 class 2)

- Electrostatic dissipation (EN 1149-5)

- Arc-Flash resistance

box test (IEC61482-1-2 / Box Test APC 2) - Mechanical strength (tensile, tear)

- Flame spread (ISO 11612 – A1 A2)

-

-

Caring & Maintaining Arc Flash Clothing

Some Tips On How To Care For Your Garment

As a reminder, the useful life of clothing depends on the use of the PPE, maintenance, storage, etc. it is therefore important to take good care of your clothing and adapt the frequency of washing to the working conditions and the degree of soiling. To wash your garment properly, there are a few simple tips to follow:

- Close all hook and loop fasteners and zips. Empty all pockets.

- Turn the arc flash garment inside out to avoid damage from rubbing against the machine drum.

- Wash separately the arc flash clothing. Do not mix with ordinary garments without similar protective properties.

- Recommended washing temperature: 40°C (104ºF).

- Do not bleach the clothing.

- Tumble dry possible at 60ºC (140ºF)

Arc Flash PPE & Electrical Safety

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Thorne & Derrick Secure New Renewable MV Cable Accessory Package Contract Order

April 13th, 2022Press Release 13.4.22 by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Image Credit: Vattenfall

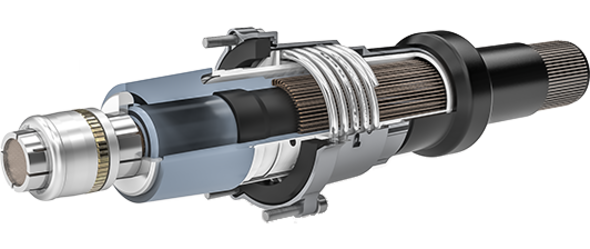

Thorne & Derrick International, a leading UK based Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt are delighted to confirm receipt today of a new purchase contract order for an offshore wind farm project – this is to supply 33kV Tee Connectors (NEXANS EUROMOLD) and Inline Cable Joints (3M COLDSHRINK) following several rounds of technical qualification, specification and commercial submissions.

Thorne & Derrick’s technical submission for the jointing of the 33kV cables was accepted by the Senior Lead Cable Specialist based upon their 3M QS2000 range – the cable joint designed utilises a unique Cold Shrink delivery system. The 3M Cold Shrink products are supplied pre-stretched on a removable core for efficiency and ease of installation by the jointer with an integral electrical field control device and faraday cage pre-installed in the insulation body to reduce complexity during the installation.

As Approved Vendors to Vattenfall, the Swedish multinational power company, Thorne & Derrick will be supplying a 33kV Inter-Array Cable Accessory Package including medium voltage joints, connectors and cable cleats to support the installation of 19/33 (36)kV Single Core Submarine Cable with 24 Fibers (IEC 60502-2).

The cable insulation system features water tree retardant (WTR) XLPE material, consisting of an inner semi-conductive screen, insulation and outer semi-conductive screen extruded in same operation (triplex extruded) – 3M Cold Shrink provides secure sealing and insulating of medium voltage cable termination and connections up to 36kV.

The MV cable originally manufactured by Prysmian Draka was installed by VMBMS under contract to Vattenfall Vindkraft A/S at the Horns Rev 3 project in Denmark.

Thorne & Derrick can support the specification and supply of standard and customised Cable Termination & Jointing Systems up to 66kV including separable connectors for Interface C-F Outer Cone and Size 3 Inner Cone gas insulated switchgear – extensive ranges of Cold Shrink and heat shrink jointing technologies are available from stock for immediate delivery to reduce downtime periods on unplanned cable outages.

➡ See more about Thorne & Derrick and our Renewable Energy projects.

Horns Rev 3

- Vattenfall Vindkraft’s agreement with the Danish State will make the production from Horns Rev 3 one of the cheapest in Europe, with a price for electricity of DKK 0.77 per kilowatt hour.

- With the construction of Horns Rev 3 with a capacity of 406.7 MW, Vattenfall is on its way to becoming one of Europe’s largest producers of wind power.

- For Horns Rev 3, Vattenfall has opted for the world’s most powerful wind turbine – MHI Vestas V164 of 8.3 MW.

Horns Rev 3 covers the annual electricity consumption of approximately 425,000 Danish households.

Fossil-free Living Within One Generation

Vattenfall are one of Europe’s largest producers and retailers of electricity and heat – a European energy company with approximately 19,000 employees. For more than 100 years, they have electrified industries, supplying energy to people’s homes and modernised our way of living through innovation and cooperation. We are determined to enable fossil-free living within one generation. To succeed we must become fossil free ourselves. But that’s not enough. Vattenfall are looking beyond their own industry to see how they can really make a difference. Together with their partners, they are taking on the responsibility to find new and sustainable ways to electrify transportation, industries and heating.

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.

Arc Flash Protection & Electrical Safety | 15 Measures to Mitigate the Hazards of Arc Faults

April 12th, 2022

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

Arc flash Protection

An arc flash is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

In industries working around high and low voltage electricity, the importance of Electrical PPE and arc flash protection is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike.

However, the dangers posed by an arc flash are not so well known in comparison. With temperatures of up to 35,000ºF, which is more than four times hotter than the surface of the sun, an arc flash has the potential to burn an operative’s skin within fractions of a second, meaning PPE really is the last line of defence for workers.

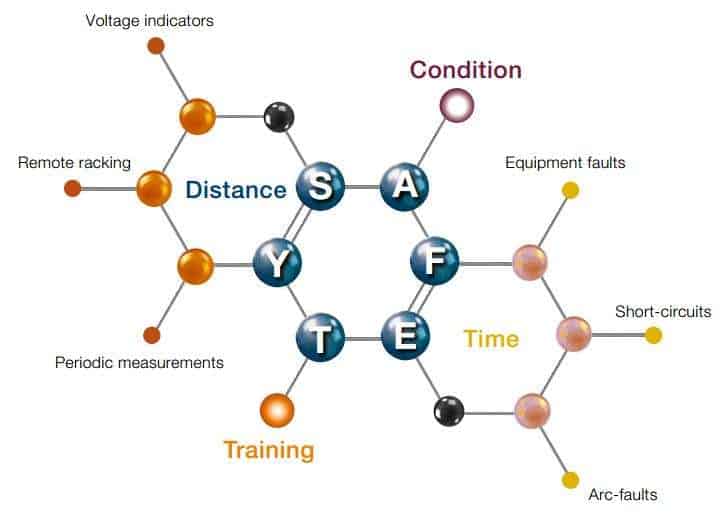

In the face of the internal arc fault risk present in low and medium voltage switchgear, prevent accidents to protect the personnel and the electric installation itself by following this proven formula.

Condition

Knowing and improving the condition of the equipment is a key factor in reducing the likelihood of failure, damage, and injury. is comprised of condition, distance, time, and training.

- Risk Assessment study – Asset risk assessments to establish the risk profile of equipment based on its condition and importance in the system, and prioritize actions to mitigate the risk before the hazard occurs

- Monitoring programs – Risk monitoring and mitigation programs to maximize improved reliability and reduced operator exposure

- Upgrades and retrofit – Equipment upgrades and retrofit which decrease operator exposure because of reduced maintenance, faster cycle times, and lower clearing times

- Diagnostic testing – Diagnostic testing to address concerns of bad connections, pollution, mechanical faults and minimize failures due to defective devices

Distance

Maintaining a safe distance between personnel and equipment during critical operations provides the most effective means of avoiding injury by keeping people out of harm’s way

- Remote racking – Remote racking provides a safer operating environment for personnel through the proven method of adding distance between the operator and arc flash incident energy at the switchgear site, bringing operation of power circuit breakers to a new level of safety. ABB vacuum circuit breakers can be provided with a fully integrated motor operated racking system for their use in new replacement switchgear or as part of the hard-bus and cradle-in-cradle retrofill solutions.

- Voltage indicators – The installation of voltage indicators on accessible power circuits can increase the operators safety and avoid accidental electrical contact injuries. VisiVolt is an ABB passive voltage indicator perfectly suiting the equipment upgrade. It is adapted for permanent installation on busbar and naked or insulated metal conductors, indicates the presence of voltage by displaying a large and well visible lightning arrow sign on its display. The relevant silicone elastomeric enclosure ensures performance also in outdoor conditions while its fluorescent orange colour provides good visibility among the other elements of the system.

- Infrared thermo-graphic inspection – Infrared (IR) thermal measurements are performed through dedicated arc-proof ports with power compartment doors closed. The periodic thermo-graphic inspection of the critical areas (e.g. power cables connections) is an efficient method for preventing associated faults. Ports can be added to existing switchgear by ABB expert engineers keeping the original equipment design characteristics.

- Partial discharge measurements – Periodic measurement of the partial discharge (PD) level is a proven method for detecting insulation degradation before real insulation failure develops. The assessment results are documented as trend curves for each switchgear compartment, where the curves with high increase of partial discharge activity level indicate compartments with high risk of insulation failure. Site work is performed with closed doors.

Time

Reduction of time for clearing fault conditions has a dramatic impact on the energy released and consequent damage and injury.

- MV equipment faults: relay upgrades with Relion® – microprocessor equipment which operate faster than electromechanical relays and support faster clearing times.

- Short-circuit current: Is-Limiter device – Is-limiter device as a fast operating interrupting device that limits the short circuit current to a level that breakers and buses can withstand, protecting property and personnel. Replacement of existing switchgear and cable connections with new equipment with higher short-circuit ratings can be technically impossible. The use of Is-limiters reduces the short-circuit current in extensions of existing systems and in new systems. The Is-limiter is capable of detecting and limiting a short-circuit current during the first current rise in less than a millisecond.

- Arc-faults: REA arc fault detection system – REA arc flash protection relay uses patented fiber-optic sensor technology that instantaneously detects light from an arc to signal a “trip” to the designated circuit breaker in less than 2.5 ms, minimizing an arc flash incident.

- Arc-faults: Upgrade with UFES – UFES, an ultra fast earthing switch, provides detection and grounding of faults in times significantly faster than breaker clearing times, leading to the avoidance of injury and damage and the reduction of production outages. A device as small as an insulator offers enhanced protection for your switchgear by the effects of internal arcs. The UFES arc protection system channels the uncontrolled release of energy by the arc into a solid metal, 3-phase connection to earth potential. The internal arc will be extinguished within an operation time of < 4ms after detection of the fault.

Training

Adequately trained personnel and proper procedures are essential to safe operations

- Personnel training – Training engineering and technical services provide personnel with a better understanding of their equipment and systems and the safest means to operate them.

- Procedure development – Arc flash studies help to determine the necessary level of protective equipment or clothing (PPE) to be worn by workers in close proximity to potential arcs and also help determine the proper application of any arc flash protection equipment to be installed.

- Engineering studies – Engineering studies determine the proper settings and system coordination, while addressing the speed of the system to handle a fault so relays and associated protective devices are set properly in order for the system to react as designed.

Electrical Safety Providers

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

Reliable Voltage Testing | Pfisterer KP-Test 5 Capacitive Voltage Detector

April 11th, 2022

Voltage Detectors Distributed from Stock | Approved Supplier | UK & Export Sales

Voltage Detectors

Pfisterer KP-Test 5

The KP-Test 5 capacitive voltage detector manufactured by PFISTERER and distributed by Thorne & Derrick can be used for indoor and outdoor medium voltage applications. It indicates the presence of operating voltage. The KP-Test 5 voltage detector is distinguished by its high level of user friendliness and user safety.

Voltage detectors in the KP-Test 5 series perform an automatic self-test when they are switched on. The detectors also give off a clear visual and audible warning to signal the presence of voltage.

Voltage detector provides wider range of application, easier handling, improved signal indication – KP-Test 5 keeps pace with increased market requirements and makes high-quality electrical safety equipment possible.

Pfisterer Voltage Detector

KP-Test 5 Voltage Detector

Tested to EN 61243-1 the capacitive voltage detector can be used in all weather conditions. As with any security-related tool, there are a few basic rules to follow:

The employers’ liability insurance association for energy, textiles, electronics and media products (BG ETEM) currently points out that the contact electrodes or test prods of voltage testers must have conductive electrical contact with the system part to be tested in order to reliably determine the absence of voltage.

Clear measuring conditions, which are covered by the IEC 61243-1 standard, only arise in direct contact with the conductive part of the system. Even the simplest adhesive strips from office supplies can cause voltage drops of a few kV on busbars and lead to incorrect test results.

In practice, busbars are often color-coded, and measurements should never be taken at these points. This fact is due to the principle and applies to devices from all manufacturers. Another important rule: Voltage testers must be checked for proper functioning both before and after the measurement. The built-in self-test function is used for this.

Voltage Detectors 11kV 33kV

The KP-Test 5 family offers the right voltage detector for every application. Medium or High Voltage, alternating or direct current for use on overhead power lines, switchgear, in substations or on railway systems. All devices are individually adapted to our customers’ requirements. PFISTERER offers solutions for all voltage levels from 1 to 420 kV AC.

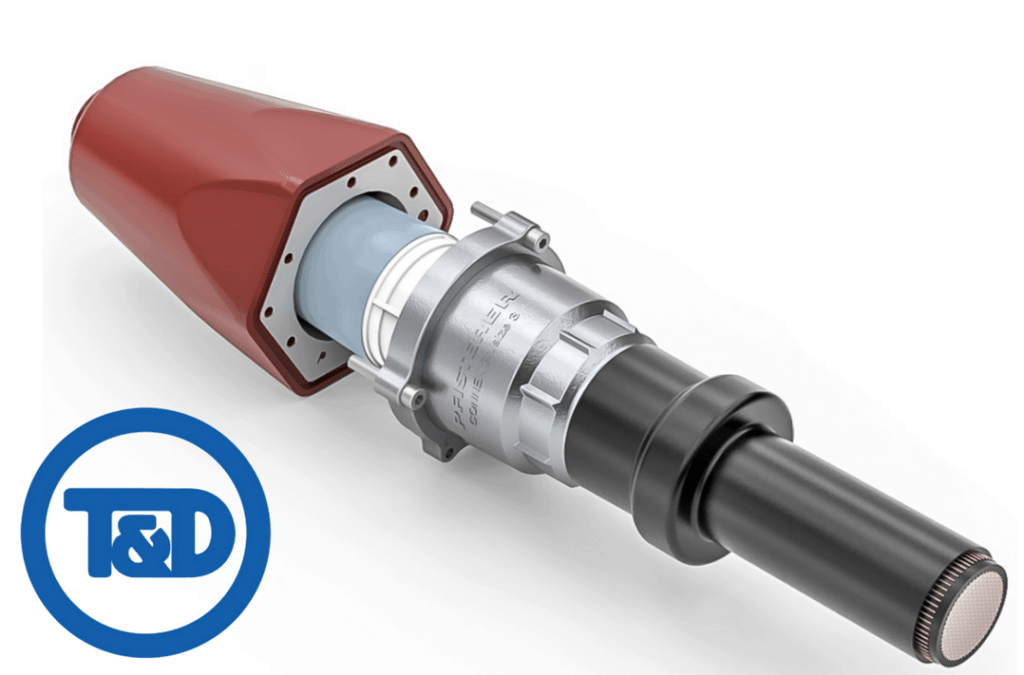

The SEANEX inner cone solution is an offshore variant of the successful Connex HV connection system that is specially adapted for 66kV inter-array cabling.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

MV Connex Products | Ex Stock Thorne & Derrick | Inner Cone Cable Connectors 33kV