Blog

The Arc Flash Risk in Electric Metering

July 30th, 2021

“30,000 Arc Flash Incidents per year” Source: ISHN

-

Special thanks to Allan Newbronner Electrical Systems Manager at Horizon Engineering Solutions Ltd for the kind permission to republish this article

Arc Flash Risk

Electric Metering

Across the country, there are millions of electricity meters. The quality of these varies from very modern installations to very old assets. An important fact is that there are certain activities undertaken by a meter operator that can only be conducted ‘LIVE’ and it’s important that if you are responsible for people working with electricity that the inherent arc flash risks are considered and addressed. The primary risk for a meter operative are activities involving the cut-out (service head):

- Fuse carrier withdrawal

- Polarity testing and voltage measurements

- Installation of a shroud

- Checking the tightness of connections within the cutout

- Withdrawal of a shroud

- Re-insertion of the cut-out (service head)

There is an additional risk around metal-clad cut-outs and the opening of the cover. As the cover is conductive if there is a problem with the hinges, or if the cover is in fact unhinged, it can drop and come into contact with energized conductors causing an arc event. A similar risk can exist around multi-way distribution boards if any of the busbar covers are missing. This can’t be established before the opening of the cover of the distribution board.

Law & Legislation

There have been a number of life-changing injuries to meter operators/engineers with engineers being hospitalized for lengthy periods of time with repeated skin grafts being needed on their hands, arms, and face. Typically engineers have not been wearing adequate Arc PPE protection which is required by law in the UK and in many countries around the world.

Electricity at Work Regulation 1989. Regulation 14 Work on or Near Live Conductors; Standard of Duty is Absolute! No person shall be engaged in any work activity on or so near any live conductor (other than one suitably covered with insulating material to prevent danger) that danger may arise unless:

(a) it is unreasonable in all the circumstances for it to be dead; and

(b) it is reasonable in all the circumstances for him/her to be at work on or near it while it is LIVE; and

(c) suitable precautions (including where necessary the provision of suitable protective equipment) are taken to prevent injury.

Arc Flash In Conclusion

If you have engineers/operators working on or near LIVE or potentially LIVE conductors then it is very likely they are exposed to the risk of an Arc Flash or Electric Shock. Adequately protecting people and the organization is paramount and is your duty under the Law.

Ensuring that understanding the risk and creating meaningful steps to mitigate that risk is something each organization is responsible to carry out.

There are various professional organizations that have dedicated technical team(s) that work through the hierarchy of controls assisting clients in ways to:

1. Eliminate the risk by physically removing the risk

2. Substitute the risk by replacing the hazard

3. Engineering out the risk by isolating people from the hazard

4. Use of administrative controls to change the way people work – Comprehensive Electrical Safety Rules

5. Mandate Correct PPE (Personal Protective Equipment) – Last but not least!

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Thorne & Derrick International supply arc flash clothing and protection equipment including coveralls, gloves, helmets, face shields and general head-to-toe PPE is used to protect against flashover – complete range of insulating matting is also available for worker protection when exposed to energised electrical switchgear and transformers.

Typical applications include LV, HV & EHV cable jointing and terminating, fuse pulling, switchgear commissioning, racking circuit breakers, electrical switching and live working on medium and high voltage electricity networks.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable cleating, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Cable Drum Handling | A Guide by LEONI Cables

July 30th, 2021

Guidelines for cable drum handling during transport and storage

Transport

Cable drums must be handled with care.

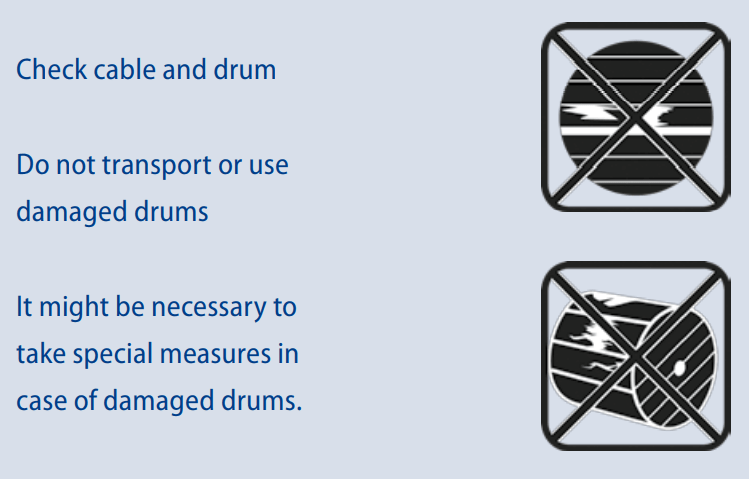

Improper handling procedures or cable drum handling equipment can easily cause damage like broken drums or visible or invisible damage of the cable itself.

Main danger comes from invisible damages leading to unusable cables.

Therefore some base guidelines shall be followed. The cable itself must always be protected and may not be touched improperly during transport and storage. A drum, damaged by handling or showing signs of wear or rotting must be checked. Special handling procedures may be necessary.

If a wooden drum is handled and/or stored properly as described in this document LEONI Kerpen GmbH gives warranty for stability and usability for a period of up to 18 months after delivery. In case of wooden drums show signs of damage from transportation any warranty obligation given for cable drums and any subsequent cable problems resulting from it are null and void.

Beside the general guidelines, please refer to the cable data sheet for additional information regarding temperature range and possible special requirements for transport and storage.

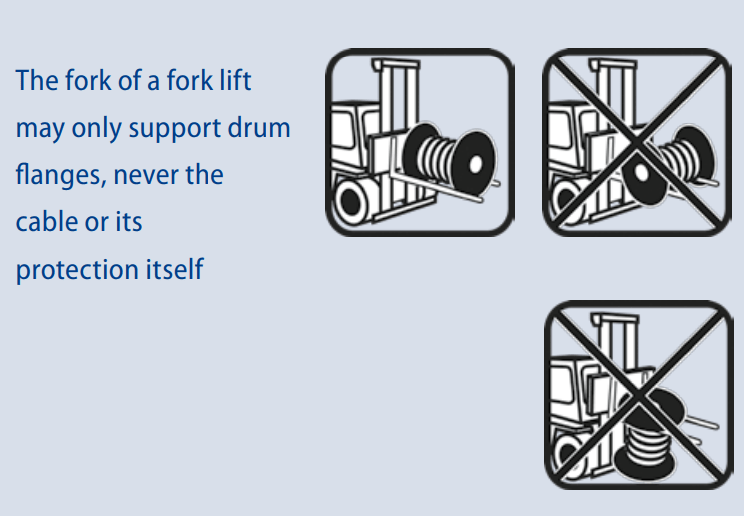

- Lifting cable drums with a fork lift is only allowed from the “flange side”. The fork may never touch the cable or its protective cover to avoid damage. The fork must support both flanges while lifting.

- If lifting a drum with a crane an axle or a spreader beam must be used to avoid lateral pressure on flanges.

- Suitable devices must be used for loading and unloading in order to avoid damage to the cable and the drum. Drums may never be dropped from a truck, ramp or container.

- Cable drums should only be transported with suitable vehicles and must be fixed, so that they cannot shift during transportation. The same applies in case cables are transported in a container.

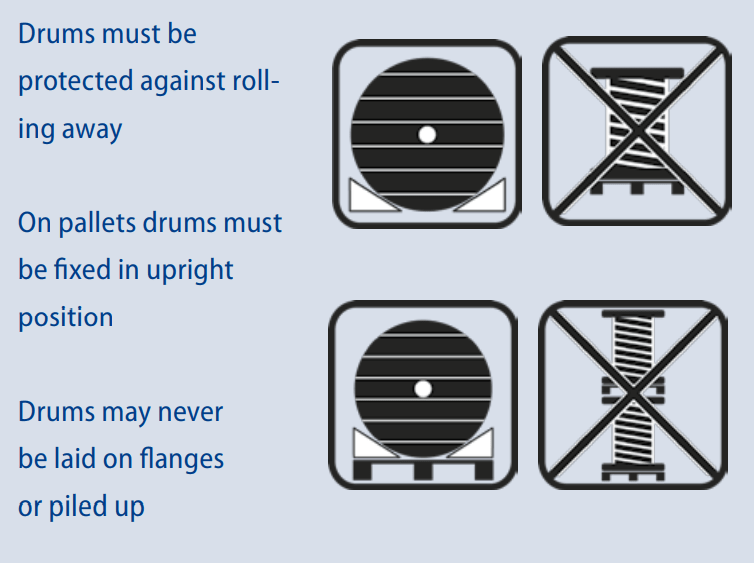

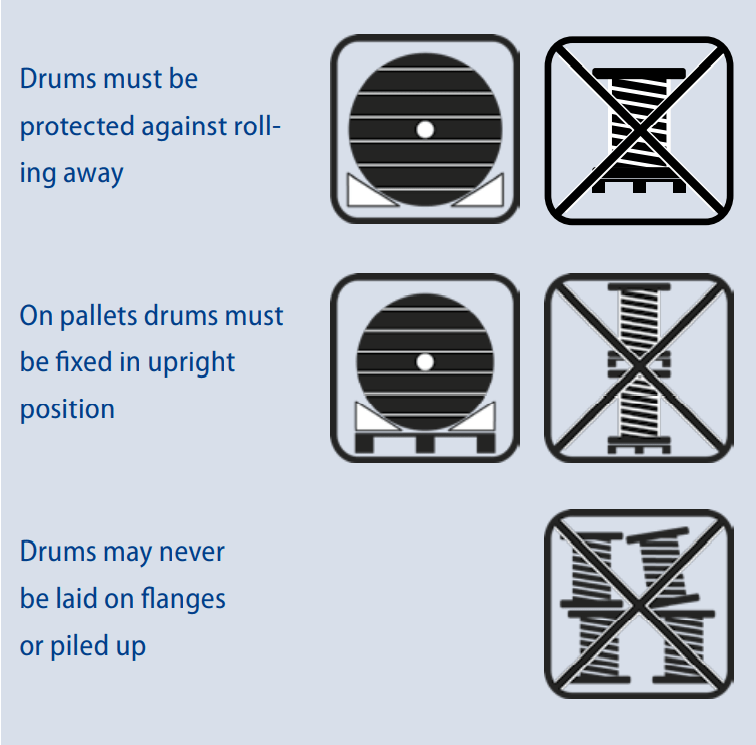

- During transport and storage drums shall always be in upright position.

Drums must be protected against rolling away. On pallets drums must be fixed in upright position. Drums may never be laid on flanges or piled up.

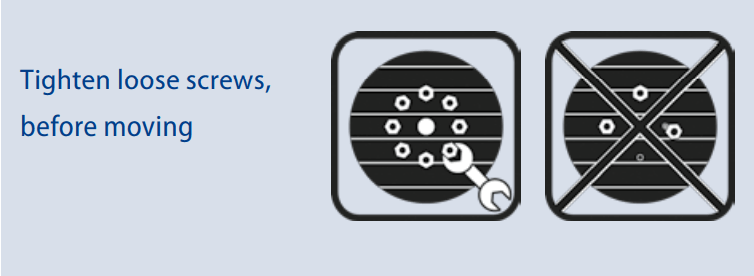

- All screws holding the flanges must be checked and tightened before moving the drums.

- In case of dry and hot weather conditions screws have to be tightened as required to compensate for shrinking of wood. Tightening of screws shall be done with a torque wrench. The force shall be as mentioned on the drum or as follows:

| Drum Size | Force |

| 700–1400 mm | 80 Nm |

| 1600–2200 mm | 100 Nm |

| 2500–2800 mm | 120 Nm |

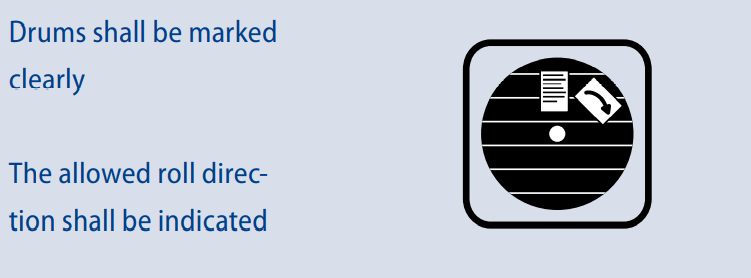

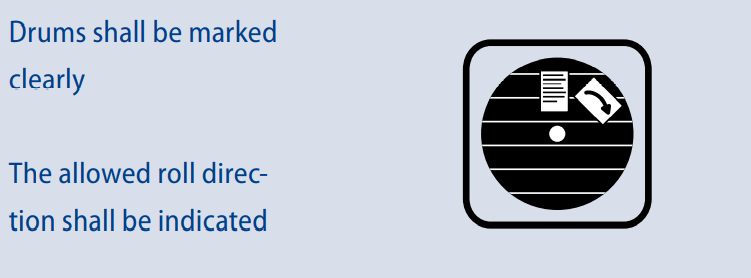

- Drums with cables may only be rolled over short distances and on a firm and even surface in the direction which is indicated on the drum (label with arrow and inscription “Roll This Way”).

- Each drum is identified by an unique drum number. In case a cable or part of it is rewound onto another drum, it is recommended to note the original drum number, otherwise backtracking is impossible.

- Drums must be labelled to allow easy and quick identification of the cable:

– identification labels showing cable type, length, code no., etc.

– other markings.

- The maximum temperature for transportation is indicated in the data sheet, section “Transport and Storage”.

- Due to interdicted stress during transportation, nails used to fix the two layers of a flange might be forced to shift into the inner side of a drum. Drums damaged or overstressed (e.g. dropped on a flange) needed to be checked carefully from the outside. Nails in question have to be removed by pliers before rolling or turning the drum to avoid continuous damages of outer sheath by rotating cable layers.

It is always a sign of incorrect cable handling, when hats of nails are sticking out of the inner flange of a cable drum. This movement is caused by shifts of the 2 wooden flange layers against each other under interdicted force while moving the drum.

In addition, multiple damages might occur by such a nail hat, due to unavoidable but “normal” movements of a cable on a cable drum while being un-drumed.

Cable Rollers

Cable Drum Storage

Cable drums shall be stored safely. Improper storage conditions can easily cause damage to cable drums or cables themselves. Therefore some base guidelines shall be followed.

The cable itself must always be protected and may not be touched improperly during transport and storage.

Check drums before moving. Check for nails, which might have shifted out of the inner side of the flange. Remove it from the surface before rolling or moving the drum.

A damaged drum must be checked. Special procedures may by necessary, like rewinding on a new drum.

If a wooden drum is handled and/or stored properly as described in this document LEONI Kerpen GmbH gives warranty for stability and usability for a period of up to 18 months after delivery. In case wooden drums show signs of damage from handling and/or storage any warranty obligation given for cable drums and any subsequent cable problems resulting from it are null and void.

Beside the general guidelines, please refer to the cable data sheet for additional information regarding temperature range and possible special requirements for transport and storage.

- Cables for indoor use shall be stored indoor.

- Cables for outdoor use may be stored outside. Their allowed temperature range for storage should cover the conditions defined for storage. See cable data sheet, section “Transport and Storage”, for any details.

- All cables on drums shall be protected with suitable protection package, such as black plastic sheeting, lagging, etc.

- Cables (especially with black sheath) exposed to direct sunlight will become warmer than the ambient temperature. It must be ensured that the temperature of the cable will not exceed the allowed maximum temperature for storage. See cable data sheet, section “Transport and Storage”, for any details.

To avoid direct exposure to sunlight the cable shall be protected with suitable package, such as a dark foil, and/or by storage in shadow.

- Cable ends must be fixed on the drum to avoid getting loose during transport, handling or storage.

- Cable ends shall be sealed with caps against ingress of water.

- Drums must be labelled to allow easy and quick identification of the cable and of main handling issues:

– identification labels showing cable type, length, code no., etc.

– a label to indicate the allowed roll direction (“Roll This Way”)

- Drums must be handled and stored always in upright position, standing on the flanges. The ground must be firm, even, well-drained and stable, so that the flanges cannot sink in. Pressure on flanges must be equal on complete flange surface in contact with ground.

- Drums must be protected against rolling away while stored.

- The drums shall not be standing in direct contact with water or damp soil to avoid rotting of the drum.

- Drums may never be transported or stored lying on a flange. Damages to cable or drum are likely in this case. Lying and handling horizontally is only acceptable for small drums and light weight cables.

- Cables shall be stored in areas without influence of high heat or close to (open) fires. Areas where chemicals, petrol, etc. could be spilled over them must be avoided.

- If stored in a secure and suitable area, periodical inspections of the drums are recommended, at least quarterly. In case of direct exposure to weather, sunlight, etc. the interval between inspections should be shortened.

- Damaged drums must be checked carefully. It might be necessary to take special care during transport or installation or to rewind the cable on another drum.

Further Reading

Cable Drum Handling | Halogen Free Shipboard Cables Recommendations

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

Cable Drum Handling | Jack Towers for LV to EHV Power Cable Lifting & Site Handling

Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct | Cable Grips

What Is An Arc Flash Study?

July 30th, 2021

Arc Flash Protection

ProGARM Arc Flash Clothing, Garments & Electrical PPE

An Arc Flash Study is a risk assessment of a workplace environment that determines Arc Flash hazards. An expert in electrical safety conducts an assessment to ensure that a company understands the risks their workplace poses to their team and how to protect against them. Assessment providers may also offer training to increase your team’s awareness and options for periodic reviews.

WHAT DOES AN ARC FLASH STUDY INVOLVE?

How big would the bang be? That is the central question that an Arc Flash study seeks to answer. Only by knowing this can you adequately protect your team against the Arc Flash risks of their working environment.

An Arc Flash study will identify areas of low risk, as well as those at high risk of an Arc Flash incident. This allows you to tailor your Arc Flash protection strategy accordingly. The study will also assess the potential severity of injury at a given distance and locate the protection boundary at which there is a severe danger of second-degree burns.

There are many facets to a successful Arc Flash assessment and generally, they are adapted to fit your specific industry and requirements. They can include Arc Flash calculations, fault level studies and comprehensive site surveys.

WHO NEEDS TO CARRY OUT AN ARC FLASH STUDY?

Companies in the UK are not currently obliged to perform Arc Flash assessments on their sites. This is in stark opposition to the USA, where there is more awareness about the dangers of Arc Flash incidents. An Arc Flash study may be optional, but the positive impact on safety within your organisation is likely to be significant.

Arc Flash protective clothing is vital to protect your team should they be at risk. An Arc Flash study will highlight what level of protection is needed, allowing you to make an informed decision about your team’s Arc Flash protective clothing requirements. Arc Flash garments are available from specialist Arc Flash and non-specialist suppliers – we believe that when lives are at stake that you should trust a specialist. All garments that are rated for Arc Flash protection conform to EN Standards, but not all Arc Flash garments are created equal.

➡ See also our range of Electrical Safety Equipment

Take a look at what it takes to create a ProGARM garment and explore how our garments protect your team, the quality and durability of our arc flash clothing and how the comfort and design of our garments contribute to protecting your team.

Thorne & Derrick distribute a range of arc flash coveralls to suit a range of requirements. Variations include ladies coveralls, designs for overhead linesmen, orange and yellow hi vis options and a wide range of sizes. Contact Thorne & Derrick with your specific PPE requirements and we will be happy to help.

The ProGARM range of Flame Resistant protective garments are designed for every-day wear and protection – the highly breathable clothing ranges are designed for comfort and safety without compromising the ability of the wearer to work productively, safely and unhampered by cumbersome garments prone to overheating.

Other garments and protection products include Arc Flash Gloves, Arc Clothing, Arc Flash Suits and Arc Flash Helmets & Visors.

Further Reading

- Arc Flash Protection Hoodie with FR Protection | ProGARM 5530

- Arc Flash Clothing Standards | EN Standards for Arc Flash Protection

- Arc Flash Protection | A Whitepaper on Clothing & Garment Selection

- Arc Flash Survivor Story – Jason Brozen

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Understanding Arc Flash | Core Body of Knowledge for the Generalist OHS Professional

July 30th, 2021Republished by Kind Permission of The OHS Body of Knowledge – The OHS Body of Knowledge (OHS BoK) is the collective knowledge that should be shared by generalist OHS professionals to provide a sound basis for understanding the causation and control of work related fatality, injury, disease and ill health (FIDI). This knowledge can be described in terms of its key concepts and language, its core theories and related empirical evidence, and the application of these to facilitate a safe and healthy workplace. The OHS BoK has been developed for the Australian OHS context but has international application.

Source is Australian Institute of Health and Safety

Uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick UK

Authored by | Brett Cleaves, Director, Engineering Safety Pty Ltd

Peer Review by | Vanessa Garbett, Team Leader, Electrical Installation Safety, Energy Safety Victoria, Australia

Acknowledgements to | The Australian Institute of Health and Safety (AIHS) financially and materially supports the OHS Body of Knowledge as a key requirement of the profession. The Australian OHS Education Accreditation Board influences, supports and monitors the OHS Body of Knowledge.

Second Edition, 2019

The Understanding Arc Flash Document includes a content page as follows:

Table of Contents

A1 Introduction

A1.1 Some electrical terms

A2 The extent of the problem

A3 Understanding arc flash

A3.1 Electrical arcs

A3.2 Arc faults, arc flash and arc blast

A3.3 Impact of arc flash

A3.4 Arc flash and nature of work

A4 Risk assessment

A5 Legislation and standards

A5.1 Legislation

A5.2 Standards

A6 Control of arc flash hazards

A6.1 Elimination

A6.2 Substitution

A6.3 Engineering controls

A6.4 Administrative controls

A6.5 Personal protective equipment (PPE)

A6.6 Resilience of controls

A7 Implications for OHS practice

A8 Summary

List of Figures

Figure A1 Arc flash and arc blast

Figure A2 Electrical work and arc flash

Figure A3 Prevention and mitigation of arc flash hazards

List of Tables

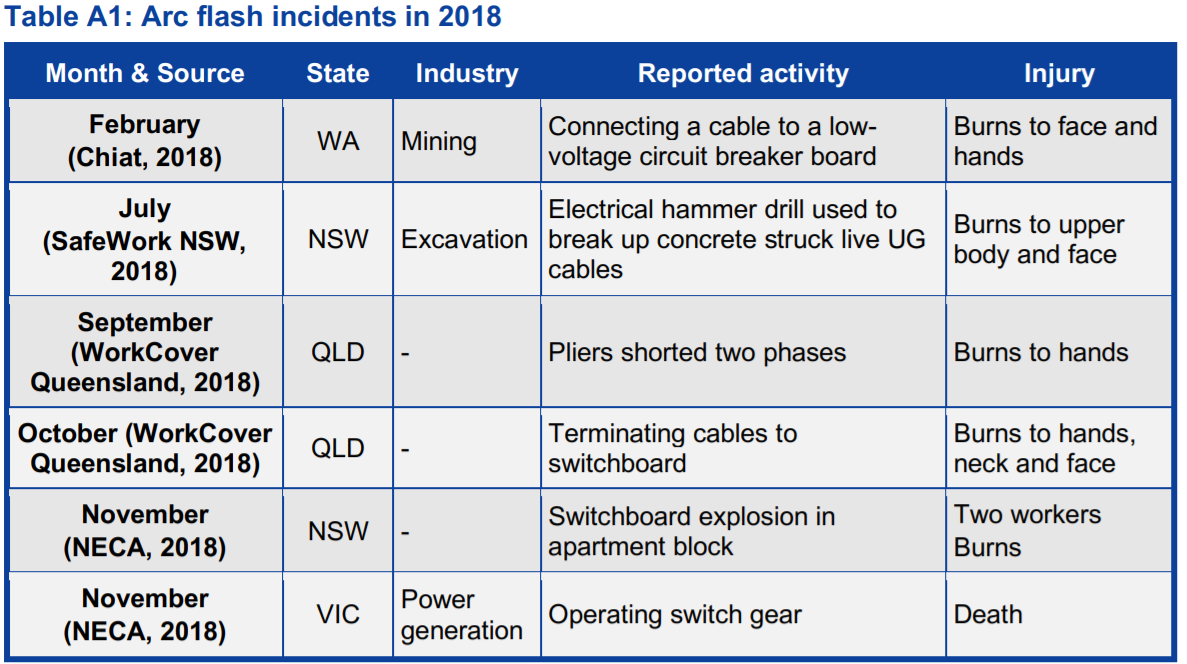

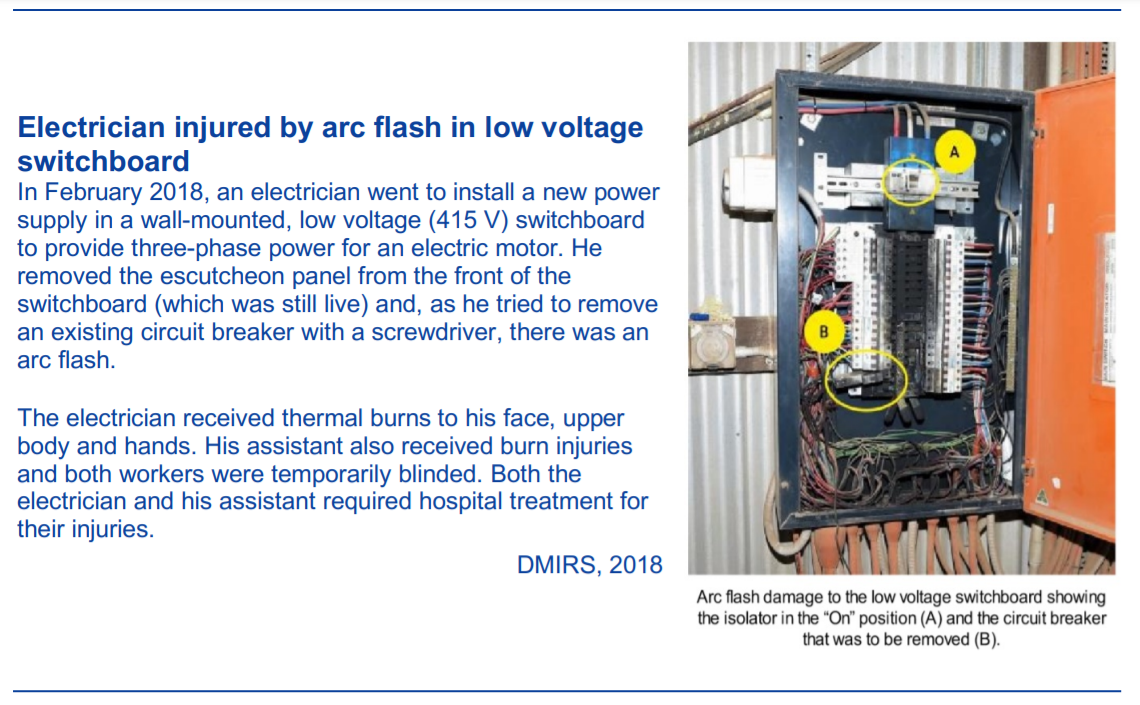

Table A1 Arc flash incidents in 2018

Table A2 Risk factors for arc flash

Table A3 Control options for arc flash

Table A4 Examples of impact of organisational context on implementation of arc flash controls

Abstract

This appendix to the OHS Body of Knowledge Chapter ‘Physical Hazards: Electricity’

focuses on the electrical hazard of arc flash from the perspective of the generalist OHS

professional. After defining relevant terms, examining the incidence of arc flash injuries and

reviewing relevant legislation and standards, it considers options for control of arc flash and

implications for OHS practice.

A1 Introduction

The OHS Body of Knowledge chapter Physical Hazards: Electricity presents information required by generalist OHS professionals to enable them to better understand the nature of electricity as a hazard, how it can harm the human body and the standard control measures.

The chapter emphasises the severity of potential consequences of an electrical incident, noting that several deaths by electrocution occur in workplaces across Australia every year. This appendix focuses on one particularly dangerous type of electrical hazard – arc flash – the consequences of which can range from inconsequential to severe burns and death as well as power outages, fire and significant property damage.

While arc flash is associated with electrical work, and may be considered a specialist topic, all workplaces have electricity and so arc flash hazards are of pervasive relevance. With the introduction of metal clad switchboards from the mid-20th century came the practice of switchboard arc flash containment and testing, and it was not until the 1980s that arc flash hazards were first quantified.

Consequently, knowledge of arc flash hazards, the risk factors and the mechanism of injury causation is still evolving. The dynamic nature of this knowledge is reflected in the existence and use of different standards and terminology across countries and organisations; this inconsistency can present problems for generalist OHS professionals working with electrical personnel to implement a risk management approach to minimising arc flash.

To Receive Your Free Copy

of the Full Report

Please Email

[email protected]

Meet the Author, Brett Cleaves BE(Elec)

Director, Engineering Safety Pty Ltd

Email: [email protected]

Since starting as a cadet with BHP in 1993, Brett has worked in steel mills, mines and electrical utilities, executing a range of duties in maintenance, engineering, governance, production and project management.

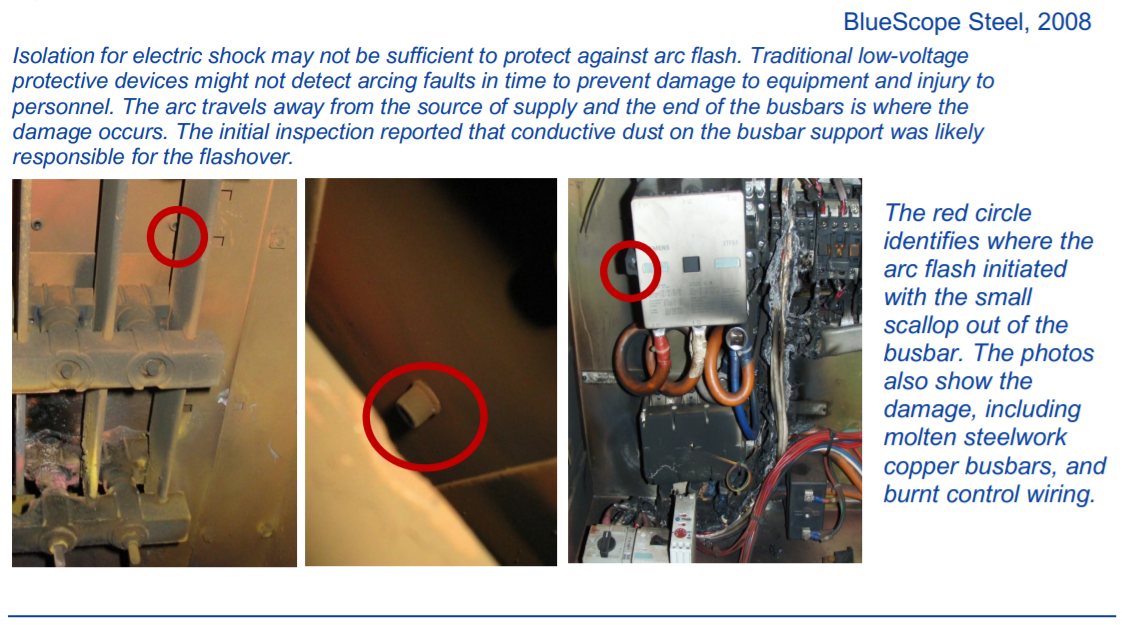

He developed a strong commitment to electrical safety, and received BlueScope awards for leadership and engagement. In 2013, Brett established Engineering Safety through which he provides project management services for a range of electrical companies together with general advice on electrical safety to industry.

At the leading edge of hazard identification, assessment and control for arc flash in Australia, Brett is a strong advocate for the need for knowledge of arc flash to evolve to provide clarity on the most appropriate practices and controls.

A Transcript | Arc Flash Survivor Story by Jason Brozen

July 29th, 2021➡ Read the original story here: Arc Flash Survivor Story – Jason Brozen

Let’s Hear Jason’s Survival Story

‘You know I ended up working on a big piece of gear, 2500 amp, it was a hotel and we got dispatched to install a new circuit for some pool equipment, a 200 amp breaker and we had to fit it in a spot that was sized for 200 amp breaker. But inside that space there’s a GE piece of equipment. They coat the bus bar in tape you know from the factory so spent a lot of time meticulously cutting that tape off while it was hot with no gear on because I’d done it before successfully and uh and I got through that process but I did call my boss to say “man this is pretty precarious here you know we might want to shut it off” and he didn’t encourage me to shut it off. So, you know as a boss now also working as a project manager now I encourage my guys to shut it off.

So, fourth section, uh it’s 208 uh which really kind of squashes the industry-wide misconception that you can’t have an arc flash of any substantial value in 208. So this was not even in the main section it was in a branch section. 2500 amp sections you know, 2500 amp gear, transformer was really close, uh 500 kva transformer. Anyways a four-section piece of GE gear, pretty standard in the industry lots of people use that um so 2500 amp main plus a bunch of branch sections three branch sections. I needed to install a 208 breaker in one spot so on that specific spot I just took the above on it and below pieces of dead front off instead of removing the whole dead front because i thought that would be safer. I mean it turns out it was a good decision it probably saved my life. As you can see in the pictures, you know a lot of the heat rolled up and that acted as a shield. There’s no doubt it would have you know burned my face off at that point but yeah I mean it’s just a standard thing that most guys do. They’ll take a box out of a you know, a breaker out of a box you know they’ll inspect it and turn it on and off a couple of times and then they’ll go you know fitting it in the gear and they’ll stick in that driver and bolt the thing in and they’ll do it hot and they do it every single day and 99% of the time they’re successful at it.

So, the second the arc flash happened I knew what was going on just because I mean it’s you know like most electricians that have been in the field for a long time have YouTubed arc flash, have seen all the nasty videos of all the arc flash events they can possibly see. Usually, some guys can’t do it but uh and so I’d been deep in fp70. I understood it, you know I knew better than doing what I was doing.

But anyway, to get back to it, so I knew what was going on, the arc flash was happening and I could feel it and as soon as the noise stopped because i can just you know describe it as just noise because it’s just you know an explosion, it’s going on. It’s just a millisecond but as I said before you slow down as soon as the noise stopped all the lights were out and the room is filled with smoke and I couldn’t see.

The very first thought was “am I on fire?” because I’d seen so many different videos from different vendors uh from you know arc fault or arc flash clothing you know arc rated workwear, where they show this kind of workwear and the mannequins on fire head to toe. So that’s the very first thought was “oh my god am I on fire” so you know just started you know kind of the vertical drop and roll type thing and then I saw a door a light crack open because somebody from the hotel management opened the door because they heard what was going on. The fire alarms are all going off and once I saw that, I was able to exit the room and then kind of gather my thoughts and see and then you know look at my hands and there was a bathroom I wanted to see what my face looked like and I just kind of assessed the damage. I’m not a real panicky guy, I don’t flip out with accidents and stuff uh I’m sure there was a level of shock of course.

Honestly, I thought after the accident I go yeah that’s pretty bad i was looking at my hands but I thought ‘a couple months’ you know I never thought I’d need skin grafts and be in a coma and sick and ICU for two weeks and off work for seven months. I never in a million years would have thought that.

The thing with burns is the first- and second-degree burns hurt and third-degree burns don’t. They burn your nerves you know and so my hands, there’s parts of my hands that hurt, they’re real tight because the burn just shrinks everything up. Uh my face was real tight and it was a little painful but it was 40 out so it was pretty cool and so it felt you know okay.

And then you see on the video man I started making calls. I called my boss you know and said ‘you need to get out here now! I blew this up it’s really bad I’m injured you know you gotta mobilize, get somebody here it’s bad’ and uh and I’m sure there was a level of panic in my voice to him because he recounts later that you know it was pretty panicked.

Uh then tried to call my wife, you know, couldn’t get a hold of her. I call her mom, say look I’m on my way to the hospital I got burnt pretty bad I’m going to KU Med so then as you saw the fire department worked on me there and carted me off you know to the hospital. Really the last thing I remember at the hospital was triage it was them just cutting clothes off, you know getting IVs set, cutting that ring off and then it’s gone. That’s it they put me out they know gave me something I was out and then that’s when they de-breed you and you always hear the stories where they oh you’re wide awake and they’re scrubbing you. That wasn’t my experience they put me out. Uh my expectation is they would put anybody out, but I’ve heard stories where they don’t uh so they de-breed which means they wire brush and you know scratch all the dead skin that they can get off. You know face, they shave your head they put me in a room, they put me in a coma for two, three, four days, something like that. I do remember coming to, it was probably two or three days somewhere at the end of that period.

The stories that you won’t hear from most arc flash guys are like the PTSD stories or the ‘I’m at a hospital bed and it’s a nurse change and there’s nobody around and I’ve got a 105-degree temp and I’m about to crap on myself and there’s nobody around to help me and you’re just like ‘hey’ there’s no button. And you’re like ‘hey’ you know and you crap on yourself.

Those are the stories you don’t hear about when guys aren’t in the hospital beds. It’s the stories you can’t work in that field anymore it’s these kinds of things and we talk about that later. But anyway, so yeah, I remember kind of coming to, had a bad fever uh infection is almost 100 guaranteed with burns because it’s just an open organ essentially. It’s open sores uh so you catch stuff. Especially guys that jump into ponds or stop drop and roll in the dirt you know whatever. So that hospital stay was largely just me being high on you know painkillers and getting a feeding tube as they don’t want you eating so they’re just feeding tube you and uh IV your liquids and you’ve got a tube stuck in your you know what and you’re peeing in a bag and it’s pretty uncomfortable.

And after a couple weeks you know, you’re ready. They got me into, I’m gonna say I had surgery I think on the fourth or fifth day because they go and the skin starts dying so they have to go pretty quickly and make that skin fresh cut it off your legs and stick that new one on there and staple it on.

Then they put you in and they were trying some new things, put my hands in bandages like this so that it would stretch and so you’re in there for days like that. But probably day six they unbandage me and I’ve got pictures of that you know that was the day they unbandaged me. And uh almost immediately they start getting you into therapy and also trimming excess skin that’s not sticking so every day you’re in there they’re snipping pieces of skin off that are tags that are hanging up that aren’t attaching or they didn’t attach. It’s still raw too so every day was that and then you know I could move my hands like this you know when I first got you know even after having this they just open and I couldn’t you know couldn’t bend. Real swollen you know that kind of stuff so uh recovery in the hospital was you know slight because the real work is for months after that you know. One thing I can tell you too is they use a yellow uh Vaseline covered kind of a canvas, uh Baxter band I think maybe is the name of it, but unfortunately my skin grew into it as they had that on there so part of my worst memories in there’s sitting under a sink and having to tear this off of a burnt hand.

It was stuck in my skin and it healed in there already and I just, oh my god it’s one of the worst. It’s probably my worst memory in there is dealing with that.

So, another thing uh that’s probably my most vivid memory of being in the hospital secondly is having to have nurses come in and wipe your butt. Your hands are, you can’t you can’t even take care of yourself you’re in there you can’t take a leak on your own you know. When they finally did pull a catheter out which again is another memorable moment uh that’s brutal. That is brutal.

So, you know there was just, starting from the hospital out you know there was trying to button shirts and put pants on and you can’t drive and you’re stuck at home and you know you’re pretty much a burden. And again, this is just 14% man. This is hands and face this isn’t arms this isn’t legs I mean my legs hurt uh you know from the graft site that was super painful but not permanent but super painful. Like I can’t even, it was worse on my hands just the graph sites so it’s 14% you know.

I got a fat head so I’m not sure how much of it was here opposed to here but you know it stops at the wrist right here on each side just past my watch and then face. Now face I didn’t get a, it largely was not third degree, I was largely just a deep second and with little spots you know of stuff where my hands were totally smoked. I mean second degree burns on my palms and then third on the back. You know the required skin grafts throughout my entire back of my hands, it’s pretty intense I wouldn’t recommend it you know. I went right back to doing what I was doing you know. It didn’t scare me out of the field.

Some guys aren’t that lucky you know. They you know they can they can lose a lot. Some of the things I tell people is you know you don’t expect the you know getting your butt wiped by nurses you know or helping people dress you. But like me, I had a wife, two kids – still do you know. When you lose the ability to support your family, as a man and speaking as a man, that’s a killer man it is not just a physical injury, it is a mental and emotional injury as much as anything.

So you can carry PTSD you know with you from explosion injuries uh but man if you can’t go back to work, and you just you’re sitting around you know I mean its depression is a major deal when you were injured and you can’t go back to work. You can’t get away from an arc flash. It’s too fast it’s instant. You get burned. You’re done. Yeah it’s an instant thing. It’s an instant mistake that you can’t, you can’t change.

So I’m Jason Brozen, got arc flashed over 10 years ago and the one point I’d tell you is don’t be me.

Plan your work – work your plan. Follow through with that plan and do not make exceptions on anything when it comes to safety.’

On LinkedIn, Jason said of his experience ‘Recently I have had a lot of exposure to my arc flash story. One thing that is misunderstood is how intense the instant heat is. Here is a picture of my watch that I was wearing. An arc flash only takes a split second to ruin your life and possibly your family’s. Do not take chances. You have the right and responsibility to turn it off. If not for you, do it for your family, your employer, and your customer.’

The watch Jason was wearing when the accident occurred.

PROGARM, THE ARC FLASH SPECIALISTS

Arc Flash Protection | Arc Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Helmets | Gloves

Thorne and Derrick distribute a range of LIFESAVING Arc Flash Protective Clothing from ProGARM – the leading UK manufacturer of high quality Flame Resistant & Arc Flash clothing, garments and workwear.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

“At ProGARM our mission is protect lives through the manufacture and supply of exceptional quality Arc Flash and Flame Resistant Clothing. Being the only specialist Arc Flash protection manufacturer in the UK we focus on providing the best protection possible to those who work at risk of Arc Flash on a daily basis with our inherent, specialist garments and industry-leading innovation. Supporting Utilities, Power Generation, Rail & Petrochemical industries we work with Thorne & Derrick to educate, inform and supply those who work at risk everyday allowing us to keep protecting lives throughout the UK & beyond.”

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Closing Thought – statistics show that between eight and ten arc flash accidents occur in the UK every week. Protect yourself, contact us to learn how.