Blog

Arc Clothing & Flame Resistant Clothing – What Is The Difference?

July 6th, 2021

Arc Clothing & Flame Resistant Clothing

Many people ask if flame-resistant (otherwise known as fire retardant) protective clothing is the same as Arc Flash protective clothing.

While all ProGARM Arc Flash safety clothing is flame resistant, not all flame-resistant clothing would provide protection in an Arc Flash incident.

To be as safe as possible, it’s crucial you wear the right type of protective clothing, appropriate to the nature of your work and your task risk assessments and method statements.

WHAT’S THE DIFFERENCE BETWEEN FLAME-RESISTANT AND ARC FLASH CLOTHING?

At ProGARM we recognise that there’s a huge difference between clothing that can resist fire and garments that are designed to protect the wearer from the intense burst of energy released in an Arc Flash incident.

For example, in a room containing around 21% oxygen (the average for normal air), temperatures five feet from the floor can be over 300°C in a fire.

Even if the environment contained a combination of pure Oxygen and Acetylene (through an explosion of a welding torch canister for example) the hottest fire it would cause is one that burns at around 3,000°C.

To survive a fire in those kinds of temperatures safely, it’s perfectly true that you would need high-quality flame resistant clothing.

But this kind of temperature pales into insignificance compared to the 19,000°C of an Arc Flash explosion that can reach people working up to six metres away within fractions of a second.

An Arc Flash happens when a short circuit or electrical discharge creates an arc of electricity moving through the air in a potentially fatal intense flash of energy – often through a cable strike, a dropped tool or a circuit fault.

In that split second, the temperature can become as hot as the surface of the sun, a pressure wave can throw workers across a room, a sound blast can rupture ear drums and the brightness can cause damage to your eyes.

PROTECT YOURSELF AND YOUR TEAM

FROM BOTH ARC FLASH AND FIRE RISKS

It’s for these reasons that anyone working in live electrical environments – even environments of low voltage – should have personal protective equipment and clothing that can provide a potentially life-saving last line of defence.

We extensively test all the individual materials – the fabrics, threads and components (such as zips, press studs and Velcro® fastenings) – that we use in our ProGARM clothing against such Arc Flash incidents.

It’s often the difference in standards of the individual parts which are the biggest differentiator in Flame Resistant and Arc Flash safety wear.

By using components that stay intact and don’t melt, the garment can be removed more easily from someone caught in an Arc Flash, making it possible to administer life-saving first aid more quickly.

But we don’t end there. Once we’ve made the garment, we test the finished item again to make sure it remains intact after being exposed to an Arc Flash.

While flame resistant garments may provide some protection in an Arc Flash incident, they’re not specifically designed and manufactured to stand up to the intensity of it and are likely to be inadequate.

We lead the way in Arc rated safety clothing, testing to either the Open Arc Test Method or the Box Test Method to make sure they comply with Arc Flash safety standards. It’s through these tests that the significant differences in Flame Resistant and Arc rated clothing are revealed.

If you want to speak to one of our sector experts about our Arc Flash and fire-resistant PPE, including how important user acceptance testing for Arc Flash PPE is, give us a call on +44 (0) 191 410 4292 to speak to a specialist member of our team for guidance.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- RIS-3279-TOM | The Orange Range of Arc Flash Clothing & Standard Overview

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Electrical PPE | When Will ProGARM’s Electrical PPE Gain UKCA & CE Certification?

July 6th, 2021

Electrical PPE | When Will ProGARM’s Electrical PPE Gain UKCA & CE Certification?

Electrical PPE

UKCA & CE Certification

Anyone responsible for safety garment procurement decisions has a responsibility to make sure the Electrical PPE products they’re buying are suitable for the risks their workers face.

To help you decide which supplier’s protective garments are the best to meet the flame resistance or arc flash safety requirements you need, you should request and compare each supplier’s certifications.

Here are 3 initial points to consider:

1. How Do I Know the Electrica PPE I’m Purchasing Has The Relevant Certifications?

The rigorous process for being awarded the EU’s Conformité Européenne (CE) mark or UK Conformity Assessed (UKCA) mark is identical, but it’s a legal requirement to have the right certification. Manufacturers operating responsibly and within the law will have a Module D registration. This is what can give you confidence you are buying quality products as it will only be issued by a Notified or Authorised Body after substantial checks. For products to have a UKCA or CE mark, the manufacturer must have a Module D registration.

To be certain the garments you’re considering have the relevant certifications, ask to see the Declaration of Conformity. This will tell you all of the standards the garment conforms to (known as Module B), as well as containing details of the Module D manufacturer’s registration. If you’re in any doubt about the authenticity of the documents you’re given, check with the Authorised or Notified Body directly.

Since 1 January 2021, all safety garments and Electrical PPE placed on the market in Britain must have obtained the UKCA mark (although until 1 January 2022, products placed on the market before that date may still display only the CE mark). The care label may carry the CE mark as well if the supplier markets the same garment on the continent.

2. What Does The UKCA or CE Certification Tell Me About The Product?

All hazards are categorized according to the level of risk they present. Safety products which protect against the lowest level of hazard (category 1) include items such as kit only designed to be waterproof.

For this low hazard category, suppliers can self-certify the product’s conformance with safety standards. However, they must still do all the same safety testing first and be able to provide all the appropriate evidence to support this, if an authorised body requests it.

Items deemed appropriate for medium to high level hazards (referred to as category 2 and 3 hazards) must go through what’s called a Notified Body for CE marks, or Authorised Body for UKCA marks, to be certified.

In these circumstances, the UKCA/CE certification tells you that an independent body (which has been officially accredited by the Government/EU) has completed a rigorous assessment process, known as Module B Type Examination, that verifies the product’s safety claims stand up to scrutiny.

3. How Do I Know Which Product Is Best?

As you would expect, the UKCA/CE certification process is robust and thorough. And, as no two garments from different companies are identical, the test data and certifications will be unique to the supplier and garment type.

Due diligence is an essential part of the procurement decision making process, so it’s vital you see the Declaration of Conformity for each product you’re considering and take the time to compare them in detail.

WHAT WILL THE UKCA OR CE CERTIFICATION TELL YOU?

Even after the lengthy process of research and development, followed by extensive safety testing of both the garment as a whole and the individual elements, the process to secure a CE or UKCA Type B Examination certification can still take a further 3-9 months.

To achieve certification, we prepare and submit a detailed specification file for each garment and send this to the accredited Notified Body. This file must contain:

- Details of what the garment or Electrical PPE is

- What it looks like

- How it’s constructed

- A detailed description of features (such as any pockets or belt loops, their design and where they’re placed)

- A full list of all the materials used (including the exact fabric(s), stitching thread(s), fastenings, other components, and the care label)

- All safety test data for the product

- Where the product is manufactured

- User information

- Essential Health and Safety requirements

- Risk assessment

Electrical PPE | Protecting People Against Arc Flash Incidents

In addition, we also send our product packaging and any user information/guidance sheets we would send to customers with the item.

We must also provide a list of each safety standard (and to what specific level) we claim the garment or Electrical PPE can meet (and all the test data to evidence this) along with quality assurance process information, evidenced by our Module D Certificate, which demonstrates every garment of the same design will be produced to the same standard.

Finally, we enclose the design for the product’s care label which, by law, must include all the certification markings and standards, including specific details about the performance levels against each standard.

The role of the Notified/Authorised Body is to inspect this extensive file of information and make sure they are 100% satisfied the garment meets the requirements of the standards and the PPE regulations before they will provide the appropriate certification marks.

Their inspection is an iterative process and one of the reasons it can take so long to achieve certification is because they can provide challenge at any time as part of their assessments.

If they believe any information is insufficient or missing from the pack (such as test data), or they believe the label isn’t clear, or they need more information about anything (such as more detail about the fabrics used), they revert to the manufacturer to provide this information before they will complete the certification process.

Ultimately, the certification acts as an official verification of the safety claims a manufacturer makes about a specific product and it’s therefore a vital consideration for buyers as part of the procurement decision making process.

NO NEED TO COMPROMISE

If you’re looking to increase arc flash protection for your team and you’re not quite sure what you need, please feel free to contact us.

We work tirelessly to understand industry specific risks and are more than happy to help.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

- The Hidden Risks of Breaking Ground | Protecting Against Arc Flash

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and Electrical PPE.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

July 6th, 2021

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

Cable Pulling & Laying

ABB manufactured, installed and commissioned the 400kV cable for the National Grid’s largest ever tunnelling project, called ‘The London Connection’, a 20km long 400kV underground cable to supply central London which was energised in 2005 and which was at the time one of the longest 400kV underground cables in Europe.

The need

With electricity demand in North West London and the City increasing twice as fast as the national average and projections showing that this growth would be sustained for a decade, National Grid set out a project called The London Connection designed to create a three phase high voltage supply for North West London and the City.

Essential to National Grid’s future licence to operate, the connection linked Elstree to St John’s Wood through a new three metre diameter, 20km long tunnel to a new £60 million substation, also constructed by ABB.

Project details

ABB manufactured a total of 61km of high-voltage cable using cross-linked polyethylene (XLPE) insulation technology, which eliminates the need to use old-fashioned oil and high maintenance gas filled cables. A similar ABB 400 kV XPLE underground cable has been in service in Berlin since 1998.

The cable was manufactured at our own plant in Germany and underwent a one-year duration test at an independent test facility, where it was signed off as fit for purpose.

Three phase HV AC cable installed in the tunnel

ABB supplied 150mm diameter cable for three 20km lengths – one for each of the three phases of the supply. At a total weight of 2,440 tonnes, the act of pulling the cable along the length of the tunnel was an element of the project that threw up significant challenges.

ABB delivered the cable to site on 63 massive separate cable drums and pulled it through the tunnel in three sections at intermediate shafts along the length of the tunnel, with the longest cable pull being around 7.5 km. ABB used a special arrangement of cable pulling equipment for the safe and smooth installation through the tunnel. A post-pulling cable insulation test proved that the cable was ready for safe service as part of the grid.

As a full turnkey project, ABB’s successful installation of the cable and connection to the new St John’s Wood substation meant that the London Connection was ready for National Grid to operate in summer 2005 and it has been in operation providing energy to London consumers ever since.

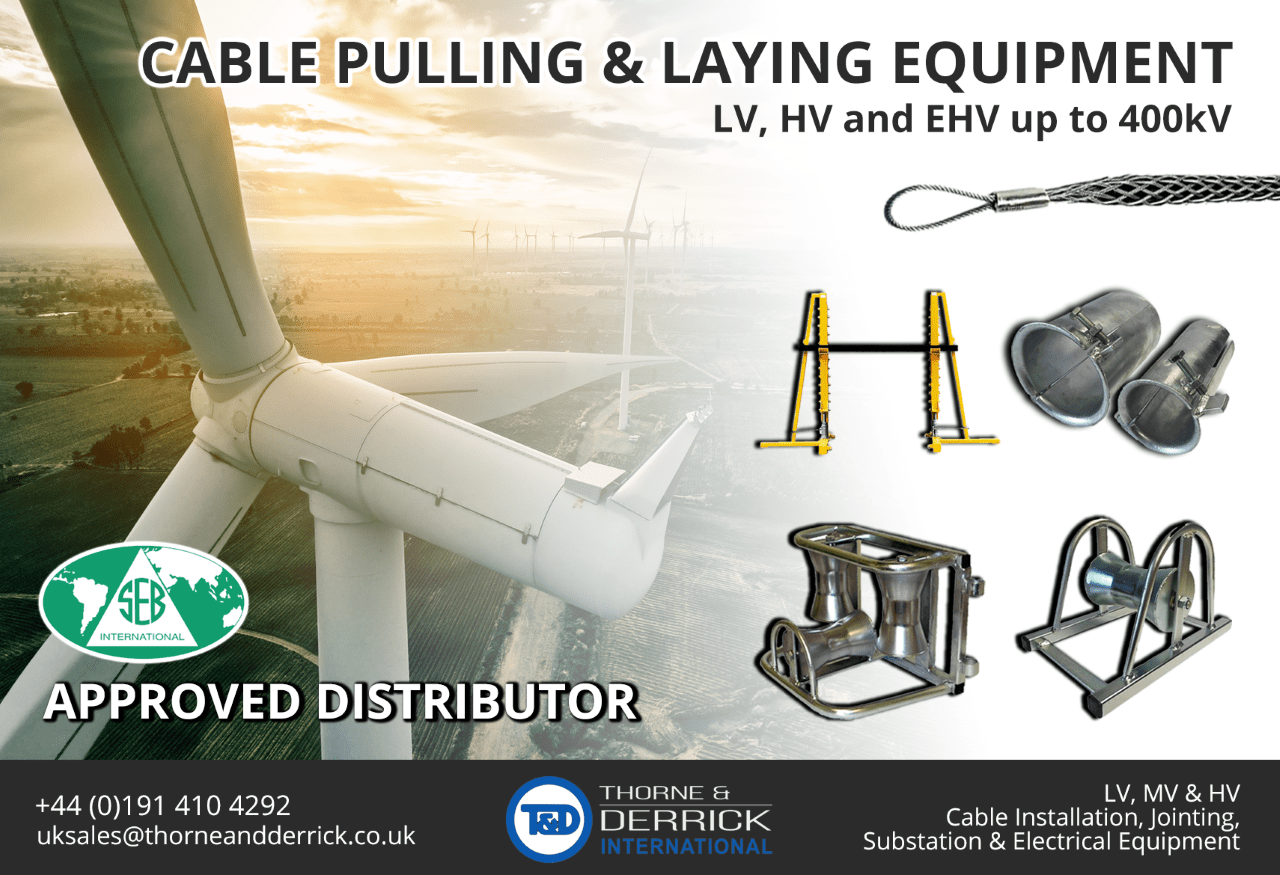

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.

How Important Are Wearer Trials When Buying Arc Flash PPE?

July 6th, 2021

Arc Flash PPE from ProGARM

In a heavily regulated world where garments have to be tested to incredibly high standards, people specifying arc flash clothing and PPE would be forgiven for relying only on the test results when making their decision.

But those results are just one part of a large jigsaw of information you need when making a purchasing decision. How your team feels about wearing the kit should also be part of the puzzle. But how important are wearer trials for Arc Flash PPE?

ProGARM Arc Flash Hoodie

MEETING MINIMUM ARC FLASH PPE STANDARDS

To do its job properly – and potentially save a life – Arc Flash PPE has to meet the standards set out in IEC 61482, the international standard for Arc Flash and flash fire hazard protection.

All our garments will have been tested using either open arc or box tests, and will have been given a Cal Rating, which can be cross-referenced with the Arc Flash Study and risk assessment for the task it’s needed for.

But tests don’t tell the full story.

Of course you need to ensure your PPE meets the criteria you need it to, but if you’re looking at kit from three different suppliers which can all meet the standards you’re looking for, how will you make a final decision? Wearer trials are a great way to inform that choice.

WHAT IS A WEARER TRIAL?

A wearer trial gives people in the field the chance to try out the PPE and garments that you’re considering purchasing while actually doing the job. It means they can experience what it’s like to wear the jackets, trousers, polo shirts and other garments while performing the tasks they are expected to.

When trialling garments ask for feedback about comfort, fit, whether the wearer can move, bend and stretch the way they need to for the tasks they do. Ask whether there are enough pockets, and are they in the right places? All of these factors are important as the kit needs to not only protect from hazards but enable the wearer to get on and do their job.

Arc Flash Helmets & Visors | Helmets & Visors for Protection Against Arc Hazards

WHY ARE WEARER TRIALS IMPORTANT &

HOW DO THEY MAKE YOUR TEAM SAFER?

PPE needs to enable people to do their job, while giving them protection from hazards. But it is only as good as their willingness to wear it properly.

For any Arc Flash protection garment to do its job effectively it must be worn properly buttoned or zipped up so that parts of the skin aren’t exposed to a potential Arc Flash blast, which could lead to a whole host of injuries. That’s why we take great care in the cut and fit of all our garments and include what might seem like small details to make our garments very comfortable. One example would be on our jackets where we have added a soft comfort strip at the top of every zip so it doesn’t rub the chin or neck.

Another would be knowing that a lot of the tasks our wearers have to undertake involve kneeling down, so we’ve created pockets for knee pads in our trousers and coveralls.

And while the majority of our end users are men, we also have a women’s range which isn’t just a shrunk down version of the men’s garments. We’ve carefully created new patterns so that our kit for women fits properly.

So, while your new Arc Flash PPE has to meet the criteria set out in your risk assessments, this isn’t the only information you should rely on when choosing new kit – wearer trials are a crucial piece of the puzzle too.

If you want to speak to one of our sector experts about our Arc Flash and fire-resistant PPE, including how important user acceptance testing for Arc Flash PPE is, give us a call.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

The Trackside Conduit

July 6th, 2021

-

Special thanks to Paul Darlington from the Rail Engineer magazine for kind permission to republish this article

Data connectivity is vital for all aspects of society and industry, and is becoming increasingly important for railway operations. Signalling, electrification control, fixed and radio communications: all rely on cables running alongside the railway.

However, the integrity and value of these rail cables is only as good as the protection offered by the lineside cable route. Often overlooked or taken for granted, it is vital for the safe, efficient operation of any railway.

The primary function of any form of cable route is to protect the cables within.

Ideally it should provide mechanical protection, so it must be robust and stable, fire and vandal proof, capable of being opened and closed to maintain the cables or run new ones, be cost effective and safe to install, and require minimal maintenance.

Cable routes can be constructed from a variety of materials and come in different sizes and shapes. Transition modules may be required along with ‘T’ junctions, bends and joint bays.

All these requirements are not easy to achieve and can conflict. An assortment of route types have been used over the years and the search for an ideal cable route is never ending.

An evolutionary approach

The first types of cable routes were open copper wires raised on wooden poles. With the introduction of overhead electrification, signalling and telecoms cables were run at ground level in some form of cable containment. On the majority of non-electrified lines or those with conductor rails, cables are now provided at ground or sub-surface level.

Wooden cable routes were used initially, but these soon rotted and have not been used for many years. Asbestos cable routes mounted on posts were then provided, but these didn’t offer much mechanical protection and introduced a health and safety risk.

One of the more successful systems was concrete ground-level troughing, generally known as GLT. With detachable lids, this has been used for many years and is supplied in various sizes, generally in 1m lengths.

It provides reasonable mechanical strength, although the natural walkway it forms encourages its use as a lineside pathway. It was not designed for this purpose and a misaligned lid can easily cause injury if walked on.

The weight of concrete troughing gives it reasonable stability, but makes it difficult to handle manually and its installation can require extensive possessions for off-loading.

Deeper and higher ballast shoulders have, in places, transformed the troughing into ballast retaining walls or totally burying it. Any displaced alignment may put strain on the cables within and make it even more hazardous to walk on. While concrete troughing is reasonably inexpensive for the protection achieved, it is costly to install with manual labour and requires frequent replacement of damaged lids

In the 1960s, to obviate many of the disadvantages of the precast concrete route whilst retaining its inherent advantages, a continuous slip-formed concrete route was trialled. A train with an earth plough formed a trench alongside the track. Concrete was then discharged from the train into the trench, after which the train made a further pass with a plough to create a trough in the concrete. Once dry, precast concrete lids were off-loaded.

This method removed much of the manual labour involved in construction, but required a site with soil suitable for the earth plough, precise control of the concrete mix consistency, accurate rate of discharge into the trench and consistent train speed. It was also found that an unplanned thunderstorm turned a near-finished length of route into a disaster area! The trial was abandoned.

Buried cables

In areas of theft risk, cables can be buried directly in the ground at a depth providing adequate protection. Installation is generally required immediately after the trench has been dug as heavy rain can collapse it prior to backfilling. Alternatively, a duct system can be buried prior to the cables being pulled through or, in the case of fibre cables, blown through with compressed air.

Any buried route is expensive to install – particularly with manual labour – and may require rail-mounted machinery for excavation. Gaining access to the cables requires careful selection of the breakout point locations, together with jointing bays. The chosen cable must be suitable for direct burial and it is not easy to subsequently connect into the cable route.

Another method of direct burial is by utilising a rail or vehicle-mounted mole plough.

This is a hydraulically controlled plough blade, with the cables fed through trackside conduits in the blade.

In the right situation the method has some advantages, but large cables can present problems as certain types of soil do not consolidate and can leave a damaged embankment or cess. The method requires careful planning and preparation, with robust buried service checks prior to the cable-laying.

It only takes one old signal base to break the plough and seriously delay the programme. In locations with sharp stones, additional cable protection is required with sheathing or sand backfill. However, ploughing small fibre cable ducts could be an answer for the future. We’ll come back to that later.

Plastic routes

Over the years, various sorts of plastic cable routes have been trialled for lineside cable containment. Unfortunately, they have generally not provided the required mechanical strength, especially when faced with ballast alongside the route. Plastic also contracts and expands as the temperature varies and it is not easy to incorporate adequate expansion mechanisms.

Railtrack had some success installing a 100mm plastic surface pipe with thermal expansion mitigation which was staked into the ground every few metres. This provided protection to a telecoms cable running between signal boxes on rural routes and is still in use 25 years later. This wasn’t suitable for larger volumes of cables on main lines and it wasn’t easy to provide regular cable breakout points.

Recycled polymer

Over the last ten years, cable routes made from 100% recycled polymers – such as polypropylene – have been introduced which offer similar high strength and impact resistance to traditional concrete, but are approximately five times lighter for the same size and far easier to cut.

A further enhancement – building on the problem of walking on narrow concrete lids – was the introduction of a combined cable route and safe walkway, also made from recycled polymer. Two routes with the equivalent capacity of two concrete troughs were located under a 700mm wide non-slip surface. The lids were constructed so that cables could be laid with half the route open. Fixings were also provided for a removable handrail and the ability to secure the lids to the troughing to deter cable theft.

Following removal of the lids for installation purposes, there have been reports of a route’s sidewalls being deflected inwards due to the weight of the adjacent ballast, preventing the lids being replaced correctly.

This caused the lids’ outer edges to be unsupported and move unexpectedly under the weight of footfall, thus creating a trip hazard. This illustrates the need for maintenance of all cable routes and, in this case, to ensure the lids were securely attached to the sidewalls and not displaced from their correct positions.

Elevated troughing

In cuttings susceptible to slippage, the toe cannot be excavated to accommodate a trough or buried route, so an elevated troughing route may be required, mounted on posts which only interfere with the soil formation at a minimal number of points. As well as early use of asbestos, elevated troughing has been constructed from a variety of materials over the years including timber, cement, glass-reinforced plastic, metal, recycled polymer and glass-fibre reinforced concrete (GRC).

Many elevated routes lose their alignment during their lifetime due to movement in the soil foundation and are particularly prone to damage as they form an obstruction to track work and make natural seats. Nevertheless, elevated GRC routes have, in particular, been widely used and are easy to transport and install.

Theft & vandalism

Vandalism and theft of copper cables have produced particular problems. Concrete routes may require lids to be fixed with metal clips or epoxy adhesive to deter theft.

In high-risk areas, cables have been sealed into GLT with concrete, but this is generally not recommended as cement can harm some cable sheath types and filling the trough route with concrete makes it unusable for other cables.

It is also expensive and labour intensive. Putting blobs of concrete in the trough is not good either as thieves have been known to cut and steal the intervening length, making it difficult to run a replacement cable.

Buried routes are quite effective as a deterrent if sufficient depth is maintained and the soil is well consolidated, although it has proved necessary in some locations to anchor the cables to prevent them being pulled from the ground using road vehicles.

Fibre cables – Trackside Conduit

When the national fixed telecoms network was deployed by Network Rail, a heavily armoured variant of the normal armoured optical fibre was chosen to deploy without any cable route. This was known as Double-Insulated Super Armoured Cable or DI-SAC which was approved for use where only optical fibre cables were required.

DI-SAC comprised 24 single-mode optical fibres divided equally into two stainless steel tubes, helically wound around a solid aluminium former, encased inside a medium-density polyethylene inner sheath and thick steel-wire armour, with a green over-sheath of fire-retardant ethylene vinyl acetate.

In walking areas and those prone to vandalism, DI-SAC was scratch-buried so it did not protrude above ground level. Nominally, it was secured into the ground every 40m, but this distance varied to prevent the DI-SAC being pulled onto the track. Its use without a cable route was questioned by many in the industry, but it saved the national fibre project several hundred million pounds. The cable was specially made in high volumes and is no longer commercially available.

Blown fibre

Fibre optic technology has now become the norm for telecoms transmission as it provides huge data transmission capability, solves the problem of inductive interference with long distance copper cables and has no theft value.

Fibre cables were traditionally installed in concrete trough routes in lengths of up to 2km. Selected fibres would be broken out to connect to the digital transmission equipment. Originally, such equipment would use local copper cable tails to provide connections to equipment such as telephones, data terminals, radio base stations and signalling interlockings.

With the introduction of all-IP (internet protocol) networks, fibre-borne digital signals right to the end device are now becoming the norm which has led to the concept of ‘blown fibre’ as an option.

This involves a composite material pipe incorporating several ducts of different sizes being installed either on the surface or buried. Bundles of fibres can then be blown into the duct using compressed air and further bundles can be similarly installed into different tubes at a later date, as required.

One drawback of normal routes is that new cables tend to be laid on top of existing cables in the route. When new signalling or telecom systems are brought into use, the redundant cabling remains in place and the trough becomes over-full. With fibre blowing it is relatively easy to remove fibre bundles and replace them should this be required.

Conventional troughing routes and copper cables are far larger than the blown-fibre solution and more expensive to install. As the blown-fibre duct can be coiled and directly ploughed into the ground using smaller machinery, it may be more cost effective and flexible than traditional buried routes.

Blown fibre has been trialled in Scotland for lineside installation, but is yet to receive national approval due to concerns with route expansion. At the very least, blown fibre may be a good option for fibre in buildings and stations.

So, the search for the ideal cable route and trackside conduit continues in order to maintain the integrity and value of the vital cables which support a safe, efficient railway.

Original Source Rail Engineer Magazine article written by Paul Darlington

About Rail Engineer

Rail Engineer is the leading independent quality monthly magazine for engineers, project managers, directors and leading rail executive decision makers.

Besides publishing the latest up-to-date rail engineering news, our team of engineer writers report on the engineering and technical aspects of many of the major projects being undertaken day in, day out, above and below ground, and across the globe.

In the UK we work in close consultation with Network Rail, Docklands Light Railway and the Underground, where our team of rail engineers actively visit the project sites, meet project engineers and provide in-depth analysis on the engineering skills being used and the latest innovations.

From trams and fleet refurbishment to new rolling stock and high speed rail, the rail engineer reports on the engineering and environmental challenges for manufacturers and operators. Our engineers visit factories and depots, meeting with specialist engineers to bring you the latest engineering updates on all aspects of rolling stock, whether onboard technology or mechanical enhancements focussing on safety, energy and the passenger experience.

To Subscribe Click Here

RAIL ENGINEER MAY / JUNE 2021

View the latest edition below or click the following link where the original The Trackside Conduit Article can be found https://www.railengineer.co.uk/rail-engineer-may-june-2021-hs2s-largest-bridge-decarbonising-scotland-and-piccadilly-line-trains/

Thorne & Derrick

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

GRP Cable Trough | GRC Cable Trough | Concrete Cable Trough | Cable Ducting