Cable Jointing Tools

Thorne & Derrick Working With JDR Cables | MV Jointers Tool Sets

January 7th, 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

Thorne and Derrick, the UK’s Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt have provided customised MV Jointers Tool Kits to JDR Cable Systems – JDR based in the UK are world leading cable manufacturers for high performance subsea and power cables for the renewable energy sector.

The Jointers Tool Kits are designed to provide their jointers with the specialist  tools needed to prepare inter array cables prior to the installation of joints, terminations or connectors to the highest standard – included in the customised tool sets are tools to enable the removal of the cable outersheath, insulation (XLPE) and semicon screens.

tools needed to prepare inter array cables prior to the installation of joints, terminations or connectors to the highest standard – included in the customised tool sets are tools to enable the removal of the cable outersheath, insulation (XLPE) and semicon screens.

Housed in Peli Protector Cases – these are rugged crushproof and waterproof cases to provide protection to the tool sets when in transit.

JDR Cables has an impressive portfolio of Inter Array Cable Termination and Test work up to 66kV.

Using their own Approved Tools & Equipment to complete all aspects of the work scope allows JDR to guarantee  the quality and consistency of tooling.

the quality and consistency of tooling.

Expertise comes from their in-house MV Jointers and Fibre Optic Technicians.

Field Services, part of JDR’s Renewable Energy Product and Installation Services group, supports the renewables industry; from project installation consultancy, to pre-commissioning, with full product life cycle support including repair and maintenance.

Market Leading Precision Engineered Cable Preparation Tools for Medium & High Voltage Power & IAC Cables

https://www.jdrcables.com/product-and-installation-services-4/

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

THORNE & DERRICK | LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Nexans Euromold | 3M Cold Shrink | Pfisterer Connex | Alroc Tools Stockists

US02 Utility Cable Tool for Semi-Con Shaving MV HV Cables by Ripley

September 17th, 2019

US02 Utility Cable Tool for Semi-Con Shaving MV HV Cables by Ripley

US02 UTILITY Cable Tool

The new Ripley US02 adjustable cable semi-con shaving tool quickly and easily removes bonded semi-conductor layers from MV to HV power cables (5kV to 33kV) on end and mid span cable preparations.

The Ripley Tool’s compact and adjustable design accommodates a wide range of cable diameters (18 to 60mm) and semi-conductor thickness of up to 2.4mm.

The unique blade shape preserves the smooth surface on MV-HV cable insulation, eliminating the need for deburring or additional surface finishing – the optimal stability design of the cable jointing tool securely supports cables with diameters from 0.71″ to 2.36″ (18 mm to 60 mm) throughout the shaving operation.

The cable cutting blade depth is easily adjustable in increments of .1″ to achieve the perfect depth.

The US02’s unique blade shape provides a smooth surface finish with a bevelled semi-con edge and eliminates the need for any additional features.

Engineered to improve workplace safety and cable preparation the US02 tool replaces the use of traditional cable jointers knives. The cable tool is ergonomic in design and increases efficiency by providing greater leverage and reducing hand strain.

Multiple contact bearings securely cradle the cable and provide stability throughout the shaving operation to ensure accuracy for preparing cables prior to jointing and termination.

Four speed positions optimise performance and a stop position easily squares of the edge without the need for an additional clamp. If necessary the factory set blade can be quickly and easily replaced.

The Utility Tool US02 is the fastest, safest and most accurate tool for removing bonded semi-con from MV HV power cables.

Ripley US02 Utility Cable Tool

US02 Utlity Cable Tool

Features & Benefits

- Compact design accurately removes semi-con within 1.18″ (30 mm) of the jacket on mid-span and end stripping applications

- Precision blade depth adjusts in increments of 0.004″ (0.1 mm)

- Adjusts for 0.71″ to 2.36″ (18 mm to 60 mm) cable diameters with semi-con thicknesses up to 0.095″ (2.4 mm)

- A revolving ergonomic handle & accessible adjustment knobs reduce effort & potential strain from repetitive shaving functions

- Stop position squares off the edge to complete the shaving operation without the need for an additional clamp

- Factory-set blade is easily replaced

| Cable Compatibility | Primary Distribution Underground |

| Cable Access | Mid-Span, End |

| Min. Cable Outer Diameter | 0.71″ (18 mm) |

| Max. Cable Outer Diameter | 2.36″ (60 mm) |

| Min. Voltage | 5 kV |

| Max. Voltage | 35 kV |

| Insulation Thickness | Up to 0.095″ (2.4 mm) |

| Material | Aluminum |

| Length | 6″ (152.4 mm) |

| Weight | 1 lb 8.6 oz (698.5 g) |

| Replacement Blade Part # | US02-7501 |

Compatibility

| Tool Part Number | Cable Voltage | Cable Size ø | Semi-con Thickness | Chamfer Angle | Replacement Blade Part |

| US02 | 5kV to 35kV | 0.71″ to 2.4″ (18 to 60 mm) | Up to 0.095″ (2.4mm) | 12″ | US02-7501 |

|

|

|

|

| Unique blade shape leaves surface of insulation extremely smooth | Extra rollers provide tool stability on a range of cable sizes | Winding pin keeps semi-con strip from getting in the way | Equipped with four speed positions to optimise performance |

RIPLEY US02 OPERATING INSTRUCTIONS

- The cable jointer should retract the cutting blade to its highest position by turning the blade adjusting knob counterclockwise

- Open the cable tool and locate the cable end at the taper transition on the blade. Secure the cable in the tool (Fig. 2a, 2b)

- Turn the blade adjusting knob clockwise until the blade touches the semi-con screen of the MV HV cable

- Set the feed lever into a stripping position. #1 is a conservative feed

- Rotate the tool on the cable. As the tool advances on the cable, observe the semi-con chip and re-adjust the blade depth for a minimal thickness of insulation removal and an optimal shaving result

- The feed lever can be re-positioned diagonally toward the #2 for a more aggressive feed or fully at the #2 for the fastest feed. The feed can be backed down by moving the lever diagonally toward the Stop position

- Observe the shaved semi-con strip during operation. During the shaving process, do not allow the strip to get caught under the cable rollers. This will disturb the shaving result. A convenient technique is to wind the shaved semi-con strip around the tool bar handle while shaving (Fig.3)

- Another option is to guide the strip around the shaved insulation using the winding pin. (Fig.4)

- After shaving to the desired length, move the feed lever to the stop position. Make one full turn to finish the shaving. Remove the tool from the cable

Ripley US02-7000 Operating Instructions

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

EPR Cable With Bonded Semicon Screen | MV HV Cable Stripping & Jointing Tools | Alroc CAMF4

July 2nd, 2019

Alroc Tools – Cable Jointing Tools (MV HV)

Video Demonstration: Stripping Bonded Semicon From EPR Insulated Cables MV HV

In the following demonstration video the Alroc CAMF4 tool is shown with the LFNS blade removing bonded semicon screen from medium voltage power cable with EPR insulation.

Thorne & Derrick International are specialist distributors and stockists of Alroc – high quality cable preparation and  jointing tools for use with medium/high voltage power cables.

jointing tools for use with medium/high voltage power cables.

T&D distribute Cable Jointing Tools from leading manufacturers including Alroc, Ripley, Boddingtons and Hivotec for all types of LV, MV or HV cable stripping, preparation and jointing requirements

THORNE & DERRICK INTERNATIONAL

LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment Distributors.

Cable Spiking High Voltage Cables – UK Power Networks

November 14th, 2018

Cable Spiking High Voltage Cables – UK Power Networks

- Information Courtesy – UK Power Networks

8.13 Procedure for Spiking Cables

Following the identification of a cable, the cable will then need to be spiked using a cable spiker to ensure that it is not Live at HV. The following procedure shall be followed:

- If the process has not already necessitated a Sanction-for-Test, then a SFT must be obtained from Control (A SFT cannot be issued for idle or abandoned cables that are not part of a network, as Circuit Main Earths cannot be applied)

- If the cable has been identified by signal injection, it is not necessary to disconnect the instrument and re-apply the Earth

- The consent of the Control Engineer must be obtained prior to spiking

- Spike the cable

- Call Control and ask if any alarms have been received

- Before the spiking gun is removed, at least one of the verification tests, given below, must be conducted

- Following a positive result of the verification test, the earths will be re-applied and remain applied whilst the spiking gun is removed under the SFT and under the Personal Supervision of the recipient of the SFT. (this does not preclude the option of the SAP to issue a PTW to remove the spike gun)

- Furthermore, under the same SFT and following the removal of the spiking gun, the cable may be opened and stripped for phase colour tests to be made under the Personal Supervision of the recipient of the SFT (this does not preclude the option for the SAP to issue a PTW to open and strip the cable)

- SFT to be cancelled and a Permit-to-Work shall be issued for work to commence on the cable.

Injected Signal Strength Verification

Listen to the signal on either side of the spiking gun.

The signal strength on the side on which the signal is being injected should be distinctly louder than that on the furthest side. This is because the spike driven into the cable will be providing a short-circuit route for the signal. Therefore much less signal, if any, will flow to the end of the cable where the circuit main earth has been applied.

Verification by Insulation (Megger) Testing.

Prior to spiking, remove all the Earths and megger the cable. The cable can be tested between phases and between phase to Earth.

The tests should show healthy insulation values.

After spiking, test the cable again. The results should show a faulty cable, thus proving that the correct cable has been spiked.

Why Must Control be Contacted Before Spiking?

It is a requirement of DSR 5.9.2.

The consent of the Control Engineer must be obtained before spiking, to alert their attention that an incorrect spiking may have occurred, if an alarm is received.

The Control Engineer also has a final opportunity to prevent the spiking, if a feeder trips on the network in that vicinity. The circuit may be required to support the load and so the job may have to be postponed.

Why Must Control be Contacted After Spiking?

It is a requirement of DSR 5.9.2.

The Control Engineer must be contacted after spiking, so that a check may be made for any alarms that could be linked to the spiking. The Control Engineer may need to check with other Control Engineers. This is because there have been occasions when cables have been incorrectly spiked and the alarm has been received and accepted by another Control Engineer and not communicated to the Control Engineer dealing with the cable spiking.

8.14 Spiking Requirements of Circuits Comprising of Single Core Cables

In normal circumstances the spiking gun should be applied such that all three cores are spiked. However in the following circumstances it is essential that all three cores are spiked:

- 11kV Networks with Arc Suppression Coils

- 11kV Networks fed from Unganged Fuses

- Pot / Stop Ended Circuits

General

There may be occasions [excluding (i), (ii) or (iii) above] where it is only required to work on one or two of the single core cables. It would therefore be undesirable to spike and damage all three.

If only one or two of the single core cables are to be spiked, then insulation tests before and after spiking shall be conducted, to confirm that the correct circuit has been spiked. It will be necessary to use an instrument that applies a sufficiently high voltage, to detect the damaged caused by the spiking. This is necessary, as the single core cables may be completely severed by the spike and may appear as an open circuit (and therefore healthy), if the voltage applied by the instrument is too low.

PICOUP 400 Hydraulic Cable Spiking & Cutting Tool

Cable Spiking & Cutting Tools | Check Voltage Absence on LV MV HV Power Cables

Hydraulic & Remote | Suit SWA Cables up to 140mm Dia | More info PICOUP 400

8.15 Re-location of point of work

Following the positive identification and spiking of a cable, it may be necessary to change the point of work after issuing a Permit to Work e.g. when dampness testing. This may be done, without reference to the Permit issuer, and without the need for further spiking, provided that the Permit holder can physically trace the cable by means of a running noose from the initial point of work, to the new point of work.

➡ Thorne & Derrick distribute Cable Spikers for low, medium and high voltage electrical systems, typically used to spike 11kV-33kV power cables – we provide competitive prices for cartridge and hydraulic type cable spiking tools from stocks to UK and international destinations.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Jointers Tools | 66kV Cable Preparation Tools | Some Recommendations

November 9th, 2018-

uploaded by Chris Dodds- Thorne & Derrick Sales & Marketing Manager

66kV XLPE Cables

Jointer Training & Tools

Thorne & Derrick are Specialist Stockists & Distributors of cable joints and terminations for 66kV power cables – this includes the provision of 66kV Jointer Training using Nexans Power Accessories UK facility. To support the installation of 66kV joints, terminations and connectors we stock and distribute a full range of Jointers Tools to enable the preparation of all critical stages of the cable stripping process – this includes removal of cable sheath, insulation XLPE, lead sheath and bonded semicon screens.

Manufacturers of cable preparation tools provide competing options in the design, functionality and application of their cable tools – it is usually a mixture of cable jointers personal preference and client approval which informs the tool selection process, nevertheless the following information provides guidance and some recommendations for tools to use when stripping 66kV cables.

Can I Use Standard 33kV Tool Sets To Prepare 66kV Cables?

Yes, but…..

Although 66kV is classed as high voltage, due to the construction diameters of 66kV cables often 33kV medium voltage cable preparation tools can be used – for the Nexans Jointers Training Courses the standard MV cable tools are compatible with the training cable up to 300sqmm at 66kV.

However, for future 66kV projects it would be necessary for the jointer to upgrade their tool set to enable the preparation of larger diameter cables above 300sqmm conductors.

Naturally, when using medium voltage category tooling there will be a requirement for the cable jointer to undertake additional glassing of the XLPE insulation to achieve the required chamfer prior to installing the MV HV joint, termination or connector.

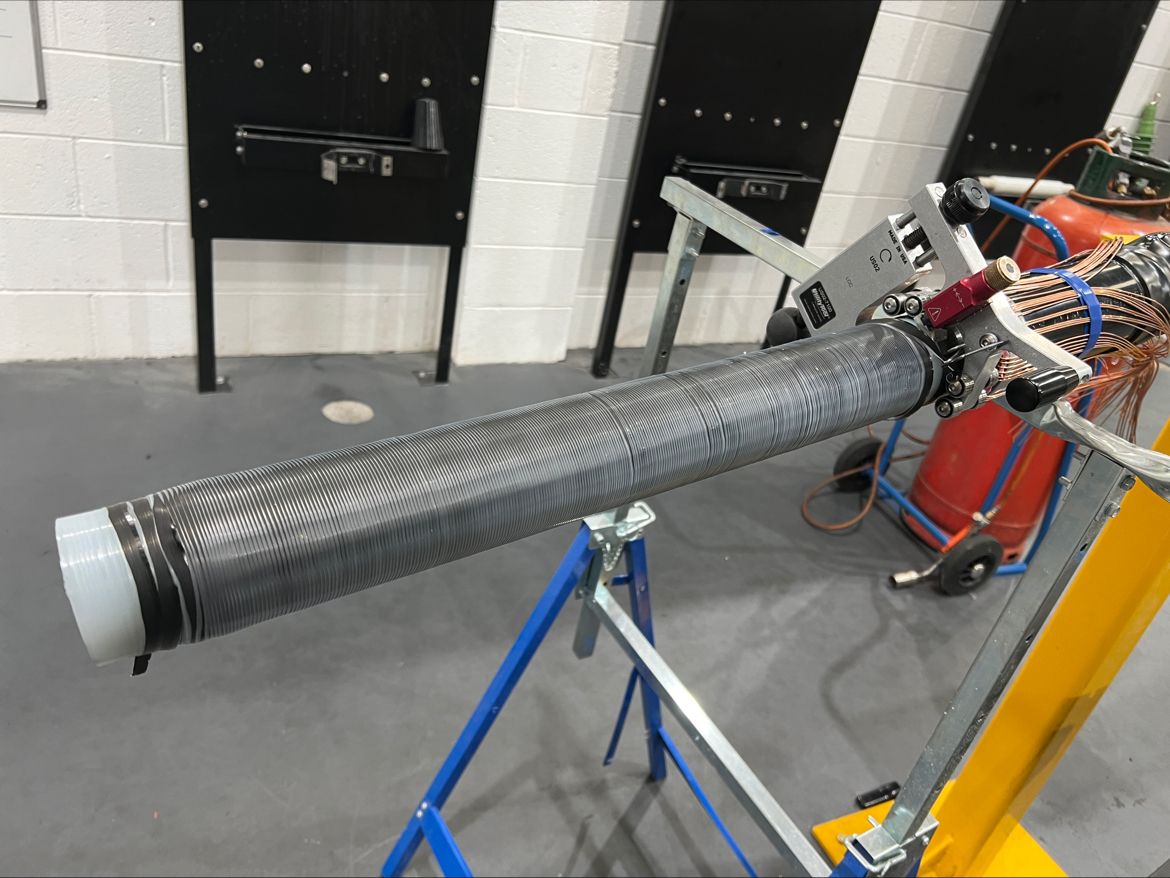

Cable Jointing Tools | 66kV IAC Inter-Array Cables

US02 MAX | here the Jointing Tool is shown here in use on the high voltage cable preparation of 66kV/72kV 1200sqmm single cable XLPE insulation with bonded semicon screen – minimal polishing and chamfering required with a clean and precise transition.

Cable Sheath & Lead Sheath Removal

Typically, Alroc cable sheath stripping pliers, PG types, would be used for removal of the outer cable sheath/jacket depending on the outside diameter of the cables to be jointed and terminated – these tools effectively strip the PE (polyethylene) sheath from medium/high voltage power cables. The lead sheath (Pb) is generally removed using jointers knives – the lead sheath should be carefully scored and then peeled from the cable.

Cable Insulation & Bonded Screen Removal

Note for larger diameter 66kV power cables, 300sqmm+, the standard 33kV cable preparation tools will be unsuitable – for removal of XLPE insulation with bonded screens we would recommend Alroc CAMF4/40-90 tool.

The 66kV Training Course utilises single core 300sqmm cables with a 48.1mm diameter over the bonded semicon screen – depending of jointers preference any semicon shaving tool from reputable manufacturers including Alroc, Ripley or Boddingtons could be used.

Similarly, any XLPE cable insulation removal tool suitable for 46.1mm primary insulation diameter cable could be used.

The preferred bonded screen stripping tool is used to leave various lengths of black insulation screen from the outer sheath cut and the measurement varies depending on the type of joint, termination or connector.

Chamfer | Groove | Shave – Alroc CAMF4/40-90-BBCF Multi-function 66kV Cable Tool

Chamfer & Polish

Aluminium Oxide

For the chamfer we would recommend the Alroc GRI tool along with conventional glass to achieve a smooth finish to the XLPE insulation – the cable insulation would then be polished using aluminium oxide abrasive strips, usually 180/240 grit and 400 grit.

The XLPE insulation must be polished smooth with an appropriate aluminium oxide grit paper until the XLPE surface is smooth and wrinkle-free. To finish this process, reverse the paper and “buff-up” with the smooth side.

Alroc GRI Tool

Cable Sanding Machines & Tools for MV HV Cables up to 130mm Diameter

Reducing Repetitive Strain & Improving Cable Preparation Processes

Typically 66kV Cable Specification

➡ The following cable specification is based on 66kV XLPE Insulated Lead Sheath Single Core 300sqmm cable to IEC 60840:

| Single Core Cable with Copper Round Compacted Conductor, XLPE Insulated, Lead Sheath, Polyethylene Oversheath | |

| 66kV Cable Code | 714242019533** |

| Standard Specification | IEC 60840 Generally according to NPS/002/022 |

| Type of Cable | XLPE/PB/MDPE |

| Rated Voltage Uo/U (Umax) | 38/66 (72.5kV) |

| Number of Cores x Nominal Cross-section | 1 x 300sqmm |

| Approximate Cable Overall Diameter | 59mm |

| Approximate Cable Overall Weight | 8.4kg/m |

| Nominal Drum Length (Tolerance) | 500m (-0%, +0%) |

Cable oversheath marking by embossing in two lines as follows:

- CABLEL 0317 2016 09* ELECTRIC CABLE 66000 VOLTS IEC 60840 1×300 CU ‘ref number’**

*Year and month of manufacture

** Insulation Core Lot number (8 digits by embossing and 2 last digits by indenting) - By ink – meter marking at on metre intervals

66kV Cable Structure

Cable Manufacturer Hellenic Cables S.A.

- Conductor:

Annealed bare copper round strand compacted class 2 BS EN / IEC 60228 of nominal cross-section equal to 300sqmm longitudinally waterblocked by waterblocking yarns and/or waterblocking tapes and/or waterblocking powder between conductor inner strands (approx diameter over 20.4mm) - Semiconductive tape applied helically with overlap

- Conductor non-metallic extruded screen:

Extruded semiconducting compound of 1.0mm nominal thickness (0.60mm minimum at any point thickness) - Insulation

XLPE super-clean according to IEC 60840 of 12.0mm nominal thickness (minimum average thickness of 11.0mm, minimum at point thickness 10.80mm – approx diameter over insulation 46.1mm) - Core non-metallic extruded screen:

Extruded semiconducting compound bonded to insulation of 1.0mm nominal thickness (0.60mm at any point of thickness) - Semiconductive waterblocking tape applied helically with overlap

- Metallic sheath:

Lead alloy type PK021S or other suitable alloy type according to EN 50307 of 2.0mm nominal thickness - Cable sheath

MDPE type ST& according to IEC 60840 of 2.7mm nominal thickness.

Sheath colour: Black - Extruded semiconducting compound serving as electrode for the DC voltage test of the oversheath

Pfisterer CONNEX | 3M Cold Shrink | Nexans Euromold | Nexans Slip-on | Heat Shrink Cable Terminations – stocked and distributed by Thorne & Derrick

Cable Innovation Tools & Accessories for Low & High Voltage Power Systems

THORNE & DERRICK are Specialist Distributors of LV HV Cable Jointing, Earthing, Substation & Electrical Eqpt up to 66kV – this includes the most extensive range of Ex Stock Innovation Tooling to facilitate safe and reliable preparation, termination and installation of cables.