Cable Joints & Terminations HV

SEANEX | PFISTERER Connections for 66kV Inter-Array Cable Connections & Termination

March 10th, 2022

Thorne & Derrick | Approved SEANEX Supplier | UK & Export Sales

SEANEX

66kV Inter-Array Cable Connections & Termination

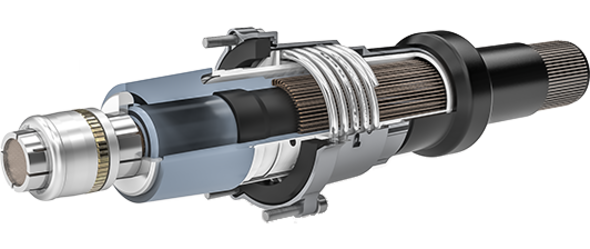

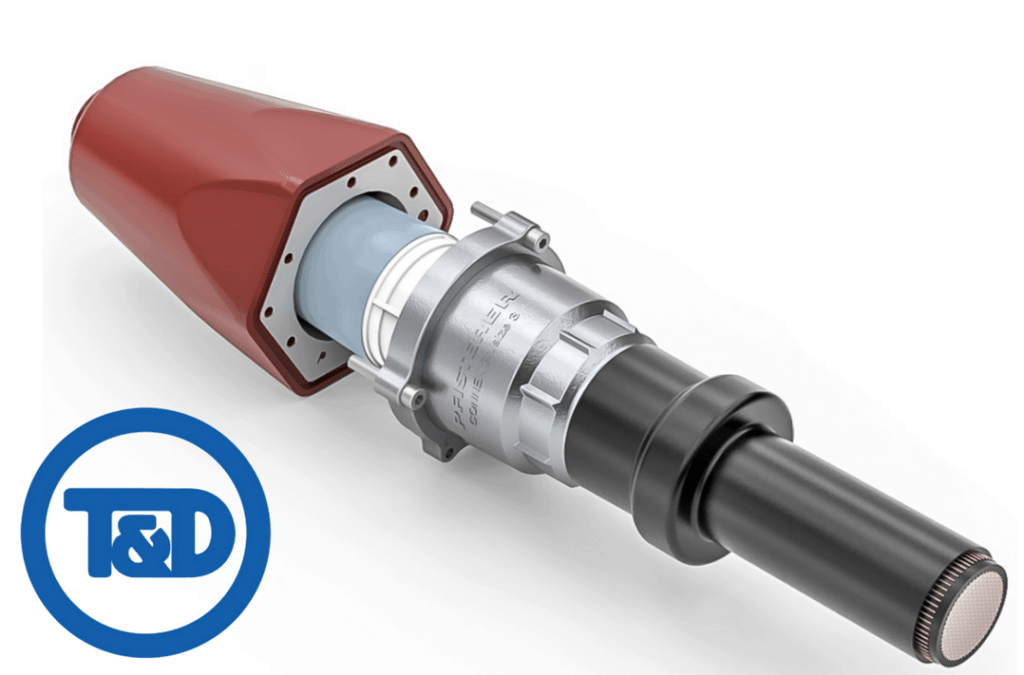

The SEANEX inner cone solution by PFISTERER distributed by Thorne & Derrick is an offshore variant of the successful Connex HV connection system that is specially adapted for 66kV inter-array cabling.

The new offshore cable accessories by PFISTERER combines all the proven performance features – salt water resistance, solid insulation, pluggable and touch-safe – yet it is much more compact, lighter in weight, and lower in cost.

Moreover, the mechanically robust inner cone technology offers clear advantages in terms of installation, corrosion resistance and reliability in harsh environments.

The optimised SEANEX HV cable connector together with the corresponding cast resin joint forms a perfect fitting for connecting and cabling 66kV offshore wind farms.

PFISTERER adapted the system specifically for this application.

Because of the growing number of projects, and particularly with the changeover from 33kV to 66kV in the wind farm networks, we set ourselves the goal of optimising our existing solution for even easier and more flexible wind turbine installation.

The cast resin connection joint in the SEANEX system enables rapid connection of the wind turbine to the wind farm network

The inner cone technology is optimally suited for this application and guarantees reliability and durability well beyond the projected operational life of a wind farm.

In combination with the cast resin joint, the solution is unique,” explains Dr. Peter Müller, Head of Renewables at PFISTERER.

During the development process, HV specialists at PFISTERER always kept the design-to-cost principle in mind. Accordingly, the HV fittings have been strictly optimised for offshore requirements. Thanks to a significantly more compact design, the new cast resin joint measures just 39cm long and weighs 28kg. “Aside from the lower costs, these advantages give our customers greater flexibility for handling and installing the HV fittings,” Müller points out.

Seanex VIDEO

SEANEX Connections for Seagreen 1 Offshore Wind Farm. As the wind turbines are installed, the pluggable connection between the submarine cable and the tower cable allows the project partners’ individual construction phases to be clearly separated. In addition, the 39cm long SEANEX cast resin joints enable more flexible handling during the offshore installation process.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

MV Connex Products | Ex Stock Thorne & Derrick | Inner Cone Cable Connectors 33kV

Thorne & Derrick | Product Training With PFISTERER

March 9th, 2022

9th March 2022 by Natalie Lundie Supply Chain: Marketing Lead | Thorne & Derrick

Thorne & Derrick welcomed Karl McFadden (Commercial Sales Manager at PFISTERER) and Drew Houghton (Commercial Sales at PFISTERER) to our offices for product training including an overview of their market-leading and new generation of SICON shearbolt connectors.

Additional manufacturer updates included an impressive presentation on their major project award at Seagreen with SSE Renewables for the SEANEX range of cable connectors for 66kV inter-array cable termination.

Seagreen Offshore Wind Farm project is located 27km off the coast of Angus in the North Sea and is a joint venture between TotalEnergies (51%) and SSE Renewables (49%). Seagreen will be Scotland’s largest and the world’s deepest offshore wind farm when complete.

The Sales and Marketing Team at Thorne & Derrick benefitted from the slick content, engaging animations and well presented slides that successfully simplified the complex.

We shall now look forward to further strengthening our business relationship in 2022 with ongoing product training, technical support and joint sales-marketing strategies.

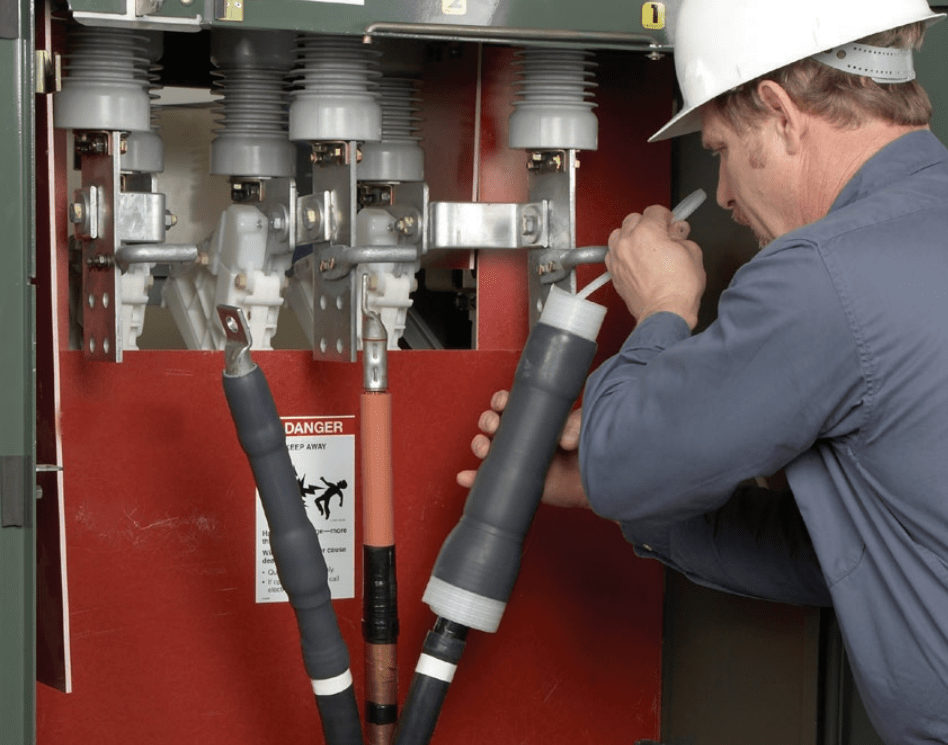

Pictured SEANEX is a dry pluggable inner cone connection and termination system designed for renewable energy offshore applications up to 66/72.5kV – based on the PFISTERER CONNEX system the SEANEX components have been further developed for the service and operational requirements in the offshore renewable industry.

SEANEX is certified by DNV GL and compliant with the new offshore standard IEC 63026.

Read Article | SEANEX | PFISTERER Connectors Selected For 66kV Wind Turbine Terminations At Seagreen Project

Connex Stocks

“I genuinely enjoyed today’s presentation – Karl and Drew demonstrated such technical authority, purpose and passion in both representing and presenting the PFISTERER brand and its credentials, that’s infectious. This week we have significantly increased stock holding levels of the CONNEX range of connectors to satisfy customer demand within substation projects for the termination of 33kV cables – our ability to specify CONNEX correctly and deliver from stock overnight has driven sales forward for Thorne & Derrick,” comments Chris Dodds (Sales & Marketing Manager at Thorne & Derrick.

The PFISTERER CONNEX range of high voltage electrical equipment includes: plug-and-sockets, multiple sockets, busbar couplings, surge arresters and voltage testing systems.

INNOVATION AS A BUSINESS DRIVER

PFISTERER meets future challenges with the knowledge that comes from one hundred years of experience. This expertise has developed continuously with advances in technology – and technology has advanced thanks to PFISTERER’s expertise.

Numerous innovations and patents continuously drive our growth with further investment in R&D planned for 2022 and beyond.

The PFISTERER corporate group has been dealing with the interfaces in the flow of electricity ever since it was founded back in 1921. Their success has turned PFISTERER into a globally active company – with a distribution network in 70 countries and 21 locations in Europe, North and South America, Asia and the Middle East.

SEANEX by PFISTERER | High Voltage Connections For Inter Array Cables 66kV

PFISTERER – DISTRIBUTORS, STOCKISTS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of PFISTERER CONNEX MV HV inner cone cable plugs and connection terminations.

Thorne & Derrick supply from stock MV HV cable plugs and terminations manufactured by PFISTERER MV-CONNEX that are suitable for medium voltage levels and applications up to 33kV where MV cables must be reliably connected, terminated and distributed within the electricity supply industry.

Network Rail Full Acceptance for Nexans Tee Connectors & Bushings for 25kV Power Transformers

March 8th, 2022

PR by Chris Dodds Sales & Marketing Manager at Thorne & Derrick | 08.03.2022

Following extensive and successful field trial testing the Nexans Euromold range of Connectors & Bushings have now received Full Acceptance by Network Rail with Official PADS Approval – specifically this includes Nexans Tee Connector model QM909TB Interface F and associated equipment bushing QM909AR.

The product authorisation by Network Technical Head Power Distribution HV/LV on behalf of the Network Rail Acceptance Panel (NRAP) permits the installation of the Tee Connectors and Bushings to ground mounted oil filled transformers up to 52kV – this covers:

Nexans Euromold Tee Connector Model QM909TB | Interface F Nexans Part Number 7009193 | PADS Catalogue No 0086/099432

Nexans Euromold 52kV 1250A Bushing | Interface F including 6 hole KBCDS-400 Clamping Kit & Sealing Gasket | PADS Catalogue No 0086/099430

➡ See Certificate of Acceptance PA05/05422 | Network Rail Certification

Thorne & Derrick are currently supplying this range of transformer terminations to several UK rail projects – we are Approved Vendors to Network Rail, CP6 Framework Delivery Partners and several HS2 Joint Ventures working on rail transport projects.

➡ For further information on Interface F Cable Accessories including Tee Connectors, Slip-on Terminations, Joints & Bushings refer to the download.

Further Reading

- 25kV Live Line Voltage Indicators | Network Rail Approved

- Rail Cable Labels with Network Rail & London Underground (LUL) Approval

- Network Rail Approved Cable Trough Delivered to South Rail Systems Alliance

- 3M LO42 Cold Shrink Tube | Track Feeder Cable Joints | Network Rail Approved

25kV Switchgear Terminations

Nexans AFN36-6 42kV single core cable terminations are Network Rail PADS Approved for indoor 25kV air insulated switchgear applications.

The cold-applied Slip-on rail cable termination is approved for use with Siemens ASG25 – 25kV air insulated switchgear for AC traction power supply systems.

Nexans 42kV Order Code AFN36-6

Network Rail 054/214930

Network Rail Certificate of Acceptance PADS PA05/06215

AFN36 cable terminations are used to connect medium voltage feeder cables to supply three-phase AC electrical power to traction substations on electrified lines.

Contact Thorne & Derrick for further information, competitive quotations or assistance with the selection and specification of Medium Voltage Rail Cable Accessories.

Rail Cable Accessories, Electrification

& Installation Equipment

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV AC.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Live Line Testers

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Transformers | Is It Time To Upgrade?

March 7th, 2022

Transformer Replacement Projects Were A Great Success For Smith Brothers In 2021

-

Special thanks to Ben Whitaker Business Development & Sales Manager at Smith Brothers for the kind permission to republish

Transformers

Alongside some of the large connections we talk about often, our services and infrastructure division are always working away in the background – to ensure our customers remain online 24-7-365.

And, as technology progresses, transformers have become more efficient in performing their duty of increasing or decreasing voltage for electrical distribution. With that in mind, our Business Development & Sales Manager, Ben Whitaker, takes a look at why replacing your transformer with a modern alternative could result in a ‘greener’ site whilst reducing energy bills.

Transformer replacement projects were a resounding success for Smith Brothers in 2021, and saw us complete 19 in total as organisations continued to strive to reduce carbon emissions and operate their sites more efficiently.

Yet, rather than simply ‘fixing a problem’, investment in new technology which can help to counter rising energy tariffs across the UK has been a firm topic of conversation for our team. It’s nothing new, though. In fact, a study in 2018 suggested that lost energy in transformers contribute to 25% of the UK’s wasted energy.

What’s more, the European Union estimates that 2.9% of all electricity generated across the continent gets wasted in lost energy in transformers, this combined figure equates to 93.4TWh – enough to power Denmark for three years.

Over the past 12 months, Smith Brothers has contributed to the energy sector in the UK significantly through the construction and delivery of renewable energy projects – but also by replacing aged and inefficient transformers.

Transformer Regulation No. 548/2014

During their operation, transformers will lose heat, but legislation imposes in the EU the maximum level of losses for transformers placed on the market or put into service after 1st July 2015. And, while most pre-2014 transformers are manufactured to an undetermined efficiency level, we refer to these as ‘standard loss transformers’.

As of 2014, the minimum requirement for installed transformer assets adhered to Tier 1 level of efficiency. Further regulations were imposed in June 2021, introducing Tier 2, which determines an improved efficiency for newly manufactured transformers.

Tier 2 transformers have been readily available via manufacturers for some time – and have been included in any Smith Brothers tender proposals as a matter of default since 2018. Further energy savings can be achieved through the provision of a Wilson e3 amorphous core transformers, which is also something which we’re proud to be able to supply and install.

No Load Losses

No Load Losses arise within the magnetic core of a transformer and happen as a result of the energy consumed in hysteresis and eddy currents within the material as it is taken through its alternating cycles of magnetisation, in the UK 50 times per second i.e. 50Hz.

There are two ways of reducing no load losses in a transformer:

1) Reduce flux density by increasing the cross-sectional area of the magnetic core. 2) By using higher grades of core steel to reduce the watts/kg for a particular flux density.

The ‘no load losses’ of a transformer is a constant loss of energy and does not vary with increase/ decrease of load.

Load Losses

Load losses arise primarily because of the resistance of the transformer windings, that is the losses produced by the flow of current within the windings. Increasing the copper or aluminium cross-sectional area within a transformer winding has the effect of reducing the current density of the winding – this has the effect of reducing the losses. The load loss of a transformer varies to the square of the load.

Generally speaking – the larger kVA rating and the higher % load of this kVA rating, the more savings can be made by minimalising load/ no load losses.

Detailed below, is a comparison of the no load losses and full load losses of a 1000kVA ‘Standard Loss’ transformer, manufactured in 2013, prior to Tier 1’s introduction and a modern, 1000kVA Tier 2 transformer. We have also included the data for a Wilson e3 amorphous core transformer for comparative purposes. The monetary savings shown are subject to the transformer being run at 80% load 24 hours a day, 365 days a year at an energy tariff average of 12p per KWH.

| “Standard Loss” 100kVA | Tier 2 1000kVA Transformer | Wilson e3 Amorphous 10000kVA |

| No load losses: 1,350 Watts per hour | No loaded losses: 693 Watts per hour (647 Watts per hour saving) | No loaded losses: 450 Watts per hour (900 Watts per hour saving) |

| Full load losses: 12,500 Watts per hour | Full load losses: 7,600 Watts per hour (4,900 Watts per hour saving) | Full loaded losses: 6,630 Watts per hour (5870 Watts per hour saving) |

| Monetary savings: £3,987 per annum | Monetary savings: £4,896 per annum |

How do I work out how much energy is being lost from my transformers?

Due to fluctuating loads pulled from individual transformers on operational sites, it’s important to find the right partner to carry out load monitoring and power quality surveyance in order to accurately determine the specific lost energy of sites’ existing transformers.

A good supplier should consider these specific elements:

- 7-day detailed power and power quality logging at nominated LV incomers. Current, voltage, kW, kVA, power factor, harmonics (I& V), flicker, frequency, harmonic loss factor and unbalance

- Load analysis and dentification of voltage dependent equipment

- Determination of PFC requirement and specification

- Detailed analysis of all logging data including harmonic analysis against ENA G5/4-1 at each LV supply (400V)

- Determine true loading of transformers using harmonic derating

- Calculation of existing transformer losses and energy savings associated with selected replacement/s

- Compilation of the technical report including savings & outline recommendations, where applicable

Smith Brothers Ltd is a large, turnkey electrical contractor with over 20 years’ experience. Since their inception in 1999, they have worked on a vast portfolio of projects throughout the UK and overseas, both as an ICP and EPC contractor on schemes up to 132kV.

Offering a range of services and can cater for everything from the delivery of a turnkey project – including design, the supply and commissioning of equipment and cabling installations from LV up to 132,000 volts (220,000V in ROI).

With over 10 years’ experience in the power industry — Ben has specialised in many power distribution projects, as well as maintenance and HV/EHV connections throughout his career. He is responsible for new sales and quotation conversion.

For further information, or an initial discussion regarding replacement transformer options, contact business development and sales manager, Ben Whitaker on: 07387 108 377 or email [email protected].

Stockists | 11kV 33kV 66kV Joints Terminations Connectors – 3M Pfisterer Nexans

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

QTII v QTIII | 3M Cold Shrink Terminations – Features & Differences

February 9th, 2022

Power Cable Terminations for MV HV Electrical Systems Utilising 3M Cold Shrink

Cold Shrink Terminations – 3M QTII v QTIII

Stocked & Supplied by Thorne & Derrick | Technical Support | Competitive Prices

UK & International Projects

Thorne & Derrick distribute 3M Cold Shrink Cable Terminations for medium and high voltage (11kV 33kV 66kV) cables and electrical power systems – we provide competitive prices for cold shrink cable terminations from extensive stocks to UK and international destinations.

3M Cold Shrink terminations are available in a Standard QTII range (3M Quick Term II – Partially Integrated) and a Premium QTIII range (3M Quick Term III – Fully Integrated).

QTII & QTIII type cable terminations are suitable for terminating and connecting MV HV cables. Below highlights the features of using cold shrink technology for both types of cable terminations as well as exploring the differences.

3M QTIII COLD SHRINK CABLE TERMINATIONS

Premium Cable Terminations | 3M Quick Term III – Fully Integrated

3M QTIII Premium cable termination offers the greatest simplicity and flexibility in the full range as it covers a wide range of cable types and sizes. One of the main features that differentiates the QTIII from the rest is a shorter adjustable tail to enable it to fit into the wide range of boxes meaning fewer installation steps so there is less room for jointer error.

➡ WATCH & LEARN Video Demonstration of QTIII Cold Shrink Terminations:

3M QTII COLD SHRINK CABLE TERMINATIONS

Standard Cable Terminations | 3M Quick Term II – Partially Integrated

3M QTII requires additional installation steps to the Premium range explained in the video below. However the Standard QTII range still offers additional benefits over heat shrink cable terminations which have many more parts to install and require heat and further tools.

➡ WATCH & LEARN Video Demonstration of QTII Cold Shrink Terminations:

QTII & QTIII Features

- Fabricated one-piece cold shrink termination body which allows fast and easy installation on a wide range of cable types and sizes

- Installation temperature ranging from -20°C to +50°C

- The high-K stress control material distributes the electrical field evenly across the insulator and minimises the electrical stress on the termination

- Permanent radial contact pressure

- Quick and easy to install by puling out the spiral core

- No heat/flame or tools are required for installation

- Meets and exceeds the requirements for European Standard CENELEC HD 629.1 and IEC 60502-4.v

COLD SHRINK TERMINATIONS

3M QTII V. 3M QTIII

The following tables and videos demonstrate the specification differences and features of both the 3M QTII and 3M QTIII versions of Cold Shrink cable termination.

| 3M QTIII Premium Cold Shrink Cable Terminations | 3M QTII Standard Cold Shrink Cable Terminations |

| Fully Integrated Cable Termination | Partially Integrated Cable Termination |

| Moisture Blocking Mastic (1.) | |

| Integrated into cable termination | Applied separately |

| Outer Insulation (2.) | |

| Very good track resistance | Good track resistance |

| Stress Control Tube (3.) | |

| Integrated into cable termination | Integrated into cable termination |

| Silicone Grease-Stress Relief (4.) | |

| No – Integrated mastic is sufficient | Yes – Applied separately |

| Stress Control Mastic (5.) | |

| Integrated into cold shrink termination | No – Requires silicone grease |

More from 3M Electrical

- Continuous Shearhead Bolt vs. Crimp Compression Technologies By 3M Electrical

- 3M Electrical Tapes Guide | The Tape For Every Task

- 3M Terminations | Surface Tracking on Medium Voltage Cable Terminations by 3M

- 66kV Terminations | NEW Stock Introduction for 3M Cold Shrink Cable Terminations

- Stress Control | MV Cable Terminations by 3M Electrical

- Q/ Can 3M Electrical Offer MV Cable Joints For Hazardous Areas?

- MV Cable Jointing & Some Jointers Tips Using 3M Scotch Tapes

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.