Duct Seals

132kV 33kV 11kV DNO Substations – A Guide To Cable Sealing By Roxtec

April 9th, 2019

132kV 33kV 11kV DNO Substations

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick International

A Guide To Cable Sealing By Roxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects water, gas and fire.

The following article discusses Roxtec cable transit products for the sealing of HV single core power cables, multicore cables and earthing arrangements into a substation environment either below ground or at a higher level.

The primary consideration of this specification is to prevent water ingress into the controlled switchroom environment, to assist in maintaining conditions within switchgear operational parameters in accordance with manufacturer’s guidelines and IEC62271-1 2007 / BSEN62271- 1 2008.

This specification also provides protection against pollution from dust, smoke, corrosive and/or flammable gases, vapours and salt in accordance with the same, reducing the potential for equipment failure due to partial discharge.

The Roxtec system also provide a means of secure cable retention under normal loads and fault conditions and/or where the exterior of the building is subject to ground settlement post back-filling of the cable trench. Cable transits also provide ingress protection in both normal and flood conditions and can be installed in running water.

Cable Sealing Technical Performance & Product Overview

Roxtec Knock Out Sleeve UG (KOS)

- Used for formation of 100mm, 150mm and 200mm cable ducts – see casting guidelines for additional information

- Complete sealing solution comprising of a sleeve with an external puddle flange and integrated sealing plate – keeps building dry during and after construction

- Cast installation for either new build or retrofit substation applications

- IP68 tested and certified to 0.3bar constant water pressure and 1bar catastrophic water pressure. Gas tight to 0.3bar

Roxtec Knock Out Sleeve UG (KOS)

| Roxtec Part Number | W (mm) | Accommodates Seal | Accommodates Extension Conduit/ Duct (mm) | Roxtec Article N° |

| KOS 100/110 UG | 180 | R 100 UG RS 100 UG |

110 | 184064 |

| KOS 150/160 UG | 230 | R 150 UG RS 150 UG H3 150 UG |

160 | 184066 |

| KOS 200/200 UG | 280 | R 200 UG H3 200 UG |

200 | 184068 |

Roxtec UG Rubber Seals

- Tested and certified to IP68 for constant water pressure to 0.3bar (3m head of water normal conditions) and catastrophic pressure to 1bar (10m head of water flood conditions). Gas tight to 0.3bar

- Certified rodent / vermin ingress protection

- Cable seals can be installed in running water conditions & retrofit around existing cable installations

- Fittings manufactured from 316L stainless steel. Minimum clearance of 3mm between rubber and metal fittings to prevent direct contact between the cable and any metal components

- Minimum seal depth 60mm to aid with cable retention. Preventing loss of seal when; movement occurs on the cable due to ground settlement post backfill, the weight of the cables and the flex during operation

- Cable retention with a pull force of up to 10,000N and a weight load of up to 1,000kg, depending on size / seal selection

Roxtec RS UG Seal

These cable transits manufactured from Roxylon EPDM rubber with Multi-diameter peelable layers at 1mm increments are designed to seal a single LV MV HV cable between 9-204mm Ø. The unique indicator window allows for a simple check that the Roxtec cable seal has been sufficiently tightened. Fully openable/split system allowing for easier installation / cable positioning.

Roxtec RS UG Seal

| Roxtec Part Number | Number of Cables | For Cable / Pipe Ø (mm) | For Aperture Dimension Ø (mm) | Roxtec Article N° |

| RS 100 UG | 1 | 0+39-63 | 100-105 | 167236 |

| RS 100 24-53 UG | 1 | 0+24-53 | 100-105 | 186250 |

| RS 125 | 1 | 0+55-88 | 125-130 | 167638 |

| RS 150 UG woc | 1 | 80-113 | 150-155 | 167246 |

Roxtec H3 UG Seal

These Roxtec H3 cable transits are manufactured from Roxylon EPDM rubber with Multi-diameter peelable layers at 1mm increments designed for use with HV single core cables between 23-68mm Ø in a trefoil formation. The unique indicator window allows for a simple check that the seal has been sufficiently tightened. Fully openable/split system allowing for easier installation / cable positioning.

Roxtec H3 UG Seal

➡ For further reading Roxtec H3 Cable Transit Seals – How To Seal Substation Cables

| Roxtec Part Number | Number of Cables | For Cable / Pipe Ø (mm) | For Aperture Dimension Ø (mm) | Roxtec Article N° |

| H3 150 UG | 3 | 24-52 | 150-155 | 151561 |

| H3 185 UG | 3 | 48-64 | 185-190 | 126283 |

| H3 200 UG | 3 | 48-68 | 200-205 | 117842 |

Roxtec R UG Seal

Designed for entries with multiple LV / Multicore cables, includings control / comms and aux cables. An openable/split round seal used in conjunction with Roxtec RM UG modules.

Roxtec R UG Seal

| Roxtec Part Number | Module Packing Space (mm) | For Cable / Pipe Ø (mm) | For Aperture Dimension Ø (mm) | Roxtec Article N° |

| R 100 UG | 60 x 60 | Refer to Module Packing Space & Multi diameter Sealing Range of RM UG Modules | 100-102 | 158522 |

| R 150 UG | 90 x 90 | 150-152 | 150071 | |

| R 200 UG | 120 x 120 | 200-202 | 150075 |

Roxtec RM UG Modules

Roxtec RM UG sealing modules feature Multi diameter, the Roxtec technology with removable layers so that they can easily be adapted to a wide range of cable sizes. The Roxtec RM UG sealing module is developed to be installed in the Roxtec R UG Seal.

Roxtec RM UG Modules

| Roxtec Part Number | Number of Cables | For Cable / Pipe Ø (mm) | Module Packing Space Dims (mm) |

Roxtec Article N° |

| RM 30 UG | 1 | 0+10-23.5 | 30 x 30 | 116837 |

| RM 40 UG | 1 | 0+9.5-31 | 40 x 40 | 116865 |

| RM 60 UG | 1 | 0+24-52 | 60 x 60 | 116869 |

| RM 90 UG | 1 | 0+48-68 | 90 x 90 | 174930 |

| RM 20 UG | 1 | 0+4-13 | 20 x 20 | 116871 |

| RM 20w40 UG | 2 | 0+2×4-13 | 20 x 40 | 116870 |

Earthing Arrangements

Flat earth tapes can be sealed using a Roxtec R Seal (AISI 316L) and a water jet cut module in Roxylon EPDM rubber. Note that the Roxtec UGTM pipe or cable sealing system is not suitable for use with braided / twisted earth rope. Solid circular earth bar can be sealed using the standard Roxtec RM modules.

Earthing Arrangements

| Roxtec Part Number | Packing Space / Module Dims (mm) | Earth Tape / Cable Dims Ø (mm) | For Aperture Dimension Ø (mm) | Roxtec Article N° |

| Seals: | ||||

| R 100 AISI 316L | 60 x 60 | 100-102 | R000001001021 | |

| R 125 AISI 316L | 80 x 80 | 125-127 | R000001251021 | |

| R 150 AISI 316L | 90 x 90 | 150-152 | R000001501021 | |

| R 200 AISI 316L | 120 x 120 | 200-202 | R000002001021 | |

| Earth Tape Modules: | ||||

| RM 60/SQ40x4 | 60 x 60 ET Module | 40×4 Copper Tape | 118418 | |

| RM 60/SQ50x6 | 60 x 60 ET Module | 50×6 Copper Tape | 118438 | |

| RM 60/SQ50x4 | 60 x 60 ET Module | 50×4 Copper Tape | 107067 | |

| RM 20w60/31×6 | 20 x 60 ET Module | 31×6 Copper Tape | 189962 | |

| RM 20w60/40×4 | 20 x 60 ET Module | 40×4 Copper Tape | 172809 | |

| RM Customised | Customised | Customised Copper Tape | Contact Roxtec | |

| RM Modules/Cable Packing Space: | ||||

| RM 30 | 30 x 30 Module | 0+10-23.5 | RM00100301000 | |

| RM 40 | 40 x 40 Module | 0+21.5-34.5 | RM00100401000 | |

| RM 60 | 60 x 60 Module | 0+28-54 | RM00100601000 | |

| RM 20 | 20 x 20 Module | 0+4-14.5 | RM00100201000 | |

| RM 20w40 | 20 x 40 Module | 0+2×3.5-16.5 | RM00120401000 | |

| RM40 (10-32) | 40 x 40 Module | 0+9.5-32.5 | RM00140101000 | |

IEC62271-1 2007

High-Voltage Switchgear& Controlgear – Part 1: Common Specifications

Note this standard is now withdrawn and superseded by IEC 62271-1:2017 (High-voltage Switchgear & Controlgear – Part 1: Common Specifications for Alternating Current Switchgear & Controlgear). This part of IEC 62271 applies to a.c. switchgear and controlgear designed for indoor and outdoor installation and for operation at service frequencies up to and including 60 Hz on systems having voltages above 1000 V.

This standard applies to all high-voltage switchgear and controlgear except as otherwise specified in the relevant IEC standards for the particular type of switchgear and controlgear. This standard cancels and replaces IEC 60694 published in 1996.

Bespoke Solutions

Contact T&D and together with Roxtec we can discuss design services for seals and customised sealing solutions which fall outside the standard range.

Manufacturing / Quality Approvals

- ISO 9001:2008 ISO 14001:2004 certified

- Seals tested and certified to IP68

- Certified rodent / vermin ingress protection

- Complies with recommendations outlined in EA Technology white paper – Humidity Effects in Substations – 2013

Thorne & Derrick Specialist Electrical Distributor

Established since 1985, T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

Distributors for : 3M, Pfisterer CONNEX, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Hivotec, Cembre, Prysmian, Ellis Patents, ABB & Furse.

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Sealing Cables In Offshore Substations – A Roxtec CPD

April 2nd, 2019

Sealing Cables In Offshore Substations – A Roxtec CPD

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick International

The Importance of Cable Sealing in Substations

An overview of sealing cables in LV MV HV offshore substations based upon industry standards and practical experience – understand and learn about the importance of sealing cable entry points and cable ducts.

The focus of the CPD relates to the causal of Partial Discharge in substation switchroom environments and looks at the primary mitigation measure of deploying proper cable sealing solutions in order to achieve optimum switchroom conditions for electrical switchgear and assets to operate in.

The CPD seminar lasts approximately 1¼ hr and is aimed at Engineers involved in the design, build and installation of electrical substations, in addition to Managers responsible for Asset Management and Maintenance, Quality, Safety and Environment.

By attending this seminar you will gain a greater understanding of:

- The impact of insufficient substation cable sealing

- The benefits of adequate sealing, including cables passing through bulkheads and decks

- The impact of main risks / hazards relating to fire – A and H class

- Ensuring the design and installation of substation seals meet the requirement of the client through clear design and specification

- Different LV and HV cables and how they are best sealed

- How to seal transformer, GIS and busduct cables

- The importance of civil structural considerations when designing and building a substation

- The design requirements for switchgear operation, manufacturers’ recommendations and control measures

Who should attend?

- Engineers involved in the design, build or installation of substations

- Managers responsible for Asset Management and Maintenance, Quality, Safety and Environmental

- Electrical, control, instrument, mechanical and civil engineers and designers

- Owners, operators, design engineering companies and site contractors

Additional Course Information

CPD Points: 1

Location: This seminar can take place at your office or Roxtec’s office in Bury, Greater Manchester.

How to book:

To arrange this free seminar contact us:

Email: [email protected]

Office tel: 0191 410 4292

➡ Also: Sealing Cables In Onshore Substations – A Roxtec CPD

ROxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects water, gas and fire.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Sealing Cables In Onshore Substations – A Roxtec CPD

April 2nd, 2019

Sealing Cables In Onshore Substations – A Roxtec CPD

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick International

The Importance of Cable Sealing in Substations

An overview of sealing cable entry points and cable ducts in substations, looking at the impact of water ingress and continuous water pressure on LV MV HV substation performance and the implications of failure and costs.

The focus of the CPD relates to the causal of Partial Discharge in substation switchroom environments and looks at the primary mitigation measure of deploying proper cable sealing solutions in order to achieve optimum switchroom conditions for electrical switchgear and assets to operate in.

The CPD seminar lasts approximately 1¼ hr and is aimed at Engineers involved in the design, build and installation of electrical substations, in addition to Managers responsible for Asset Management and Maintenance, Quality, Safety and Environment.

By attending this seminar you will gain a greater understanding of:

- The benefits of adequate sealing in cable trenches

- The design requirements for switchgear operation, manufacturers’ recommendations and control measures

- The importance of civil structural considerations when designing and building a substation

- Ensuring the design and installation of substation seals meet the requirement of the client through clear design and specification

- Sealing earth tapes and trefoil single core cables

Who should attend?

- Engineers involved in the design, build or installation of substations

- Managers responsible for Asset Management and Maintenance, Quality, Safety and Environmental

- Electrical, control, instrument, mechanical and civil engineers and designers

- Owners, operators, design engineering companies and site contractors

Additional Course Information

CPD Points 1

Location: This seminar can take place at your office or Roxtec’s office in Bury, Greater Manchester.

How to book:

To arrange this free seminar contact us:

Email: [email protected]

Office tel: 0191 410 4292

➡ Also: Sealing Cables In Offshore Substations – A Roxtec CPD

Roxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects of water, gas and fire.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

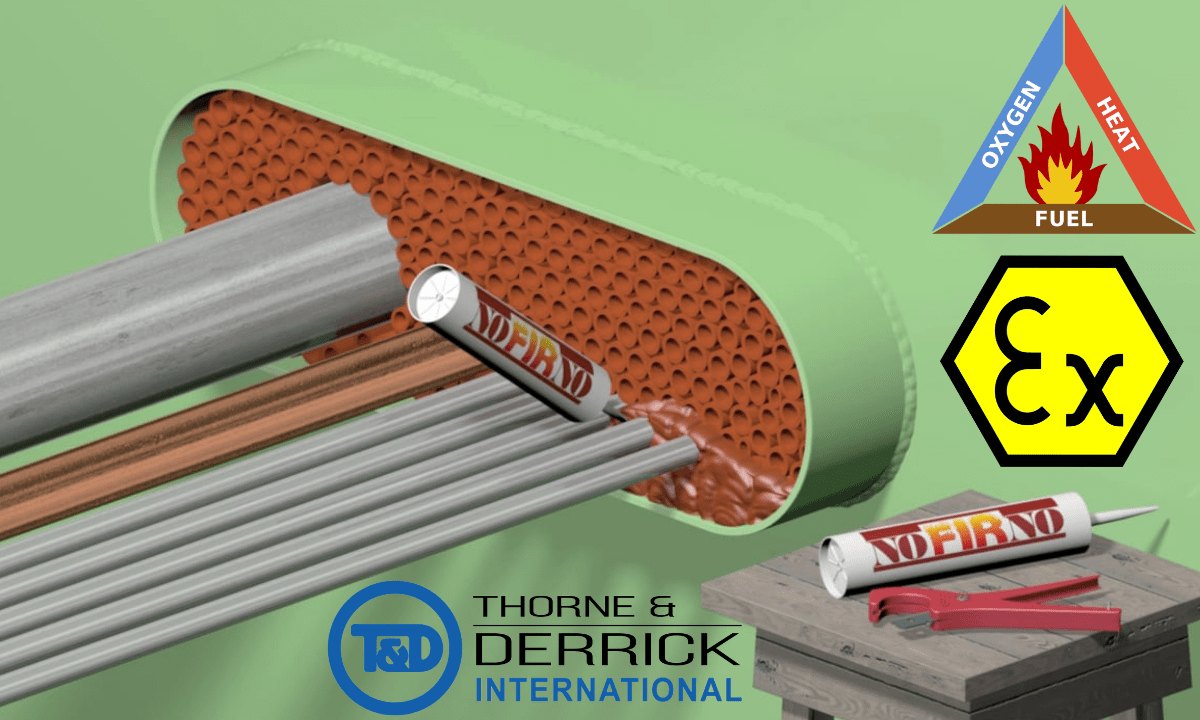

NOFIRNO Sealant | Sealing For Cable & Pipes 2 Hour Jet Fire Tested

January 31st, 2019

NOFIRNO Sealant For Cable & Pipes

NOFIRNO Sealant For Cables & Pipes

The CSD NOFIRNO is a Single & Multi Pipe Penetration Sealing System – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

The offshore sealing system for pipework maintains the integrity of vessels providing fire protection and ensuring bulkheads and decks remain gas and watertight when pipes need to pass through them – the CSD NOFIRNO pipe penetration sealing system provides fire protection seals to A60 H120 for offshore and marine ships bulkheads and decks.

An uncontrolled discharge of combustible gas under pressure poses a serious fire hazard in areas such as petrochemical plants, offshore petroleum rigs and other hazardous area locations and environments that are sensitive to extreme fires.

NOFIRNO is manufactured by Beele Engineering.

What Are Jet Fires?

A jet or spray fire is a turbulent diffusion flame resulting from the combustion of a fuel continuously released with some significant momentum in a particular direction or directions. Jet fires can arise from releases of gaseous, flashing liquid (two phase) and pure liquid inventories.

Jet fires represent a significant element of the risk associated with major accidents on offshore installations. The high heat fluxes to impinged or engulfed objects can lead to structural failure or vessel/pipework failure and possible further escalation. The rapid development of a jet fire has important consequences for control and isolation strategies.

The properties of jet fires depend on the fuel composition, release conditions, release rate, release geometry, direction and ambient wind conditions. Low velocity two-phase releases of condensate material can produce lazy, wind affected buoyant, sooty and highly radiative flames similar to pool fires. Sonic releases of natural gas can produce relatively high velocity fires that are much less buoyant, less sooty and hence less radiative.

Source: UK HSE.

Jet Fire Testing

If high pressure flammable gas, pressure liquefied gas or flashing liquid fuels are emitted at high velocity and ignited, the result will be a jet fire. Withstanding these jet fires is most demanding for a pipe sealing system.

BEELE Engineering’s NOFIRNO sealing system for multi-cable and pipe transits has successfully completed a jet fire test, in accordance with ISO 22899-1:2007 and ISO/CD 22899-2 for two hours at the Health & Safety Laboratory at Buxton in England. The jet fire test was recorded on DVD; copies of the DVD can be ordered via BEELE Engineering.

From a time/temperature perspective, jet fire tests are similar to hydrocarbon (H-Class) fire tests.

During the hydrocarbon test, an instantaneous temperature rise up to 800°C (1472°F) takes place, with the overall exposure temperature rising to 1150°C (2102°F).

However, during the hydrocarbon test, there are no extreme conditions imparted to the penetration seal, such as thermal and mechanical loads or severe erosive forces, as is the cases with the Jet Fire Test.

Jet fire tests simulate the most onerous conditions of a hydrocarbon fuelled fire on an offshore oil rig, or a missile strike on a military warship.

Jet fires give rise to high convective and radioactive heat fluxes as well as high erosive forces.

To generate both types of heat flux in sufficient quantity, a 0.3 kg/second sonic release of gas is aimed into a hollow chamber, producing a fire ball with an extended tail.

The flame thickness is thereby increased and hence so is the heat radiated to the test specimen. Propane is used as the fuel since it has a greater propensity to form soot than natural gas and can therefore produce a flame of higher luminosity. Strong erosive forces are generated by the release of sonic velocity gas jet, 1 meter from specimen (bulkhead) surface. The jet velocity is ca. 100 meter/second at 0.25 meter from the back of the recirculation chamber (e.g. the front of the web of a structural steel specimen) and ca. 60 meter/second at the back of the chamber.

For the Jet Fire test, a cable penetration with dimensions 600x300mm with armoured and non-armoured cables up to 3x400mm² (102mm OD) and bundled LAN cables, representing a shipboard cable installation, was tested. The conduit sleeve for the NOFIRNO pipe transit was 406.4 mm ID and a steel pipe with an OD of 273mm was passed through. Both penetrations maintained their integrity for the full two hours.

Despite the jet speed of about 360 km/hour, causing high erosive forces, and the flame temperatures of about 1200°C, the temperature rise measured on the surface of the NOFIRNO sealant at the unexposed side was only max; 160°C. This proves the high thermal insulation values under fire load of the NOFIRNO sealing system. After dismantling it was noticed that the NOFIRNO filler sleeves were not consumed by the fire and were even hardly affected by the fire. Based on the positive outcome of this harsh fire tests, BEELE Engineering will apply for Jet Fire Certificates.

➡ NOFIRNO – Jet Fire Testing For Cable Duct & Pipe Penetration Sealing Systems

Sealing Pipes, Cables & Ducts Using NOFIRNO

NOFIRNO is one of BEELE Engineering’s ‘rapid cable and pipe sealing systems’ for use on board ships, on offshore pipework installations, in building and construction and other environments where the safety of people and installations has to be guaranteed.

NOFIRNO offers the ultimate fire safe sealing solution for metallic and plastic pipes. Even combined penetrations for metal and plastic pipes and cables can be sealed effectively. That means that one sealing system can be used for all types of pipe penetrations.

NOFIRNO is also tested on full scale bulkheads and decks in accordance with IMO Res. A.754 (18). An EC (MED) certificate according to the European Union Council Directive 96/98 EC on Marine Equipment has been issued by Det Norske Veritas.

The system has also been tested for H-class partitions and has obtained a Type Approval Certificate of Det Norske Veritas as well. Important is that both for A-0 and H-0 class the system has been tested without any insulation. For building and construction applications RISE/NOFIRNO has been tested according to EN1366-3:2004 and classified according to EN 13501-2:2003 for a fire rating of two hours (fire class E120 (flame resistance) and EI120 (flame resistance and thermal insulation) and lately in-house for a four hours fire rating.

Contact us for duct sealing systems for onshore and offshore sealing of medium/high voltage (MV-HV) substation cables.

NOFIRNO – A Brand of CSD Sealing Systems | Distributed by Thorne & Derrick

NOFIRNO has been developed for a service life of over 20 years and offers the best Total Cost of Ownership on the market of pipe and cable sealing systems in both onshore and offshore locations. The sealing system is resistant to weathering, UV and ozone resistant and is capable of absorbing temperature changes. The system is shock and vibration resistant and can be used in wide range of temperatures (-50°C up to +180°C).

Fire-safe NOFIRNO is also watertight. The system has no metal parts thus avoiding corrosion on the pipe work. The perfect sealing of the NOFIRNO sealant also avoids (invisible) corrosion within the penetration.

BEELE Engineering

BEELE Engineering is market leader in the field of passive fire safety. This position is based on the company’s ongoing R&D and innovation, advanced manufacturing technology and first class service. All the cable and pipe sealing products are developed and manufactured on the basis of an integrated approach to fire safety. All components are made in the company’s own factory under stringent ISO quality system.

Further Reading ➡

- A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

- NOFIRNO – Cable & Pipe Sealing Systems

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

Thorne & Derrick distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, CSD Sealing Systems, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

NOFIRNO – Sealing Systems

January 29th, 2019

NOFIRNO – A Brand of CSD Sealing Systems | Distributed by Thorne & Derrick

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Explosive Environment Sealing Systems For Hazardous Areas (ATEX Directive)

Sealing systems for cables and pipes are used in a diverse range of industry sectors including hazardous area locations and potentially explosive atmosphere applications in the onshore and offshore oil and gas industries. ATEX Directive requirements can be imposed for specific uses in hazardous area environments where there is a risk of explosion.

Kiwa has thus investigated the extent to which the NOFIRNO sealing system fulfils ATEX Directive 2014/34/EU – Kiwa is an autonomous global organisation in Testing, Inspection and Certification (TIC), Training and Consultancy services.

What is ATEX?

ATEX is the name given to the two European Directives for controlling explosive atmospheres in designated hazardous area locations:

1) Directive 99/92/EC (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’) on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

2) Directive 94/9/EC (also known as ‘ATEX 95’ or ‘the ATEX Equipment Directive’) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

The NOFIRNO systems is comprised of rubber and filler sleeves and sealant, the system is used to treat transit openings for cables and pipes in walls, floors, bulkheads or decks, so that they are fire-resistant and sealed against gas, smoke and water.

Kiwa’s research has shown that NOFIRNO, from CSD Sealing Systems, is extremely suitable for use in environments such as those covered by the ATEX Directive and described in the European standard EN 1127-1 ‘Explosive Atmospheres – Explosion Prevention & Protection – Part 1: Basic Concepts & Methodology’.

Because the NOFIRNO sealant, NOFIRNO rubber sleeves and the complete NOFIRNO sealing system do not fulfil an autonomous role and are not equipment in the sense of the ATEX Directive, the risk evaluation focused on use of the NOFIRNO in cable and pipe transits. All possible ignition sources related to the sealing system were also investigated.

Among the possible ignition sources which were assessed, were hot surfaces, flames and hot gases (including hot particles), mechanically-generated sparks, electrical equipment and power leakages, cathodic corrosion protection, static electricity, lightning, electromagnetic and ionising radiation, ultrasonic sound waves, adiabatic compression and shockwaves and exothermic reactions, including materials self-igniting.

How? A 20mm thick layer of NOFIRNO sealant is applied to each side of the conduit – clean and dry the conduit opening and pipe thoroughly to remove all dirt, rust or oil residue to ensure excellent adhesion of the NOFIRNO to the conduit. The conduit should be overfilled with NOFIRNO sealant as some sealant will be pushed between and into the empty filler sleeves during finishing and completion of the pipe or cable seal.

Conclusion

Safe Cable & Pipe Sealing Solution For Hazardous Area & Explosive Atmospheres

Kiwa concluded that for all hazardous situations as described in EN 1127-1, there is no ignition source for NOFIRNO sealant, NOFIRNO rubber sleeves, NOFIRNO rubber filling sleeves and the complete, installed NOFIRNO system.

NOFIRNO is manufactured by Beele Engineering.

Contact us for duct sealing systems for onshore and offshore sealing of medium/high voltage (MV-HV) substation cables.

NOFIRNO

Some benefits of the sealing system include:

• Ensuring ATEX, DSEAR & WIMES compliance

• Age tested to prove 50 years of sealing protection

• Quick and easy to install in both horizontal and vertical cable ducts

• Easy re-entry for adding, removing or replacing cables LV MV HV

• Installed in any sized or shaped opening, penetration or duct

• Resistant to submersion in petrol and diesel

• Resistant to methane, hydrogen sulphide and chlorine

• Suitable for trefoil and large diameter 11kV/33kV power cables

• Prevents rat and rodent ingress into low, medium and high voltage substations

NOFIRNO cable duct and pipe penetration sealing system is jet-fire tested for offshore applications.

➡ Contact Thorne & Derrick to discuss the NOFIRNO Duct Seal System – 0191 4104292.

Sealing Pipes, Cables & Ducts Using NOFIRNO

Watertight & Gastight Sealing For Building Entries & Cable Duct Terminations

A simple and long term solution designed for sealing cable ducts and building entries against ingress of water, gas or flooding – the NOFIRNO system is used extensively across the onshore utilities and construction sectors to protect LV MV HV electrical substations, equipment rooms and cabinets, wind turbines and critical infrastructure.

➡ For marine and offshore applications see: A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

Jet Fire Testing

➡ NOFIRNO – Jet Fire Testing For Cable Duct & Pipe Penetration Sealing Systems

Some site installation photographs of NOFIRNO ➡

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

Thorne & Derrick distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.