Cembre B500NDE Battery Crimping Tool (up to 300sqmm cables)

Cembre B500NDE

LV-HV Cable Crimping Tools | Distributed from Stock | Approved Cembre Supplier | UK & Export Sales

Cembre B500NDE battery crimping tool is an 18.0V cordless hydraulic crimping tool which can be operated with one hand and is balanced for greater control. The first of a new generation of hand-held cordless tools, characterised by the “Bilinear” structure of the tool’s mechanics. Equipped with intelligent automatic return at the end of the pressing cycle (Smart Release).

The crimping tool is equipped with Li-Ion 18 V-2Ah rechargeable high capacity batteries and is suitable for a wide range of connectors up to 500 MCM using die sets common to the Cembre 6 ton tooling range.

The B500NDE battery crimping tool is fitted with a maximum pressure sensor for enhanced precision and repeatability of the maximum pressure cycle, and a pressure relief valve providing additional safety for the operator.

B500ND is suitable for crimping electrical connectors onto conductor cross sections up to 300 mm² and uses the die sets common to all CEMBRE 50kN tools and heads.

Additionally an OLED display provides operating information data such as the crimping force being generated, battery power remaining, tool identification, LED state, rest, number of operational and service crimping cycles and a tool service to maintain optimum condition.

The Electronic Pressure Sensor (EPS) guarantees the precision of the crimping operation, checking the actual value of pressure and informing the operator about possible errors.

Cembre’s B500NDE crimping tool can be fitted with many crimping dies common to 50kN and are supplied with a spare battery, battery charger, USB cable and plastic carrying case.

Cembre B500NDE crimping tool

Specification

- Rated Crimping Force: 60kN

- Bilinear mechanical design

- Smart Release system to automatically retract the ram at the end of the crimping cycle

- OLED multifunctional display with touch button

- Electronic Pressure Sensor (EPS)

- SMARTOOL technology for viewing and downloading operational data

- 180° rotating head

- Start button protected against accidental operation

- Manual pressure release button

- Illumination of working area via 4 x LED lights

- Bi-component plastic body

- Ergonomic design for operator comfort

- Li-Ion 18.0 V-2Ah rechargeable high capacity battery

- Battery connection system with release button

Cembre crimping tools should be cleaned daily (or after use) with a clean cloth removing any residue in particular particles close to pivots and moveable parts. Every six months it is essential check the oil level in the reservoir. If necessary fill oil level to the top lip and remove any excess air from the reservoir.

Expressed in the design of the tool, the weight and balance have been reconfigured to yield advances in handling and convenience. The more rigid structure of the bi-component plastic body of the B500DE provides greater mechanical protection while its rubber inserts boost operator safety and comfort.

Quieter operation, illumination of the working area via LED lights and a minimum of vibration make for even more practical use.

The integrated memory card enables the user to store data from up to 200,000 compression cycles for transfer to a computer via a USB communication interface.

Smart Release Technology

“Smart Release Technology” is an original development of a new, intelligent oil pressure release system developed by Cembre.

When “Smart Release” is selected, the motor stops at the end of the cycle and the ram retracts automatically only when the start button is released allowing the operator to visually check the press jaws have contacted before releasing.

It’s worth knowing that similar tools with ‘standard’ automatic return do not permit this visual verification that full compression has taken place before releasing pressure.

Electronic Pressure Sensor

The EPS guarantees the precision of the crimping operation, checking the actual value of pressure and informing the operator about possible errors.

New multifunction OLED display with touch button

The OLED display provides essential real time operating data, including:

- Crimping force generated, thus verifying compliance with best practice

- Battery charge status

- General operating information

- The number of work cycles completed and remaining before recommended maintenance

OLED display with touch button

“Bilinear” Structure

To move the centre of gravity of the mechanism to a position closest to the operator’s wrist holding the tool, Cembre decided to opt for a misalignment between the drive mechanism of the pumping group and the hydraulic.

This also allowed for a wider support for the hand by optimizing the overall ergonomics of the tool. Two solutions that advantageously reduce the torque generated on the operator’s wrist and best distribute the stresses acting on his hand.

Cembre B500NDE Battery Crimping Tool

Technical Specification

| Application Range |

Suitable for installing electrical compression connectors on conductors up to 300 sqmm (600 MCM) |

Rated crimping force

kN (US sh. ton) |

60 (6.75) |

Minimum operating pressure

bar (psi) |

661 (9587) |

Dimensions

mm (inches) |

396 x 136 x 81 (15.6 x 5.3 x 3.2) |

Weight with battery

kg (lbs) |

3,15 (6.9) |

Motor

V |

18 |

Operating temperature

°C (°F) |

-15 to +50 (+5 to +122) |

| Recommended oil |

TOTAL DIEKAN 1640 or equivalents |

| Operating speed |

Twin speed operation and automatic switching from a rapid advancing speed of the ram to a slower, more powerful crimping speed |

| Safety |

Maximum pressure valve |

Rechargeable battery

V / Ah / Wh |

18 / 2.0 / 36 |

| Type |

CB1820L (Li-Ion) |

Weight

kg (lbs) |

0,4 (0.9) |

Battery charger

Type |

ASC55-EU |

ASC30-36-UK |

ASC30-36-AUS/NZA |

Input

V / Hz

W |

220 – 240 / 50 – 60

85 |

Acoustic noise (1)

LpA dB (A)

LpCPeak dB (C)

LWA dB (A) |

67,7

89,2

74,2 |

Vibration (2)

m/s2 |

ahv 0,724 |

(1) Directive 2006/42/EC, annexe 1, point 1.7.4.2 letter u LpA = weighted continuous acoustic pressure level equivalent. LpCPeak = maximum value of the weighted acoustic displacement pressure at the work place. LWA = acoustic power level emitted by the machine. (2) Directive 2006/42/EC, annexe 1, point 2.2.1.1 Weighted root mean square in frequency of the acceleration the upper limbs are exposed to for each biodynamic reference axis. Tests carried out in compliance with the indications contained in EN ISO 5349-1/2 Standard, and under operating conditions much more severe than those normally found.

Cembre B500NDE Battery Crimping Tool

User Instructions

- When introducing or changing dies, the battery must first be removed from the Cembre B500NDE tool.

Preparation

- The Cembre tool can be easily carried using either the handle or the shoulder strap attached to ring.

- To replace the battery, remove it by pressing the release button, then insert the new battery, sliding it into the guides until it locks.

- The display shows the operational parameters of the tool; to customise them proceed as described.

- Select the appropriate Cembre die set for the connector.

- Open the latch and release the upper die holder.

- Insert one die into the upper die holder until locked by the ball and one die.

- Close the crimp tool head.

- Insert the conductor into the connector.

- Position the connector between the dies and ensure the correct location of the crimp.

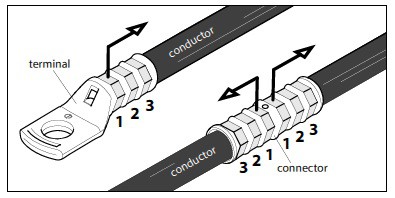

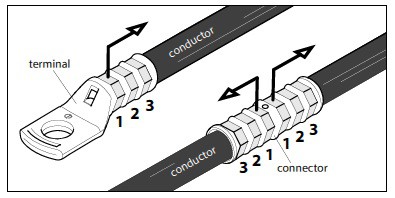

Note: when more compression is required, proceed according to the sequence and direction indicated in the figure.

Ensure that the latch and the upper die holder are fully secured, otherwise damage may occur during tool operation.

Die Advancement

- Grip the tool firmly and comfortably and press operating button to activate the motor pump and advance the lower die. To halt the advancement, release the operating button and the motor will cut out.

- Make sure the dies are exactly positioned on the desired crimp point otherwise re-open dies and reposition the connector.

Compression

- By keeping the operating button pressed, the motor continues to operate: the ram will gradually move forward until the two dies touch.

- The motor will stop automatically when the set pressure has been reached.

- To display the momentary force or pressure during the work cycle, select the appropriate display from the menu. When the operating button is released before the motor stops automatically, the display will show the peak force (Fp) or the peak pressure (Pp) reached at that instant. To complete the work, press the operating button again until the motor stops automatically; the display will show the maximum force or pressure reached followed by “OK” to confirm correct operation.

- The display “ERROR”, combined with a beep and the LEDs flashing indicates an incorrect crimping procedure caused by the work cycle being interrupted before the control parameters (force/pressure) of the tool are reached. This error appears when the pressure release button has been operated and the tool has already reached a pressure > 100 bar. In this case, repeat the compression by pressing and holding the operating button until the motor stops automatically.

Release of Dies

- Press the pressure release button, the ram will retract and open the crimp dies.

LED Worklights

- Whilst the tool is in operation, the compression area is illuminated by two high luminosity LED Worklights that switch off automatically at the end of the cycle.

Head Rotation

- For ease of operation the Cembre B500NDE tool head can rotate through 180º, allowing the operator to work in the most comfortable position.

- Warning: Do not attempt to rotate the head when the hydraulic circuit is pressurised.

Capacitive Touch Button For Menu Selection

- This button is located under the display and allows selection of various screens; it only works when the display is on. Wearing gloves or using other objects may inhibit the operation of the button, therefore use a bare finger to apply only a light touch.

Battery Status

- The battery is equipped with LED indicators that indicate the remaining battery life at any time by pressing the adjacent button.

- 4 LEDs illuminated: Fully charged

- 2 LEDs illuminated: 50% capacity

- 1 LED flashing: Minimum charge, replace the battery.

- With the battery inserted into the tool, the remaining battery life can also be checked on the display, via touch button selection.

When the battery voltage has dropped below a minimum safety threshold, the tool will not start, and it is necessary to recharge or replace the battery. The approximate time to fully recharge a battery is about 80 minutes.

After each working cycle, and after the extraction of the battery from the tool, an integrated battery cut-off device will operate after 70s approx. Then the LED nearest to button will flash 5 times each 14s approx. The battery will be reactivated when it is reintroduced into the tool and the operating button is pressed.

Using The Battery Charger

- Carefully follow the instructions in the battery charger user manual

Supplied with:

- CB 1820L, Li-Ion 18.0 V 2.0 A h Battery (2 pcs)

- ASC 30-36, Battery charger (INPUT 220-240 V / 50-60 Hz; OUTPUT 12-42 V DC / 3.0 A MAX.)

- USB cable

- Shoulder strap

- Plastic carrying case

Order Code – Cembre B500NDE

LV- HV Cable Crimping Applications

The Cembre B500E cordless hydraulic crimping tool with new 18V Li-Ion battery has the following crimp ranges:

- LV Lugs & Splices – up to 300sqmm cable conductors

- Insulated Terminals – up to 120sqmm cable conductors

- End Sleeves – up to 120sqmm cable conductors

- “C” Sleeve Connectors – up to 70sqmm cable conductors

Cembre B500NDE Battery Crimping Tool & Carry Case

➡ For Cembre electrical connections, see Cable Crimps, Lugs & Connectors

Contact T&D to discuss crimping cables at MV-HV, including 11kV-33kV, to ensure correct Cembre tool, lug/splice and die set selection.

Full range of battery cable cutting tools also available.

➡ See Cable Jointing Tools for a complete range of LV-HV-HV Tools to enable outer sheath removal, insulation removal and screen stripping from power cables operating typically at 11kV, 33kV, 66kV, 132kV and up to 400kV.