Cembre HT51 | Crimping Tool (up to 240sqmm cables)

Cembre HT51 Crimping Tool (up to 240sqmm cables)

LV-HV Cable Crimping Tools | Distributed from Stock | Approved Cembre Supplier | UK & Export Sales

Cable Crimp Capacity LV 4-240sqmm | C Connectors 70sqmm

HT51

Cembre HT51 hydraulic crimping tool is a manual tool for the crimping and compression of low voltage cable lugs, splices and connectors up to 240sqmm.

Cembre HT51 crimping tool is lightweight and ideal for use in working confined switchgear and other LV cable jointing, splicing and terminating applications. The hydraulic crimping tool features spring loaded handles allowing the Cembre die sets to be advanced with one hand – the other hand free to position the electrical connector prior to crimping.

In addition, the crimp tool head is fully rotatable through 180 degrees wide-opening jaws for ease of use and comfort for the user enabling crimping in confined or restricted areas including LV switchgear, substations and electrical panels.

The built in safety valve also by-pass the oil supply when maximum pressure has been reached – a pressure releasing system being easily operated at any stage of the compression process. The Cembre HT51 crimping tool is suitable for installing electrical compression connectors for conductors up to 240sqmm (500 MCM).

The hydraulic crimping tool manufactured by Cembre has a twin speed operation and automatically switches from a rapid advancing speed of the ram to a slower move powerful crimping speed.

Cembre HT51-kV insulated version of the standard hydraulic crimping tool is also available for Utilities, Distribution Network Operators and Power Supply Companies.

Cembre HT51-kV – Insulated Crimping Tool

Cembre HT51 crimping tool

Specification

- Rated Operating Pressure: 600 bar (8,700 psi)

- Dimensions: Length 380mm, Width 130mm

- Cable Crimper Weight: 2.75kg

- Oil: AGIP ARNICA 32 or SHELL TELLUS TX 32 / equivalent (Approved by Cembre)

Cembre crimping tools should be cleaned daily (or after use) with a clean cloth removing any residue in particular particles close to pivots and moveable parts. Every six months it is essential to check the oil level in the reservoir. If necessary fill oil level to the top lip and remove any excess air from the reservoir.

For storage and protection the Cembre HT51 tool is supplied in a robust carrying case for storage of the crimping tool and up to 20 sets of die sets.

- Dimensions 445x290x95mm

HT51 Crimping Tool Main Applications

| LV Cable Lugs Splices | C Sleeve Connectors | Crimping Force |

| 4-240sqmm | 70sqmm | 50kN |

HT51 Dimensions

| Cable Crimping Force | Length | Width | Weight |

| 50kN | 380mm | 130mm | 2.7kg |

Cembre HT51 Hydraulic Crimping Tools

User Instructions

Cembre HT51

- Select the appropriate die set for the connectors (crimp lugs or splices)

- Open the latch and release the upper die holder of the Cembre HT51 crimping tool

- Insert one die into the upper die holder and one die into the lower die holder

- Close the latch

- Remove the handle holder to release the moveable handle

- Insert the conductor into the connector (crimp lug or splice)

- Locate the connector between the crimping dies at the desired crimp position

- Operate the crimp tool handle for die set advancement

- Ensure crimp dies are positioned exactly on the desired crimp point

- Continue crimping with the Cembre HT51 using the moveable handle (See picture)

- Crimp tool will change to high pressure stage, ram will advance until dies meet

- Continue pumping the crimp tool until maximum pressure valve is activated

- Listen for “click”

- Press pressure release lever for retraction of ram and die re-opening

- The crimped connector will be released

- Press the pressure release lever to release the oil pressure in the HT51 crimp tool

Cembre HT51-KV version is a hydraulic crimping tool provided with additional external coatings to protect the user and crimp tool against accidental brush contact with energised conductors. Users should never rely solely on the insulating properties of Cembre HT51-KV when working around energised conductors.

Cembre HT51 Crimping Tool

Technical Specification

| Cembre Crimping Tool Part Reference | ||

| Tool Type | Cembre HT51 | Cembre HT51-KV |

| Crimping Force | 50kN | |

| Rated Operating Pressure | 600bar | |

| Dimensions | 380mm x 130mm | 386mm x 130mm |

| Weight | 2.75kg | 3.0kg |

| Recommended Oil | AGIP ARNICA 32 SHELL TELLUS OIL TX 32 or equivalent | AGIP ITE360 or ESSO TRANSFORMER P60 or equivalent |

| Operating Speed | the tool has a twin speed operation and automatically switches from a rapid advancing speed of the ram to a slower more powerful crimping speed | |

| Safety | the tool is provided with a maximum pressure valve: MPC1 gauge is available to check the correct setting of the valve | |

Cembre HT51 Crimping Tool

Maintenance

The following information provides some general advice of the operation and maintenance of Cembre HT51 crimping tool – for further information contact Thorne & Derrick.

Air in the hydraulic circuit may affect the performance of the Cembre HT51 tool; e.g. no lower die advancement, slow advancement of the lower die; lower die pulsating.

In this case proceed as follows:

To purge air bubbles from hydraulic circuit

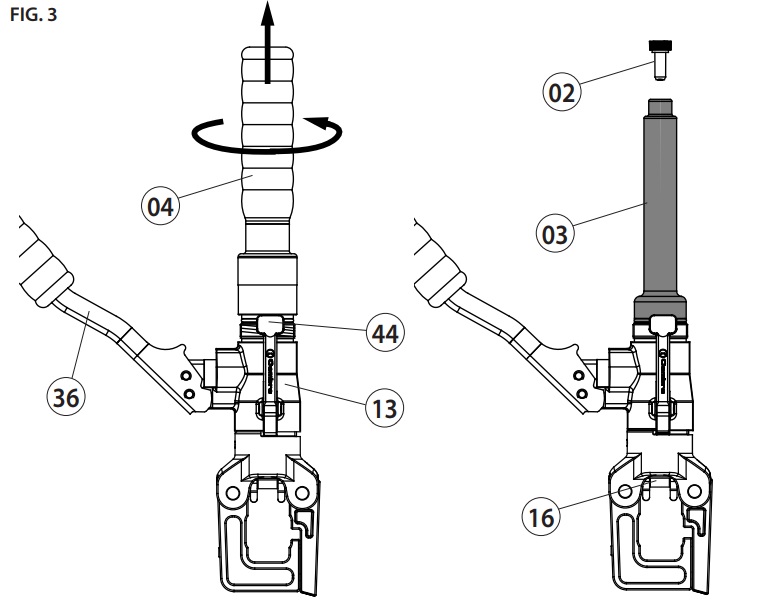

a – Hold HT51 tool upright in a vice with handles open (Fig. 3).

b – Unscrew the main handle (04) from the body (13) to expose the rubber oil reservoir (03).

c – Remove reservoir cap (02).

d – Operate moveable handle (36) several times, in order to advance the ram (16).

e – Press the pressure release lever (44) to retract the ram (16), discharge oil pressure from the circuit and return all oil to the reservoir.

f – Repeat points (d – e) five times, to ensure all air bubbles in the hydraulic circuit are purged into the reservoir.

g – Remove all air from reservoir.

If the oil level is low,top up as directed in paragraph 4.2.

h – Fit reservoir cap (02).

i – Assemble main handle (04) to Cembre HT51 tool body.

If the tool continues to malfunction, return the tool for service/repair as detailed in § 5.

Oil top up

Every six months check the oil level in the reservoir. If necessary, top up the oil level to the top lip of the reservoir and remove all air from the reservoir, see 4.1, points a, b, c and e, finally, complete with operations h and i.

Always use clean recommended oil, see § 1.

Do not use old or recycled oil.

Do not use hydraulic brake fluid.

HT51-KV tool contain oil with a high insulating power, do not pollute it with other types of oil!

➡ Ensure that disposal of used oil is in accordance with current legislation.

Cembre HT51 Hydraulic Crimping Tool

Cembre HT51 supplied with protective carrying case, tool manual and crimp die sets

Die Set Options

A complete range of die sets are available for crimping all types of LV cable lugs and connectors for use with the Cembre HT51 tool up to 240sqmm.

| Cable Conductor Size | A Range Lugs Low Voltage LV 600/1000V | Flexible Copper Lugs | Cord End Ferrules |

| 4sqmm | ME1-50 | – | – |

| 6sqmm | ME1-50 | – | – |

| 10sqmm | ME2-50 | – | – |

| 16sqmm | ME3-50 | – | MTT16-50 |

| 25sqmm | ME5-50 | – | MTT25-50 |

| 35sqmm | ME7-50 | ME9-50 | MTT35-50 |

| 50sqmm | ME10-50 | ME12-50 | MTT50-50 |

| 70sqmm | ME14-50 | ME17-50 | MTT70-50 |

| 95sqmm | ME19-50 | ME20-50 | MTT95-50 |

| 120sqmm | ME24-50 | ME29-50 | MTT120-50 |

| 150sqmm | ME30-50 | ME35-50 | – |

| 185sqmm | ME37-50 | ME40-50 | – |

| 240sqmm | ME48-50 | – | – |

Cembre offer a range of crimping tools including HT45-E | HT120 | HT81-U | HT131-C | HT131LN-C | HT131-UC

LV- HV Cable Crimping Applications

Cembre HT51 hydraulic crimping tool is generally used to terminate conductors during the installation of LV cable glands (up to 240sqmm) – this includes both Cold Shrink and heat shrink types.

- LV Cable Lugs & Splices – up to 240sqmm cable conductors

- Insulated Terminals – up to 120sqmm cable conductors

- End Sleeves – up to 120sqmm cable conductors

- “C” Sleeve Connectors – up to 70sqmm cable conductors

➡ For Cembre electrical connections, see Cable Crimps, Lugs & Connectors

Contact T&D to discuss crimping cables at MV-HV, including 11kV-33kV, to ensure correct Cembre tool, lug/splice and die set selection – visit battery crimping tools for repetitive crimping of cables without strain injury or worker fatigue.

➡ How To Purge Air Bubbles From Cembre Hydraulic Crimping Tool – Model HT51

CRIMPING DIE SET GUIDE FOR CEMBRE HT51

Cembre provides a matched crimping system to ensure secure LV MV HV electrical connections (lugs and splices) manufactured from copper or aluminium in accordance with CE Marking and international standards – includes a full range of nest, indentor and die sets compatible with their hydraulic and battery crimping tools, all manufactured by Cembre.

Cembre Copper Tube Connectors & Cable Lugs

| Copper Conductor sqm | Connector | Hexagonal Crimp | Indent Crimp | |||||

| Low Str | Flex | Terminal Lug | Through Connector | Die Set | No of Crimps* | Nest | Indentor | No of Crimps* |

| 4-6 | A1-M | L1-M | ME1-50 | 1 | MA1-50 | PA1-50 | 1 | |

| 10 | A2-M A2-P12 |

L2-M | ME2-50 | 1 | MA2.3-50 | PA5-50 | 1 | |

| 16 | A3-M A3-P14 |

L3-M | ME3-50 | 1 | 1 | |||

| 25 | A5-M A5-P16 |

L5-M | ME5-50 | 1 | MA5-50 | 1 | ||

| 35 | 25 35 |

A7-M A7-P20 |

L7-M | ME7-50 | 1 | MA7-50 | PA10-50 | 1 |

| 35 | A9-M | ME9-50 | 1 | MA9-50 | 1 | |||

| 50 | 50 | A10-M A10-P25 |

L10-M | ME10-50 | 2 | MA10-50 | 1 | |

| 50 | A12-M | ME12-50 | 2 | MA12-50 | PA19-50 | 1 | ||

| 70 | 70 | A14-M A14-P30 |

L14-M | ME14-50 | 2 | MA14-59 | 1 | |

| 70 | A17-M | ME17-50 | 2 | MA17-50 | 1 | |||

| 95 | 95 | A19-M | L19-M | ME19-50 | 2 | MA19-50 | 1 | |

| 95 | A20-M | ME20-50 | 2 | MA20-50 | 1 | |||

| 120 | 120 | A24-M | L24-M | ME24-50 | 2 | MA24-50 | PA24-50 | 1 |

| 120 | A29-M | ME29-50 | 3 | |||||

| 150 | 150 | A30-M | L30-M | ME30-50 | 3 | |||

| 150 | A35-M | ME35-50 | 3 | |||||

| 185 | 185 | A37-M | L37-M | ME-37-50 | 3 | |||

| 185 | A40-M | ME40-50 | 3 | |||||

| 240 | 240 | A48-M | L48-M | ME48-50 | 3 | |||

For crimping applications including ABC conductor fittings, copper “C” connectors, nylon insulated copper connectors, overhead line fittings and end sleeves please contact us.

Full range of battery cable cutting tools also available.

Cembre HT51 Crimping Tool & Case

➡ See Cable Jointing Tools for a complete range of LV-HV-HV Tools to enable outer sheath removal, insulation removal and screen stripping from power cables operating typically at 11kV, 33kV, 66kV, 132kV and up to 400kV.

Alroc Tools – Cable Jointing Tools (MV HV)