Blog

Vinyl Electrical Tape | A Toolbox Essential from 3M Electrical

March 26th, 2021

Electrical Tapes

Any electrician will tell you that no toolbox is complete without vinyl electrical tape.

Using it feels like second nature. Whether you’re splicing, re-jacketing or labelling, you can unwind it, stretch it and wrap it with unparalleled ease. In the cold winter months you tuck it into your coat pocket to keep it warm, and in the summertime the empty cases become storage boxes for your fishing flies, kept at the ready for when the day is done.

What would you do

if there was no electrical tape?

A life without this sticky companion might sound like a nightmare, but for early electricians that scenario was a reality – because electrical tape simply didn’t exist.

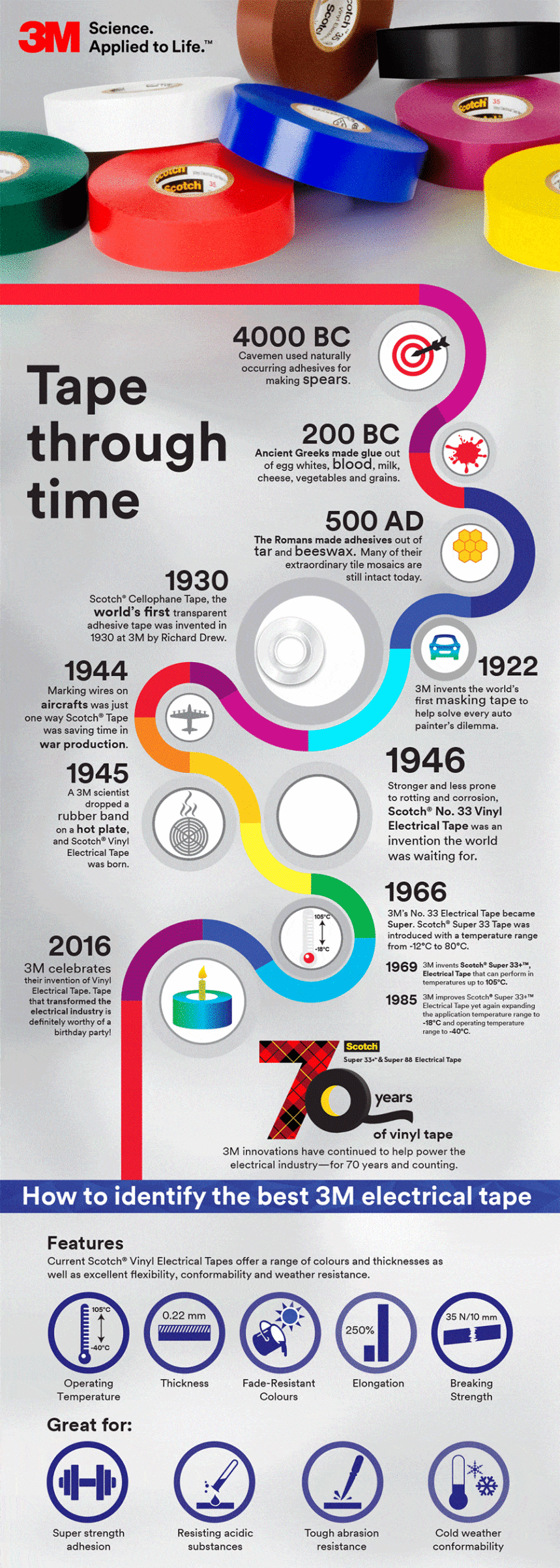

In fact, the vinyl electrical tape that we all know and love came into existence 70 years ago, when 3M inventors Snell, Oace, and Eastwold created it and saved electricians from the weak, corrosive and rot-prone tape of yore, which was made of tar-coated cotton with a vulcanized rubber adhesive.

Electrical tape has evolved with you in mind so you can find the best tape for your job.

A lot has changed in the world of vinyl electrical tape since its inception in the 1940’s – today there’s almost more tape selection than you can handle. If you’ve ever wondered about the history of tape – look no further. Some of the facts in this infographic may surprise you! ➡ This handy-selector guide shows the differences between 3M’s vinyl electrical tapes so you can be sure that you’re keeping the right one for you – right at hand.

➡ This handy-selector guide shows the differences between 3M’s vinyl electrical tapes so you can be sure that you’re keeping the right one for you – right at hand.

| Best For General Use | Most Versatile | Best In Cold Weather |

| Vinyl Electrical Tape Temflex |

Scotch Vinyl Electrical Tape Super 33+ |

Scotch Vinyl Electrical Tape Super 88 |

|

|

|

Thorne & Derrick Stockist & Supplier | 3M Scotch Electrical Tapes

3M Electrical | Expert Tip: Why You Should Choose Premium Electrical Tape

March 26th, 2021

3M Electrical Tapes

Electrical tape is second nature to you – used so frequently it’s often something that you don’t think twice about.

But is the electrical tape you’re picking up strong enough for your job?

Choosing a premium electrical tape from 3M Electrical can make a difference in efficiency, quality, workmanship – and overall safety.

Here’s what you need to know about choosing electrical tape for long-lasting performance.

What is the difference between premium and general use electrical tape?

Premium tapes like Scotch® Super 88 and Scotch® Super 33+™ Vinyl Electrical Tape can help improve performance versus a mid-grade or general use electrical tape that is designed for bundling and pulling wire and cable.

3M Electrical Tapes

➡ Did you know? 3M invented vinyl electrical tape in 1946!

What makes premium electrical tape “premium”?

The elongation (high-stretch), elasticity (memory), and adhesion (bond) capabilities of the electrical tape contributes to an overall better underlying seal aiding in weather and corrosion resistance – the Scotch tape also acts as an outer layer for extra UV and abrasion resistance.

What should you look for when choosing a premium electrical tape?

For me it comes down to efficiency, performance, and elasticity.

That’s why I recommend Scotch® Professional Grade Heavy Duty Vinyl Electrical Tape Super 88 and Scotch® Super 33+™ Vinyl Electrical Tape.

Key benefits of these premium, professional grade electrical tapes include:

- excellent cold weather performance

- water resistance

- mechanical protection

- stretch and memory for easier taping of irregular objects

Another added bonus is that Scotch® Professional Grade Heavy Duty Vinyl Electrical Tape Super 88 is available in various widths.

Oftentimes, when talking electrical tape with electricians I reinforce a “decision-making trifecta”, which really means factoring in application(s), weather, and environmental/field conditions when it’s time for them to restock on electrical tape.

Thorne & Derrick International | MV HV Joints, Terminations & Cable Connectors

3M Scotch | Choosing The Right Electrical Tape For Your Application

March 26th, 2021

3M Scotch Electrical Tapes

There are many electrical tapes on the market, and it can be difficult to choose the right one for your specific application.

Each type of Scotch Electrical tape is designed for specific applications and using the wrong one can impact the quality of your installation and/or repair.

Here are three applications and my recommendations for the most suitable electrical tapes for each. These applications are:

- Environmental sealing and re-jacketing of cables LV MV HV

- Low-voltage primary insulating

- Medium-voltage primary insulating and waterproofing of cables, joints and accessories

1. Choose mastic tapes for environmental sealing and re-jacketing

Mastic tapes are effective for environmental sealing applications – and for good reason.

Their sticky adhesive allows them to seal on most surfaces and they can easily fuse to themselves. This is important because, as you wrap the tape, it creates a strong and reliable seal. It’s important to remember that, when working on a cable jacket, you will need abrasion resistance. Also, keep in mind that not all mastic tapes are created equal and each have their own purposes.

Here is what you need to know when choosing a 3M™ Mastic Tape:

- For normal sealing and filling, I recommend using 3M™ Scotch-Seal™ Mastic Tape 2229 or Scotch® Rubber Mastic Tape 2228. They’re designed to help you get your job done just right and efficiently. From the thick construction of 3M™ Scotch-Seal™ Mastic Tape 2229 to the easy release liner on Scotch® Rubber Mastic Tape 2228 that allows for quick application build–up. Both options work well for environmental sealing applications, especially 3M™ Scotch-Seal™ Mastic Tape 2229 for filling.

- For re-jacking applications, I recommend using Scotch® Cable Jacket Repair Tape 2234. This flame-retardant mastic acts as a barrier and offers optimized adhesion on jacket materials for longer lasting seals, and great abrasion resistance.

Watch this video on how to apply 3M™ Scotch-Seal™ Mastic Tape 2229.

Watch this video to see how you can repair a cable jacket with 3M™ Mastic Tapes.

2. Choose vinyl tapes for low-voltage primary insulating.

Before you start your low-voltage cable splicing (600V and less) project, ask yourself where the cable splice is going to be.

If it’s in a sealed box, or in an environment that is always dry, vinyl electrical tape is the best choice because it has excellent dielectric strength and durability.

If the splice will be buried or could become wet, vinyl electrical tape alone won’t be enough.

To ensure the longevity and durability of the application, you will also need to seal the splice. The easiest way to do this is by using a rubber tape first and then covering it with vinyl electrical tape.

Here is what you need to know when choosing a 3M™ Vinyl Tape:

- For dry low-voltage splicing, I recommend Scotch® Professional Grade Vinyl Electrical Tape Super 88 because it is thicker and will help provide additional protection.

- For wet low-voltage splicing, I recommend starting first with a rubber tape like Scotch® Linerless Rubber Splicing Tape, 130C – it’s highly conformable and self-fusing. Next, apply Scotch® Professional Grade Vinyl Electrical Tape Super 88 or Scotch® Super 33+™ Vinyl Electrical Tape on top for abrasion resistance and additional UV protection.

Watch this video on how to apply Scotch® Grade Vinyl Electrical Tape Super 88.

3. Choose rubber tapes for medium-voltage primary insulating and waterproofing.

If you need to splice a primary cable and for whatever reason using a cold shrink product like 3M™ Cold Shrink Splice QS-III is not an option, a splice can be made of tape as long as the proper steps are followed.

To do this, you will need two different types of rubber tape: Scotch® Electrical Semi-Conducting Tape 13 to rebuild the semi-conductive layers, and Scotch® Linerless Rubber Splicing Tape, 130C to rebuild the insulation. When installed correctly, these two rubber tapes self-fuse without leaving any air gaps behind – and this is key in these applications. You can cover the splice using rejacketing tapes or vinyl tapes.

Watch this video on how to apply Scotch® Linerless Rubber Splicing Tape, 130C.

Thorne & Derrick Stockist & Supplier | 3M Scotch Electrical Tapes

Nexans Power Cable Accessories & Resource Centre

March 26th, 2021

Main UK Stockists & Distributors

Resource Centre | Education & Learning with Nexans

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Nexans MV-HV Connectors, Joints & Terminations to connect, splice, repair and maintain medium/high voltage cable and power distribution systems.

A complete range of Joints, Terminations & Connectors utilising EPDM rubber, heat-shrink and cold applied technologies are available for medium and high voltage power cable networks up to 66kV.

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Top 20 Blogs

See our collection of the Top 20 Nexans Blogs featuring their complete range of Medium Voltage Power Cable Accessories & Cable Services:

- Essential Reading – Medium Voltage Cable Accessories Book Published By Nexans

- Nexans Euromold Connectors : EPDM Screened Separable Connectors MV

- Nexans Euromold Screened Separable Connectors | SSE Approval

- Nexans Euromold Connectors – Webisodes

- Jointer Training Courses – Medium & High Voltage Jointer Competency Training

- Network Rail Full Acceptance for Nexans Tee Connectors & Bushings

- MV Cable Joints | Nexans New Product Launch

- Nexans MONOi Heat Shrink Termination | XLPE Indoor Single Core 12kV-36kV

- Nexans MONOe Heat Shrink Termination | XLPE Outdoor Single Core 12kV- 36kV

- 66kV Connectors, Cables & Junctions Boxes – An Interview With Nexans

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

- Facilitating Sensor Installation In Power Networks By MV Cable Accessories

- Nexans Euromold Bushings & Connectors – How To Select MV HV Connectors

- Nexans Power Cable Accessories For Wind Energy Projects – MV & HV Cables

- Nexans NX600 Alsecure Cable : Fire Resistant, Low Smoke & Halogen Free Cables

- Nexans Cable Leads Keep HV Transmission Flowing – 110kV, 132kV & 220kV

- 33kV Nexans Offshore Cable Terminations Into Ormazabal Panel

- Nexans Connector Kits Terminating 33kV XLPE Cables Into Siemens Switchgear

- Nexans Euromold 11kV Connectors Terminating Cables Into Siemens Transformers

- Nexans AFN 33kV Substation Termination With GPH Mechanical Shearbolt Lugs

Also | MV Cable Leads | Pre-Terminated Cable Leads for 33kV Power Networks

Nexans Windlink® Cables To Electrify The Future Of Onshore Wind Turbines

March 26th, 2021 Vestas turns to Nexans Windlink®

Vestas turns to Nexans Windlink®

- Two-year contract will see around one million Windlink cable kits installed inside Vestas turbines across the globe

- A local extended supply chain to match Vestas global footprint while reducing carbon impact

- A successful partnership for the development of the EnVentus platform thanks to our resident engineer program

Paris, February 16, 2021 – Nexans has secured a two-year global supply contract with Vestas Wind Systems to provide around one million Windlink® cable kits for turbines destined for onshore wind farms in Europe, the US, China and Brazil. This latest agreement extends Nexans’s long-standing position as a leading global supplier for Vestas.

The Vestas contract demonstrates Nexans’s ambition to lead the change to a new world of electrification through cost-effective wind power projects. The low voltage (LV) and medium voltage (MV) cable kits will be installed inside Vestas onshore wind turbines rated at 2, 3 and 4 megawatt (MW). They will provide pre-connected, pre-tested and easy-to-fit connections for power, control and communication functions within the nacelle, tower and control panels.

The cables that Nexans is supplying to Vestas feature rubber, thermoplastic or silicone insulation according to their specific application. A significant new development for this latest contract will be the use of completely lead-free materials in the construction of Medium Voltage cables.

In addition to the performance and reliability of the Windlink cables, Vestas also appreciates the comprehensive portfolio and dedicated expertise in technical support provided by Nexans. The Windlink cable kits also benefit from a supply chain support worldwide thanks to Nexans’s manufacturing footprint in Europe, US, China and Brazil, including a recent extension of capacity in Poland and China.

Christopher Guérin, CEO of Nexans said: “We are delighted to further extend our relationship with Vestas. Our vision is to build a world that is safer, sustainable, renewable, decarbonized and accessible to everyone and the wind turbines manufactured by Vestas are a perfect fit for that vision. It is also especially pleasing that our solutions will be fitted within the next-generation EnVentus platform that enables turbines to provide more wind energy efficiently.”

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV