Blog

Identifying Workmanship Issues With Factory Grade Technology

March 8th, 2021

Identifying Workmanship Issues With Factory Grade Technology

Guest Article: IMCORP by Ben Lanz

uploaded by Natalie Lundie – Thorne & Derrick Supply Chain: Marketing Lead

IMCORP’s Factory Grade technology proven 100% effective in identifying workmanship issues and providing Precision Reliability feedback to utility clients and their contractors.

We all know that foreign objects, contamination, or moisture in any medium voltage cable accessory or component will certainly lead to a shortened lifecycle.

An oversight in cleaning and inspecting this 600AMP TBODY during its installation was recently discovered during partial discharge testing at a solar site.

Partial discharge detected, below the manufacturer’s standards led to an inspection of the termination connector which yielded a Hex nut pressed into the wall of the TBODY. That’s right a Hex head nut was causing PD, but maybe more interesting is this had been in service for 2 months prior to IMCORP’s QA testing and had previously passed a VLF test.

Had this cable termination faulted it would have caused the site owners significant financial loss in revenue.

A critical step in the installation is to decontaminate and inspect any medium voltage connections before landing them was clearly missed here!

IMCORP is the technology leader in Medium & High Voltage Power Cable Systems life cycle condition assessment and performance – IMCORP have been helping their clients achieve maximum cable reliability for more than 20 years and have assessed over 130,000 5kV to 500kV cable systems spanning in excess of 160 million feet.

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

All international sales enquiries can be serviced and supplied by our Export Power Team.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

DENSOBAND | Sealing Joints In Highway Construction & Maintenance

March 8th, 2021

Highway Joint Sealing

Densoband

Densoband™ is a polymer modified bitumen compound in strip form, used for sealing joints between asphalt to asphalt, concrete and road castings in road construction and bridge expansion joints. It can also be used for airport runway joints and light railway/tram construction to form a flexible seal between the track and the surrounding asphalt.

Containing filler, a flow control additive and a root deterrent, Densoband forms a flexible watertight seal which allows for road movement from cyclic traffic load and thermal changes to prevent cracking and subsequent erosion.

Providing a uniform flexible seal across the joint face, Densoband™ is ideal for base and wearing course joints and prevents deterioration by sealing out water, chemical pollutants, weed seeds and other pollutants/contaminants.

When applying Densoband with a gas torch, a uniform, consistent joint is recommended rather than a randomly poured joint.

➡ See also Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Densoband Features

- Used in road, tramway, railway and airport runway repair and construction

- Sealing bridge and flyover expansion joints

- Minimises return maintenance visits

- Uniform flexible seal for base and wearing course joints

- Adheres to asphalt, concrete and ironware

- Withstands road movement from traffic load and thermal changes

- Over 25-years use in the UK

- Densoband fully complies with the Department of Transport Specification for Highway Works, 7th Edition

Instructions For Use

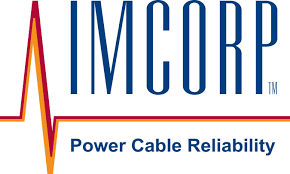

Joint Surface

The joint surface should be sawn for preference to present an even vertical face throughout its length.

Cleaning (see Fig 1.)

Do not apply Densoband to wet or oil contaminated surfaces.

- Ashpalt, concrete, kerbstone surfaces: Clean with a stiff broom or wire brush to remove all dust, dirt, debris

- Metal surfaces such as road castings: Wire brush to remove all loose rust, dirt, etc.

Priming (see Fig 2.)

Apply Densoband™ Primer to the vertical joint face and allow to dry.

Applying Densoband (see Figs 3 & 4)

- Cut Densoband to length.

- Remove interleaving paper.

- Heat one surface of the Densoband with a gas torch.

- Apply the molten surface to the primed face using the applicator spatula or similar tool to assist adhesion. Densoband should stand 5mm proud of the existing road surface. Trim flush to metal.

- Mitre Densoband into corners of right angle joints.

Compaction

After laying and levelling the new wearing course asphalt, the first pass of the roller should be along the joint edges, compacting the Densoband to form a ‘rivet head’.

Further Reading

Sealing & Waterproofing of Cable Ducts Using Densoseal 16A | Thames Water Project

Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Denso Bore-Wrap | Prevent Coating Damage During Pipeline Installations

About Denso

Denso North America Inc. is a subsidiary of Winn & Coales International, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics, primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems. Winn & Coales was originally established as a business in London, England, in 1883, and the first petrolatum tape manufactured in the UK was Denso tape, manufactured under license by Winn & Coales (Denso) Limited.

Denso tape was developed over 80 years ago for the “Long Life Protection” of buried steel pipelines against corrosion. The Denso SeaShield Marine Systems include fiberglass forms, epoxy grouts, underwater epoxies, injectable epoxies, petrolatum tape and wrap systems.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

MV & HV Cold Shrink | Cable Accessory Failure Modes

March 8th, 2021

MV & HV Cold Shrink | Cable Accessory Failure Modes

MV & HV cold Shrink

What is Cold Shrink for Medium and High Voltage Cables?

Developed in the 1970’s by 3M, MV & HV Cold Shrink technology has been found to be safer, more reliable and easier to install for the jointing, terminating and abandoning of power cables.

3M Cold Shrink is made from either EPDM (Ethylene-Propylene-Diene-Monomer) or silicone rubber, that is expanded onto a spiral core. After the cold shrink tube has been placed over the joint or cable termination end, this inner spiral is pulled out. The insulating tube then contracts to its pre-stretched size and shrinks onto the cable, exerting constant radial pressure for the lifetime of the joint or termination.

Cold Shrink Offers the Maximum Mechanical Protection

Cold shrink products have a 45+ year track record of performing exceptionally well in indoor and outdoor environments, including under harsh conditions.

The silicone material conforms well to cable bends, which ensures long term reliability against moisture ingress, or voids within the installation. It is shows excellent performance in the following environments:

- Refineries

- Coastal environments

- Altitude

- Dusty environments eg. solar power plants, wind farms

- Vibrations eg. railroad, subway

- Underwater environments

- Overhead joint applications

Cold shrink

Cable Accessory Reliability

There are a variety of issues that can impact on the reliability of MV & HV cable accessories.

These issues include:

- Improper Accessory Selection

- Difficult to Follow Instructions

- Workmanship

- Number of Installation Steps

- How the Accessory is Delivered to the Cable

- Materials Used to Manufacture the Accessory

- Tolerances & Product Design

- Environment Factors

- Training & Support

Medium Voltage cable accessories

3M Electrical manufacture a range of cable accessories for medium and high voltage cables, including cold shrink, which enable quick and easy installation and efficient operation.

Terminations |

Separable Connectors |

Joints / Splices |

||

|

|

|

|

||

| 3M™ Cold Shrink QT II and QT III Indoor and Outdoor (skirted) | 200 Amp Load Break Elbows | 3M™ Cold Shrink QS III Cable Splice Kits | ||

| 600 Amp Dead Break T bodies |

3M™ Cold Shrink QS4 Integrated Splice Kits |

|||

|

|

|

Further Reading

- 66kV Terminations | NEW Stock Introduction for 3M Cold Shrink Cable Terminations

- Stress Control | MV Cable Terminations by 3M Electrical

- Cable Jacket Repair | 3M Electrical Webinar

3M – DISTRIBUTORS, STOCKISTS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of 3M Scotchcast and Cold Shrink cable joints, terminations, resins and Scotch electrical tapes – we stock high voltage cable joints and terminations manufactured from 3M using Cold Shrink for 11kV and 33kV cables.

Thorne & Derrick

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Convex Cable Hangers | Supporting Rail Cables & Tunnel Wall Applications

March 8th, 2021

Convex Cable Hangers

Thorne & Derrick distribute a range of Cable Hangers, including convex cable hangers from Ellis, for low, medium and high voltage electrical systems; typically distributing LV 6.6kV-11kV-33kV electrical power.

Our cable hangers and accessories range include:

- Cable Hangers – Galvanised Steel Cable Hanging Systems (LV MV HV Cable)

- Cable Hangers – Non Metallic Cable Hanging Systems (LV MV HV Cable)

- Cable Hooks – LV MV HV Cable Suspension Hooks

Cable hangers support single or multiple cables – hangers are available in both galvanised steel and nylon and are used to support horizontal cable routes to building and tunnel structures. A complete range of steel cable hooks are also available compliant with 18th Edition of the IET Wiring Regulations (BS7671) is effective as of January 1, 2019.

CABLE hangers IN THE RAIL INDUSTRY

Convex Cable Hangers | Supporting Rail Cables & Tunnel Wall Applications

Investment in the rail sector has grown rapidly over the last decade and much greater funding is expected going forward. Both UK and worldwide, there is a growing ambition for more modern, reliable and sustainable mass transit systems.

Ellis has the most extensive range of cable cleat designs and accessories on the market which are suitable for all applications within the rail industry. Overground and underground rail sectors use an extensive range of cable types including telecoms, alarm and control cables, signalling and data, and a range of power delivery and electrification cables. Many rail cables are installed using cable hangers. Ellis has improved the design of the basic galvanised steel hanger with reduced weight, radiused corners (to reduce damage to cables during installation) and a convex hanger profile for cable sagging.

Cable hangers are curved to fit the profile of a tunnel to assist with tunnel wall applications.

These reduce the level of supporting steel structures necessary as the hangers can attach directly to the tunnel profile. Where the kinematic envelope of trains is tight and space is restricted, these profiled hangers provide an effective solution.

NEW convex cable hangers | ellis Patents

Ellis has now enhanced a cable hanger product that has been one of its best-sellers for over 20-years. The technical team have taken the company’s cable hangers, which are used primarily in the rail industry and made them stronger and, remarkably cheaper.

Stephen Walton, Ellis’ Technical Director, said: “We’ve been successfully manufacturing and selling our cable hangers for two decades, and it’s fair to say that the design is tried, tested and completely trusted by all those who use it.”

Ellis achieved this by looking at every aspect of the product and looking at ways to improve on it. The first key development is that there are two different versions of the new Ellis cable hanger – a standard Mk2 cable hanger, and a convex hanger; the latter designed specifically for use in tunnels, where the mounting surface is often curved.

Benefits of the new Mk2 cable hangers include:

- Rounded corners that reduce snagging points

- Spin galvanized (55µm or 150µm thickness) to protect against erosion

- Only 6mm thick, leading to reduced product and shipping costs

- Wide range of sizes available

- Suitable for cables up to 100mm diameter

- Custom designs available

- Rolled designs for tunnels available

Meanwhile, the convex cable hanger has all the benefits of Mk2, plus:

- The removal of all sharp edges presented to the cable by traditional hangers

- Through innovative design, it’s the same strength as Mk2, but only 5mm thick

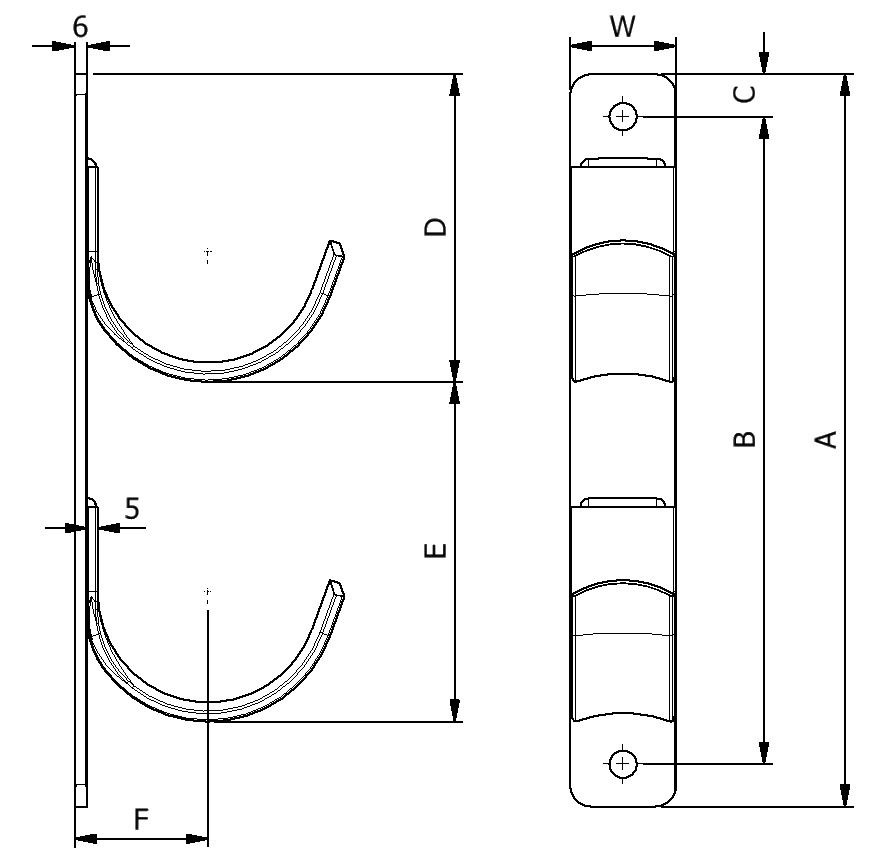

Convex Cable hanger

Technical Information

Material: Galvanised Mild Steel

Application: Hang cables on walls and support structures

The NEW convex cable hanger are manufactured in Galvanised Mild Steel and have a curved back plate to suit tunnel wall applications. The convex profile of this hanger reduces the risk of cable damage and facilitates cable sag. The main use of these hangers is to hang cables on walls and support structures in the rail industry.

*Special designs available on request – e.g. Girder Hanging, 90° Twist, side by side cables.

*sample available on request

Convex Cable Hanger – Dimensions

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Denso Bore-Wrap | Prevent Coating Damage During Pipeline Installations

March 8th, 2021

Denso Bore-Wrap – A heavy-duty, sacrificial Abrasion Resistant Outerwrap (ARO) for trenchless pipeline installations, severe handling of installations in difficult terrain.

Denso bore-Wrap

We are excited to announce the launch of the latest innovation from Denso.

The Denso Bore-Wrap is an Abrasion Resistant Outerwrap (ARO) which has outstanding performance against impact, gouge, abrasion, and fracture.

Bore-Wrap creates a superior sacrificial outer laminate layer, which protects both pre-approved field joint coatings and mainline coatings. These coating include liquid epoxy coating, heat shrink sleeves, 3LPE, 3LPP and FBE coatings; which are protected from damage during pipeline installations with Bore-Wrap, in difficult terrain or by means of trenchless installation methods, such as directional drilling, HDD or boring.

Denso Bore-Wrap is easily applied in the field.

With no mixing required, it is simply wrapped over the existing pipeline coating and cured with water. Due to its flexibility and exceptional level of mechanical protection, Bore-Wrap minimises the need for costly spot repairs or re-pulling pipe from damage.

Bore-Wrap Features & Benefits

- Prevents coating damage during trenchless pipeline installations, severe handling or difficult terrain

- Outstanding impact, gouge, abrasion and fracture resistance

- Minimises the need for spot repairs or re-pulling pipe from damage

- Easy to apply with no mixing and a rapid cure time

- Resistant to water, acid, salts, or soil organics

- Excellent flexibility, hardness and adhesion

- VOC free

ABOUT DENSO

Denso North America Inc. is a subsidiary of Winn & Coales International, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics (Densoseal 16a), primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems. Winn & Coales was originally established as a business in London, England, in 1883, and the first petrolatum tape manufactured in the UK was Denso tape, manufactured under license by Winn & Coales (Denso) Limited.

Denso tape was developed over 80 years ago for the “Long Life Protection” of buried steel pipelines against corrosion. The Denso SeaShield Marine Systems include fiberglass forms, epoxy grouts, underwater epoxies, injectable epoxies, petrolatum tape and wrap systems.

Densoseal 16A – Self-supporting & Non-setting Mastic for Sealing Cable Entries & Ducts

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV