Blog

The Case for Low Smoke Zero Halogen Cable Labels & Public Safety

November 11th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Low Smoke Zero Halogen Cable Labels

Today’s world of modern, intelligent and complex buildings demands the highest safety performance from their electrical cables and cable accessories including cable labels.

Traditional BS5467 cable (LV power cable) is constructed with PVC sheathing – in a fire PVC cables release toxic smoke and gasses posing safety threats to people and plant.

To enhance public safety a Low Smoke Zero Halogen (LSZH) power cable was developed for installation in highly populated enclosed public areas.

This low voltage power cable is a LSZH version of the established BS5467.

The cable was given a specific British Standard category – BS6724.

Installing BS6724 Low Smoke Zero Halogen (LSZH) power cable is an investment in public safety – therefore why compromise that safety by then installing sub-standard cable accessories, such as cable labels?

BS6724 power cable is extensively specified for low voltage power distribution to electrical construction and building projects in the UK – especially in public areas where fire, smoke emissions and toxic fumes could potentially threaten both lives and equipment.

Typical BS6724 cable applications include hospitals, museums, retail, offices, airports, rail stations, sports stadium, tunnels, shopping centres and commercial developments.

Silver Fox & The Rail Industry

Network Rail & LUL Approved

T&D are Main Distributors for Silver Fox, the UK leading manufacturer of Wire & Cable Labeling Systems for the identification of Electrical, Instrumentation, Security, Data & Telecoms cables in the rail industry.

When exposed to fire, BS6724 Low Smoke Zero Halogen cable sheathing emits very low levels of smoke and non-toxic levels of halogen gas (typically under 0.5% HCl emission).

Silver Fox “Fox-Flo®” cable labels are safe and provide protection against all aspects of fire hazard including smoke and gas emissions, flame spread and heat release.

Network Rail & LUL Approved

Why Use Low Smoke Zero Halogen Cable lABELS?

Safe, risk free cables should not be compromised by sub-standard cable accessories, such as cable labels, which could emit life-threatening levels of toxic smoke and gasses in the event of a fire. In fire situations, PVC based cables and cable markers can be a vehicle for flame propagation whilst also generating smoke, corrosive and toxic fumes.

Effectively fuelling the fire.

Where contractors are installing low smoke, zero halogen and flame-retardant power cables for low voltage distribution indoors, outdoors, buried or in air, careful attention should be made to specifying equal-specification cable accessories to preserve LSZH circuit integrity.

Tie-on LS0H Cable Labels (Heat Shrink) – Silver Fox Fox-Flo®

For instance The Silver Fox “Fox-Flo®” cable labels are the perfect cable marking system for Prysmian Afumex Low Smoke Zero Halogen cables. Prysmian Afumex, is the market leading Low Smoke Zero Halogen Cable.

Afumex

Other LSZH Cable Applications for Silver Fox Cable Labels : 6491B Single Core Conduit Cables, 6242B Twin Flat Wiring Cables, Screened Wiring Cables and LSZH building cables for power, lighting and sub mains distribution.

Silver Fox Cable Labels

Relationship with Fire

- Low Smoke Emission – traditional PVC and plastic cable markers release thick black smoke which obscures escape routes and causes asphyxiation, reducing the public’s ability to respond in an emergency which can result in mass panic.

- Low Corrosive Gas Emission – although often invisible, when burnt, PVC emits acidic gas which causes corrosion and failure of electronic equipment. Toxic gasses incapacitate the public trying to escape the burning building.

- Reduced Flame Propagation – when exposed to flame cables and labels should self-extinguish when the flame source is removed.

Silver Fox Fox-Flo Zero Halogen Tie-on Cable Labels – Flame Test

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Impact & Mitigation of Icing on Power Network Equipment

November 11th, 2019

Courtesy INMR

INMR offers expert technical content for power engineers in the fields of electrical insulators, surge arresters,  bushings, cable accessories MV HV and utilities.

bushings, cable accessories MV HV and utilities.

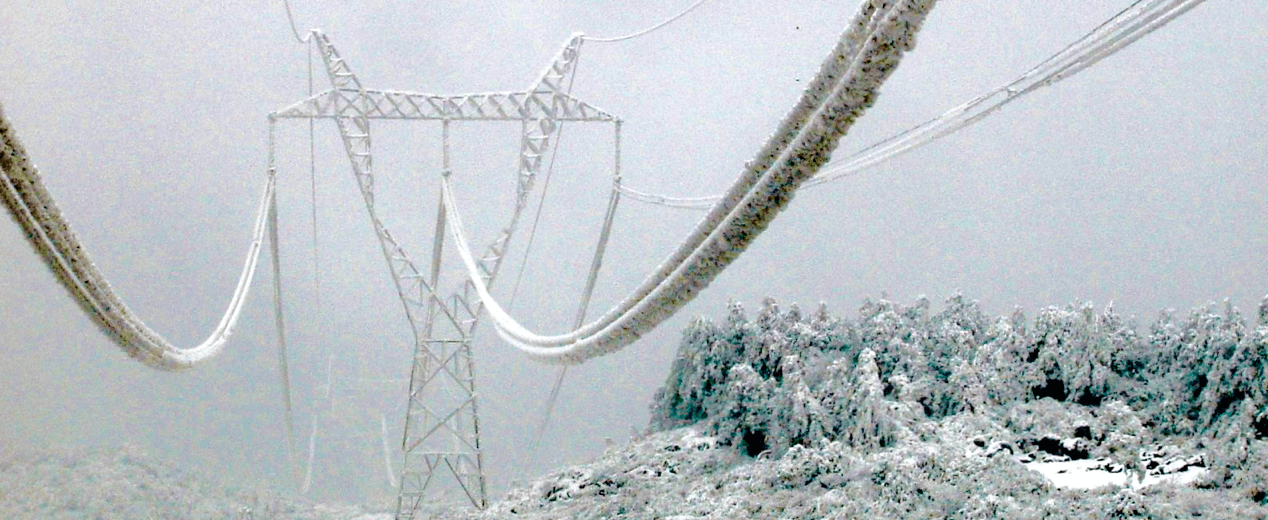

In many parts of the world, ice and snow accretion on network equipment such as conductors, ground wires and insulators are a great concern for power system operators. The disruptive effects of icing result from excessive ice or snow accumulation, combined with wind forces, as well as subsequent jumping of cables and conductors following sudden ice shedding. Other potential sources of failure include dynamic phenomena such as galloping often involving extensive dynamic forces.

Electrical flashover along iced or snow-covered insulators is another major problem affecting reliability of overhead lines and outdoor substations. The catastrophic socio-economic impact of some major icing events such as those that struck regions of North America and China in 1998 and 2008 respectively sparked substantial R&D collaborative projects between academia and industry. This concerted action led to much innovation and improvement of overhead network design, construction and operation.

However, despite the progress, the knowledge base when it comes to this complex and unpredictable phenomenon is still not sufficient – all the more so when considering increased extreme meteorological events likely caused by climate change. Furthermore, continuous increase in energy consumption and the need for upgrading existing networks, and constructing more reliable transmission lines, call for innovative solutions to icing issues. This edited contribution to INMR by Professor Emeritus, Masoud Farzaneh, of the Université du Québec à Chicoutimi in Canada deals with the impact of icing on conductors, ground wires and outdoor insulators as well as mitigation options to improve reliability under such conditions.

Atmospheric Icing Processes

Atmospheric icing (or simply icing) refers to freezing and sticking of water in various forms on the surface of an exposed object. Therefore, icing describes both ice and snow growth on exposed structures such as power network equipment.

Icing can be classified into different categories:

i. Precipitation icing, such as freezing rain and snow;

ii. In-cloud icing, involving freezing of supercooled water droplets in a cloud or fog upon impact with an exposed structure;

iii. Hoar frost, resulting from condensation of water vapor in air on a structure when temperature is below 0°C.

Impact & Mitigation of Icing on Power Network Equipment

Types of Accretion

Depending on atmospheric and metrological parameters (air temperature, wind speed, precipitation rate, relative humidity, liquid water content, etc.) various types of accretion can occur on overhead lines and outdoor substations. These are classified as:

• Glaze ice with density of 900-920 kg/m3 has clear structure without air bubbles and generally forms with icicles. Glaze ice accretion on an exposed structure is typically the result of accretions from freezing rain or drizzle. It may also result from in-cloud icing when influx of cloud water is high.

• Rime ice has density ranging from 150 to 700 kg/m3 and occurs at temperatures below –5°C when impinging small supercool water droplets freeze spontaneously on an exposed structure. This type of accretion is typically formed on structures in hilly areas over the cloud base or on structures exposed to cold fog. Depending in its physical appearance, structure and density, rime ice is classified as hard rime or soft rime. Hard rime is characterized by a homogenous opaque structure and density varying from 300 to 700 kg/m3 and is grown homogeneously with air bubble inclusions. Soft rime has a granular opaque structure and a density ranging from 150 to 300 kg/m3. It grows in a granular structure with many air bubbles.

• Wet snow occurs at air temperatures above the freezing point, usually between 0.5 and 2ºC. Depending on liquid water content and localized wind speed, density of wet snow varies from 100 to 850 kg/m3.

• Dry snow with density not exceeding 100 kg/m3 occurs at sub-freezing temperatures and can accumulate on exposed structures under low wind speed conditions.

• Hoar frost has density of less than 100 kg/m3 and is deposited as interlocking ice crystals formed by direct sublimation of freezing water vapor in air on an exposed structure.

Due to variations in meteorological conditions, atmospheric ice accretion can be a mixture of two or more different types of icing. Among these, glaze, hard rime and wet snow with relatively high water content have strong adhesive force when accumulating on exposed structures. As for dry snow, soft rime and hoar frost, adhesion strength is normally low such that these accretions are easily blown off by wind or shaken off from conductors or earth wires. In the case of hoar frost, while the increase in ice load is usually small, it can nevertheless cause high corona losses on HV and UHV lines.

Atmospheric Icing Processes

Impact of Ice & Snow Accretion

Mechanical Issues

Icing or combined loads of wind and icing can severely impact overhead transmission and distribution networks in regions with cold climates. For example, overloading of conductors and ground wires by heavy icing, sometimes combined with wind forces, can cause them to break sometimes leading to tower collapse. In addition to excessive loading, other phenomena such as conductor and ground wire galloping, ice or snow shedding from conductors and ground wires as well as rolling of bundled conductors can induce severe loading issues, as detailed below.

Galloping of Conductors & Ground Wires

Galloping, a wind-induced instability, occurs under moderate and strong wind on ice or snow-covered conductors and ground wires. This perturbing phenomenon, with peak-to-peak amplitude reaching up to 15 m, can result in phase-to-phase flashover or in direct contact of phase conductors resulting in short-circuits and outages. This dynamic phenomenon can also result in fatigue problems as well as serious mechanical damage to conductors, hardware and support structures.

Ice & Snow Shedding from Conductors & Ground Wires

Ice or snow shedding from conductors and ground wires can induce dynamic forces similar to those from conductor galloping. The rate of ice or snow shedding at the source of these dynamic transient forces is affected by ice or snow morphology, meteorological conditions, wire and conductor characteristics and temperature, as well as structural design of lines. Sudden ice or snow shedding from conductors could cause high dynamic forces and consequently rebounding of conductors and their high amplitude vibration. This can lead to the reduction of clearance between the affected conductor with an adjacent phase, ground wires or part of tower causing electrical flashovers. The excessive induced dynamic forces could also cause failure of the tower arms and even cascade failure of several adjacent towers. Ice shedding over roads and highway also endangers public safety.

Rolling of Bundle Conductors

This phenomenon is observed in mountainous areas subjected to excessive rime ice accretions on transmission line bundle conductors. It can also occur under glaze ice on long spans over valleys or rivers and the instability can cause damage to spacers and conductors resulting in power outages. Fig. 1 illustrates physical modeling of this phenomenon. Tests were carried out with two- and four-conductor bundles using two span lengths, several arrangements of spacers and six different types of spacers.

Fig.1 | Outdoor test line used for bundle torsional stability studies showing twisted sub-conductors in mid-subspan following collapse

Electrical Issues

In addition to the above phenomena that are the origin of mechanical damage and failure of power equipment and support structures, ice and snow accretion on high voltage equipment are sources of other types of perturbations resulting from interaction between electric field, liquid water, ice crystals and surrounding air. Possible electrical issues from icing include the following:

• Partial discharges and local arcs;

• Corona noise and power loss;

• Electromagnetic interference;

• Flashovers of insulators.

Among the above-mentioned electrical phenomena, flashover of ice- and snow-covered insulators have attracted attention by researchers as well as power utilities since these can be a source of failures and outages. Indeed, insulator flashover problems under icing conditions have been reported from various countries experiencing atmospheric icing. According to these reports, the number of such incidents increases during icing precipitation or after accretion followed by a rise in air temperature above 0ᵒC.

For example, a 2006 CIGRE survey reported that icing flashover problems occurred on 400 kV to 735 kV networks at 35 utilities in 18 countries and involved station as well as line insulators, whether clean or pre-contaminated. Flashover problems on 115 to 230 kV networks have also been reported under combined ice and pollution conditions. Icing flashover is of particular concern for insulators in service close to high-traffic areas where road salt or other types of anti-icing fluids are used. These conditions can cause rapid build-up of contamination on exposed insulators from salt spray. This is also the case for insulators installed near by cooling towers.

Mitigation Option Related to Conductor & Ground Wire Icing

Different strategies have been used by line designers and utilities to prevent or limit extended power outages caused by mechanical icing issues. These include a range of different measures. In general, the designers of overhead power networks do what is necessary for an appropriate design of lines and structures to withstand the effects of ice and snow accretions, taking into account wind forces, based on the prescription of available standards and information provided in technical guides. When possible, areas prone to high icing loads are avoided during the design process. However, prevention of mechanical damage and failures caused by extreme ice and snow loading would require the construction of lines with larger diameter conductors and wires as well as stronger towers. This generally would involve major investments that are not profitable and realistic. On the other hand, an appropriate design of the lines, even with reinforced elements, cannot always resolved all the icing problems. Hence the necessity of monitoring ice and snow accretion and integrating techniques to prevent ice and snow adhesion and accretion, or their removal, before exceeding a critical ice or snow thickness. These techniques are classified as follows:

1. Anti-Icing (AI)

2. De-Icing (DI)

3. Use of passive devices

4. Line design approach

Anti-Icing Techniques

These techniques are used to prevent or reduce atmospheric ice (glaze ice, snow, rime or frost) from accumulating, based on ice adhesion strength reduction or freezing of supercool droplets.

Use of Passive Coatings

A number of physico-chemical properties of icing surface, including surface energy and surface roughness, influence the adhesion force between atmospheric ice and substrate. One of the methods to reduce ice adhesion is based on so-called passive coatings that require no external energy to be effective.

Viscous Coatings

Ice adhesion on an exposed surface can be reduced by applying a viscous or liquid coating such as industrial lubricants, oils and grease. These lead to ice release by gravitational, vibration or wind forces. Indeed, laboratory investigations have demonstrated that lithium grease and industrial lubricants can reduce ice adhesion strength on an aluminium surface by a factor of as much as 63. However, this type of protection is temporary and would require re-application as well as accurate field observation to predict the next ice storm. Finally, since these products are not biodegradable, they constitute an environmental threat. For these reasons, such coatings are not considered suitable for broad use but can still represent a last resort to protect strategic line sections when severe icing storms are being forecast.

Freezing Point Depressant Fluids

This technique makes it possible to avoid ice adhesion and formation on an exposed object. These fluids are generally prepared by mixing commercial liquid products with water and are commonly used on roads, runways, aircraft and other structures to prevent icing. Durability of these coatings on aircraft wings, for example, is limited to about one hour. As such, application of such fluids to power equipment does not seem practical considering limited durability, cost effectiveness and harm to the environment.

Solid Coatings

This approach consists of decreasing ice adhesion by elaborating ice-phobic coatings from materials of low surface energy, such as Teflon or silicone-based polymers, or by using heterogeneous polymer coatings. However, from a practical viewpoint and in spite of their ability to reduce ice adhesion strength, these materials cannot be considered as ice-phobic, considering that accreted ice on cables and wires will not detach under its own weight or from the action of the wind. Recent development in research concerning surface wetting and ice adhesion as well as new advances in material and surface science have resulted in development of advanced super-hydrophobic coatings with self-cleaning and ice-phobic properties. These coatings, featuring nano/micro surface roughness, can prevent or considerably reduce ice adhesion strength on surfaces by breaking the chemical bonding involved in ice adhesion and/or by intercalating air between the solid surface and the ice.

Application of these coatings to conductors, ground wires and supporting structures can potentially reduce mechanical loads due to ice and snow accretion thus increasing reliability of transmission during winter conditions. A comprehensive review of these coatings was carried out by CIGRE WG B2.44 and resulted in publication of Technical Brochure 630 in 2015. An update of this study is currently in progress within the framework of CIGRE WG B2.61. Despite investigations in many countries and progress in development of ice-phobic coatings, there are still limitations in regard to application to overhead conductors and ground wires. This is due mainly to the stability and durability of coatings developed so far. Conductors or wires coated by a black or an efficient heat absorbent can create favourable conditions to capture energy from the sun and atmospheric light to accelerate ice and snow shedding. This technology, now used on solar panels installed in cold climate regions, would be of potential for application to conductors and especially to ground wires.

Use of Active Coatings & Devices

In contrast to passive coatings, active coatings need external energy to be effective. In the same way as passive coatings, active ones can prevent or reduce ice-adhesion strength on surfaces by breaking the chemical bonding involved in ice adhesion and/or by intercalating air or other gases between the solid surface and the ice. Other such coatings work by weakening ice-adhesion strength by generating heat or an interfacial mechanical stress between ice and substrate in order to produce adhesion failure of the ice layer.

Ice Electrolysis System

One of these methods is based on ice electrolysis and consists of applying a DC voltage between a grid-electrode and a conductive surface to be protected when ice forms on the surface and bridges the circuit (see Fig. 2). The grid-electrode is insulated from the conductive surface (Fig. 2 a) and can have different configurations, as shown in Figs. 2b and 2c. The ice electrolysis gases produced by this system are intercalated between the ice and the solid surface. Gas also accumulates in the form of bubbles that contribute to produce interfacial cracks.

![Fig. 2: Principle of generation of ice electrolysis by application of a DC Voltage, US Patent 6027075, reproduced and published in ref. [10] by permission of Victor F. Petrenko.](https://www.powerandcables.com/wp-content/uploads/2019/11/Fig.-2-Principle-of-generation-of-ice-electrolysis-by-application-of-a-DC-Voltage-US-Patent-6027075-reproduced-and-published-in-ref.-10-by-permission-of-Victor-F.-Petrenko.-min.jpg)

Fig. 2: Principle of generation of ice electrolysis by application of a DC Voltage, US Patent 6027075, reproduced and published in ref. [10] by permission of Victor F. Petrenko.

![Fig. 3: Ice electrolysis method for conductor application (International patent 2005083862, reproduced and published in ref. [10] by permission of Victor F. Petrenko.](https://www.powerandcables.com/wp-content/uploads/2019/11/Fig.-3-Ice-electrolysis-method-for-conductor-application-International-patent-2005083862-reproduced-and-published-in-ref.-10-by-permission-of-Victor-F.-Petrenko.-min.jpg)

Fig. 3: Ice electrolysis method for conductor application (International patent 2005083862, reproduced and published in ref. [10] by permission of Victor F. Petrenko.

This method relies on the injection of a pulsed current into a conductive coating surrounding the conductor for heat generation at the interface of ice and an external conductive layer. As shown in Fig. 4, the external coating is isolated from the body of the main conductor by a dielectric layer. Compared to de-icers using alternating or direct current, this de-icer requires an average power approximately 100 times lower. Problems such as the need for significant changes in conductors and its thermal limitation caused by the addition of the dielectric layer, limit the use of this concept.

Fig. 4: Principle of pulse electrothermal de-icer for conductors.

LC-Spiral Rods

Another such a technique, reported in CIGRE Technical brochures, is based on use of a ferromagnetic coating (see Fig. 5). The principle of such a system consists of absorbing energy by a Low-Curry (LC) Spiral Rod from the alternating magnetic field produced by conductor current. The heat energy necessary for snow melting is generated by hysteresis and induced eddy current.

Fig. 5: Snow-melting magnetic wire used in Japan.

LC-Spiral Rod has been implemented in Japan about three decades ago to prevent accidents caused by sudden fall of large chunks of snow. One of the advantages of this de-icing device is its capacity to generate a relatively large amount of heating energy during winter and a small amount in summer. The heating generated can be adjusted by winding tightness using a wrapping machine. Based on experiments at a Hydro-Québec natural site, this technology, efficient for wet snow melting also seems effective under icing conditions with favourable weather and current conditions.

Active Materials

Another potential active coating for application to conductors or ground wire is based on active materials such as piezoelectric films and electro-active polymers. Piezoelectric polymers such as PVDF seem appropriate for this purpose since they are thin, flexible and can support high mechanical and electrical stresses. Electro-active polymers, and particularly dielectric elastomers consisting of a polymer material sandwiched between two compliant electrodes, can also provide thin-film active coatings. Applying a high electric field to the electrodes makes it possible to stretch the polymer under Maxwell stress. The mechanical stress generated, i.e. up to 7 MPa at the ice/substrate interface, seems sufficient to de-bond the ice layer. Further research is necessary to verify the efficiency and applicability of PVD and electro-active polymers to overhead conductors and wires.

De-Icing Techniques

De-icing techniques are used to remove ice accretion on conductors or ground wires during or following an icing event. Generally, both thermal and mechanical approaches are used: Thermal techniques are based on heating conductors or ground wires to melt ice deposits so as to force its shedding; Mechanical techniques, by contrast, are based on ice breakage in order to force ice shedding. A comprehensive review of these techniques was carried out in several publications and a review of de-icing and anti-icing techniques was also recently presented recently in IWAIS 2019. Following is an overview of such de-icing techniques:

Thermal De-Icing Techniques

These techniques, using the Joule effect for de-icing conductors and ground wires have been developed and used widely for about a century using both AC and DC currents.

Conductor De-Icing

a. Load Shifting Method

This technique consists of using the heating effect of load currents to prevent or to remove ice from conductors. As such, it requires no additional equipment on a system. In general, in order to circulate enough current to the conductor to cause ice melting, normal operating conditions must be modified by transferring or shifting loads from other circuits linking the same two substations. However, controlling current intensity during the de-icing period is not always feasible since it is determined mainly by load demand of customers. This method is more suitable for de-icing single conductors given that much more current is needed for de-icing bundled conductors.

b. Reduced Voltage Short-Circuit Method

This technique involves heating conductors by creating a three-phase short-circuit at one end of a line and applying a three-phase voltage source on the other side. The intensity of the short-circuit current needed for de-icing is a function of applied voltage, length of the circuit and electrical characteristics of conductors. This technique requires installation of equipment such as switches, connections to power the lines to be de-iced and a protection system to support de-icing current.

c. DC Current Method

This technology is advantageous for de-icing long transmission lines with large diameter conductors since reactive losses are eliminated. The method has been successfully developed and used in the former USSR for de-icing long 500 kV lines with large bundle conductors. The basic principle consists of forming a closed loop using line conductors, as shown in Fig. 6.

Fig. 6: One of two-step sequences required to de-ice conductors using DC current.

d. On-Load Network De-Icer

Unlike previous de-icing techniques that require disconnecting sections to be de-frosted, this system can be activated without disrupting the network. The On Load Network De-Icer (ONDI) relies on use of a special three-phase transformer called a phase-shifted transformer (PST), used to control energy flows on transmission lines. By adequate adjusting phase-shift of the PST, it becomes possible to increase current flow by a factor of four in the line opposite to the PST line while also maintaining voltage in the network during the de-icing period.

e. De-icing by Current Transfer of Bundled Sub-conductors Through Contactor Devices

The principle of this technique is to transfer the current flow in all the bundled conductors to a single sub-conductor during a de-icing sequence. Thus, for a 4- bundled conductors, for example, the current flowing in a sub-conductor is multiplied by four and the joule losses by 16. This process allows to generate enough heating for ice melting. The process is repeated at regular intervals until all sub-conductors are clear of ice.

Ground Wire De-icing by Joule Effect

In order to heat the ground wires for de-icing by the Joule effect, it is necessary to first electrically isolate them from towers, as shown in Fig. 7. The de-icing current can then be supplied by a voltage transformer. With this method it becomes possible to de-ice several kilometers of ground cables. In remote areas, it is also possible to use an auxiliary diesel generator to de-ice ground cables in strategic line sections, such as river crossings.

Fig.7 Simultaneous de icing of two ground wires.

Mechanical Techniques

Compared to thermal de-icing techniques, mechanical de-icing has the advantage of being easy to use and allowing timely and rapid intervention of critical sections of an overhead network. In addition, these methods require 100 times less energy.

Generally, most mechanical methods are based on breaking the ice by scraping or on releasing energy from shock waves or vibrations to break and pull office.

a. Scraping Methods

One of the frequent methods to release ice from conductors is using a rope to which scrapers, rollers or cutters thrown over the conductor are attached. The traction force for pulling the rope is applied manually by linemen or other trained personnel or by motorized equipment. More recently, after the 1998 ice storm in Québec, a high traction robot called ROV (Remotely Operated Vehicle) was developed by researchers at Hydro-Québec. This compact device was successfully tested on 315 kV energized conductors. The ice-scraping tool is comprised of a set of steel blades mounted on the ROV (see Fig. 8).

Fig. 9: De-icing conductors using insulated pole.

Following the 1998 ice storm, Hydro-Québec developed a portable shock wave de-icing device for ground cables, called the De-icer Actuated by Cartridge (DAC). This device (see Fig.10), which is fully operated from the ground, consists of using a portable cylinder-piston equipped with blank cartridges that can be remotely fired to create shock waves. Hydro-Québec tested a method of de-icing of bundled conductors by generating short-circuit faults involving twin or quad conductors at rated voltages of 315 kV and 735 kV. The electromagnetic forces induced by the short-circuit currents following through the conductors create the oscillatory movement of conductors forcing them to knock against each other and de-ice the span, as shown in Fig.11. Impact studies on the Hydro-Québec grid revealed that this method could be applied to 315 kV lines but only in case of emergency during severe ice storms.

Fig. 10: DAC prototype held in place by taut rope and ready to be fired.

Fig. 11: De-icing of twin bundle conductors.

c. Vibrating Devices

The principle of these techniques is based on generation of sustained vibrations of conductors or earth wires by devices connected to them to release ice or snow.

One of the vibrating devices, called Automatic Ice Control (AIC), is permanently installed at mid span. It comprises a current transformer, a camera, different sensors for ice detection, a control box with a HF emitter/receiver, and a commercial electromagnetic vibrator, all placed in a rigid protective housing (see Fig.12).

Fig. 12: Automatic Ice Control.

The second vibrating apparatus, called ice-shedder (Fig. 13) is comprised of a motor activating an unbalanced weight whose imbalanced motion is tuned to the natural frequency of the span. This device can be easily installed and driven by power from the conductor or from an external source. Special precautions should be taken when using vibrating devices for de-icing purposes since strong oscillations of conductors or ground wires can cause long-term mechanical damage to power line components.

Fig. 13: Ice-shedder apparatus.

Use of Passive Devices

Passive devices take advantage of natural forces such as wind, gravity or solar radiation to limit ice or snow loads on conductors and ground wires. Use of some special devices, equipment, conductor stiffness, configuration or span length could influence ice and snow loads and avoid the formation of uniform and circular shape, thus facilitating their shedding. Some of these methods have been already successfully used.

a. Use of Vibrating Devices Anti-Torsion Devices

One of these methods consists of using anti-torsion devices such as counterweights (see Fig.14), inter-phase spacers and spacer dampers to increase torsional stiffness of conductor spans so as to limit their rotation. Such measures can prevent formation of cylindrical deposits of wet snow, thus facilitating its shedding by gravity and wind forces.

Fig.14: Illustration of counterweight.

b. Use of Rubber or Plastic Rings, Wires or PTFE Tapes

Another method to reduce wet snow accumulation is use of rubber or plastic rings, equally spaced, around the conductors. As seen in Fig. 15 (top), snow tends to accumulate on the top of the conductor and slide down along the direction of the strands. The rings (Fig. 15, middle) cause the sliding wet snow to shed as it impacts. A wire wound to the conductor in the opposite direction to the strands can have the same effect as rings (Fig. 15, bottom). PTFE tapes wound to the conductor can also have the same effect.

Fig. 15: Top: Path of wet snow accretion sliding in strand direction. Middle: Snow rings. Bottom: Wire wound in opposite direction of strand to facilitate shedding.

In Japan, except for Okinawa where there is no snow, all overhead lines are equipped with snow rings. Overhead lines with single conductors are also equipped with counterweights, as shown in Fig. 16.

Fig.16: Combination of rings and counterweights for reduction of wet snow accretion on conductors.

Line Design Approaches

These approaches, considered as the best prevention techniques, should be complementary to above-mentioned mitigation options for superior and more effective protection of overhead lines under icing.

Improved Line Routing

Line route selection is the first optimization step that should be carried out during a transmission line project. In this regard, statistical data on icing are valuable to prevent passing high risk zones when designing and constructing a new line.

Profile of Conductor, Diameter, Stiffness & Bundle Configuration

Conductor diameter and its surface roughness are two parameters that influence ice accretion and shedding. A smaller diameter conductor, with a similar torsional stiffness, collects less ice than a bigger conductor diameter. Also, a smoother surface decreases ice adhesion to the conductor and reduces convection heat transfer to the surrounding air. Taking these in consideration, under the same conditions, a conductor such as a compact trapezoidal strand with a smaller diameter and smoother surface takes less time to shed ice comparing to an equivalent standard stranded conductor. The number of conductors in a bundled configuration is another factor influencing ice and snow accretion load and time of shedding. On one hand, an increase in number of conductors will cause an increase in accretion loads. On the other, it causes decrease in the shedding time since it provides higher rotational stiffness that prevents formation of cylindrical ice. Use of a single rigid conductor under icing conditions seems to be a better choice than bundled conductors of slightly smaller diameters. In any case, more laboratory and field investigations are necessary to clarify the role of conductor diameter, shape, surface roughness and rigidity as well as number and configuration of bundled conductors and span length, in order to clarify the impact of all these parameters on ice and snow loads and time of shedding.

No Ground Wire

This solution can be considered in regions prone to icing where lightning is infrequent. Use of lightning arresters might also be of interest to replace ground wires to protect overhead lines against lightning.

Increased Design Ice Loads

This approach is a generally good solution for increasing reliability of transmission under icing conditions. However, this method should ideally be combined with other solutions.

Load Reducing Devices or Mechanical Fuses

Use of such devices could prevent damage caused by heavy ice or unbalanced loads. This method is not generally an efficient de-icing technique but rather a damage reduction approach. For example, automatic release of ground wires under icing conditions has been used with success by EDF in France.

a. Anti-Cascade Towers

There are a number of possible reasons for transient dynamic loads, e.g. rupture of a conductor in a span caused by high intensity wind, heavy ice or snow accumulation or by sudden ice shedding. The dynamic loads created by supporting tower collapses under such conditions will increase the forces on adjacent or subsequent towers giving rise to multiple tower failures. Integration of anti-cascade towers in a line can limit the extent of possible damage caused by a winter storm, thus keeping repair costs at a reasonable level.

b. Underground Conductors

Use of underground cables to resolve problems caused by ice accretion on overhead lines could be considered a good solution, especially for distribution lines. Advancements in cable technology make this option possible for higher voltage levels as well. Underground cables are also well supported by the public from the aesthetic point of view.

Mitigation Options Related to Insulator Icing

Various remedial methods have been developed to improve reliability of insulators exposed to icing.

Insulator Dimension & Configuration

Increased Dry-Arc Distance

Test results show that the critical flashover voltage of iced- and snow-covered insulators increases with increase in dry-arc distance. This correlation is linear for insulator length ranging from 0.3 to 3 m. This option remains the most reliable way to improve insulator performance under icing conditions.

Increased Leakage Distance

Contrary to dry-arc distance, increasing the leakage distance as a remedial measure becomes less effective under moderate and heavy ice accretion that bridges the inter-shed insulator spacing. However, this measure can be efficient under cold fog conditions, where a thin ice film is formed along the leakage distance. Retrofit of insulators with increased leakage distance is only useful in areas where ice and snow accretion is not severe.

Insulator Diameter, Shed Size & Inter-Shed Spacing

Insulator diameter, shed size and inter-shed spacing are other important parameters influencing the amount and the level of ice and snow accretions as well as the level of shed-spacing bridging. Generally, flashover performance of insulators is better with a smaller shed diameter and larger shed spacing.

Combining Insulators with Different Diameters

Combination of insulators of different diameters, such as illustrated in Fig. 17, increases effective shed-to-shed spacing. Under a certain range of icing conditions, this retrofit option will perform better than standard profiles. This convenient option can be applied to both existing lines and new designs.

Fig. 17: Ice accretion on bell-bell-disc and bell-disc-disc suspension insulator strings.

Insulator Orientation

Under icing conditions, horizontal string and V-string insulators are proven to perform better than vertical insulators. This is mainly because much more ice is needed to achieve full bridging of these insulator strings compared to vertical strings. Laboratory tests and mathematical modeling have shown that minimum flashover voltage, VMF, of a horizontal string of four discs under heavy icing condition is about 60% higher than that of the same string at an inclined position and 100% higher than for the vertical position (see Fig. 18).

Fig. 18. Simulation and experimental results of VMF for string in vertical, inclined and horizontal positions.

Accessories

a. Booster Sheds & Creepage Extenders

These accessories, which are used to protect bushings and station post insulators against wetting or contamination flashover, have also proven efficient to provide shelter during ice accretion. Each booster shed can create an ice-free zone (air gap) long enough to increase the flashover strength by 10 to 20 kV (see Fig. 18)

Fig 18: Station post insulators with booster sheds.

b. Grading Rings

Application of corona rings (see Fig.19a) can degrade rather than improve flashover performance of an EHV post station insulator under icing conditions. Results have shown that uniform electric field of an effective corona ring on the insulator surface tends to promote full ice bridging rather than forming air gaps near the high voltage terminal, as shown in Fig.20a. When the upper surfaces of corona rings are covered with a fine metallic mesh, air gaps form near the rings (see Fig. 20b), leading to improved flashover performance. Booster sheds, however, perform this function better and at lower cost.

Fig.19. Ice accumulation on station post insulator,

(a) with grading ring (b) with modified, screen-covered grading rings.

Surface Material

a. RTV Silicone Coating

RTV coatings, developed for improved contamination flashover performance, have also been used as a countermeasure under icing conditions. In cold-fog conditions (very light icing), for example, an increase of about 25% in flashover strength per meter of leakage distance is gained when an RTV silicone coating is applied to porcelain insulators. However, for heavy icing causing icicle bridging of insulator shed spacing, RTV is not effective and cannot reverse the situation. In fact, ice is retained for a longer period on RTV-coated porcelain during the dangerous melting phase. Thus, effectiveness of these coatings to prevent insulator icing flashover is questionable.

b. Semi-Conducting Glaze

The use of semi-conducting glaze insulators under icing conditions offers several benefits. Firstly, low leakage current in the semi-conducting layer, normally around 1 mA, heats the insulator surface above ambient temperature and can help prevent frost formation. The resistive leakage current can also improve voltage distribution along the insulator, which in turn promotes formation of more uniform ice accretion. The relatively uniform voltage stress along the insulator also delays arcing activity across ice-free zones or dry bands in the case of contamination. Both laboratory tests and field exposure of semi-conducting post insulators have shown that these insulators develop large ice-free zones during melting periods which leads to higher flashover strength compared to normal glaze. These insulators have therefore proven highly effective in mitigating icing problems. Direct comparison of performance of conventional and semi-conducting glaze insulators for a 2.0 m dry arc tested under heavy ice conditions showed an improvement of about 20 percent.

c. Super-Hydrophobic Coatings

Super-hydrophobic coatings (SHC) with self-cleaning and ice-phobic properties are attractive to improve the flashover performance of insulators under pollution as well as under icing conditions. These coatings with static water contact angle of more than 150˚ and a hysteresis contact angle of less than 10˚ can be achieved by a combination of low surface energy materials having a micro-nanostructured surface. A review of such coatings with potential application to outdoor insulators is reported in CIGRE TB 631. Fig. 21 shows an example of the effectiveness of a SHC in reducing ice accretion on insulators. As can be seen, unlike on the uncoated insulator, no icicles formed on the coated insulator even after 3 hours of icing exposure. This can be explained by shedding of accreted ice from the coated insulator surface before icicles could form.

Fig. 21: Comparative icing appearance on bare and SHC-coated insulators after 30 minutes and after 3 hours.

Recently, a technique, using direct replication method, was developed to produce micro-nanostructured silicone rubber surfaces by compression molding and injection molding systems with application to polymeric insulators. The replicated silicone rubber surfaces tested in this project displayed a contact angle CA>160˚ and a contact angle hysteresis CAH <10˚. The self-cleaning and ice-phobic properties of these surfaces has been successfully verified on a laboratory scale. Research is presently continuing at the University of Québec in Chicoutimi in view of practical application.

d. Semi-Conductive RTV Coatings

In a laboratory research study, RTV coatings were enhanced with carbon doping, making them semi-conductive with sufficient current flow to prevent ice formation, or by blending them with sub-micrometer scale materials rendering them superhydrophobic, self-cleaning and ice-phobic. Fig. 22 shows an example of using a semiconducting RTV as an anti-icing coating. In this figure, ice was artificially accreted on both clean and contaminated insulators. The semi-conductive silicone rubber coating was applied only to the bottom side of the insulator to eliminate the power loss when there is no precipitation. For the semi-conductive coated string, there were no icicles and no ice covering the surface of the insulators. Also, the coated string showed an obvious surface heating effect. The temperature was about 16°C in the area near the cap and pin but about 0°C in most other parts.

Fig. 22: Thermal picture of specimens in icing test. Left side: uncoated sample; right side: coated sample with anti-icing semi-conductive silicone rubber.

Reduced System Voltage

Reducing transmission system operating voltage during critical ice or snow conditions can be an effective way to lower insulator flashover probability. In one case study, a 5% reduction in operating voltage with 50 parallel insulators under full ice bridging decreased flashover probability from 49.5% (maximum operation voltage) to 11.7%. A voltage reduction of 10%, if available, would have decreased flashover probability down to only 1.2%.

Insulator Washing

Washing energized ice-covered insulators with hot pressurized water has been successfully tested under laboratory conditions. Also, long-term insulator washing during winter using de-ionized water as an electrical barrier has been successfully tested by several utilities in North America as well as Japan.

Conclusions

Icing of overhead power network equipment, including conductors, ground wires and insulators, occurs in many regions of the world and can result in serious failures and damage with major socio-economic consequences. Such effects are aggravated by excessive ice accretion combined with the force of wind giving rise to dynamic phenomena such as galloping and jumping of conductors caused by sudden ice shedding. Despite great progress in research, some phenomena related to ice adhesion, accretion and shedding are still not fully understood. A better understanding of these phenomena would lead to more appropriate protection of power networks during winter conditions.

Various approaches to mitigate the effects of icing on power network equipment, including anti-icing, de-icing, passive devices and line design are overviewed. The anti-icing methods are used to prevent or reduce ice or snow accretion, and mainly consist in using passive and active coatings. New technologies based on the use of ice-phobic materials have a great potential for future applications. The development of efficient, durable and cost effective ice-phobic coatings still needs great R&D efforts. As concerns active coatings almost no significant progress has been made during the past decade. The few previously proposed concepts such as ones based on ice electrolysis and injection of a pulsed current into a conductive coating are likely inefficient or unpractical. One of the active methods presently in use and efficient for wet snow melting is based on the use of a ferromagnetic coating. However, application of this technique for conductor ice melting would require further R&D effort. The efficiency of other potential active coatings based on using materials such as piezoelectric films or electro-active polymers still needs to be demonstrated.

As concerns de-icing techniques, these are used to remove ice or wet snow accretion on conductors or ground wires during or following an icing event. Generally, thermal and mechanical approaches are used to this end. Many utilities have adopted thermal methods based on the Joule effect for de-icing conductors and ground wires on a large-scale and countries have been using these methods for almost a century. For a thermal de-icing strategy to be efficient, however, an adequate detection and monitoring of evolution of ice/snow build-up is necessary, which would still require further R&D. On the other hand, mechanical methods, needing shorter de-icing times compared to thermal methods, are preferred by utilities for the protection of shorter strategic line sections. Mechanical methods are well suited to reduce the risk of the damage or collapse of towers in extreme emergency situations.

In regard to protection of ground wires against icing, this remains one of the important issues and concerns in cold climate regions. Nevertheless, few existing methods, such as removing them in low-risk icing areas, seem to be operational for application. In high-risk icing areas, ground wires could be replaced with lightning arresters to protect overhead lines against lightning.

Techniques based on special devices, equipment, conductors with high stiffness or with improved configuration or span length, have proven to limit ice or snow loads. Some of these devices and equipment, presently in use, can prevent formation of uniform and circular shapes, thus facilitating shedding.

Flashover across insulators under ice and snow conditions, combined sometimes with pollution, is another source of failure. Risk of flashover can be reduced in several ways depending on icing and pollution severity. For light ice accretion with high surface pollution created under cold fog conditions, RTV silicone coating has been found efficient. Under more severe icing conditions, solutions such as substituting insulators with others with improved profiles or with semi-conductive glaze can be adopted. Under heavy icing conditions and very low contamination, the use of devices such as booster sheds was shown to considerably improve the electrical performance of substation insulators. Another solution consists in washing the insulators more frequently during winter or in constructing the line and substations with insulators having longer dry-arc distance. Much progress has been achieved in surface engineering and superhydrophobic coatings with self-cleaning and ice-phobic properties with potential applications to ceramic and non-ceramic insulators. Further efforts in R&D are necessary to find efficient and cost-effective techniques to protect insulators against flashover problems under icing, pollution or a combination of them.

Thank you to INMR for allowing us to Share this Blog.

Frost Protection | Hot Water Temperature Heating | Ramp Heating | Gutter Heating

Cable Cleats from Ellis Patents | Better By Design

November 11th, 2019

-

uploaded by -

Chris Dodds - Thorne & Derrick Sales Marketing Manager

Major projects, new trains, bewildering technology: these are the big-ticket items that command everyone’s attention these days. And why wouldn’t they?

Who cares about the high-volume, low-cost bits and pieces that literally hold the railway together? Nuts, bolts, pins, clips, arms, brackets…

Politicians don’t cut ribbons at the installation of a cable cleat, but they might – conceivably – have to explain the havoc wreaked by one failing following an electrical big bang.

A single dodgy component can inflict disruption and embarrassment that’s wholly disproportionate to its size and cost, by a very significant factor.

With this in mind – as the magazine’s unofficial Analogue Correspondent (my heart was hewn from the earth by Victorian navvies) – I was despatched to Rillington in North Yorkshire to visit a company that’s been keeping cables in check for almost 60 years.

In parts, the experience proved surprisingly digital.

Basic Principles Of Cleating Cables

In case you’re unfamiliar with the term, a ‘cleat’ is used to secure LV MV HV electrical cables to a structure by installing them at intervals along the cables’ length. What could be simpler?

But there are a number of factors affecting its ability to fulfil that role safely and effectively, including environmental conditions, the materials used, performance in the case of fire or impact, resistance to corrosion and the cleat’s strength.

Installing Ellis brackets in the Severn Tunnel

The latter is often determined using a mechanical tensile test; however, the results can prove misleading as the force is applied in a slow, controlled manner.

The electromagnetic forces in short-circuit conditions act almost instantaneously and oscillate in every direction, sometimes with destructive consequences.

A cable cleat is most likely to fail at peak current, about 0.01 seconds after the event starts; a breaker won’t have woken up by then.

So, the only reliable way of demonstrating that a cleat will withstand the resulting forces is to also conduct a short-circuit test – International Standard IEC 61914 provides a formula for calculating those forces between two conductors in a three-phase supply. Potentially, they can amount to several tonnes.

Restraining cables during a fault is a fundamental role of the cable cleat; it’s a means of protection as well as support. In order to withstand the applied forces, the optimum spacing between each cleat can be determined using a formula which takes account of the required loop strength and peak short-circuit current.

Production of Centaur Cleats

Potted History Of Cable Cleats

None of this is news to the specialist team at Ellis – formerly Ellis Patents – which boasts a skilled workforce of around 60, mostly residing in the towns and villages around Rillington.

The firm was founded by Arthur Ellis, who piloted more than 90 bombing missions for the RAF during the Second World War.

Back on civvy street, he trained as a plumber and set about manufacturing plastic pipe clips and cable clamps, with electricity boards as his major customers.

That was 1962; today the firm has an annual turnover of around £7 million.

The operation moved to its current site in 1974, about a mile from the York-Scarborough line. Unfortunately, the village station had closed 44 years earlier. Following Arthur’s retirement in 1987, the company was acquired by Chris Calvert – its current chairman – and fellow investors from Walkern Victoria Industries. It acquired EDL Cable Supports in 2002 and has since become a global force, offering one of the most comprehensive catalogues of cleats, clamps, hangers and associated peripherals to international clients and projects.

As you walk around, you get the sense of an open, collaborative culture and an engaged workforce. Innovation is encouraged and facilitated through ongoing – and sometimes speculative – investment in new kit. This is not a company that’s resting on its laurels, but neither are staff being driven to distraction. Managing Director Richard Shaw tells me they are encouraged to go home at the appointed time and not check their emails. One culprit habitually ignores the edict whilst another recycles redundant equipment to assist with his construction of a traction engine! This seems a happy place.

Vertical Integration

Production tooling manufactured by Ellis

Unlike many competitors, Ellis is fully resourced in-house – not only designing its own products, but also building CAD models and subjecting them to finite element analysis. “This tells us where a component will break and under what force”, says Richard. “Then we can 3D-print it.

“We know the printed model is about 40 per cent of the strength of the real thing due to the difference in plastics so – when we test it – if it comes out at 40 per cent of the figure we were expecting, we know we’re on the right track. We can do all that work without ever making anything, but it gives us the exact volume of materials needed, how long it will take to manufacture and the price.”

Beyond that, Ellis’ capabilities extend to prototyping and tooling for die-cast and injection moulding. This creates enormous flexibility and an inventive mindset: when a client comes with a problem, ways and means are readily available to develop custom-made solutions.

Through the 37 miles of tunnel on High Speed 1, there’s an Ellis cable cleat every 600mm. When the consulting engineer first approached the company during construction, he told them he needed 70,000 bespoke aluminium cleats in 12 weeks. They were designed, tested and delivered on time.

Ellis products are deeply embedded on the London Underground and Hong Kong Metro; they also formed part of the design for the recent installation of overhead line equipment through the Severn Tunnel. Thousands of its Centaur cleats can be found in the London Power Tunnels – extending for 20 miles under the capital – as part of the firm’s biggest ever order, worth £1.5 million. And the UK’s Astute-class nuclear-powered submarines also feature its cable clamp products.

Attention To Detail

As we know, though, the railway is different; visit most of our classic tunnels and you’re unlikely to see many cleats. Instead, the approach taken since the advent of power, telecoms and signalling was to place the associated cables on hangers, fixed to the sidewall. It’s quick and makes life easy. But even here, there’s scope for improvement.

Stephen Walton, Ellis’ Technical Director, revealed: “We’ve reworked the traditional pressed-steel hanger to be stronger and safer by adopting a curved profile; they use less material so the shipping costs are cheaper. We’ve also developed polymer cable hangers which are lighter-weight, offer more insulation resistance and will never corrode.

Emperor Cleats

“A lot of what we’re doing is about making the products easier to carry and improve speed of install, responding to the needs of the contractors we’re increasingly working with.”

When legacy hangers become life-expired, Ellis has a modular retrofit system which can be secured in place without disturbing the existing cable system. There’s a delightful simplicity and elegance about these products. I spent much of my chat time with Richard and Stephen fiddling with a stackable twist-to-fit no-bolts cleat, a unique device conceived in response to a Network Rail enquiry. The action had something very pleasing about it.

Inevitably, there is a procurement challenge here. Ellis’ polymeric products are more expensive than its metal variants, but being less heavy improves installation efficiency – a big issue for the rail industry given the scarcity of possession time – whilst their longevity means that whole-life costs are lower.

Cable cleats can be supplied pre-assembled with the requisite fixings – pushing up the initial purchase price but delivering benefits that reduce costs overall. Until we get our heads around these issues and learn to buy smarter, better products and lower expenditure will elude us.

All That Glitters…

2019 represents another busy year for Ellis as it continues to grow the business. It has much to offer the rail sector through a sharp focus on innovation, responsiveness and value. Of course, its competitors would say the same thing – they have similar brochures, product ranges and part numbers. “Their ‘innovation’ is copying us,” Richard reflects ruefully.

It’s indicative of the company’s position in this market that others closely follow Ellis’ lead. However, whilst imitation is often flattering, it rarely compares favourably with the original.

By Graeme Bickerdyke

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

➡ Read: Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

Internal Promotion | Natalie Lundie Supply Chain (Marketing Lead)

November 8th, 2019

Natalie Lundie

Press Release

08.11.19

uploaded by Chris Dodds

Sales & Marketing Manager

THORNE & DERRICK

Specialist Distributors of LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Today, it is with great pleasure that I am announcing the promotion of Natalie Lundie to Supply Chain (Marketing Lead) at Thorne & Derrick International.

Natalie has been with Thorne & Derrick for close to 7 years in her Social Media & Marketing Support role demonstrating dedication and combining commitment with outstanding success.

Over these years Natalie has achieved and maintained an exceptional personal performance – she has supported the development of our online presence by undertaking transformative work in the fields of UK and international search engine optimisation, social media strategy and digital marketing campaigns.

Natalie’s personal knowledge of and expertise in internet marketing has made an enduring and positive contribution to the business development of Thorne & Derrick.

Now as Marketing Lead of our Supply Chain, Natalie accepts the lead role and responsibility for maximising the potential business value of existing supplier relationships to both parties advantage.

Natalie will be contacting and meeting our suppliers to discuss joint marketing initiatives to increase our sales together through the attainment of agreed targets – this mutual business development effort will embrace SEO, social and digital opportunities to accelerate sales.

Strategy planning for 2020 is now underway.

We encourage all current and any prospective suppliers to contact Natalie to discuss engagement in partnership marketing with Thorne & Derrick.

Natalie will be supported by myself and our Marketing Team to develop and deliver content marketing strategies and lead generation campaigns that get results for us and for our suppliers – talk today to Natalie on 0191 410 4292.

Let us all congratulate Natalie on this well deserved promotion and wish her continued success with Thorne & Derrick.

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

The Kiss Of Life

November 7th, 2019-

uploaded by: Chris Dodds | Sales & Marketing Manager Thorne & Derrick International

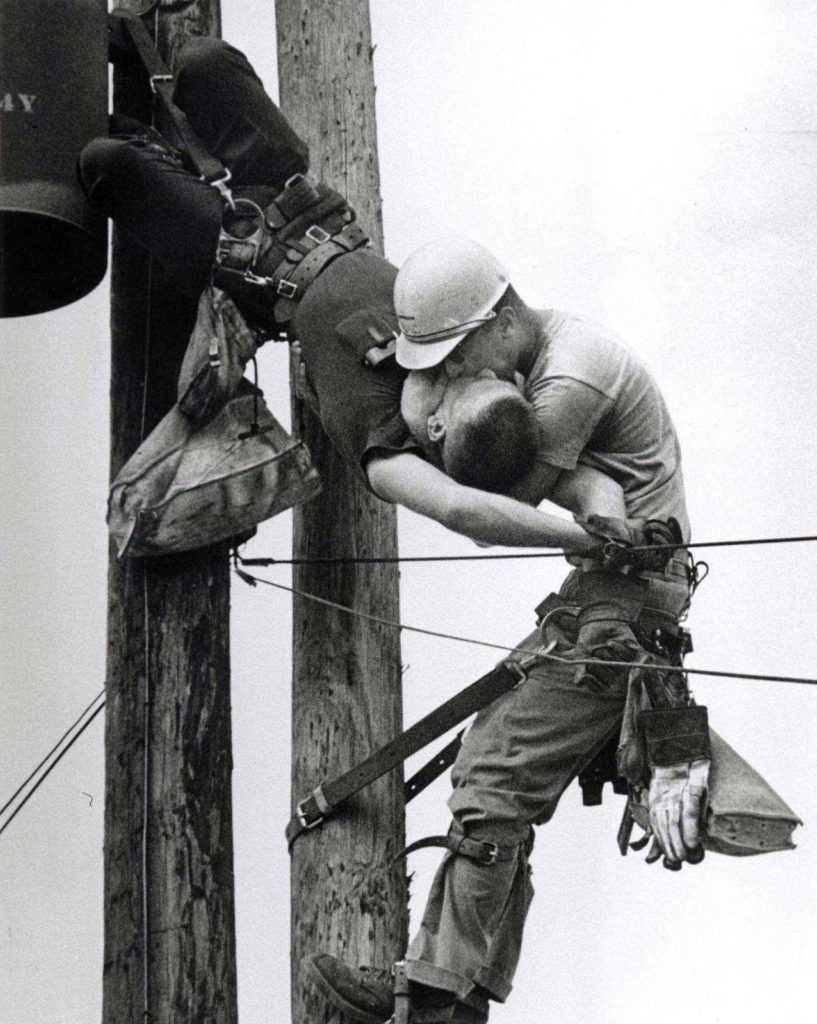

Pictured: The Kiss of Life – A utility worker giving mouth-to-mouth to co-worker after contacting a low voltage overhead line wire. 1967.

Taken in 1967 by Rocco Morabito, this photo called “The Kiss of Life” shows a utility worker named J.D. Thompson giving mouth-to-mouth to co-worker Randall G. Champion after he became unconscious following contact with a low voltage line.

They had been performing routine maintenance when Champion brushed one of the low voltage lines at the top of the utility pole.

His safety harness prevented a fall, and Thompson, who had been ascending below him, quickly reached him and performed mouth-to-mouth resuscitation.

He was unable to perform CPR given the circumstances, but continued breathing into Champion’s lungs until he felt a slight pulse, then unbuckled his harness and descended with him on his shoulder. Thompson and another worker administered CPR on the ground, and Champion was moderately revived by the time paramedics arrived, eventually making a full recovery.

Champion lived an extra 35 years. He died in 2002 at the age of 64.

Thompson is still alive today.

Subscribe to PowerLineman Magazine TODAY! Premier resource for news, articles, events, and announcements for the journeymen power linemen.

Rocco Morabito won the 1968 Pulitzer Prize for Spot News Photography for “The Kiss of Life”.

“I passed these men working and went on to my assignment”, says Morabito. “I took eight photos at the strike. I thought I’d go back and see if I could rind another picture”.

But when Morabito went back to the linemen, “I heard screaming. I looked up and I saw this man hanging down. Oh my God. I didn’t know what to do. I took a picture right quick. J.D. Thompson was running toward the pole. I went to my car and called an ambulance. I got back to the pole and J.D. was breathing into Champion. I backed off, way off until I hit a house and I couldn’t go any farther. I took another picture. Then I heard Thompson shouting down: He’s breathing!”.

The photograph was published in newspapers around the world. Morabito, born in Port Chester, New York, moved to Florida when he was 5, and by age 10 was working as a newsboy, selling papers for the Jacksonville Journal.

Overhead Line Equipment – Suppliers Of Medium & High Voltage Electrical Equipment

Thorne & Derrick

Specialist Electrical Distributor

Established since 1985, T&D International based in the UK distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Access Chambers, Cable Cleats, Duct Seals, Cable Transits, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

Distributors for : 3M, Pfisterer CONNEX, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Cembre, Prysmian, Ellis Patents, ABB & Furse.

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold